Brief Introduction

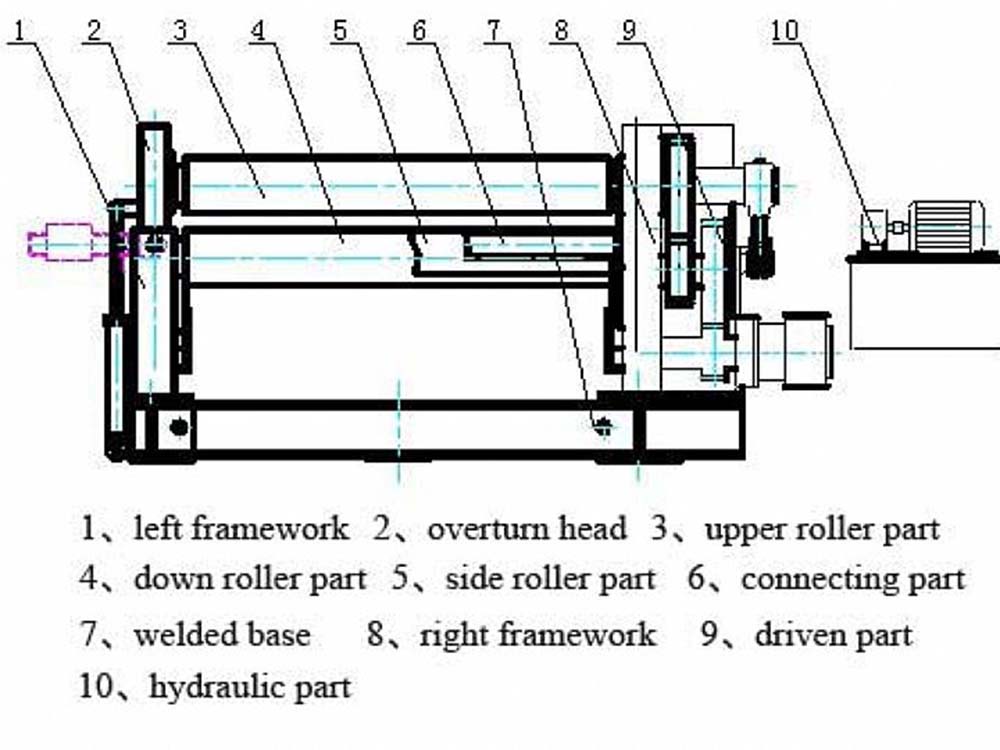

The CNC Press Brake is a machine that can bend thin plates. Its structure mainly includes a bracket, a working table and a clamping plate. The working table is placed on the bracket. The working table is composed of a base and a pressing plate. The base is connected with a hinge and a clamping plate and composed of a seat shell, a coil and a cover plate. The coil is placed in a recess of the seat shell, and the top of the recess is covered with a cover plate. When in use, the wire is energized to the coil, and the gravitational force is generated on the pressing plate after being energized, so as to realize the clamping of the thin plate between the pressing plate and the base. Due to the electromagnetic clamping, the pressing plate can be made into a variety of workpiece requirements, and the workpiece with side walls can be processed, and the operation is very simple.

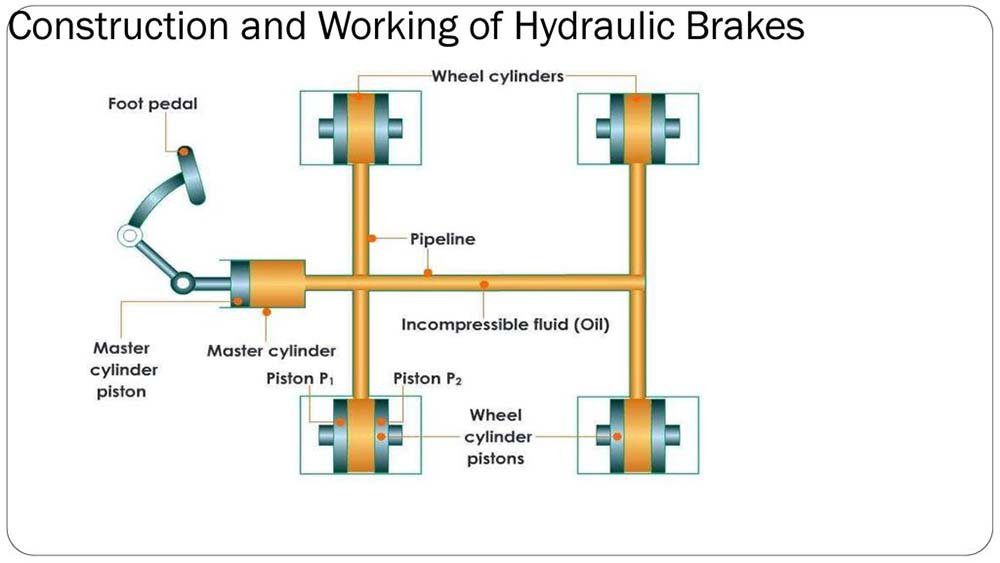

Working Principle

The hydraulic Press Brake includes a support, a workbench and a clamping plate. The workbench is placed on the support and composed of a base and a pressure plate. The base is connected to the clamping plate through a hinge and composed of a housing, a coil and a cover. It is placed in the recess of the seat shell, and the top of the recess is covered with a cover plate.

When in use, the wire is energized to the coil, and the gravitational force is generated on the pressing plate after being energized, so as to realize the clamping of the thin plate between the pressing plate and the base. Because of the electromagnetic clamping, the pressing plate can be made into a variety of workpiece requirements, and the workpiece with side walls can be processed. The bending machine can meet the needs of various workpieces by changing the mold of the bending machine.

Generally, the overflow of the CNC Press Brake is realized by the proportional electromagnetic (liquid) overflow valve controlled by NC, and the pressure can be adjusted and adjusted according to your bending program settings. It is to add a proportional electromagnet or a proportional electrohydraulic mechanism on the basis of an ordinary relief valve (high, medium, and low type).

Structure and Composition

- It adopts all-steel welded structure with sufficient strength and rigidity;

- Hydraulic upper transmission, the oil cylinders at both ends of the machine tool are placed on the sliding block to directly drive the sliding work;

- The slider synchronization mechanism adopts torsion shaft for forced synchronization; Adopt mechanical block structure, stable and reliable;

- The stroke of the slider is adjusted quickly by motor, fine-tuned manually, and the counter displays;

- Wedge type deflection compensation mechanism to ensure high bending accuracy.

- Slider part: hydraulic transmission is adopted, and the slider part is composed of a slider, an oil cylinder and a fine-tuning structure of a mechanical stop. The left and right oil cylinders are fixed on the frame, the piston (rod) drives the slider to move up and down through hydraulic pressure, and the mechanical stop is controlled by the numerical control system to adjust the value;

- Worktable part: controlled by the button box, the motor drives the stopper to move back and forth, and the distance of the movement is controlled by the numerical control system. The minimum reading is 0.01 mm (the front and rear positions have travel switch limits);

- Synchronization system: The machine consists of a mechanical synchronization mechanism composed of torsion shafts, swing arms, joint bearings, etc., with simple structure, stable and reliable performance, and high synchronization accuracy. The mechanical stop is adjusted by the motor, and the numerical control system controls the value.

Main Function

CNC Press Brake is a kind of forging machinery, the main function is the metal processing industry. Products are widely used in: light industry, aviation, shipbuilding, metallurgy, instrumentation, electrical appliances, stainless steel products, steel structure construction and decoration industries. The bending machine is currently the preferred machine for sheet metal processing of sheet materials, especially large sheets. , Through the selection of various molds, the sheet metal can be bent, stretched, rounded, punched, etc.

Scope of Application

As small as non-ferrous metals, ferrous metal sheets, automobiles, ships, electrical appliances, decoration, electrical power sheets, chassis cabinets, and the cutting and bending of elevator cabinet doors; as large as the aerospace field, bending machines play an important and irreplaceable role.

Mold manufacturing:

In the mold manufacturing process of the mold manufacturing industry, almost all links such as forming molds, hot work molds, cold work molds, and plastic molds need to use CNC bending machine molds.

Decoration Industry:

In the decoration industry, high-speed CNC shears are widely used, generally used with CNC bending machines to complete the production of stainless steel doors and windows and the decoration of some special places.

Electrical Power Industry:

The shearing machine can cut the plate into different sizes and then process it again by the bending machine, such as computer cases, electrical cabinets, refrigerators and air conditioner shells.

Kitchen and Catering Industry:

Stainless steel kitchen utensils of various varieties and specifications are then processed in secondary processing, such as welding and bending.

Wind Communication Industry:

Wind power poles, road light poles, communication tower poles, traffic light poles, traffic signal poles, monitoring poles, etc. are bent.

Aerospace Industry:

Generally, high precision is required, and high-precision CNC shears can be used, which is accurate and efficient.

Automotive and Marine industry:

Generally, large-scale CNC hydraulic shears are used, mainly to complete the shearing work of the plate, and then in the secondary processing, such as welding, bending, etc.

Main Production Area

CNC Press Brake is an important branch of machine tool equipment with a wide range of applications. At present, the main production areas are in Europe and Asia, including Germany, Italy, Switzerland, Spain, the Netherlands, Sweden, France, United Kingdom, Austria, Belgium, Czech Republic, Turkey , Romania, Finland, Denmark, Russia, Poland, China, Japan, Taiwan, Singapore, South Korea, India, the United States, Canada, etc.

As far as China is concerned, the production of bending machines in China is mainly concentrated in Bowang District, Ma’anshan City, Anhui Province.

There are a large number of Chinese mold blade machinery manufacturers in Bowang District. 90% of the bending machines in China come from here. There are factories everywhere in this place. The main industry is sheet metal machine tools, namely bending machines, shearing machines and then There are various machine blades and bending machine moulds. The bending machine mold can be regarded as a relatively simple mold, and it is not complicated to make. It is hoped that many small factories can produce better quality bending machine molds on a small scale.

Bowang District is also the characteristic industrial base of Bowang shearing machine tools and blade molds of China’s National Torch Plan, a well-known brand demonstration zone of the national shearing machine tool industry, and the National Machine Tool Supervision and Inspection Center. With the further development of economic integration in the Yangtze River Delta, Bowang will fully integrate into the Yangtze River Delta region, providing more and more advanced production factors for the development of Bowang sheet metal equipment industry, promoting the local economy, and providing domestic customers with more high-quality sheet metal products and services.

Advantages of China's CNC Press Brake

CNC Press Brake is a product that highly depends on processing accuracy and assembly accuracy. The professionalism and experience level of front-line workers determines the quality of the bending machine. Workers in Germany, Japan, Switzerland and the Nordic countries have certain technical advantages in the production of bending machines, and this advantage is difficult to copy.

However, since China’s reform and opening for more than 40 years, China’s industry has developed at a speed that shocked the world, and now it has become the second largest economy after the United States. The development of industry has also promoted the establishment of sheet metal processing equipment factories. , China’s sheet metal processing industry is very mature and large in scale. The number of sheet metal equipment companies is the largest in the world. After decades of development, it has mature production and technical experience,Many national brands that are well-known at home and abroad have emerged The national brand, with its extremely high cost performance, extremely fast delivery and service response speed, makes China’s bending machine always invincible under the wave of economic globalization.

Learn more about our products, please visit and subscribe to our Youtube channel