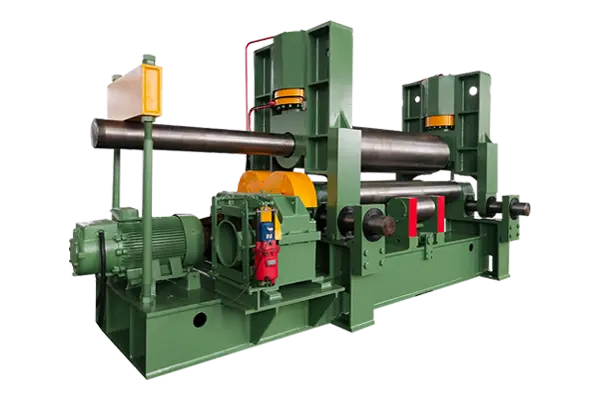

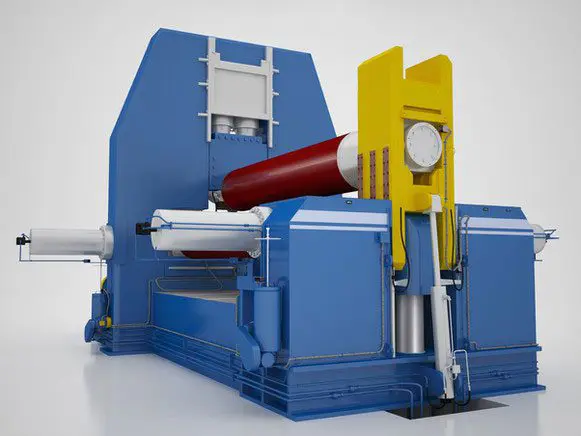

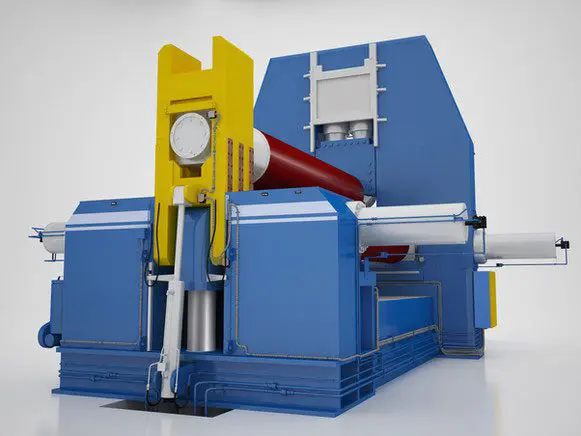

W11S 3-Rollers Variable Geometry Plate Rolling Machine

Unmatched capacity. Superlative precision. Optimal turnout.

Experience Hassle-free Bending By Plate Roller Machine

Our top-of-the-art Plate Rolling Machines are accessible and energy efficient. Ensure the steel plate bending work of peace of mind and convenient operation. KRRASS’s linear guided machine tools provide multiple benefits to your manufacturing infrastructure: efficient and long-lasting performance, unmatched edge bending accuracy, reduced capital expenditure, and reduced ongoing operating and maintenance costs.

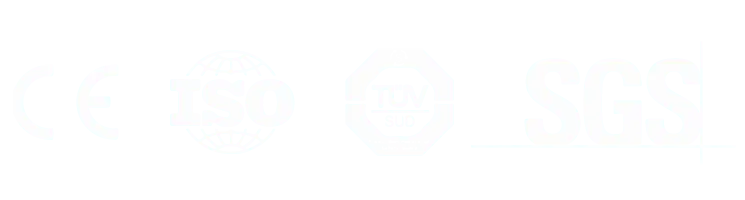

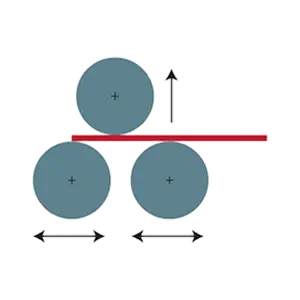

Superiority of Variable Geometry Design

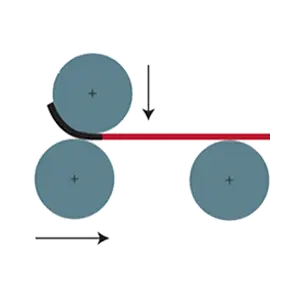

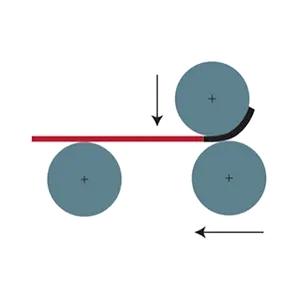

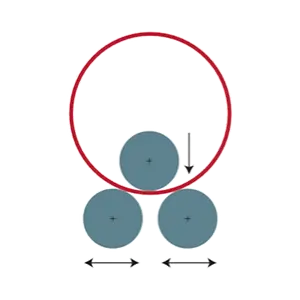

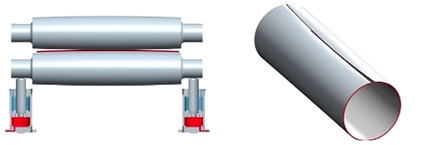

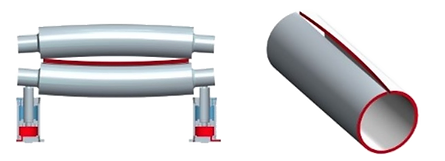

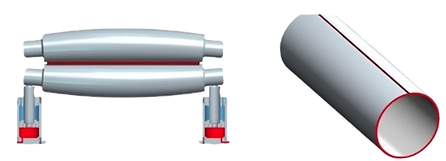

Plate bending/rolling process

①

②

③

④

KRRASS’s Variable Geometry machines deliver performance equivalent to that obtained with the more expensive 3-roll Plate Rolling Machine and are therefore ideal for medium-to-heavy-duty plate roller machines.

Exceptionally high rolling capacity is achieved due to the variable bending span of the bottom rolls. The rolling power can be 15-20 % higher than linear guideway and swing-guide designs of the same top roll dia machines.

The particular configuration of this design provides for the plate bending rolls to move independently by hydraulic cylinders – the top roll moves vertically; the bottom rolls move horizontally – and are rotated by integrated planetary gearboxes with hydro-motors. This allows for optimal central distance between the bottom rolls and the distance between the bending points offering immense advantages.

- For thin plates, the roll span can be drastically reduced, generating excellent traction, and avoiding driving slippage and spring-back.

- The bending span can be significantly increased for thick plates, thus reducing the bending load and plate deformation.

- Additionally, bottom rolls can be moved independently from each other and can be placed asymmetrically to achieve high-quality edge bending.

Another critical benefit of horizontally moving bottom rolls is that the plates can be fed using a simple unpowered conveyor, saving costs.

The variable geometry machines deliver multiple advantages to your fabrication infrastructure – a remarkably increased rolling capacity, reduced capital expenditure, and lower ongoing operational costs. They are the most attractive investment for heavy plate thickness (Above 80mm) applications.

The Advantage Of Plate Rolling Machine

Extensive Infrastructure

16,000 square meters of manufacturing facility in Nanjing, China’s Engineering Hub that strategically allows us easy access to infrastructure facilities like transport, raw materials, skilled workforce, power supply etc.

40+ Years Of Excellence

Our manufacturing excellence is underpinned by continuous product development. We have been leading the industry since over 40 years in design, build quality, performance and value for money. All our designs have been developed in-house and are fully supported by us.

Over 2500 Machines In Operation

We have manufactured and commissioned over 2500 machines across China and overseas. The first machine we ever sold is still in operation and is proudly supported by us.

400+ Repeat Clients

We enjoy loyalty of over 400 delighted clients. Beyond excellent performance of our machines, they also enjoy our on-demand service and our ever-ready inventory of a full set of spares for all machines we manufacture.

Enjoy the peace of mind that you are in good hands.

W11S-Series Plate Rolling Machine Product Range

| Model | Pressure of Top Roller (T) | Max. Bending Thickness (mm) | Pre-bending Thickness (mm) | Max. Bending Width (mm) | Top Roller Diameter (mm) | Bottom Roller Diameter (mm) | Central Distance (mm) | Main Motor (Kw) | ||

| For Drive | For Hydraulic | For Movement | ||||||||

| W11S-4x2500 | 25 | 4 | 3.5 | 2500 | 200 | 125 | 160 | 4 | 2.2 | 1.1 |

| W11S-6x2500 | 30 | 6 | 5 | 2500 | 210 | 125 | 160 | 4 | 2.2 | 1.1 |

| W11S-8x2000 | 37 | 8 | 6.5 | 2000 | 210 | 135 | 180 | 4 | 2.2 | 1.1 |

| W11S-8x2500 | 37 | 8 | 6.5 | 2500 | 235 | 135 | 180 | 5.5 | 2.2 | 1.1 |

| W11S-10x2000 | 37 | 10 | 8 | 2000 | 235 | 135 | 180 | 5.5 | 2.2 | 1.1 |

| W11S-10x2500 | 55 | 10 | 8 | 2500 | 250 | 145 | 200 | 7.5 | 4 | 1.1 |

| W11S-12x2000 | 65 | 12 | 10 | 2000 | 250 | 145 | 200 | 7.5 | 4 | 1.1 |

| W11S-12x2500 | 75 | 12 | 10 | 2500 | 265 | 145 | 200 | 7.5 | 4 | 1.5 |

| W11S-12x3000 | 75 | 12 | 10 | 3000 | 290 | 150 | 245 | 11 | 4 | 1.5 |

| W11S-16x2000 | 75 | 16 | 13 | 2000 | 265 | 150 | 245 | 7.5 | 4 | 1.5 |

| W11S-16x2500 | 100 | 16 | 13 | 2500 | 300 | 165 | 270 | 15 | 5.5 | 1.5 |

| W11S-16x3000 | 130 | 16 | 13 | 3000 | 330 | 180 | 300 | 15 | 5.5 | 2.2 |

| W11S-20x2000 | 100 | 20 | 16 | 2000 | 300 | 165 | 270 | 15 | 5.5 | 1.5 |

| W11S-20x2500 | 130 | 20 | 16 | 2500 | 330 | 180 | 300 | 15 | 5.5 | 2.2 |

| W11S-20x3000 | 160 | 20 | 16 | 3000 | 380 | 200 | 330 | 18.5 | 7.5 | 2.2 |

| W11S-20x4000 | 230 | 20 | 16 | 4000 | 440 | 235 | 380 | 30 | 11 | 4 |

| W11S-25x2500 | 190 | 25 | 20 | 2500 | 380 | 220 | 360 | 22 | 7.5 | 4 |

| W11S-25x3000 | 230 | 25 | 20 | 3000 | 410 | 235 | 380 | 30 | 11 | 4 |

| W11S-25x4000 | 270 | 25 | 20 | 4000 | 490 | 250 | 400 | 30 | 11 | 4 |

| W11S-30x2500 | 230 | 30 | 25 | 2500 | 410 | 235 | 380 | 30 | 11 | 4 |

| W11S-30x3000 | 270 | 30 | 25 | 3000 | 450 | 250 | 400 | 30 | 11 | 4 |

| W11S-30x4000 | 380 | 30 | 25 | 4000 | 550 | 275 | 460 | 45 | 22 | 5.5 |

| W11S-35x2500 | 320 | 35 | 28 | 2500 | 450 | 250 | 400 | 30 | 11 | 4 |

| W11S-35x3000 | 380 | 35 | 28 | 3000 | 510 | 275 | 460 | 45 | 22 | 5.5 |

| W11S-40x2500 | 380 | 40 | 32 | 2500 | 500 | 275 | 460 | 45 | 22 | 5.6 |

| W11S-40x3000 | 430 | 40 | 32 | 3000 | 540 | 290 | 500 | 55 | 22 | 7.5 |

| W11S-40x4000 | 540 | 40 | 32 | 4000 | 630 | 340 | 610 | 55 | 22 | 11 |

| W11S-45x3000 | 540 | 45 | 36 | 3000 | 590 | 340 | 610 | 55 | 22 | 11 |

| W11S-50x2500 | 430 | 50 | 40 | 2500 | 580 | 290 | 500 | 55 | 22 | 7.5 |

| W11S-50x3000 | 540 | 50 | 40 | 3000 | 600 | 340 | 610 | 55 | 22 | 11 |

| W11S-50x4000 | 690 | 50 | 40 | 4000 | 700 | 380 | 700 | 75 | 30 | 15 |

| W11S-55x3000 | 610 | 55 | 45 | 3000 | 620 | 360 | 650 | 75 | 30 | 15 |

| W11S-55x4000 | 850 | 55 | 45 | 4000 | 750 | 420 | 780 | 90 | 37 | 15 |

| W11S-60x3000 | 690 | 60 | 50 | 3000 | 650 | 380 | 700 | 75 | 30 | 15 |

| W11S-60x4000 | 930 | 60 | 50 | 4000 | 780 | 440 | 820 | 90 | 37 | 15 |

| W11S-70x3000 | 850 | 70 | 56 | 3000 | 710 | 420 | 780 | 75 | 37 | 15 |

| W11S-70x4000 | 1150 | 70 | 56 | 4000 | 840 | 480 | 920 | 110 | 45 | 18.5 |

| W11S-75x3000 | 930 | 75 | 60 | 3000 | 740 | 440 | 820 | 90 | 37 | 15 |

| W11S-80x3000 | 1050 | 80 | 65 | 3000 | 770 | 460 | 880 | 90 | 37 | 18.5 |

| W11S-90x3000 | 1150 | 90 | 75 | 3000 | 820 | 480 | 920 | 110 | 45 | 18.5 |

| W11S-100x3000 | 1350 | 100 | 80 | 3000 | 860 | 480 | 920 | 110 | 45 | 22 |

| W11S-110x4000 | 1800 | 110 | 90 | 4000 | 950 | 600 | 1120 | 132 | 55 | 37 |

| W11S-120x3000 | 1800 | 120 | 100 | 3000 | 920 | 580 | 1120 | 132 | 55 | 37 |

| W11S-120x4000 | 2300 | 120 | 100 | 4000 | 990 | 640 | 1280 | 275 | 75 | 37 |

| W11S-150x3000 | 2300 | 150 | 120 | 3000 | 1050 | 660 | 1280 | 2x75 | 75 | 45 |

| W11S-160x3000 | 2500 | 160 | 130 | 3000 | 1080 | 700 | 1360 | 2x75 | 75 | 45 |

| W11S-160x4000 | 2800 | 160 | 130 | 4000 | 1260 | 720 | 1380 | 2x90 | 90 | 45 |

* All Sizes in mm.

* All capacities are as per 260 MPA.

We offer machines with fixed and variable speeds according to your application and feed requirements.

Build Quality & Benefits

Sturdy Steel Structure

KRRASSs’s Plate Rolling Machine have a strong steel structure made from heavy metal plates. These frames are connected through a sturdy box design chassis and are equipped with interlocking and stiffening ribs. Rolling guides are machined together utilizing a single fixed reference point, which allows for parallel of all shafts and precision surfaces, as well as the machine’s life and critical precision characteristics.

Rolls Of Plate Rolling Machine

The rolls are the most important elements of our sheet metal plate bending machine. KRRASS designed the optimum diameter roll and used a forged carbon steel roll machined with a high-precision CNC lathe. Our rollers have a unique spline-based design, which effectively connects the rollers with the planetary gear system. This design reduces roll failure points compared to welded connections offered by other manufacturers.

Crowning Of Plate Rolling Machine

Our rolls are crowned to compensate for roll deflection during the bending process. Custom crown-machined rolls for different materials or thickness can be selected when ordering.

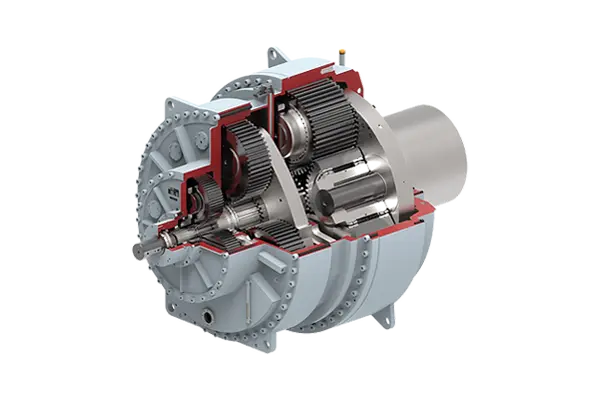

Hydraulic Gear System Of Plate Rolling Machine

Additional energy saving is ensured in our 4-Rolls sheet metal plate bending machine by a hydraulic system which can work at less than full capacity when jobs less than maximum thickness are rolled.

KRRASS Planetary driving system ™ used in our machines is efficient and eliminates energy wastage associated with heavy-transmission systems and yet achieves the goal of speed reduction by increasing the stages in gears and pinions.

Operational Benefits

Pre-Pinching (Pre-Bending)

Edge bending can be done before or after shell rolling depending on operator skill and choice. Thin plates can be rolled and edge-bent in a single pass.

Easy Cone Bending

The cone bending process with the W12 series is simple. The bottom rolls need to be inclined to achieve cone bending geometry. This is controlled and monitored by electronic microprocessor (on some models).

Our control system also ensures easy and accurate return to parallel setting after cone bending resulting into precision on repetitive jobs.

High Productivity

- State-of-the-art in forming cylinders and cones.

- Easy to install, extremely user-friendly and convenient to service.

- Simple to learn and operate. No extensive operator training required.

- Robust construction reduces wear & tear.

- Readily available spare parts.

- Tropicalized oil cooling system ensures non-stop operations in hot working conditions.

- Easy to understand hydraulic and electrical system reduce unwanted down time.

Versatility

Other than cylinders and cones, other non-circular shapes like oil tankers and elliptical shells can be made using a PLC version.

High Productivity

- State-of-the-art in forming cylinders and cones.

- Easy to install, extremely user-friendly and convenient to service.

- Simple to learn and operate. No extensive operator training required.

- Robust construction reduces wear & tear.

- Readily available spare parts.

- Tropicalized oil cooling system ensures non-stop operations in hot working conditions.

- Easy to understand hydraulic and electrical system reduce unwanted down time.

Additional Features Of Sheet Metal Plate Bending Machine

Alongside our excellent design and build quality, we provide the following additional features and accessories upon request from our client.

1

Surface-Hardened Rolls

Induction Hardened Rolls having Surface Hardness between 42 to 55 HRC for additional durability and longevity.

2

Complete Windmill Tower Manufacturing Package

Including central and side shell support, tilting conveyors, hardened rolls and PLC/CNC capabilities

3

Central & Side Shell Supports

Central & side shell supports provide ease of operation, operational cost saving and productivity while increasing safety of workers.

4

Hard Chrome Plated Rolls

Hard chrome plated rolls for special applications in Pharma and Dairy Industry.

5

Tilting Table

Tilting tables for support while feeding plates at specific angles. Specially useful for plates of larger lengths.

6

Conveyors

Powered Conveyors that provide ease of plate feeding in case of longer plate lengths, improved machine performance and longevity.

7

PLC Control

PLC Controllers provide precision, ease of operation, while identifying needs for preventive maintenance to increase machine life and optimize productivity.

FAQs For Sheet Metal Plate Bending Machine

What is done to compensate for deflection of rolls during pre-bending and rolling?

All rolls are crowned (cambering) for compensating deflection.

What is the arrangement provided for balancing of top roll when swing arm is opened?

Top roll is counter balanced automatically once the drop end is opened without any jacks or manual arrangement.

Is there any method to know the position of bottom rolls?

DRO (Digital Readout) is housed on the operating console which gives the position of the bottom rolls with respect to the top roll.

What is the capacity for cone bending?

Cones can be bent up to the edge-bending capacity of the machine. The bottom rolls can be inclined for the required cone angle.

What is the level of protection for electrical components?

Some of the electrical bough outs are IP 55 like motors, switchgears etc. The electrical cabinet will be manufactured as per our standard practices and will meet IP 55 protection.

Is the main drive reversible?

Forward and reverse to the main drive is provided. The bottom rolls can be moved up and down individually.

What is the type of oil required?

Hydraulic oil – Enklo 68 Planetary Gear box – EP 90

Where are the main machine controls?

Operating console houses push buttons for all the operations of the machine. The console is movable so that the operator can keep it at any desired location.

Can we bend hot plates on the machine to get higher thickness capacity?

Although the standard machine is not meant for hot rolling, occasional hot rolling can be done (a few jobs per month) provided that suitable precautions are taken.

Some plates have high yield point. The machines are rated for 26kg/mm2. How to find the equivalent thickness?

A. Divide the Actual YP by 26. Find square root of this number. Multiply this value by actual plate thickness to get effective thickness.

Reviewed by 3 users

i bougth W11S 20*3000mm rolling machine from KRRASS.

I’m impressed with W11S-12*2500 plate rolling machine quality. I would buy again from this seller.

I was apprehensive before making the purchase, but I received a perfect machine after communicating with the Krrass

Plate rolling machine

This machine very good.I bought one two years ago.