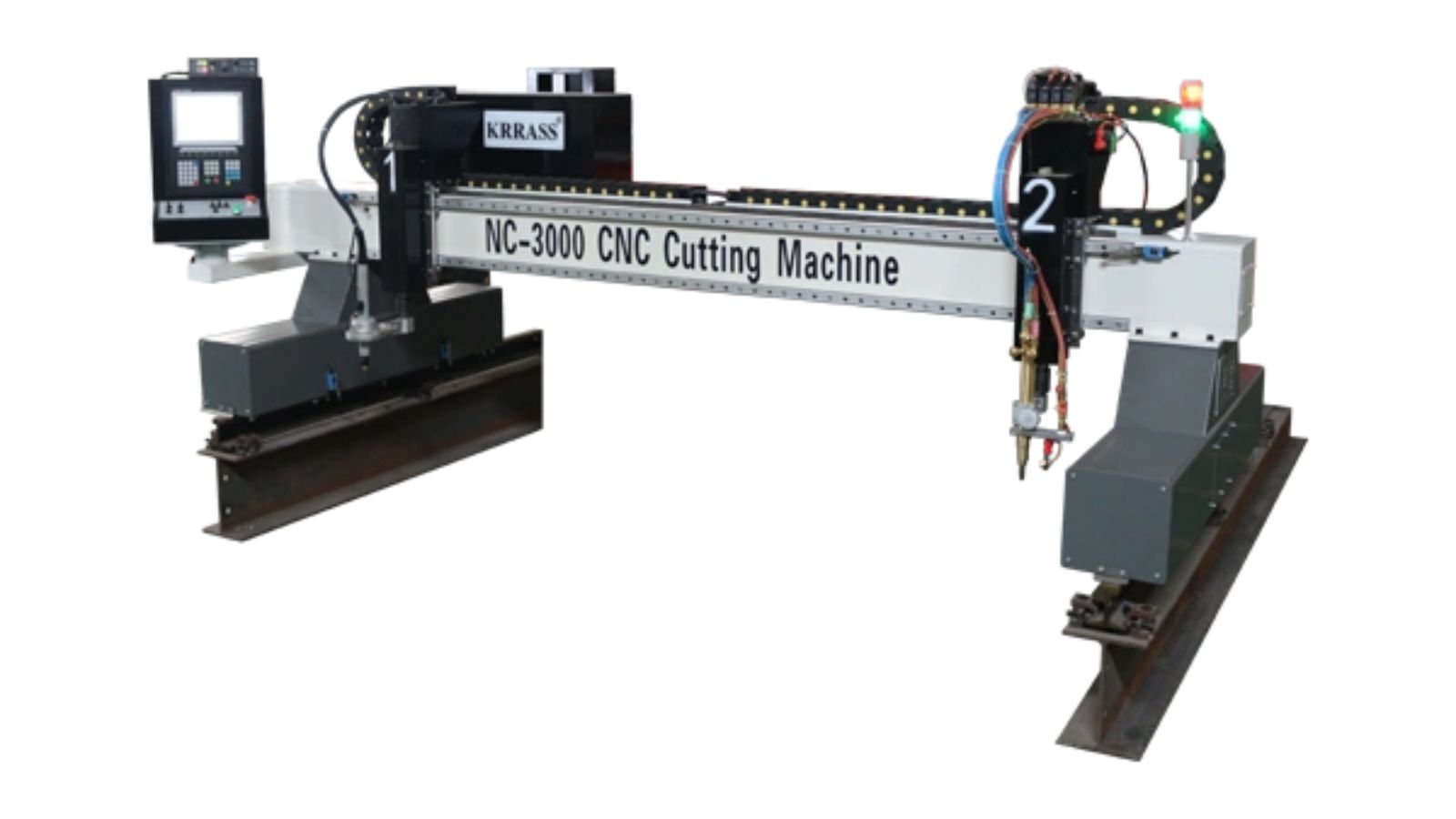

In the field of metal processing, choosing the appropriate cutting process can better improve production efficiency. Compared with traditional cutting methods, Plasma Oxy Cutters have more efficient cutting capabilities and precision. Traditional cutting methods are slower and present challenges in maintaining cut quality and accuracy. However, Plasma Oxy Cutters can complete cutting tasks at a faster speed and provide higher cutting accuracy. This makes Plasma Oxy Cutters the first choice in many manufacturing industries. This guide will focus on how to leverage the benefits of a Plasma Oxy Cuttersto bring greater success to your manufacturing business by maximizing productivity.

Table of contents

I. Comparison of advantages: plasma oxygen cutting machine vs. other cutting methods

II. Plasma oxygen cutting machine operating skills

III.Maintain the plasma oxygen cutting machine

I. Comparison of advantages: Plasma Oxy Cuttersvs. other cutting methods

Cut faster:

The Plasma Oxy Cuttersquickly melts metal with its high-temperature plasma arc, so the cutting speed is significantly faster than traditional flame cutting or mechanical cutting methods.

This means that within the same period of time, more workpiece cutting can be completed using a plasma oxygen cutting machine, improving production efficiency.

Higher cutting accuracy:

Plasma Oxy Cutters use high-energy plasma arcs for cutting, which can achieve more precise cutting and ensure the accuracy and quality of workpieces.

Compared with traditional cutting methods, its cutting accuracy is higher and can meet processes and projects that require higher precision.

More cost effective:

Although the acquisition and maintenance costs of a Plasma Oxy Cuttersmay be higher, considering its efficient cutting speed and precision, as well as the need for fewer auxiliary processes, it is more cost-effective in long-term operation.

Using a Plasma Oxy Cutterscan reduce waste and secondary processing steps during the cutting process, thereby saving time and costs.

II. Plasma Oxy Cuttersoperating skills

Equipment preparation:

Before starting cutting work, the status of the Plasma Oxy Cuttersmust be carefully checked to ensure that all parts are functioning properly and the cutting machine is in good working order.

Ensure that the cutting machine has sufficient air supply and stable power supply, and inspect and maintain the cutting head to ensure cutting quality and safety.

Adjustment parameters:

During the cutting process, the operator needs to adjust the cutting parameters, including plasma gas flow, cutting speed, and nozzle spacing, according to the type, thickness, and required cutting quality of the cutting material.

By correctly adjusting these parameters, stability, efficiency and quality during the cutting process can be ensured.

Maintain stability:

During operation, maintain stable control of the cutting machine to ensure a clear cutting path and avoid cutting deviation or quality problems caused by operating errors or vibrations.

In addition, timely clean up waste and debris in the cutting area to keep the cutting environment clean and prevent it from affecting cutting quality and stability.

Choose the right gas and tool:

According to the characteristics and requirements of the cutting material, select the appropriate plasma gas and tool to ensure stability and efficiency during the cutting process.

Different gas and tool combinations may be suitable for different cutting materials and thicknesses, so selection and adjustment will need to be made on a case-by-case basis.

III.Maintain the plasma oxygen cutting machine

Preventing mistakes is always the prerequisite for victory, and properly protecting the Plasma Oxy Cuttersis the prerequisite for improving productivity.

Regular inspection and maintenance:

Establish a regular inspection and maintenance schedule, including inspection of mechanical components, electrical systems, gas supply systems, etc. Discover and fix potential problems promptly to prevent equipment failures and production interruptions.

Cleaning and Lubrication:

Clean the cutting area and nozzle regularly to remove accumulated metal shavings and waste to ensure a smooth cutting process. At the same time, lubricate the machine regularly to ensure that each component operates flexibly.

Parts replacement:

Regularly replace severely worn parts, such as electrodes, nozzles, and cutting nozzles. Seriously worn parts will affect cutting quality and efficiency. Timely replacement can ensure the stability and performance of the cutting machine.

IV.Conclusion

This guide provides a basic understanding of what an plasma oxy cutters is and how to use it appropriately. To learn more about other sheet metal equipment, read our guide here. For more information about related services, see our other product guides, or visit the KRRASS Supplier Discovery Platform to find potential sources or view details on specific products.