Welcome to the definitive guide to mastering Press Brake U Bending, a skill essential for metalworking professionals and enthusiasts alike. This comprehensive article delves into the intricacies of Press Brake machines, offering insights into the selection of materials, tooling essentials, advanced bending techniques, and much more. Whether you're a seasoned expert or a newcomer to the field, this guide is designed to enhance your understanding and skills in Press Brake U Bending, ensuring precision and efficiency in your projects.

- Key Components and Their Functions of Press Brake Machine

- Selecting the Right Material

- Pre-Bend Preparations

- U Bend Techniques

- Step-by-Step Guide to Performing a U Bend

- Quality and Precision in U Bending

1.Key Components and Their Functions of Press Brake Machine

Understanding the key components of a Press Brake machine and their functions is crucial for anyone looking to master the art of Press Brake U Bending. This chapter delves into the essential parts of the Press Brake, each playing a pivotal role in achieving precise and efficient U bends.

The Bed and Ram

At the heart of the Press Brake machine lies the bed and ram. The bed serves as a robust support for the material being bent, while the ram, moving vertically, applies the necessary force to create the U bend. This synchrony between the bed and ram is fundamental for achieving consistent and accurate bends.

Tooling: Punches and Dies

Tooling, comprising punches and dies, is a critical aspect of Press Brake machines. Punches, attached to the ram, interact directly with the material, imparting the desired bend. Dies, situated on the bed, provide the necessary support and shape for the material during bending. The right combination of punches and dies is vital for efficient Press Brake U Bending.

Back Gauge

The back gauge is an integral component for precision. It accurately positions the workpiece before each bend, ensuring repeatability and accuracy in the U bending process. This component is especially important for complex projects requiring multiple bends.

Control System

Modern Press Brake machines are equipped with advanced control systems. These systems provide operators with the ability to program and control the bending process, ensuring that each U bend is consistent with the specified requirements. This digital oversight is key in the era of precision engineering.

Safety Features

Safety cannot be overstated in the realm of Press Brake U Bending. Press Brakes come with various safety features like light curtains, safety guards, and emergency stop buttons to protect operators from potential hazards during operation.

2.Selecting the Right Material: Material Properties and U Bend Performance

The selection of the appropriate material is a pivotal step in achieving excellence in Press Brake U Bending. Different materials possess unique properties that directly impact the performance and quality of the U bend. This chapter focuses on guiding you through the process of selecting the right material for your Press Brake U Bend needs, highlighting how various material properties influence the bending process.

Understanding Material Strength

The strength of the material is a primary consideration. Materials with higher tensile strength require more force to bend, impacting the choice of Press Brake and tooling. Selecting a material with the appropriate strength level is crucial for efficient bending and machine longevity.

Ductility and Flexibility

Ductility plays a significant role in determining how well a material can be bent without cracking. Materials with higher ductility are more suitable for complex U bends, as they can withstand significant deformation without failure. Flexibility is also key to achieving precise angles and shapes.

Thickness and Grain Direction

The thickness of the material affects the amount of force required for bending and the tooling setup. Additionally, the grain direction of the material can influence the bend quality. Aligning the bend line with the grain direction can enhance the integrity and appearance of the U bend.

Material Springback

Springback is the tendency of a material to return to its original shape after bending. Understanding the springback characteristics of different materials is essential for accurate U Bend angles, as it dictates the need for over-bending or specific tool adjustments.

Corrosion Resistance

For applications where the end product will be exposed to harsh environments, selecting a material with good corrosion resistance is crucial. This ensures the longevity and durability of the U bent components, maintaining their integrity over time.

| Material Property | Description | Impact on U Bending |

| Strength | Materials with higher tensile strength require more force to bend, impacting tool and machine choice. | Influences machine and tool selection; higher force needed for stronger materials. |

| Ductility and Flexibility | High ductility materials are more suitable for complex U bends as they can withstand significant deformation. | Critical for achieving precise angles and shapes in complex bends. |

| Thickness | The material's thickness affects the required bending force and tooling setup. | Directly affects the amount of force required for bending. |

| Grain Direction | Aligning the bend line with the grain direction can enhance the integrity and appearance of the U bend. | Influences bend quality; proper alignment enhances bend integrity. |

| Springback | The tendency of a material to return to its original shape after bending. Requires over-bending or tool adjustments. | Dictates the need for over-bending or specific tool adjustments for accuracy. |

| Corrosion Resistance | For harsh environments, materials with good corrosion resistance ensure the longevity and durability of the bent components. | Ensures the long-term durability and integrity of the U bent comp |

3.Pre-Bend Preparations

3.1 Tooling Essentials

Before diving into the intricacies of Press Brake U Bending, it's imperative to understand the tooling essentials. The right tools not only enhance the precision of bends but also ensure efficiency and safety during operation.

Types of Press Brake Tools

Press Brake tools are categorized mainly into punches and dies, each available in various shapes and sizes. Standard, acute angle, gooseneck, and hemming punches, among others, cater to diverse bending needs. Similarly, dies like V-dies, U-dies, and rotary bending dies are chosen based on the specific requirements of the U Bend project.

Importance of Tool Selection for U Bends

The selection of appropriate tools is crucial in achieving precise U bends. The right combination of punch and die not only defines the bend's angle and radius but also influences factors like material springback and minimal deformation. Choosing the correct tools reduces wear on the Press Brake and improves the overall quality of the final product.

3.2 Machine Setup and Calibration

Setting up the Press Brake machine and calibrating it accurately is a step that cannot be overlooked. Proper setup and calibration are foundational to achieving precision in Press Brake U Bending.

Step-by-Step Machine Setup Guide

The setup process involves several key steps: starting with the selection and installation of the right tools (punches and dies) based on the material and bend requirements. Next, the back gauge is positioned to ensure accurate placement of the material. It's essential to verify that all components are aligned and secured to prevent any movement during bending.

Calibration for Precision Bending

Calibration involves adjusting the Press Brake for the specific material and tooling being used. This includes setting the correct force, bending speed, and back gauge positions. The machine's control system often assists in this process, allowing for precise adjustments that cater to the unique properties of each material and the specifics of the U Bend.

4.U Bend Techniques

4.1 Understanding U Bend Mechanics

To excel in Press Brake U Bending, a comprehensive understanding of the mechanics behind the U bend is essential. This section breaks down the basic principles and factors that directly impact the accuracy of the bend.

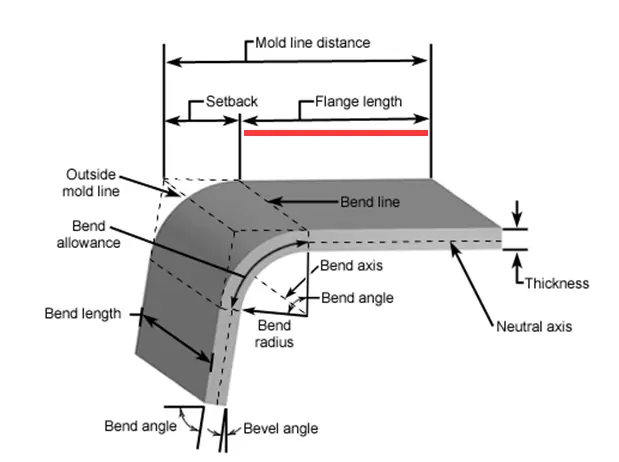

Basic Principles of U Bend

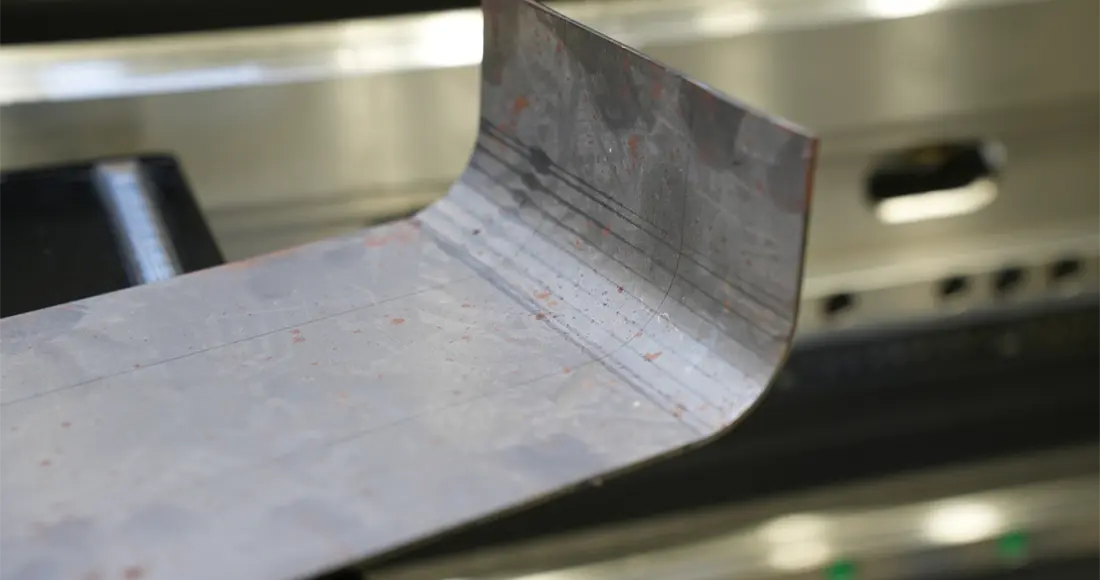

The U Bend process involves creating a 'U' shaped bend in a metal sheet or plate using a Press Brake. This is achieved by pressing the material between a punch and die, where the punch forces the metal into the die cavity, forming the desired U shape. The depth and angle of the die determine the bend radius and angle of the U bend, respectively.

Factors Influencing Bend Accuracy

Several factors influence the accuracy of a U Bend. These include the type of material, its thickness, and properties like ductility and tensile strength. Tooling selection also plays a crucial role, as the right punch and die shapes are vital for achieving the desired bend. Additionally, machine precision and operator expertise significantly affect the outcome.

4.2 Advanced Bending Techniques

Moving beyond the basics, mastering advanced bending techniques is key for handling complex U Bends and ensuring high-quality results.

Techniques for Complex U Bends

Complex U Bends may require techniques like step bending, where a large bend is achieved through multiple smaller bends, or air bending, which allows for flexibility in the bend angle. Using specialized tooling and adjustments to compensate for material springback can also be essential in executing complex bends accurately.

Avoiding Common Bending Errors

To avoid common bending errors, it's important to ensure proper material handling, accurate tool alignment, and precise back gauge settings. Understanding the nuances of material behavior under stress and applying corrective measures for factors like springback is crucial. Regular machine maintenance and calibration also play a vital role in preventing errors.

| Technique Aspect | Description | Importance |

| U Bend Mechanics | Involves understanding the basic principles of U Bend and the factors influencing bend accuracy. | Fundamental for achieving consistent and accurate bends. |

| Advanced Bending Techniques | Implementing techniques for complex U Bends, such as step bending and air bending. | Essential for handling complex bending projects and achieving precise bend angles. |

| Common Error Avoidance | Proper material handling, accurate tool alignment, precise back gauge settings, and regular machine maintenance. | Key to ensuring high-quality results and minimizing defects in the bending process. |

5.Step-by-Step Guide to Performing a U Bend

Performing a U Bend with a Press Brake requires precision, attention to detail, and a clear understanding of the process. This step-by-step guide is designed to walk you through the essentials of executing a perfect Press Brake U Bend, from preparation to the final bend.

Step 1: Material Preparation

Begin by selecting the appropriate material for your U Bend, considering factors such as thickness, ductility, and strength. Ensure the material is clean and free from any debris or coatings that might affect the bend quality.

Step 2: Tool Selection

Choose the correct punch and die based on the material thickness and the desired bend radius. Ensure that the tools are in good condition and properly aligned in the Press Brake.

Step 3: Machine Setup

Configure the Press Brake settings according to the specific requirements of your project. This includes setting the correct bending force, back gauge position, and bend angle.

Step 4: Test Bend

Before proceeding with the final bend, perform a test bend on a scrap piece of the same material. This allows you to verify the machine settings and make any necessary adjustments.

Step 5: Performing the U Bend

Place the material on the Press Brake, aligning it carefully against the back gauge. Engage the Press Brake to perform the bend, applying consistent pressure until the material forms the desired U shape.

Step 6: Inspection and Adjustment

After the bend, inspect the piece for accuracy. Check the angle and dimensions against the project specifications. If necessary, make slight adjustments to the machine settings for subsequent bends.

Step 7: Repetition and Consistency

For multiple U Bends, repeat the process ensuring each bend is consistent with the first. Consistency is key in batch production or projects requiring multiple pieces.

By following this step-by-step guide, practitioners of Press Brake U Bending can achieve precise and consistent results. Each step is crucial in ensuring the quality and accuracy of the U Bend, contributing to the overall success of the bending project.

| Step | Description | Importance |

| Material Preparation | Select the appropriate material, considering factors like thickness and ductility, and ensure it is clean and debris-free. | Ensures the material is suitable and prepared for bending. |

| Tool Selection | Choose the correct punch and die based on the material thickness and desired bend radius. | Critical for achieving the desired bend shape and minimizing tool wear. |

| Machine Setup | Configure the Press Brake settings according to the specific project requirements. | Guarantees that the machine is correctly configured for the bending task. |

| Test Bend | Perform a test bend on a scrap piece to verify machine settings and make necessary adjustments. | Allows for fine-tuning of machine settings to achieve the desired bend. |

| Performing the U Bend | Place the material on the Press Brake, aligning it against the back gauge, and perform the bend. | The core step where the actual U Bend is executed. |

| Inspection and Adjustment | Inspect the bent piece for accuracy and make slight adjustments to the machine settings if necessary. | Essential for ensuring the bend meets quality and specification requirements. |

| Repetition and Consistency | For multiple U Bends, repeat the process ensuring each bend is consistent with the first. | Important in batch production to maintain uniformity across all bends. |

6.Quality and Precision in U Bending

6.1 Measuring and Controlling Bend Angles

Achieving precision in bend angles is a cornerstone of quality in Press Brake U Bending. This section explores the tools and techniques essential for measuring and controlling bend angles accurately.

Tools and Techniques for Angle Measurement

The precision of U Bends largely depends on accurate angle measurement. Tools like protractors, angle finders, and laser angle measurement devices are commonly used. Advanced Press Brakes might incorporate real-time angle monitoring systems that provide instant feedback during the bending process, allowing for immediate adjustments.

Achieving Precision in Bending Angles

Achieving precision in bending angles requires a combination of accurate tooling, machine calibration, and operator expertise. Regularly calibrating the Press Brake, using the correct tooling for the material and thickness, and employing skilled operators who understand the nuances of metal bending are key factors in achieving precise angles.

6.2 Managing Material Springback

Material springback is a common challenge in Press Brake U Bending, affecting the final angle and shape of the bend. Understanding and compensating for springback is vital for achieving desired outcomes.

Understanding Springback

Springback occurs when a material tries to return to its original shape after bending. This phenomenon varies with different materials and thicknesses and must be anticipated and accounted for during the bending process.

Techniques to Compensate for Springback

Compensating for springback involves over-bending the material slightly beyond the desired angle, allowing it to spring back to the correct position. The amount of over-bending required depends on the material's properties and the bend radius. Trial and error, along with experience, play a significant role in mastering this technique.

Achieving U Bend Perfection with KRRASS

In conclusion, mastering Press Brake U Bending is a journey of precision, skill, and the right tools. It's about understanding the nuances of the process and applying this knowledge to produce high-quality bends. As China's leading Press Brake manufacturer, KRRASS prides itself on offering top-tier Press Brake machines that cater to all your bending needs. By choosing KRRASS, you're not just acquiring a machine; you're gaining a partner in precision engineering. Visit our website to explore our range of products and start your journey towards bending perfection.

Read More:

What Is Press Brake Forming: All You Need to Know

Deciding Between Press Brake and Roll Forming: Key Factors to Consider