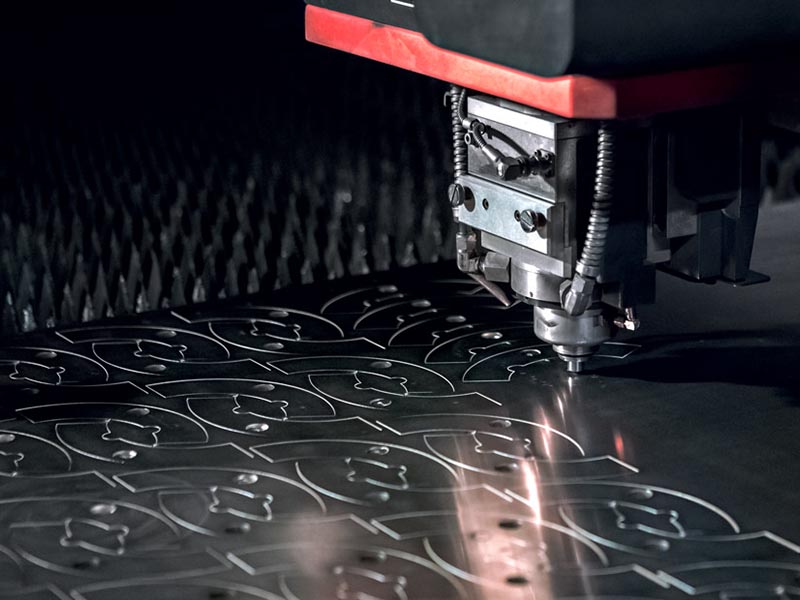

Although the Metal Laser Cutting Machine itself product performance is very good, but to its full effect, stable play out, then the equipment’s working environment must be in line with its working conditions, so that the equipment can better work, otherwise once in line with its working conditions in the place, it will not only affect the efficiency of the equipment, but also will cause loss. So what are the working conditions of the equipment? Let’s take a look.

1, temperature

Metal Laser Cutting Machine is generally a constant temperature environment work, only under constant temperature conditions, in order to ensure the normal operation of equipment and equipment processing accuracy. The semiconductor operating temperature in the laser cut stainles steel is required to be below 40 to 45 degrees, when the room temperature reaches 35 degrees , the internal temperature of the electrical cabinet can reach more than 40 degrees, when the room temperature is too high, the failure rate of the CNC system will increase, so in order to make the system can work well, the operating temperature should not exceed 35 degrees.

2, humidity

Laser cut stainless steel requirements of the working environment of the relative humidity is generally less than 75%. Because the cutter in high temperature and high humidity is powered off, the water molecules in the air can produce condensation on the circuit board of the power supply or drive unit, causing a short circuit when the dew on the circuit board occurs when it is working again, causing a machine failure.

3, voltage

The supply voltage fluctuations, will lead to the laser cutting machine underpressure or overvoltage alarm, or even the loss of data. Therefore, the voltage is generally required to be within the range of the rated operating value of 10%. It is recommended to be equipped with a regulated power supply if the voltage is unstable.

4, dust

In the long-term cutting process, if there is no good dust removal, conductive dust will affect the health of the operator, and if not close the electrical cabinet, dust into the electrical cabinet and deposit on the circuit board or module, will lead to damage to electrical components, especially high-voltage components. Therefore, the equipment is required to work with a good dust removal equipment.

5, ground

The normal operation of the equipment must have a good ground.

6, lighting

Avoid the sun directly to the laser cutter, indoor should be equipped with good lighting equipment.

7, ventilation

We mentioned in the above working conditions humidity and conductive dust, ventilation is a very natural method of exclusion, effective ventilation can better ensure the good operation of the cutting machine and the health of the operator.

Therefore, when we install the laser cutting machine, we must install it in a place that meets the above working conditions, so as to better avoid some environmental factors and other external factors of interference, so that the cutting machine equipment can work well.

Learn more about our products, please visit and subscribe to our Youtube channel