The following article will discuss essential guidelines and precautions for operating a hydraulic press brake. It is crucial to follow these instructions to ensure safe and efficient operation. Let's delve into the details.

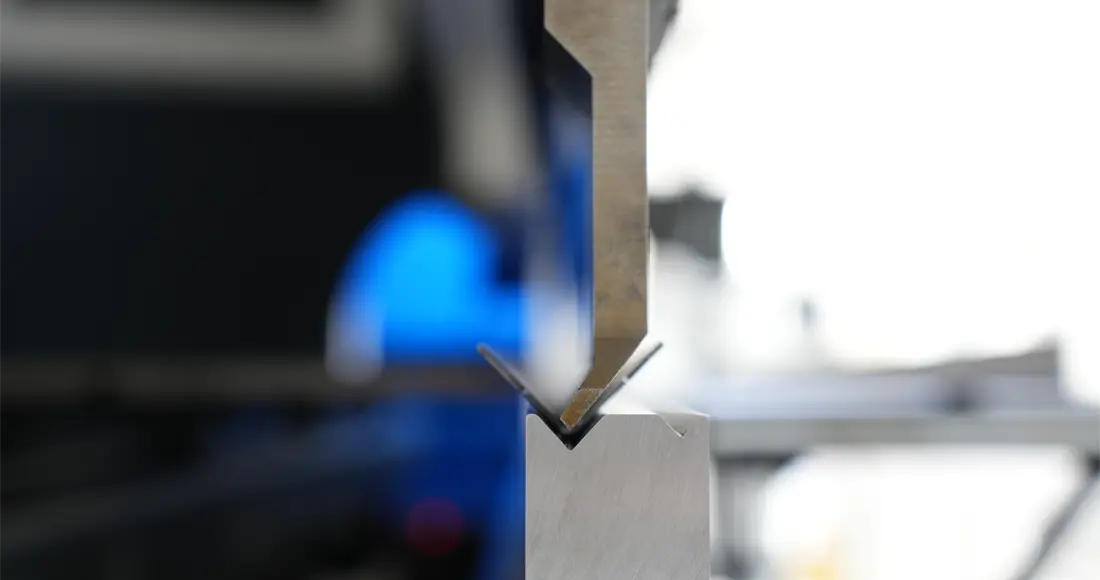

- Check the overlapping and firmness of the upper and lower molds; inspect if each positioning device meets the processing requirements.

- When the upper slide and each positioning axis are not at the origin, run the program to return to the head.

- After starting the hydraulic press brake, let it idle for 1-2 minutes and move the slide up and down 2-3 times throughout the stroke. If any abnormal sound or malfunction occurs, immediately stop the operation, troubleshoot the issue, and resume work only when everything is normal.

- During operation, one person should be in charge to ensure close coordination between the operator, feeding personnel, and pressing personnel. This ensures the collaborating individuals are safe before the bending signal is issued.

- During bending, the metal plate must be compressed to prevent it from lifting and causing harm during the bending process.

- When adjusting the sheet metal mold, the power supply must be cut off, and the operation should be stopped.

- When changing the opening of the variable lower mold, no material should come into contact with the lower mold.

- No one is allowed to stand behind the machine while operating.

- If any incorrect workpiece or mold is detected during operation, stop and correct it. It is strictly prohibited to fix it by hand to avoid hand injuries.

- It is prohibited to fold iron plates or quenched steel plates, high-alloy steel square bars, and thin plates that exceed the performance of the sheet metal press brake to prevent damage to the device.

- Regularly check the overlapping of the upper and lower molds and ensure that the pressure gauge meets the specified requirements.

- In case of any abnormalities with the hydraulic press brake, immediately stop the operation, investigate the cause, and promptly rectify the issue.

- Before shutting down the hydraulic press brake, place wooden blocks on the lower portion of the molds under both side cylinders to support the upper slide.

- First, exit the control system program and cut off the power supply.

Summary: Operating a hydraulic press brake requires careful attention to various aspects. Ensuring the proper alignment of molds, conducting routine checks, and promptly addressing any abnormalities are vital for safe and efficient operation. Additionally, strict adherence to safety protocols, such as avoiding manual corrections and standing behind the machine, is essential to prevent accidents. By following these guidelines, operators can enhance productivity and maintain a secure working environment.

KRRASS: the best choice for

all sheet metal processing manufacturers

When considering the overall costs of purchasing, maintaining, and operating a sheet metal equipment setup, a sheet metal fabrication service: KRRASS brand is your best choice. KRRASS has a tremendous reputation in the market due to its focus on consistency and quality at the most competitive price. Whether it's hydraulic press brake or any other application equipment, our team of experts has the right combination of industry knowledge and the latest tool to provide you with the best products and services on the market. Moreover, we set ourselves apart with our advanced system that is completely online. Just let us know what your product needs, request a quote, and start the process.

Make a request and Get Started Today

Get Instant Quote

Learn more about our products, please visit and subscribe to our Youtube channel