Plasma Cutter Machine combines the precision of plasma cutting with the power of oxy-fuel cutting, making it a versatile choice for both industrial and artistic applications. By harnessing the heat generated by a plasma arc and the chemical reaction of oxygen with metal, this process can cut through a wide range of materials, offering flexibility and efficiency in creating intricate designs for artistic and decorative projects.

Table of contents

II. Designing for Plasma Cutter Machine

IV.Project Ideas and Inspiration

I. Materials and Equipment

Compatible Materials

Plasma Cutter Machine is primarily used with metals such as steel, stainless steel, and aluminum, ranging in thickness from thin sheet metal to thick plates. Non-metal materials like ceramics may also be cut using specialized techniques.

Required Equipment

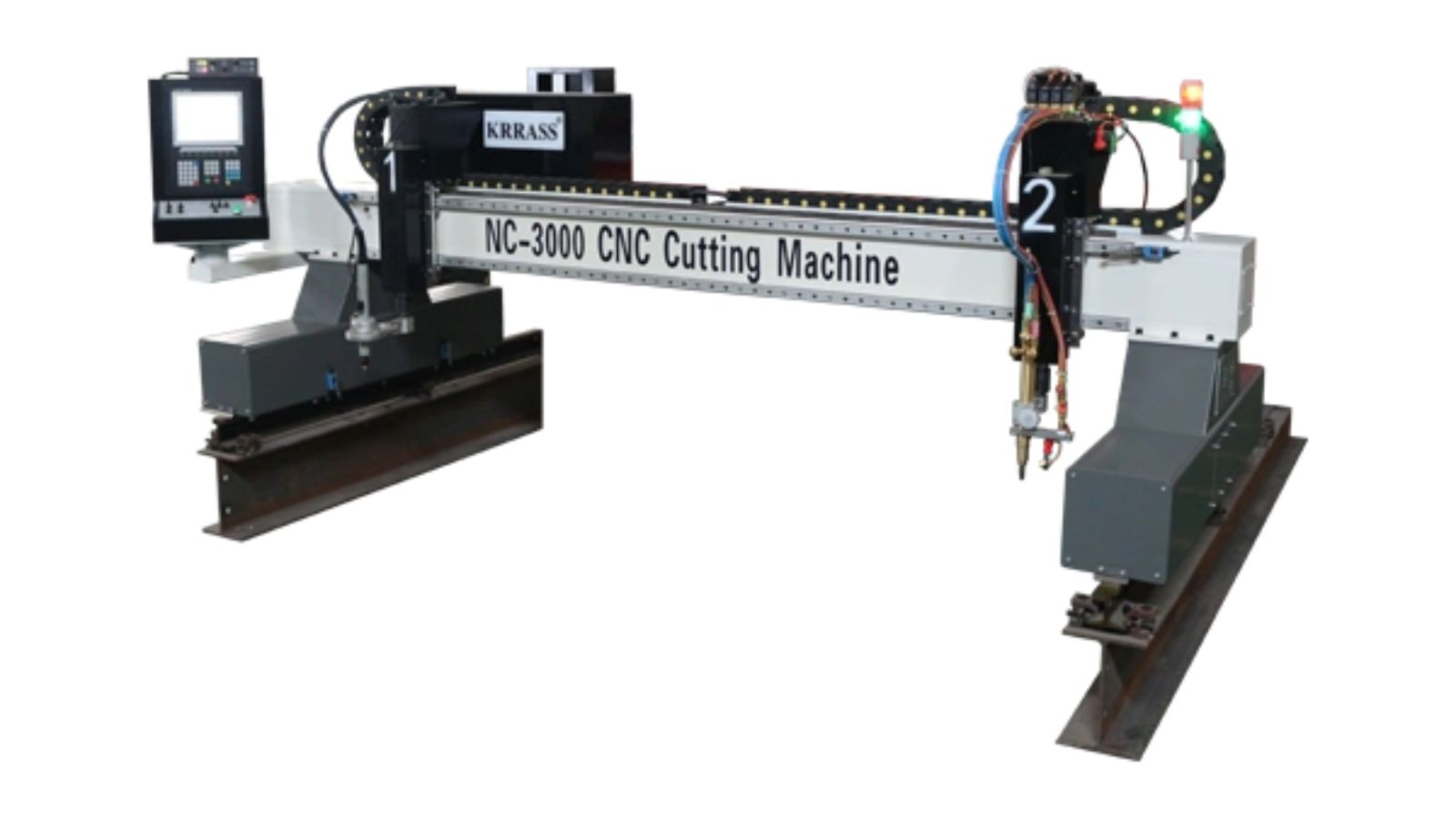

To perform Plasma Cutter Machine, essential equipment includes a plasma cutting machine equipped with oxy-fuel capabilities. Safety gear such as gloves, goggles, and protective clothing is crucial due to the intense heat and sparks produced during cutting.

II. Designing for Plasma Cutter Machine

Design Best Practices

Designing for Plasma Cutter Machine involves creating vector-based designs that account for the cutting path and material thickness. Software tools like CAD (Computer-Aided Design) programs or dedicated plasma cutting software assist in designing intricate patterns and shapes.

Transferring Designs

Designs are typically transferred to the material using templates, stencils, or direct programming of the cutting machine. Precision in design ensures accurate reproduction of artistic elements and decorative features.

III.Techniques and Tips

Basic Cutting Techniques

Techniques for Plasma Cutter Machine include:

- Straight-line cutting

- Curved and circular cuts

- Piercing and starting holes

Tips for Precision

Achieving precise cuts requires:

- Maintaining consistent cutting speed and torch height

- Adjusting cutting parameters based on material thickness

- Conducting test cuts to optimize settings

Creating Artistic Effects

Techniques such as varying cutting speeds, torch angles, and using different consumables can produce textures, gradients, and dimensional effects in metal artworks.

IV.Project Ideas and Inspiration

Artistic and Decorative Projects

Plasma Cutter Machine lends itself to a variety of projects:

- Metal sculptures and artwork

- Decorative panels and signage

- Architectural elements and custom designs

Examples and Case Studies

Showcase successful projects like intricate metal artworks, personalized signs, or bespoke furniture components, highlighting the versatility and creativity achievable with Plasma Cutter Machine.

Finding Inspiration

Drawing inspiration from nature, geometry, or cultural motifs helps generate unique design concepts for Plasma Cutter Machine projects.

V.Finishing Touches

Post-Cutting Finishing

After cutting, finishing techniques may include:

- Deburring to remove sharp edges

- Grinding and polishing for smooth surfaces

- Surface treatments such as painting, powder coating, or patination to enhance aesthetics and durability

Assembly and Display

Assembling cut pieces into final artworks or installations and choosing appropriate display methods ensures the artwork's integrity and visual impact.

VI.Conclusion

This guide provides a guide to using Plasma Oxy Cutting for art making. To learn more about other metalworking methods, read our guides here.