In the realm of modern manufacturing, metal laser cutting machines have become indispensable tools, owing to the relentless advancement of technology and the evolving needs of various industries. These machines find applications across a broad spectrum, ranging from automotive components to aerospace parts and household appliances. However, for many enterprises and individuals, their initial encounter often revolves around one crucial question: What is the metal laser cutting machine price? This query delves into a multitude of factors, prompting a deeper exploration.

Introduction

Metal laser cutting machines play a pivotal role in modern manufacturing processes, offering unparalleled precision, speed, and versatility. These machines have revolutionized the way industries handle metal fabrication, allowing for intricate designs and rapid production of various components.

Understanding the pricing factors associated with metal laser cutting machines is crucial for businesses looking to invest in this technology. The cost of these machines can vary significantly based on several factors, and having a comprehensive understanding of these elements is essential for making informed purchasing decisions.

Understanding Laser Cutting Machines in Modern Manufacturing

Laser cutting machines are indispensable tools utilized across diverse industries to achieve precision cutting and intricate design projects. These machines harness the power of a high-intensity laser beam to cleanly cut or etch materials such as steel, plastic, or wood. Primarily employed in industrial manufacturing, laser cutting machines utilize their focused beams to burn, vaporize, or melt away excess material, resulting in superior finished designs or edges.

Mechanisms and Components of Laser Cutting Machines

A laser cutting machine operates with precision through its computer numerical control (CNC) settings and laser optics. These components manage and direct the laser beam's intensity to achieve the desired design effect or specific cuts necessary for manufacturing or design projects. The laser beam is generated through a process where electrical discharges or a lamp trigger a lasing material within a confined container, initiating a chemical reaction that releases a high-powered beam. This beam is then guided by mirrors, producing a stream of monochromatic light. From the mirrors, the light is directed through fibre optics or additional mirrors to the work area, with the narrowest point of the beam executing the cutting or design etching on the material.

Applications and Uses of Laser Cutting Machines

In engineering, laser cutting machines are vital for precisely cutting machine components. Industrial applications often involve the cutting of structural and piping materials, as well as flat sheet metal. Additionally, laser cutting machines can be adjusted via CNC settings to engrave or etch designs onto metal, wood, or plastic surfaces. Specialty CAD (computer-aided design) software programs are utilized to program the CNC and direct the machine to perform cutting, engraving, or etching tasks as per project specifications. The size and capacity of the laser cutting machine determine its suitability for small-scale or large-scale manufacturing projects.

Metal Laser Cutting Machine Price

The price of a metal laser cutting machine can vary significantly depending on various factors such as the machine's specifications, brand, size, and additional features.

Entry-level metal laser cutting machines can start from around $20,000 to $50,000 for smaller desktop models with basic functionalities and lower laser power.

Mid-range metal laser cutting machines, offering a balance between performance and affordability, typically range from $50,000 to $150,000. These machines may have higher laser power, larger cutting areas, and additional features such as automatic focus adjustment and shuttle tables.

High-end industrial-grade metal laser cutting machines, equipped with advanced features, higher laser power, and larger cutting areas, can cost anywhere from $150,000 to over $1 million. These machines are designed for heavy-duty industrial applications and offer exceptional precision, speed, and reliability.

It's important to note that these price ranges are approximate and can vary based on factors such as the specific model, brand reputation, geographic location, and additional services such as installation, training, and warranty coverage.

Additionally, customized or specialized metal laser cutting machines may have higher price tags depending on the unique requirements of the buyer. Potential buyers should thoroughly research their options and consult with manufacturers or distributors to get accurate pricing information based on their specific needs.

Different Types of Cutting Machines and Its Cost

| Type of Cutting Machine | Description | Price Range |

| CO2 Laser Cutting Machine | Excellent for non-metal materials | $8,000 - $50,000 |

| Nd: YAG Laser Cutter | Versatile, precise cutting for various materials | $40,000 - $300,000 |

| Diode Laser Cutting Machine | Cost-effective option for various materials | $5,000 - $20,000 |

| Fiber Laser Cutters | Specifically for cutting metal materials | $20,000 - $500,000 |

| Entry-Level Laser Cutter | Ideal for small businesses and beginners | $3,000 - $10,000 |

| Tube Laser Cutters | Precise cutting of tubes for industries | $30,000 - $200,000 |

| Hobbyist Laser Cutter | Designed for hobbyists and personal projects | $500 - $3,500 |

| Mid-Range Laser Cutter | Offers advanced features at an affordable cost | $10,000 - $50,000 |

| Industrial Laser Cutter | Powerhouse for heavy-weight manufacturing tasks | $20,000 - $500,000 |

| Metal Laser Cutter | Customized for robustness and accuracy | $15,000 - $300,000 |

| Small Laser Cutter | Affordability and efficiency in a smaller machine | $2,000 - $15,000 |

Why Fiber Laser Machine Is Higher Than CO2 Machines

Fiber Laser Cutting Machine Price

Fiber laser cutting machine is a laser cutting machine that uses a fiber laser generator as the light source. The fiber laser generator can output a high density laser beam, which can be focused on the surface of the workpiece. The area irradiated by the focus spot on the workpiece is melted and vaporized instantaneously. Move the laser spot by the numerical control mechanical system to realize automatic cutting.

Due to the high cost of a laser generator, the fiber laser cutting machine price is relatively high, ranging from $30,000 to $200,000. The price difference of fiber laser cutting machines mainly lies in the power of fiber laser generator, and the size and components of the fiber laser cutter. The higher the power of laser generator, the higher the fiber laser cutter price. Similarly, the bigger the working size, the higher the fiber laser cutter price.

CO2 Laser Cutting Machine Price

CO2 laser cutting machine adopts the CO2 laser beam generated by the CO2 laser tube. Its major working substance is a mixture of carbon dioxide, helium, and nitrogen. Through the focusing mirror inside the laser head, the laser beam emitted by the CO2 laser tube is focused into a high-energy laser beam for cutting.

Compared with fiber cutting machines, the CO2 laser cutting machine price is cheaper, which is about $3,000-$60,000. The price difference also mainly lies in the laser power, machine size and so on. The greater the power and size, the higher the CO2 laser cutting machine price.

Power of the CO2 laser cutters can be 50W to 2000W. They are mainly for cutting non-metal materials. For example, wood, acrylic, glass, leather, crystal, paper, plastic, etc. Co2 laser cutters with high laser power can also cut thin metal sheets.

Factors Affecting Metal Laser Cutting Machine Price

Power

Different powers correspond to different maximum limits for plate cutting. Choosing the appropriate power will help to better utilize the performance of the laser cutting machine;

Laser cutting machine table size

The laser cutting machine table sizes on the market are 30001500mm, 40001500mm, 40002000mm, 60001500mm, 14000*2500mm.Different manufacturers can also customize according to customer needs. Currently, the sizes of steel plates on the plate market are:

| Type of Steel Plate | Thickness (mm) | Width (mm) | Length (m) |

| Thick Steel Plate | >4, 5, 6, 8, 10 | <2000 | 4, 5, 6, 8, 10, 12, 14, 16, 20, 25, 30, 40, 50, 10-12 |

| Thick Steel Plate | >4, 5, 6, 8, 10 | 2000, 2500 | 4, 5, 6, 8, 10, 12, 14, 16, 20, 25, 30, 40, 50, 10-12 |

| Thin Steel Plate | <4 | 500-1500 | 1.5-4 |

Laser brand

Different brands have different service lifes of lasers. Large brands are relatively better and guaranteed. Common laser brands include IPG, Max and Raycaus, etc.

| Feature | IPG Photonics | Maxphotonics (MAX) | Raycus |

| Reputation | Global leader, high quality and reliable | Cost-effective, reliable | Rapid growth, wide range |

| Laser Power Range | Few watts to several kilowatts | Hundreds of watts to several kilowatts | Low to high power (up to several kW) |

| Performance | High beam quality, high efficiency | Good beam quality, good efficiency | Competitive beam quality, good efficiency |

| Technology | Advanced, proprietary | Standard, cost-effective | Accessible, balanced cost/performance |

| Applications | Cutting, welding, drilling, medical | Cutting, welding, marking, engraving | Cutting, welding, marking, industrial |

| Support and Service | Extensive global network | Growing global network | Expanding global network |

| Pros | High quality, reliable, strong support | Competitive pricing, versatile | Affordable, wide range, strong Asian presence |

| Cons | Higher price, complex technology | Fewer advanced features | Developing support network, not top-tier performance |

Cutting material performance

Different materials absorb laser energy to different degrees, such as aluminum plates and copper, which are highly reflective materials and require special lasers;

Other features and accessories

Some customers need to add some large enclosures or vacuum and smoke-proof treatments, which is also possible. The appearance, color, etc. are all customizable.

Additional Costs for Laser Cutting Machines

Apart from the initial purchase cost, there are ongoing expenses associated with operating laser cutting machines. These include electricity costs, expenses for auxiliary gases such as oxygen and nitrogen, and the consumption of consumables like focusing lenses, nozzles, and ceramics. All of these factors should be considered when budgeting for a metal laser cutting machine.

How To Choose A Right Metal Laser Cutting Machine Within Your Budget

- Material and Job Specifications: Determine the dimensions (length, width, and thickness) of the materials you intend to cut and the expected duration of use. This information will help you choose the appropriate laser power and cutting table size.

- Brands: Research and compare multiple brands within your budget range to find the one that best suits your needs.

- Get Quotes: Request quotes from suppliers or manufacturers, and compare configurations, prices, and the services offered, including delivery, lead time, and technical training.

- Service: Consider the support and services provided by the manufacturer or supplier, such as after-sales service, technical support, and warranty coverage.

- Seek Professional Advice: Consult with industry experts or individuals who have experience using laser cutting equipment (Key Opinion Leaders – KOLs) to gain insights into machine performance and identify reputable manufacturers that offer suitable laser cutting machines.

TOP 10 Metal Laser Cutting Machine Brands and Price

Here is a list of the top 10 metal laser cutting machine brands along with approximate price ranges for their machines. These prices can vary based on specific models, configurations, and additional features.

1. Trumpf

- Price Range: $150,000 - $1,500,000

- Overview: A German company known for its high-quality and innovative industrial laser cutting machines, offering advanced features and exceptional precision.

2. Bystronic

- Price Range: $100,000 - $1,200,000

- Overview: A Swiss company specializing in sheet metal processing, Bystronic provides highly efficient and reliable laser cutting machines with advanced automation options.

3. Amada

- Price Range: $200,000 - $1,000,000

- Overview: A leading Japanese manufacturer, Amada offers a wide range of metal laser cutting machines known for their reliability, precision, and ease of use.

4. Mazak

- Price Range: $150,000 - $900,000

- Overview: Another reputable Japanese company, Mazak provides high-performance fiber laser cutting machines designed for various industrial applications.

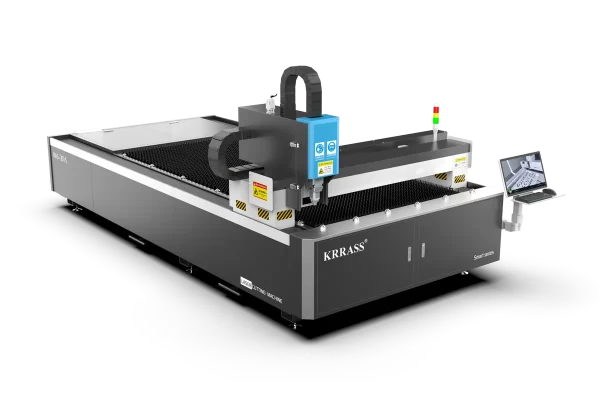

5. Krrass Machinery

- Price Range: $15,000 - $128,000

- Overview: A leading Chinese brand offering a broad range of laser cutting solutions, Krrass Machinery is known for its cost-effective and high-quality machines.

6. IPG Photonics

- Price Range: $100,000 - $600,000

- Overview: An American company renowned for its high-power fiber lasers, IPG Photonics offers machines with superior performance and reliability.

7. Mitsubishi Electric

- Price Range: $100,000 - $700,000

- Overview: Mitsubishi Electric provides advanced laser cutting machines that are known for their cutting-edge technology and robust performance.

8. LVD Group

- Price Range: $80,000 - $600,000

- Overview: A Belgian company that offers innovative sheet metalworking solutions, including high-quality fiber laser cutting machines.

9. Bodor

- Price Range: $40,000 - $500,000

- Overview: A Chinese brand gaining popularity for its affordable and efficient laser cutting machines, suitable for a variety of applications.

10. Salvagnini

- Price Range: $100,000 - $600,000

- Overview: An Italian company known for its automated sheet metal processing solutions, Salvagnini provides reliable and high-performance laser cutting machines.

Krrass Metal Laser Cutting Machine For Sale

KRRASS top rated fiber laser cutting machine is designed for metal fabrication, including steel, aluminum, titanium, alloy, brass, copper, and iron, with different laser powers(1000W, 1500W, 2000W, 3000W, 4000W, 6000W, 8000W, 12000W, 20000W). The affordable fiber laser cutter is for sale at a low price, with the best fiber laser cutting system service and support.

KRRASS laser cutting machines offer a combination of advanced technology, precision, and reliability. With a range of models designed to meet various industrial needs, KRRASS provides efficient and cost-effective solutions for metal cutting applications. Whether you are involved in large-scale manufacturing or require specialized cutting capabilities, KRRASS laser cutting machines are a valuable addition to your production processes.