Electric NC Hydraulic Tube Bender - ECO Series

Advanced Electric NC Hydraulic Tube Bender

The hydraulic tube benders of the ECO-NC series are easy to operate, robustly constructed and achieve excellent bending results. Entering new bending programs is intuitive, thanks to an industrial touch controller and the accurate and user-friendly KRRASS 2D software. The NC program controls the bend angle (Y axis) and rotation (Z axis). The distance between elbows (X-axis) is configured using easily adjustable and precise mechanical stops.

Simple, durable and with excellent bending results.

Work area can be customized and all types of tool clamping can be installed.

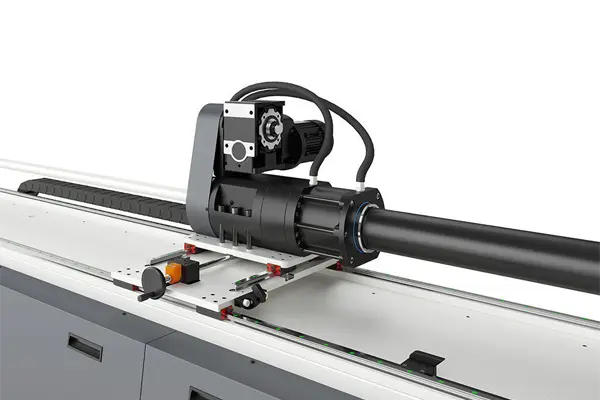

Supporting hydraulic drive.

General Information

The basic movements – bending angle and rotation of the pipe – are fully electric to ensure exact repeatability. A powerful hydraulic group drives the supporting bending movements. All activities are electronically controlled. These properties make these machines versatile and suitable for high-quality bending work in small and medium-sized series.

- Simple, durable and with excellent bending results.

- Very intuitive programming of bending angle and rotation with industrial touch controller.

- Drive of bending and rotation of the tube partly electrically.

- Supporting hydraulic drive.

- Quick change of bending tool, with easy adjustment possibility.

- Revolutionary clamping system, with a compact bending head.

- Powerful and low maintenance bending machine with reduced bending head increases the possibilities of complex bending work.

- Integrated tool cabinet with interior lighting.

- Compact and ergonomic design, takes up little production space and improves operating and maintenance comfort.

Evolutionary Design

Our hydraulic tube benders are the result of decades of experience in the world of bending. The user experience of thousands of customers worldwide has resulted in unique application-oriented solutions for these machines. We facilitate human-machine “communication” using visual status indicators and warning messages.

Advantage:

- Compact design

- Semi-automatic bending machine

- Fixed radius

The ECO series of semi-automatic fixed-radius hydraulic tube benders are versatile, powerful, and easy to program and operate. They are intended for sectors that choose versatility and bending quality in speed and productivity. Sectors include urban furniture, agriculture, prototyping, chemical industry, and ship repair.

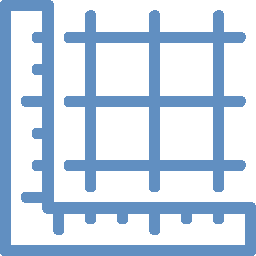

NC Hydraulic Tube Bender Technical Parameter

| Parameter | Unit | NC38 | NC50 | NC63 | NC75 | NC89 |

|---|---|---|---|---|---|---|

| Max.Pipe Diameter | mm | Φ38×2 | Φ50×3 | Φ63×4 | Φ75×4 | Φ89×5 |

| Max. Bending Capacity for Carbon Steel Pipe ( Outside Dia. * Wall Thickness) | mm | Φ38×2 | Φ50×2 | Φ60×3 | Φ70×6 | Φ89×3 |

| Max. Bending Capacity for Square Pipe ( Outside Dia. * Wall Thickness) | mm | 30*30*2 | 40*50*2 | 50*50*2 | 60*60*2 | 70*70*2 |

| Max. Bending Radius | mm | R200 | R350 | R350 | R400 | R450 |

| Min. Bending Radius | mm | Depending on pipe diameter(2 times of pipe outer diameter) | Depending on pipe diameter(2 times of pipe outer diameter) | Depending on pipe diameter(2 times of pipe outer diameter) | Depending on pipe diameter(2 times of pipe outer diameter) | Depending on pipe diameter(2 times of pipe outer diameter) |

| Max.Bending Angle | Degree | 190 | 190 | 190 | 190 | 190 |

| Max.Core-Piercing Distance | mm | 1600 | 2200 | 2600 | 2800 | 3200 |

| Main Oil Cylinder Diameter | mm | 75 | 95 | 110 | 140 | 160 |

| Die Center height from ground | mm | 950 | 1000 | 1000 | 1100 | 1100 |

| Cycling Speed Every 90 Degrees | S | 3 | 4 | 5 | 8 | 10 |

| Controller | Single chip | Single chip | Single chip | Single chip | Single chip | |

| Data Input Mode | Manually input | Manually input | Manually input | Manually input | Manually input | |

| Max.Bending Number Per Pipe | PCS | 16 | 16 | 16 | 16 | 16 |

| Working Speed | Deg/sec | 65 | 55 | 45 | 35 | 30 |

| Degree | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | |

| Main Motor Power | Kw | 4 | 5.5 | 7.5 | 7.5 | 11 |

| Max.Pressure | MPa | 12 | 12 | 12 | 12 | 16 |

| Hydraulic Control Control | Solenoid valve | Solenoid valve | Solenoid valve | Solenoid valve | Solenoid valve | |

| Oil Tank Volume | L | 150 | 220 | 220 | 250 | 450 |

| Machine Weight | Kg | 750 | 1220 | 1500 | 2000 | 4000 |

| Outline Dimension | mm | 2400×700×1220 | 3000×700×1030 | 3500×750×1100 | 400×100×110 | 4600×1200×1400 |

Reviewed by 2 users

Buena calidad de la máquina dobladora de tubos hidráulica NC63 y el servicio al cliente fue de primera clase. Los usaremos para cualquier necesidad futura que tengamos

cnc pipe bending machine

Purchased your pipe bending machine, very good machine.