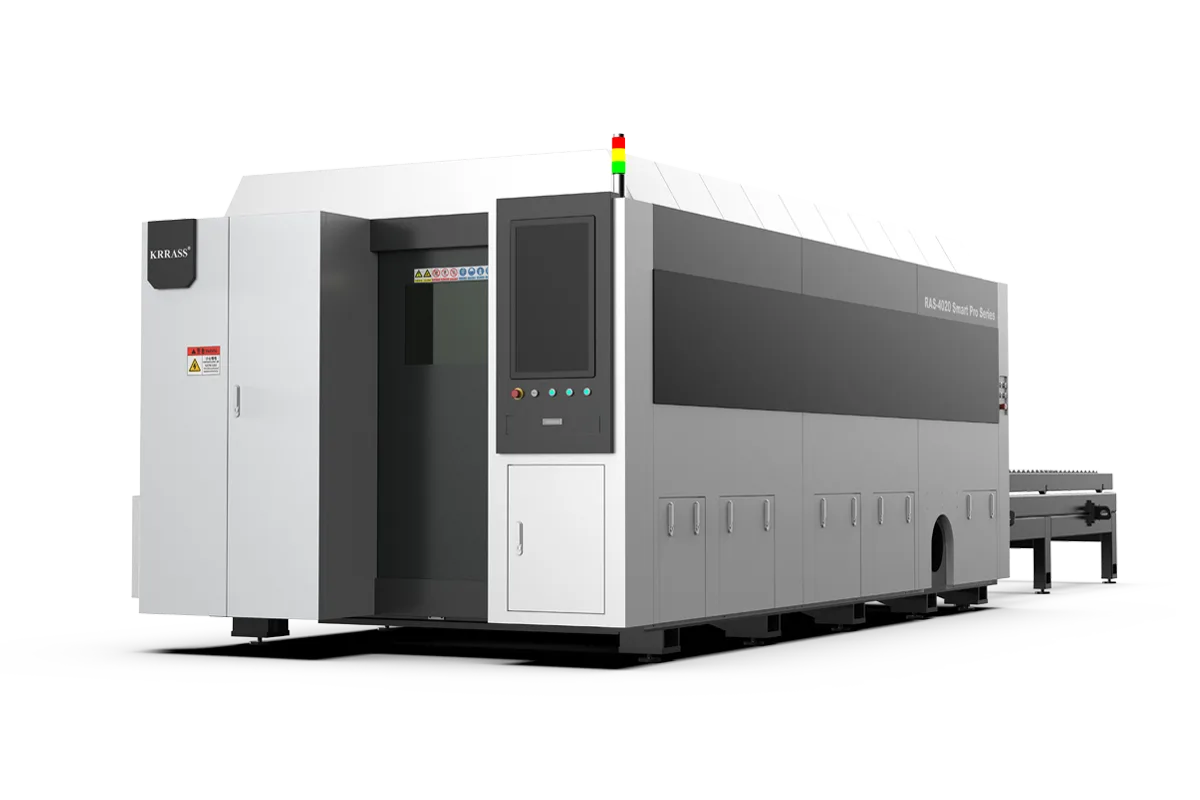

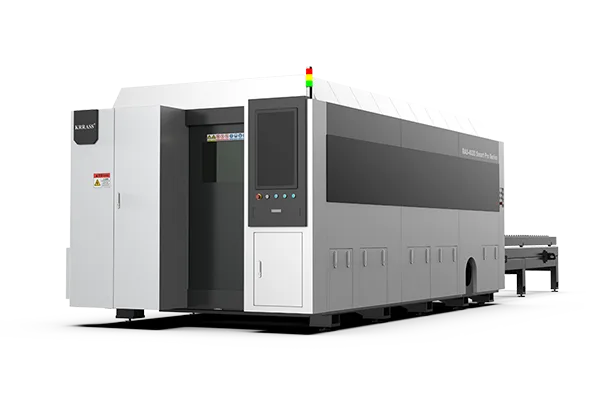

Fiber Laser Metal Cutting Machine

Fiber Laser Metal Cutting Machine

The 4th generation KRRASS fiber laser metal cutting machine is mainly designed for high power from 2kw to 20kw. A full-protection cover can protect the worker from the harm of laser radiation and reduce environmental pollution. Laser cutting machines equipped with auto-exchangeable platforms can save loading time and improve processing efficiency. It only takes the exchange platform 20 seconds to complete the exchange.

High Precision Welding Bed

Integrated bed with sheet production line, self-sufficiency, shorter delivery, various working size optional

Auto Oil-filling

Intelligent system for auto oil filling, oil cut-off avoided

Cost-Effective

Low waste of raw materials, low investment with a short payoff period

Introduction to Configuration

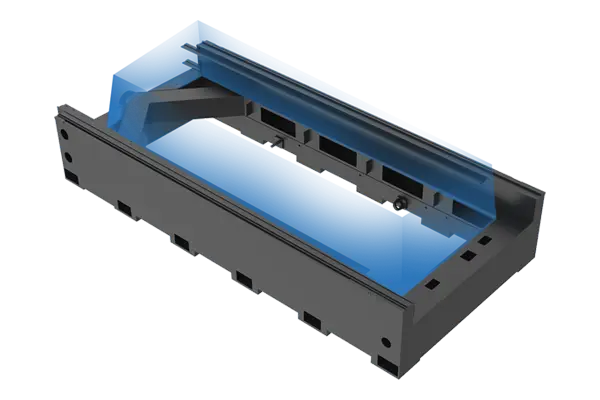

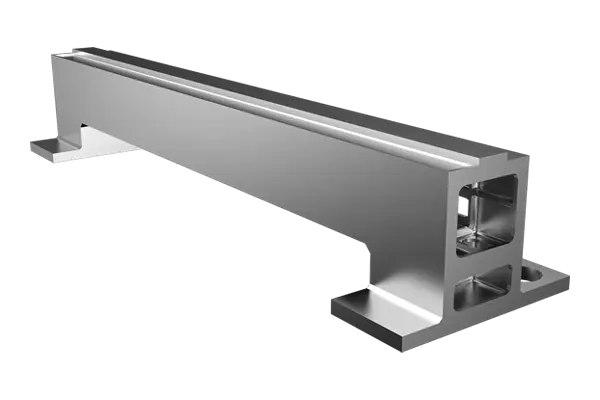

Heavy-load Thermal Isolated Hollow Bed

The heavy-duty heat-insulating hollow bed of the metal laser cutting machine is welded with high-quality steel plates and pipes. After welding, stress relief annealing, secondary aging treatment, and precision machining, super-large gantry milling machines ensure that the bed has sufficient structural stability and shock resistance. The mattress will not deform after long-term use, which improves the service life of the equipment.

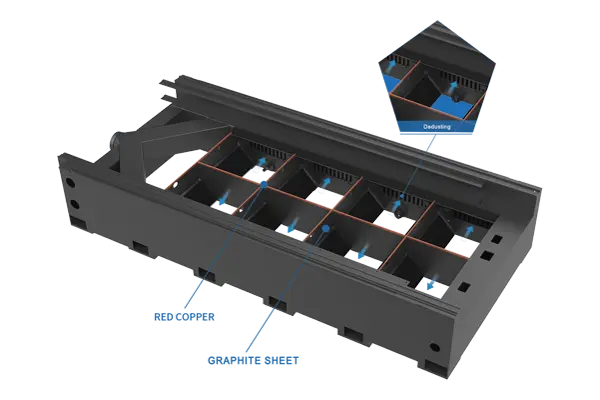

Intelligent Spiral Vacuum Dust Removal

Intelligent spiral vacuum dust removal is a time-sharing system with an automatic air outlet switch and sectional air exhaust. It can cooperate with the back-shaped sealing structure design at the bottom of the base to realize smokeless cutting.8kw or higher power machine has graphite and copper protection.

The Fifth-generation Aviation Aluminum Alloy Beam

The T6 heat treatment process processes the full beam of the laser metal cutting machine to make the shaft obtain the highest strength. Solution treatment improves the strength and plasticity of the beam, optimizes and reduces its weight, and speeds up the movement.

Intelligent Control System

“CypCut plane cutting” software is a set of software specially developed for the deep customization of the laser cutter machine industry. Easy to use, rich in functions, and suitable for various processing occasions.

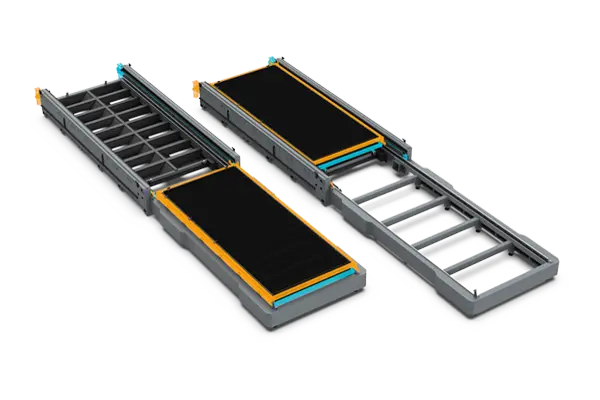

Lightning swap for laser metal cutting machine

The laser cutting machine is equipped with a six-sided steel track, the pulley and the track are inlaid tightly, powerful pneumatic tightening, and the built-in pulley runs smoothly. The fastest can achieve a complete exchange in 10s.

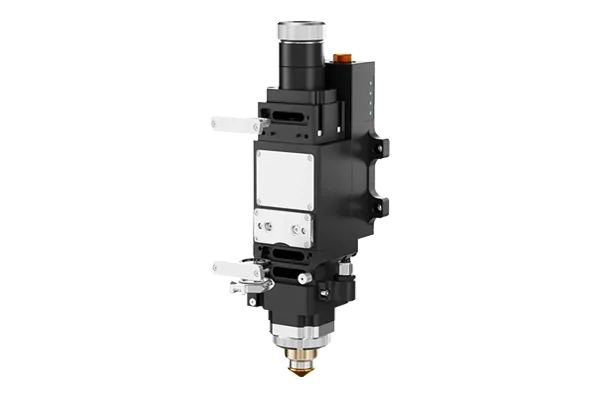

BOCHU Smart Cutting Heads

BOCHU smart cutting heads are quite cost-effective smart cutting heads designed for the laser cutting. Being impact and lightweight, it still integrates multiple sets of intelligent sensors, which ensure real-time closed-loop monitoring to give rapid diagnosis and instant warning.

What is this Machine Used for?

The Steel Laser Cutting Machine is to cut mild steel used, stainless steel, aluminum alloy, brass, and other steel; Application in the automobile industry, sheet metal industry, furniture industry, advertising industry, Etc.

Parameter of laser cutter machine for Steel

| Model | RAS-3015T/RAS-4015T/RAS-4020T/RAS-6015T/RAS-6020T metal laser cutting machine |

|---|---|

| Working Area | 3050*1525/4050*1525/4050*2020/6050*1525/6050*2020 |

| Laser Power(kw) | 1/1.5/2/3/4 |

| Maximum Speed(m/min) | 80 |

| Maximum acceleration(g) | 0.8 |

| X/Y Axis positioning accuracy(mm/m) | ±0.05 |

| X/Y Axis repeated positioning accuracy(mm) | ± 0.02 |

What is the Maximum Cutting Thickness?

| Material | 1KW | 1.5KW | 2KW | 3KW | 4KW | 6KW | 8kw | 12000W |

|---|---|---|---|---|---|---|---|---|

| Carbon Steel(mm) | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-20 | 0.4-25 | 0.4-25 | 0.4-25 | 0.4-45 |

| Stainless Steel(mm) | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 | 0.4-12 | 0.4-20 | 0.4-28 | 0.4-40 |

| Aluminum (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-22 |

| Brass (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-6 | 0.4-8 | 0.4-14 | 0.4-16 | 0.4-20 |

Reviewed by 13 users

The quality of the cuts is outstanding, with minimal burr and clean edges, reducing the need for additional finishing processes,Great Laser machine

i bought the 12000w fiber laser cutting machine and it lasts 5 years .

6000W máquina de corte por láser de fibra es de alto rendimiento, KRRASS es una buena fabricación

6020T fiber laser cutting machine keep my worker safe as well as High efficiency output.

Tudo funcionou muito bem, o serviço de vendas foi muito eficiente. A máquina de corte a laser de fibra de 2KW e seus acessórios funcionam perfeitamente. Estou muito satisfeito com a compra