Welcome to the comprehensive guide on Panel Bender Machine Techniques for Efficient Fabrication. In today's competitive manufacturing landscape, leveraging the right technology and techniques is paramount for success. This article explores the ins and outs of panel bender machines, from basic operations to advanced automation, and how they revolutionize metal fabrication. Whether you're a small-scale operator or part of a large industrial setup, understanding these machines' capabilities can significantly enhance your production efficiency and product quality.

- Basics of Panel Bender Machines

- Key Components and Their Functions

- How Panel Bender Machines Work

- Types of Panel Bender Machines

- Preparing for Panel Bending

- Design Considerations

- Setting Up the Machine

- Bending Process Techniques

- Advanced Techniques and Tips

- What materials can be processed with a panel bender?

- How do I choose the right panel bender machine for my needs?

- Can panel bender machines be used for small-scale projects?

- How does automation affect the cost-effectiveness of panel bending?

Basics of Panel Bender Machines: Components and Mechanics

Diving into the world of fabrication, the panel bender machine stands out as a cornerstone for efficient and precise metal forming. This marvel of engineering not only streamlines the bending process but also ensures unmatched accuracy and repeatability. At its core, the panel bender machine is designed to manipulate metal sheets into specific angles and shapes, catering to a wide array of industrial applications. Let's peel back the layers to understand the components and mechanics that make up this innovative machine.

Firstly, the frame of the panel bender machine provides the necessary support and stability. Made from high-strength materials, it withstands the rigors of bending operations without compromising on precision. The bending blade, a critical component, executes the actual bending action. Its design varies according to the machine model and the specific requirements of the bending process. The blade's material and structure are pivotal in achieving clean, crisp bends.

The control system serves as the brain of the operation. Modern panel benders are equipped with sophisticated software that allows for precise control over the bending process. This system enables operators to input parameters such as bend angle and sheet thickness, ensuring each bend is executed with precision. Furthermore, the control system provides the ability to store and recall programs for repeated production runs, enhancing efficiency and consistency.

Another essential element is the clamping system. It securely holds the metal sheet in place during the bending operation, preventing slippage and ensuring accuracy. The design of the clamping system varies, with some machines featuring pneumatic or hydraulic clamps for added strength and reliability.

Lastly, the backgauge plays a crucial role in positioning the metal sheet accurately before each bend. This component is adjustable and can be programmed to move to specific locations, allowing for precise control over the bend location. The backgauge ensures that each piece is processed consistently, which is vital for batch production and maintaining high-quality standards.

Key Components and Their Functions

To harness the full potential of panel bender machines in the realm of efficient fabrication, it's essential to delve deeper into the key components that drive their functionality. Each part plays a pivotal role in ensuring the machine operates at peak efficiency, delivering precision and reliability in every bend. Here, we explore these components and their indispensable functions within the system.

Bending Blade: The heart of the panel bender, the bending blade is responsible for the actual bending of the metal sheets. Its design is tailored to accommodate various material thicknesses and bend angles, ensuring flexibility across a range of applications. The quality and material of the blade directly influence the precision and quality of the bends it produces.

Control System: Acting as the brain of the machine, the control system orchestrates the bending process with precision and efficiency. Advanced software enables operators to set detailed parameters, such as bend sequences and angles, while also offering the capability to store programs for future use. This digital backbone ensures repeatability and accuracy in production runs.

Clamping System: Essential for securing the metal sheet in place during bending, the clamping system prevents movement that could lead to inaccuracies. Depending on the machine's design, these clamps may be operated pneumatically or hydraulically, offering robust performance and reliability.

Backgauge: Precision in bending is not solely about the bending action but also about the correct positioning of the sheet prior to bending. The backgauge facilitates this by accurately positioning the metal sheet for each bend. Adjustable and programmable, it ensures that each piece is bent at the correct location, crucial for consistent output.

Frame: The structural backbone of the panel bender machine, the frame supports all other components. Its robust construction is designed to absorb the forces exerted during bending operations, maintaining machine stability and alignment, which are vital for achieving precise bends.

Together, these components form a cohesive system that defines the panel bender machine's capabilities. Understanding the role and importance of each component can help operators maximize the machine's efficiency and productivity, leading to streamlined operations and superior fabrication quality.

How Panel Bender Machines Work

The magic behind the seamless operation of panel bender machines lies in their sophisticated working mechanism, which combines precision engineering with advanced technology. This synergy enables the machines to transform flat metal sheets into precise shapes and angles, crucial for various applications in industries ranging from automotive to construction. Let's unravel the process step by step to grasp the fascinating workings of panel bender machines.

Initially, the preparation phase begins with the selection of the metal sheet to be bent. The operator inputs the necessary parameters into the control system, including the type of metal, thickness, dimensions, and desired bend angles. This setup phase is critical for ensuring the machine's settings align with the specific requirements of the job at hand.

Following setup, the metal sheet is positioned on the machine's worktable. The backgauge adjusts according to the programmed settings to align the sheet precisely for the first bend. This positioning is crucial for the accuracy of the bend locations and angles.

Once the sheet is in place, the clamping system activates to secure the metal sheet, preventing any movement during the bending process. This stability is key to achieving precise bends and maintaining the integrity of the material's dimensions.

The bending process commences as the bending blade applies force to the metal sheet, creating a bend at the specified angle. The control system meticulously regulates the force and angle, ensuring each bend is executed with precision. Depending on the complexity of the part, the machine may perform multiple bends in sequence, repositioning the sheet as necessary with the help of the backgauge.

Throughout the operation, the control system continuously monitors the process, making adjustments in real-time to compensate for any variations in material properties or external factors. This adaptive capability ensures that the final product meets the specified dimensions and tolerances, showcasing the machine's precision and flexibility.

In conclusion, panel bender machines operate through a meticulous process of preparation, positioning, securing, bending, and continuous monitoring. This process underscores the machine's role in modern fabrication, where precision, efficiency, and adaptability are paramount. By understanding how these machines work, operators can optimize their use, leading to improved productivity and quality in metal forming operations.

Types of Panel Bender Machines

Panel bender machines come in various types, each designed to meet the diverse needs of the fabrication industry. From manual to fully automatic models, the choice of machine significantly impacts productivity, precision, and the type of projects it can handle efficiently. Let's explore the different types of panel bender machines, along with their pros and cons, and identify the projects they are best suited for.

Manual Panel Benders

Pros: Manual panel benders offer simplicity and affordability. They are ideal for small workshops or businesses just starting out in metal fabrication. These machines provide direct control over the bending process, allowing for adjustments based on the operator's skill and experience.

Cons: The main drawback is their reliance on manual labor, which can lead to inconsistencies in production and limit the speed and volume of output. Additionally, they require a higher level of operator skill to achieve precision in bends.

Suitable Projects: Manual panel benders are best suited for custom or low-volume projects where the flexibility and craftsmanship of the operator can be leveraged to produce unique or bespoke items.

Semi-Automatic Panel Benders

Pros: Semi-automatic models strike a balance between manual and fully automatic machines, offering a higher level of precision and productivity without the full investment in automation. They require less manual effort and provide more consistent results than manual benders.

Cons: While they improve on efficiency and consistency, semi-automatic panel benders still require operator intervention for certain tasks, limiting their output compared to fully automatic models.

Suitable Projects: These machines are ideal for medium-sized production runs or workshops that deal with a variety of projects, providing a good balance of speed, flexibility, and cost.

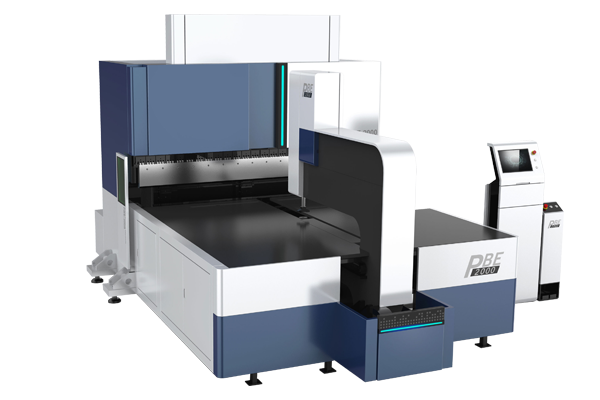

Fully Automatic Panel Benders

Pros: Fully automatic panel benders are the pinnacle of technology and efficiency in metal fabrication. They offer the highest level of precision, speed, and consistency, with minimal human intervention required. These machines can handle large volumes of work with ease, thanks to advanced control systems and automation technologies.

Cons: The main disadvantages are the higher cost of investment and the complexity of operation and maintenance. Additionally, the flexibility to handle unique, one-off projects may be somewhat reduced compared to manual or semi-automatic machines.

Suitable Projects: Fully automatic panel benders are best suited for high-volume production environments where efficiency, speed, and repeatability are critical. They excel in industries such as automotive, appliance manufacturing, and construction, where precision and productivity are paramount.

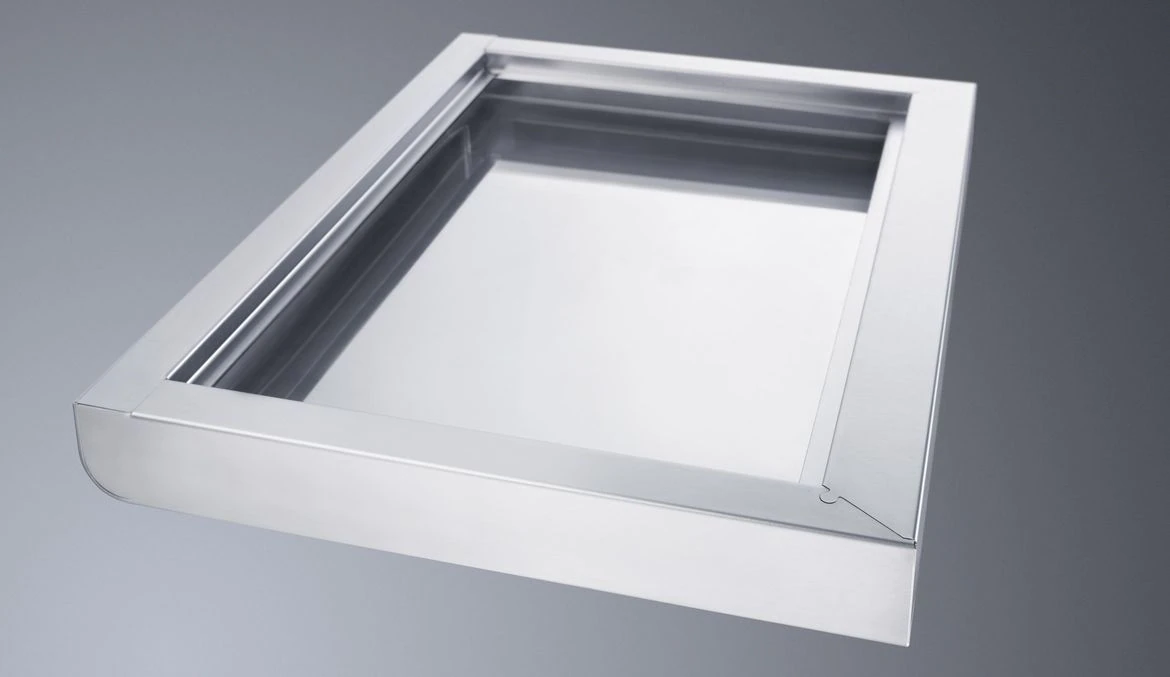

Preparing for Panel Bending: Material Selection

The foundation of any successful panel bending operation is the careful selection of materials. This process goes beyond merely picking a metal type; it involves a thorough assessment of the material's properties, including its thickness, grain direction, and suitability for the intended application. The right material selection ensures not only the efficiency of the bending process but also the quality and durability of the final product. Let's take a deeper dive into the factors that influence material selection in panel bending.

Types of Metals and Their Suitability

Each metal brings its unique set of properties to the bending process, influencing both the technique used and the outcome achieved:

- Aluminum: Highly valued for its exceptional weight-to-strength ratio, aluminum is versatile but requires precision due to its propensity for surface marring and cracking if not handled correctly.

- Steel: Its strength and resilience make steel a go-to material for structural components. The type of steel, whether it's mild or high-tensile, can greatly affect the bending process and machine settings.

- Stainless Steel: Preferred for its corrosion resistance and finish, stainless steel poses challenges in bending due to its strength and work hardening characteristics. Proper tooling and techniques are essential to prevent cracks and maintain surface integrity.

- Copper and Brass: These metals are often selected for their electrical conductivity and aesthetic properties. Their softness requires a delicate approach to prevent over-bending and distortion.

Impact of Material Thickness and Grain Direction

Understanding the material's physical characteristics is crucial for preparing the bending process:

- Material Thickness: Thicker materials demand higher bending forces, impacting machine capacity and wear. Adjusting bending parameters to accommodate material thickness is vital for achieving precise angles without damaging the equipment or the workpiece.

- Grain Direction: The orientation of the grain relative to the bending axis affects the material's behavior during bending. Bending against the grain can increase the risk of cracking, especially in metals like aluminum and stainless steel. Knowledge of the material's grain direction enables operators to plan bends that minimize stress and potential defects.

Moreover, the choice of material and its characteristics directly influences the selection of the appropriate panel bender machine and its settings. Factors such as bending speed, clamping force, and blade gap need to be adjusted based on the material's properties to ensure optimal bending performance.

In conclusion, the meticulous preparation for panel bending through informed material selection lays the groundwork for successful fabrication projects. By understanding and respecting the unique properties of each type of metal, fabricators can optimize their processes, reduce waste, and achieve high-quality results that meet or exceed project specifications. This level of preparation and knowledge ensures that every bend in the fabrication process is a step towards excellence in the final product.

Design Considerations for Panel Bending

When it comes to panel bending, success is not only determined by the operation of the machine but also by the initial design considerations. These considerations include understanding bend allowance, designing for minimized waste, and operating panel bender machines efficiently. Let’s delve into these aspects to ensure that your fabrication process is as efficient and effective as possible.

Understanding Bend Allowance

Bend allowance is a critical concept in sheet metal fabrication, referring to the amount of material needed to accommodate a bend. It varies based on the angle of the bend, the thickness of the material, and the method of bending. Incorrect calculations can lead to significant material waste or parts that do not fit their intended purpose. To accurately calculate bend allowance, fabricators must consider the specific radius of the bend and the material's properties, ensuring that the final dimensions are precise.

Designing for Minimized Waste

Efficient material use is not just an economic concern; it’s also about sustainability. Designing for minimized waste involves strategic planning of the layout and nesting of parts on a sheet. Utilizing software that can optimize these layouts can significantly reduce scrap material, lowering costs and environmental impact. Additionally, considering the sequencing of bends and the direction of grain in the material can help in reducing adjustments and rework, further minimizing waste.

Operating Panel Bender Machines Efficiently

The operation of panel bender machines plays a pivotal role in the fabrication process. Efficiency in operation not only speeds up production but also ensures the quality of the final product. This involves regular maintenance of the machine, proper training for operators, and the use of technology to streamline operations. Advanced panel benders come equipped with software that allows for pre-programming of bending sequences, automatic adjustment of bending parameters based on material data, and even simulation of the bending process to identify potential issues before they occur.

Incorporating these design considerations from the outset can dramatically improve the efficiency and quality of the panel bending process. By understanding and applying the principles of bend allowance, designing for minimal waste, and efficiently operating panel bender machines, fabricators can ensure that their projects are not only successful but also sustainable and cost-effective.

Setting Up the Machine: Calibration and Material Setup

The initial setup of a panel bender machine is a crucial step that directly impacts the efficiency, accuracy, and quality of the bending process. Proper calibration and material setup, along with careful tooling selection and configuration, are essential to ensure optimal performance. Let's explore the key considerations and steps involved in setting up the machine for operation.

Calibration and Material Setup

Calibration is the process of configuring the machine to perform accurately according to the specifications of the material being used. This involves adjusting the machine settings such as bend angle, force, and backgauge position to match the material's thickness, type, and other properties. Accurate calibration is vital to compensate for any variances in material characteristics and to ensure that each bend is consistent and precise.

Material setup also plays a significant role in the preparation phase. This includes loading the sheet metal onto the machine and ensuring it is positioned correctly. The alignment of the material before the bending process begins is critical to achieving the desired outcome, as even slight misalignments can lead to defects in the final product.

Tooling Selection and Configuration

Selecting the appropriate tooling for the panel bender machine is another critical aspect of the setup process. The choice of tools, such as the bending blade and clamping bars, should be based on the specific requirements of the job, including the material type, thickness, and bend geometry. Each tool has its specifications and capacities, and using the wrong tool can result in poor quality bends or damage to the machine.

Configuration of the tooling involves adjusting the setup to align with the material and the desired bend. This may include setting the correct blade gap, adjusting the clamping force, and configuring the backgauge for precise material positioning. Proper configuration ensures that the machine operates efficiently, with minimal risk of error or waste.

In conclusion, the setup of the panel bender machine is a foundational step that requires careful attention to calibration, material setup, and tooling selection. By meticulously configuring the machine to suit the specific needs of the material and the project, fabricators can achieve high-quality bends with optimal efficiency. This preparation not only enhances the performance of the machine but also contributes to the overall success and profitability of the fabrication process.

Bending Process Techniques: Sequential Bending Operations

Mastering the bending process involves more than just understanding how to operate the machine. It's about knowing the best techniques to handle various projects, especially when dealing with sequential bending operations and complex shapes and angles. These techniques are crucial for ensuring the production of high-quality, precise components efficiently. Let's dive into the strategies and considerations that make for successful bending processes.

Sequential Bending Operations

Sequential bending is a technique where multiple bends are performed in a specific order to create the desired part. This approach requires careful planning to ensure that each bend does not interfere with or impede subsequent bends. Key considerations include:

- Planning the bend sequence to minimize the movement of the material and reduce the risk of collision with the machine parts.

- Adjusting the bending force and backgauge positions for each step to accommodate the changing geometry of the part.

- Using specialized software to simulate the bending sequence before actual production, identifying potential issues and optimizing the process.

Handling Complex Shapes and Angles

Complex shapes and angles present unique challenges in the bending process. Techniques to manage these complexities include:

- Utilizing advanced tooling that can accommodate intricate bends and shapes, ensuring precision and quality.

- Implementing incremental bending techniques for creating complex angles or curves, allowing for greater control over the bend profile.

- Employing 3D modeling and simulation tools to plan and visualize the bending process, ensuring the accuracy of complex parts.

In summary, the success of the bending process relies on a deep understanding of sequential bending operations and the ability to handle complex shapes and angles with precision. By applying these techniques, fabricators can navigate the challenges presented by intricate designs, ensuring that each project is completed to the highest standards. This level of expertise not only enhances the capabilities of the panel bender machine but also significantly contributes to the efficiency and quality of the fabrication process.

Advanced Techniques and Tips: Precision Bending

To elevate the art of panel bending to its pinnacle, mastering advanced techniques and tips is essential. Achieving high precision and consistency, dealing with springback, and optimizing speed are all facets of expertise that differentiate good fabricators from great ones. Let's delve into these advanced techniques and uncover tips that can transform the bending process.

Techniques for Achieving High Precision and Consistency

Precision and consistency in bending are paramount for quality fabrication. Here are techniques to achieve them:

- Utilizing software with advanced algorithms to calculate the exact bend allowance and compensate for material variances.

- Adopting precision tooling that matches the specific requirements of the material and the design, ensuring consistent bends every time.

- Implementing a rigorous calibration routine to maintain the machine's accuracy over time, addressing any deviations promptly.

Dealing with Springback

Springback — the tendency of metal to return partially to its original shape after bending — can be a significant challenge. Combatting springback involves:

- Understanding the material properties and how they influence springback, allowing for adjustments in the bending process to compensate.

- Using overbending techniques where the angle of the bend is slightly greater than the desired angle to account for springback.

- Experimenting with different tooling options and bending speeds to minimize the effect of springback on the final product.

Speed Optimization

Enhancing the speed of the bending process without compromising quality requires workflow optimization. This includes:

- Streamlining the setup process with quick-change tooling and preset programs for common jobs.

- Optimizing the sequence of operations to reduce machine downtime and material handling.

- Leveraging automation where possible to maintain a continuous workflow and reduce manual interventions.

Machine Maintenance for Efficiency

Regular and proactive maintenance of the panel bender machine is crucial for sustaining its efficiency and extending its lifespan. Key maintenance tips include:

- Adhering to a scheduled maintenance program, including the inspection and lubrication of moving parts, to prevent wear and tear.

- Regularly calibrating the machine to ensure it operates at peak accuracy.

- Training operators to identify and address minor issues before they escalate into costly repairs.

By integrating these advanced techniques and tips into the panel bending process, fabricators can achieve unparalleled levels of precision, efficiency, and quality. These practices not only enhance the capabilities of the panel bender machines but also significantly contribute to the overall success and profitability of the fabrication operations.

What Materials Can Be Processed with a Panel Bender?

Panel benders, with their versatile bending capabilities, have become indispensable tools in the metal fabrication industry. These machines are designed to handle a wide range of materials, each with its unique properties and applications. Understanding which materials can be processed is crucial for maximizing the potential of a panel bender and ensuring the efficiency of fabrication projects. Here's an overview of the materials most commonly shaped by these dynamic machines.

- Aluminum: Due to its lightweight and corrosion resistance, aluminum is a popular choice for a variety of applications. Panel benders can easily process aluminum sheets, making them ideal for automotive, aerospace, and construction projects.

- Steel: Known for its strength and durability, steel is a fundamental material in fabrication. Panel benders can handle both mild steel and high-strength steel, used extensively in manufacturing, construction, and infrastructure.

- Stainless Steel: Valued for its aesthetic finish and resistance to corrosion and oxidation, stainless steel is commonly used in medical, food processing, and architectural projects. Panel benders are capable of shaping stainless steel sheets for such applications.

- Copper: With excellent electrical conductivity, copper is often processed by panel benders for electrical components, roofing, and decorative elements.

- Brass: Brass, an alloy of copper and zinc, is known for its malleability and corrosion resistance. It is frequently used in decorative, architectural, and marine applications.

These materials, among others, can be effectively processed by panel benders to create parts with precise bends and angles. The capability to work with such a diverse array of materials makes the panel bender a vital asset in the metal fabrication industry. By choosing the appropriate machine settings and tooling, fabricators can achieve high-quality bends across different materials, meeting the specifications and requirements of various projects.

How Do I Choose the Right Panel Bender Machine for My Needs?

Selecting the appropriate panel bender machine is a critical decision that can significantly influence the efficiency, productivity, and quality of your metal fabrication operations. With various models and configurations available, it’s important to consider several key factors to ensure you choose a machine that meets your specific needs. Here's a guide to help you make an informed decision.

- Material Types and Thicknesses: Evaluate the range of materials you plan to bend, including their thicknesses. Different machines have varying capacities, so it's crucial to choose one that can handle the diversity of your projects.

- Complexity of Bends: Consider the complexity of the parts you need to produce. If your projects require intricate bends or complex shapes, look for a machine with advanced capabilities and programmable features to accommodate such requirements.

- Production Volume: Assess your production volume. For high-volume operations, a fully automatic panel bender might be the best choice due to its speed and efficiency. For lower volumes or more varied short runs, a semi-automatic or manual machine may offer the flexibility you need.

- Space Constraints: Panel bender machines come in different sizes. Make sure to choose a machine that fits within your available workspace without compromising operational efficiency.

- Budget: Budget is always a consideration. Fully automatic machines offer the highest productivity but also come with a higher price tag. Weigh the initial investment against the potential ROI based on your production needs and efficiency gains.

- Future Needs: Think about your future projects and potential growth. Investing in a machine with capabilities beyond your current needs can provide flexibility and prevent the need for an early upgrade as your business expands.

- Support and Maintenance: Look into the support and maintenance services offered by the manufacturer. Reliable post-sale support and accessible maintenance are vital for minimizing downtime and maintaining productivity.

By carefully considering these factors, you can choose a panel bender machine that not only meets your current needs but also aligns with your long-term operational goals. The right machine will be a valuable asset in your fabrication arsenal, enhancing your capabilities and helping you maintain a competitive edge in the market.

Can Panel Bender Machines Be Used for Small-Scale Projects?

The versatility and advanced capabilities of panel bender machines might suggest they're solely suited for large-scale industrial operations. However, these innovative machines can indeed be adapted for small-scale projects, making them an invaluable asset for workshops and fabricators of all sizes. Let's explore how panel bender machines can be leveraged for smaller projects and the benefits they offer.

Panel bender machines are designed to efficiently process metal sheets into precise shapes and angles, a function that is not limited by the scale of production. For small-scale projects, these machines offer several advantages:

- Precision and Quality: Regardless of the project size, the precision and quality of bends remain paramount. Panel benders provide high-quality, consistent bends, enhancing the professionalism and finish of even the smallest projects.

- Flexibility: Many panel bender machines offer the flexibility to handle a variety of materials and thicknesses, as well as complex bending operations. This makes them suitable for custom work and prototypes where versatility is key.

- Efficiency: Small-scale projects can benefit from the efficiency and speed of panel benders, reducing production time and allowing for quicker turnaround times for clients.

- Reduced Waste: The precision and advanced control of panel bender machines help in minimizing material waste, which is crucial for small businesses looking to maximize the use of their resources.

- Cost-Effective: While the initial investment may be higher than traditional bending tools, the long-term savings in labor, material waste, and the ability to produce higher-quality products can make it a cost-effective solution for small-scale operations.

Furthermore, the availability of smaller, more compact panel bender models means that even workshops with limited space can accommodate these machines. By selecting the appropriate machine for their capacity and operational needs, small businesses can enjoy the benefits of advanced metal forming technology without the necessity for large-scale production.

In conclusion, panel bender machines are not just for large manufacturers but can play a significant role in small-scale projects, offering precision, efficiency, and flexibility. They represent a valuable investment for businesses aiming to enhance their fabrication capabilities and competitiveness in the market.

How Does Automation Affect the Cost-Effectiveness of Panel Bending?

The integration of automation in panel bending machines has revolutionized the metal fabrication industry, significantly impacting the cost-effectiveness of operations. Automation brings precision, speed, and efficiency to the bending process, but its value extends beyond just enhancing production capabilities. Let's delve into how automation in panel bending affects cost-effectiveness, exploring both the immediate and long-term impacts.

Automation in panel bending machines offers several key advantages:

- Increased Production Speed: Automated panel benders operate at a faster pace than manual or semi-automated machines, significantly reducing production times. This increased speed allows for higher throughput, enabling businesses to fulfill larger orders more efficiently.

- Reduced Labor Costs: Automation reduces the need for manual labor in the bending process. While skilled operators are still needed to oversee operations, the number of personnel required is lower, resulting in substantial savings on labor costs.

- Enhanced Precision and Consistency: Automated machines deliver high precision and consistency in bends, reducing the rate of errors and rework. This consistency ensures that materials are used more efficiently, minimizing waste and improving the quality of the final product.

- Optimized Material Utilization: Advanced software used in automated panel benders can optimize material layout, further reducing waste and maximizing the use of resources. This optimization contributes to cost savings on materials over time.

- Reduced Downtime: Automation includes sophisticated monitoring and diagnostic features that can predict and prevent machine failures, reducing downtime and maintenance costs.

While the initial investment in an automated panel bender machine is higher than that of a manual or semi-automatic machine, the return on investment (ROI) can be significant. The savings in labor costs, increased production capacity, reduced waste, and lower error rates all contribute to a more cost-effective operation in the long run.

Moreover, the ability to produce higher-quality parts at a faster rate allows businesses to meet client demands more effectively, enhancing customer satisfaction and opening up opportunities for new business. In a competitive market, these factors can be crucial for growth and sustainability.

In conclusion, automation significantly enhances the cost-effectiveness of panel bending by improving efficiency, reducing waste, and lowering operational costs. While the upfront costs may be higher, the long-term benefits of automation present a compelling case for investment, particularly for businesses looking to scale up their production capabilities and improve their market competitiveness.

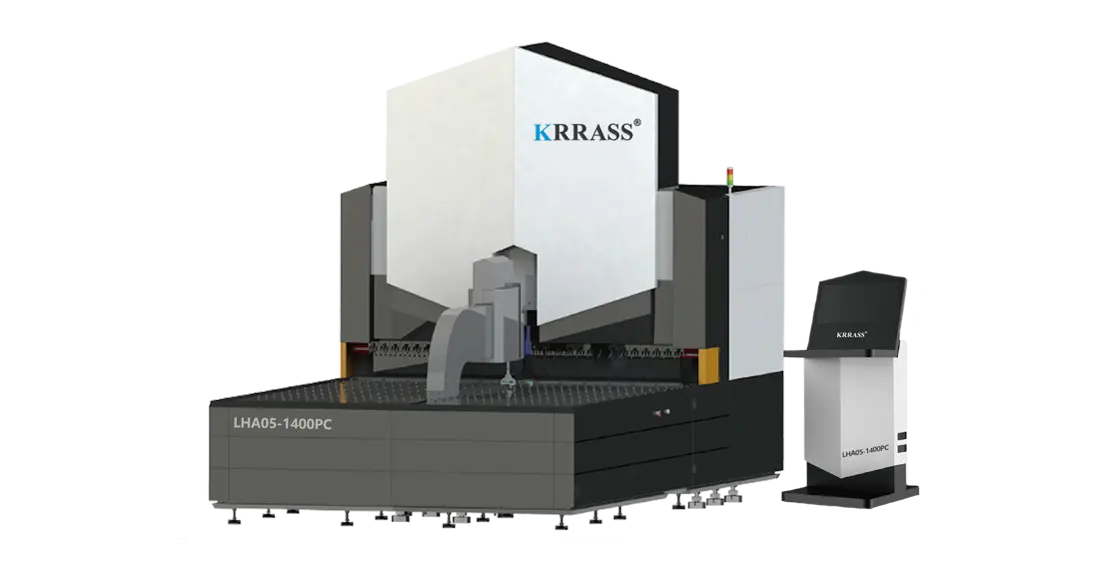

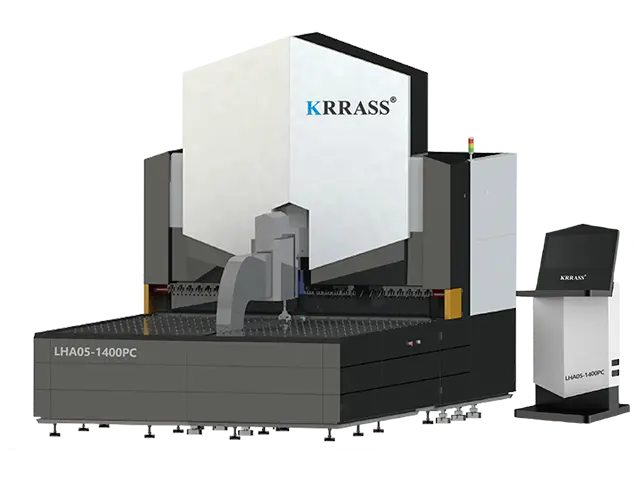

Embrace the Future of Fabrication with Krrass

As we've navigated through the intricacies of panel bender machines, it's clear that the right tools and techniques are crucial for staying ahead in the metal fabrication industry. Embracing advanced technologies and efficiency-driven practices is not just an option but a necessity for businesses aiming for excellence. Leading the charge in innovation and quality, Krrass stands out as a premier manufacturer and service provider of Panel Bender Machines. With a commitment to excellence and a focus on cutting-edge solutions, Krrass is your go-to partner for all your fabrication needs. Visit our global website at www.krrass.com to explore how our expertise can transform your production line and elevate your projects to new heights.