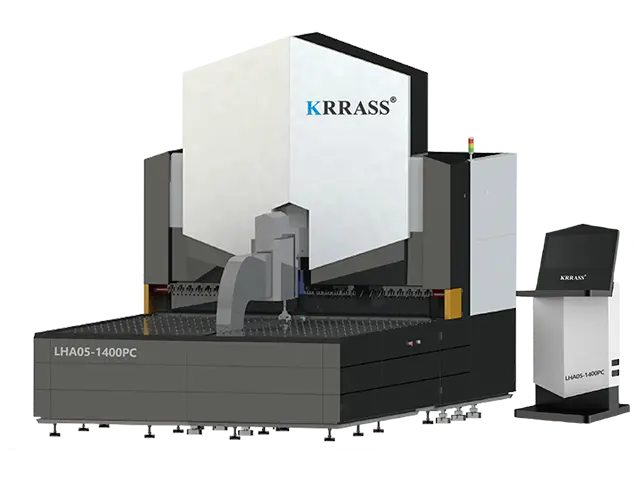

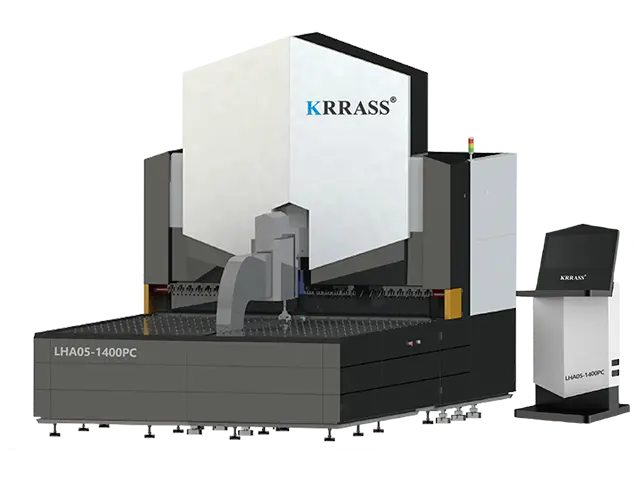

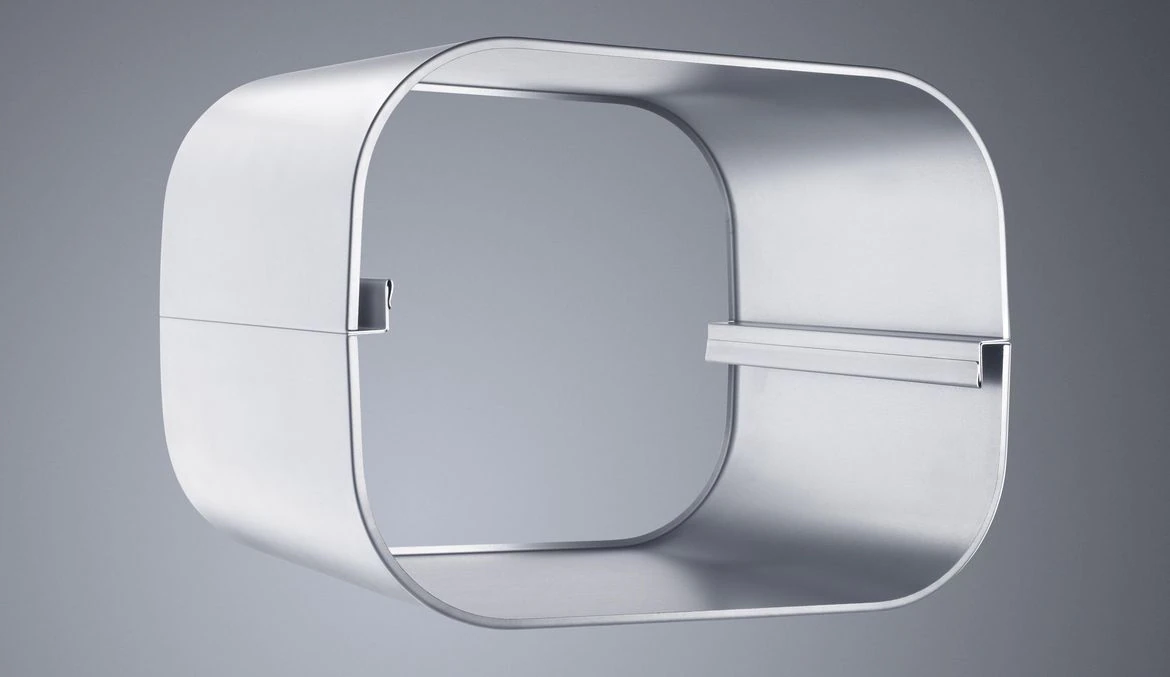

Panel Bender Machine

Servo Electrical Fully-automatic Panel Bender Machine

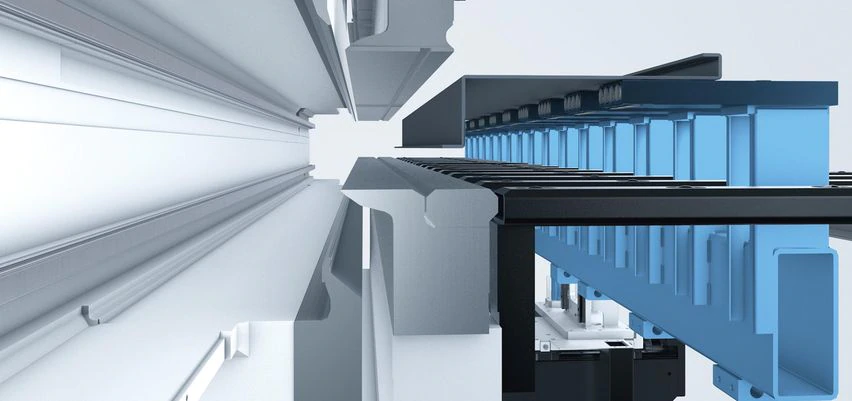

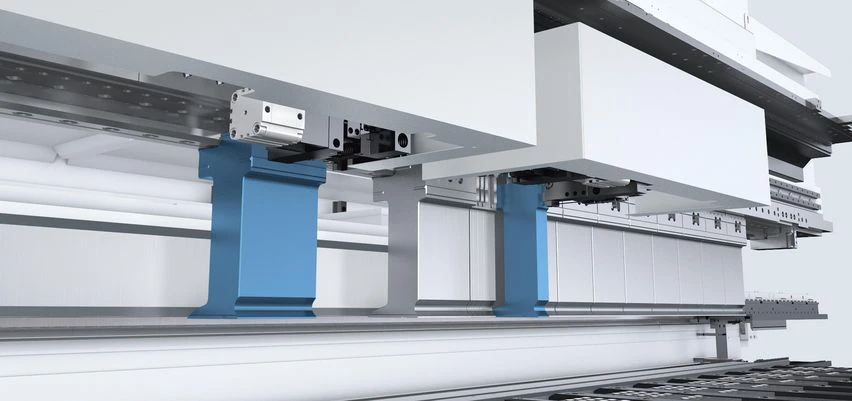

The intelligent CNC automatic panel bender machine / press brake machine is equipment for processing thin plates and folding them. The machine’s structure mainly includes a tool holder, a worktable, a clamping feeding device, and a CNC operating table. The machine’s worktable comprises a base and a clamping piece feeding structure.

Panel bender machine with high speed, high productivity and low energy consumption

High degree of automation, simple operation, no need to replace the upper and lower mold, save time

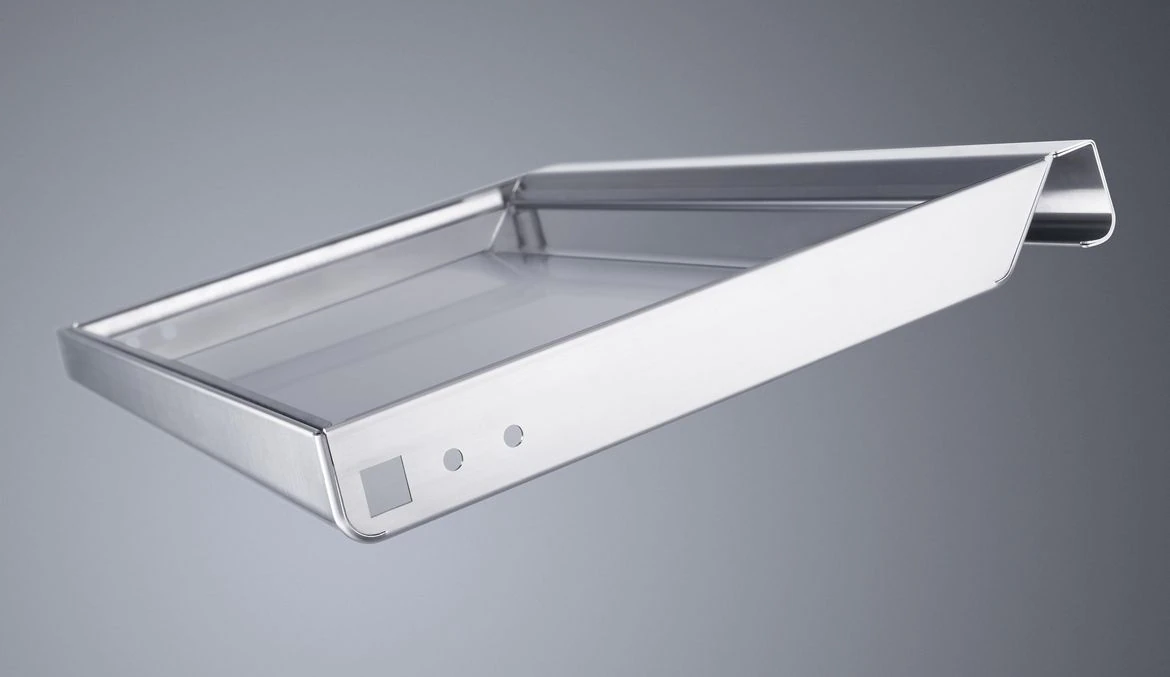

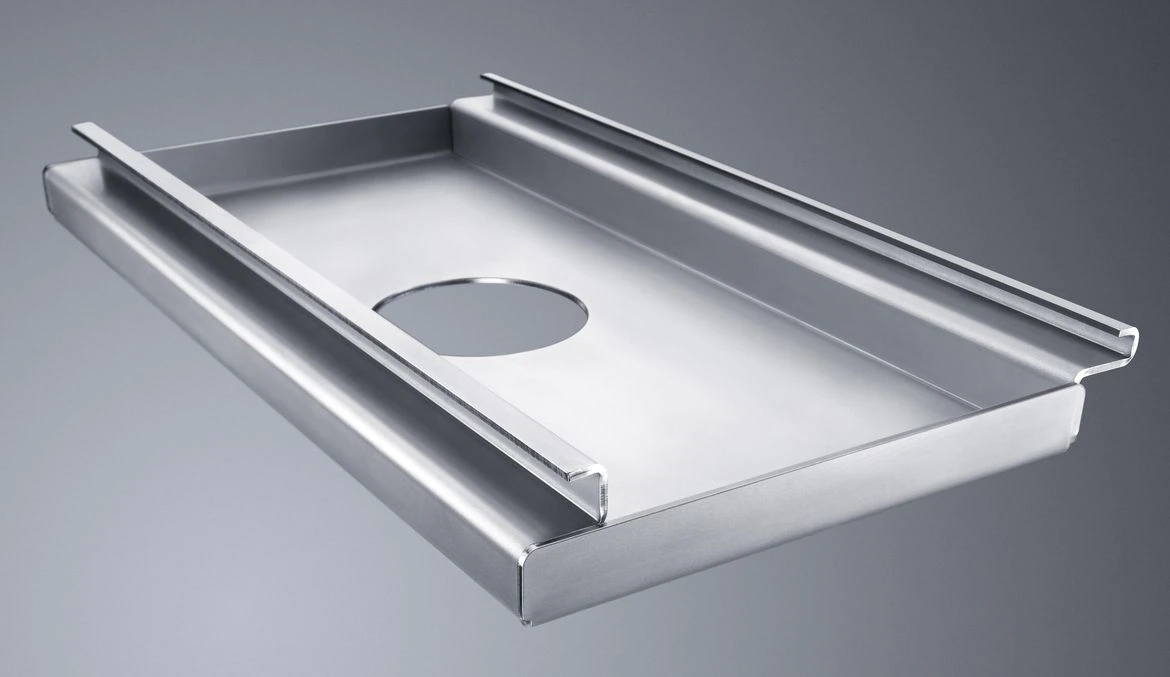

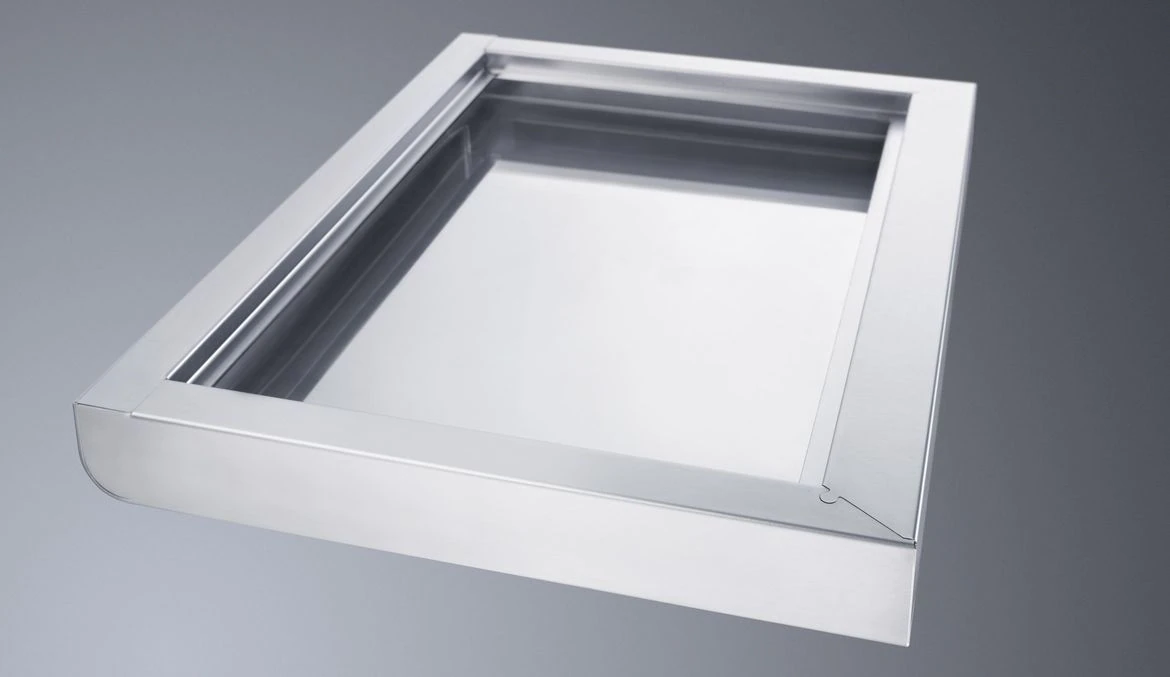

The bending tool can complete the shape of non-right angle, right angle, circular arc, pressing dead edge, etc.

GENERAL INFORMATION

The intelligent CNC automatic panel bender machine / press brake machine is equipment for processing thin plates. The machine’s structure mainly includes a tool holder, a worktable, a clamping feeding device, and a CNC operating table. The machine’s worktable comprises a base and a clamping piece feeding structure.

- Rotary part manipulator: The rotary part manipulator secures the blank and rotates it to the required position completely independently.

- Two axes, limitless possibilities: The 2-axis part manipulator positions the sheet metal and even enables negative bends.

- Precise angles: First part, perfect part – with the ACB laser

- Programming in the blink of an eye: The easiest and fastest offline programming among panel benders: TecZone Fold.

- Integrated tool change: Set up the right upper blank holder tools automatically with the integrated tool changer ToolMaster Bend.

- Every component under control: Various gripper systems help to hold the components.

- Automatic loading and unloading: Higher productivity due to loading and unloading that is parallel to production.

- On-Demand Servo Drive: The on-demand servo drive works quickly, quietly, and in an energy-efficient way.

Introduction to Configuration

Rotary part manipulator

Every bend is fully automatic with the innovative rotary part manipulator. It secures the blank and, if necessary, rotates it to the correct position at a speed of 118 in/sec. The operator has a lighter workload and is only responsible for loading and unloading. This makes the bending operation highly productive.

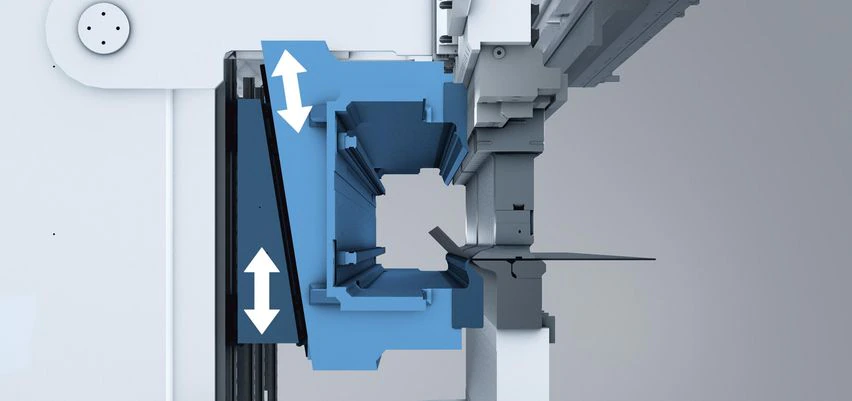

2-axis part manipulator

The 2-axis part manipulator automatically positions the sheet metal for all bends on every component edge. An additional height axis enables components to be secured in different positions. With this height axis, parts with negative angles are also unloaded reliably. This increases your part flexibility and lets you produce narrow profiles and components with multiple bends or formed sections and cutouts while maximizing process reliability.

Angle drive

With its ingeniously simple continuous path control, the innovative angle drive of the TruBend Center ensures maximum accuracy. The interaction between two axes provides the ideal traverse path to protect the surface of your component. The drive design also makes your TruBend Center particularly robust for everyday industrial applications.

Integrated tool changer (optional)

The integrated tool changer, ToolMaster Bend, automatically sets up the right upper blank holder tools. It also takes care of a whole host of work for you. It prevents setup errors, reduces setup times, and enables cost-effective single part production.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

Technical Parameters of fully-automatic panel bender machine

| Model | RAS-1500/RAS-2000/RAS-2500 |

|---|---|

| Minimum continuous bending speed | 0.5s/knife |

| Bending thickness | 201 stainless steel 0.8mm, 304 stainless steel 1.0mm cold steel 1.2mm, aluminum steel 1.6mm |

| Max bending length(mm) | 1500/2000/2500 |

| Max bending height(mm) | 170 |

| Min molding size of four sides (mm) | 280*280 |

| Bending angle | 0-180 |

| Max feeding speed(m/min) | 120 |

What are the industrial application of panel bender machine?

This panel bending machine is a high-tech product developed and produced for the sheet metal industry to improve productivity, reduce the labor intensity of operators, and improve product quality. They are widely used in refrigeration, medical treatment, building materials, kitchen utensils, environmental protection, wind turbines, and other industries.

Reviewed by 2 users

panel bender machine

Very good panel bender machine. We’ll be working with KRRASS. It’s a great honor to be your agent.

Хороший сгибатель

Доставка отличная, сроки изготовления заказа отличные, качество гибочного станка отличное.Спасибо Amy.