Hydraulic Shearing Machine is an important equipment in the forging industry. Whether it can achieve the expected shearing action is the prerequisite to ensure accuracy. The conventional design in the past mainly relied on experience and analogy of the same type of machine, with large design repeatability, long cycle and poor reliability. This machine not only has the function of ordinary shearing machine, but also adds side knives. It can also meet the trimming and shearing of longer sheets. It has a broader application prospect in steel rolling, boilers, shipbuilding and other industries.

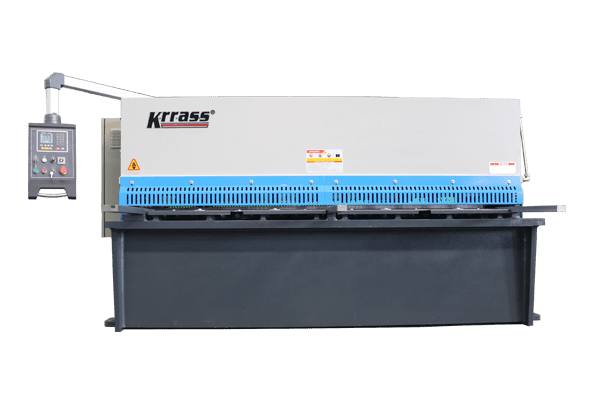

Hydraulic Shearing Machine is mainly composed of frame, tool rest, oil cylinder, presser foot, alignment device, gap adjustment device, hydraulic system and electrical system. When the shearing machine cuts the sheet material, the pressure setting value of the hydraulic system and the value of the edge gap directly affect the quality of the cut. The hydraulic system is composed of integrated block valves, motors, oil pumps and pipelines in a cartridge structure.

The hydraulic directional control valve, pressure control valve, and flow control valve can no longer meet the parameter requirements of this system, so the cartridge valve structure is adopted. Hydraulic system. The cartridge valve hydraulic system is a combination of several cartridge components in different combinations and corresponding pilot control stages to form control valves such as direction control, pressure control, flow control and compound control. This structure control valve has large flow capacity and control With significant advantages such as automation, it has become the leading control product in the field of high pressure and large flow.

Hydraulic Shearing Machine Since most of the tool holder mounting surface manufacturing adopts simplified processes, the blade mounting surface is simplified from a space spiral surface to a plane, which results in the change of the shearing gap and the shearing angle during the shearing process.

The change of the shearing gap will change the magnitude of the shearing force during the shearing process, and the quality of the shearing will be reduced; and the change of the angle after the shearing can aggravate the wear and even extrusion of the blade and the plate, thereby increasing the shearing force. Therefore, the shear force value calculated by the Nosari formula is only used as a reference value for adjusting the magnitude of the shear force. The magnitude of the shear force required in the actual shearing process is obtained at the production site through continuous adjustments supplemented by the shearing test.

Therefore, when dealing with the failure of the hydraulic system of the cartridge valve structure, it is necessary to clearly understand the role of each component in the system. If necessary, it can be equivalently simplified to a common hydraulic valve, so as to more intuitively analyze the entire cartridge circuit. The role of the hydraulic system, so as to quickly and accurately find out the system fault, and remove it in time.

Learn more about our products, please visit and subscribe to our Youtube channel