Proper maintenance of your press brake tooling requires a few important considerations. Firstly, avoid storing it in a general storage rack away from the press brake when it's not in use. This practice, commonly seen in the back of the shop, can significantly reduce productivity. It forces the press brake operator to leave the machine to retrieve the required tooling for the next job or wait for tooling to be delivered by a forklift driver or setup person.

When multiple press brake operators share the same tooling across different machines, the tooling often ends up spread out in multiple locations. This leads to time-consuming searches for the necessary tools for each job, resulting in a considerable loss of time.

Due to the different types of Press Brake machines on the market, it can be difficult to decide which one is the best for your needs. But don’t worry, KRRASS are here to help!

Request a callback

Visit our product

To address these issues, it's always better to store press brake tooling in an organized tool cabinet at the press brake where it will be used. In shops with limited tooling requirements, sharing one dedicated tool cabinet between two press brakes is ideal.

Another crucial aspect is investing in a tool cabinet specifically designed for storing press brake tooling. Storing the tooling in a general storage rack leaves it exposed to airborne dust, debris, and a higher risk of damage. Handmade wooden storage units with individual slots for each tool may seem appealing, but they actually promote rust and corrosion due to moisture content in wood.

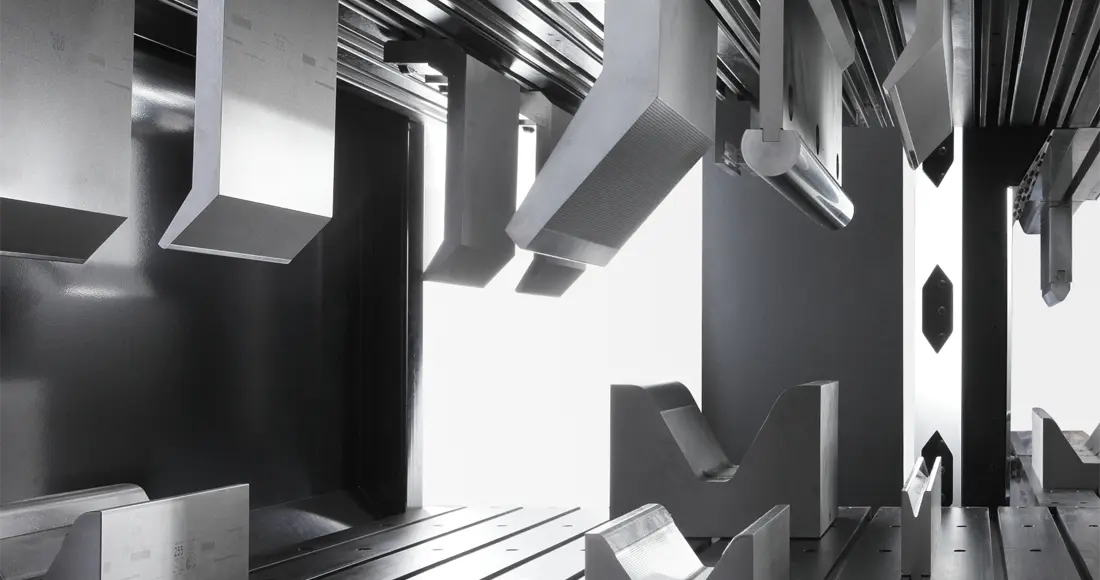

Tool cabinets that store press brake tooling horizontally with metal dividers are not always optimal, as the dividers often fail to provide secure and dedicated storage space for each tool. This can result in tools moving around, potentially damaging their working surfaces when drawers are opened or closed. Damage to punch tips and shoulder radii on dies can cause sheet marking during bending, which poses a significant problem for materials like aluminum, stainless steel, copper, and brass that are often left unpainted.

Based on experience, press brake tooling cabinets that store the tools vertically using nylon, neoprene, or polyurethane pads with individual slots offer the best overall storage method. This approach ensures organized storage while providing maximum protection against potential damage. Additionally, a good tooling cabinet should have lockable drawers to secure your investment and prevent tooling from being moved away from its designated location.

Portability and safety are also crucial factors when implementing an effective press brake tooling storage system. While some tooling cabinets come with wheels for easy relocation, caution is advised due to the potential hazards of moving heavy cabinets on uneven shop floors. Forgetting to set the brakes on the wheels after moving the cabinet could lead to safety risks if the cabinet moves while tools are being loaded or unloaded.

Safety should be the foremost consideration in any press brake tooling storage system. Given the weight stored in these cabinets, interlocks should be provided to prevent more than one drawer from being opened simultaneously. Opening multiple loaded drawers creates an unsafe condition where extended drawers and tooling may fall towards the person loading or unloading, posing a risk of serious injury.

In rare cases, large manufacturers may transfer press brake tooling between facilities to optimize capacity, proximity to customers, or cost-efficiency. However, this practice carries a higher risk of losing or damaging expensive and unique tooling during transit. Proper planning is essential to ensure facilities receiving transferred tooling have suitable storage arrangements from the beginning, preventing valuable assets from being left vulnerable.

Proper maintenance is essential for press brake tooling due to its steel composition, which is prone to rust and corrosion. It is crucial to keep the tooling clean and free of moisture, handprints, and acid. Simply wiping it down with a petroleum-based lubricant after handling is insufficient and will only cover the tooling with oil. The correct approach involves the following steps:

- After each handling, thoroughly wipe the tooling with a clean rag lightly soaked in isopropyl alcohol to remove handprints and acid residue.

- While wearing gloves, coat the tool with a preservative lubricant and wipe off any excess.

- Place the tool in a tool cabinet.

- Alternatively, wipe down the tooling with a cleaner/preservative before placing it in a tool cabinet.

- Ensure the tool cabinet contains at least one package of silica gel. In high humidity environments, use at least two packets of silica gel.

These steps will not only maintain the cleanliness and prevent rust and corrosion but also protect the laser markings containing vital technical data used for identification and loading into the press brake's control system.

Precision-ground and hardened press brake tooling made from high-quality steel is a durable investment that can provide 10 years or more of accurate service when used and maintained properly. Although some may initially avoid purchasing a tool cabinet to save costs, the expense of damaged tooling quickly surpasses the cost of a cabinet. As a result, the majority of purchasers ultimately opt for a tool cabinet to prevent tooling damage.

Like any valuable asset, it's wise to protect your investment by storing and using it wisely, ensuring maximum returns.

Request a callback

Visit our product

Visit our Youtube channel

Which press brake machine is right for you?

If you need any questions answered or to discuss your press brake requirements for your unique business, please contact us today on 0086 18952087956 or using our online contact form.