During the bending process, the force between the upper and lower dies is applied to the material, causing the material to undergo plastic deformation. Working tonnage refers to the bending pressure of hydraulic press brake during bending.

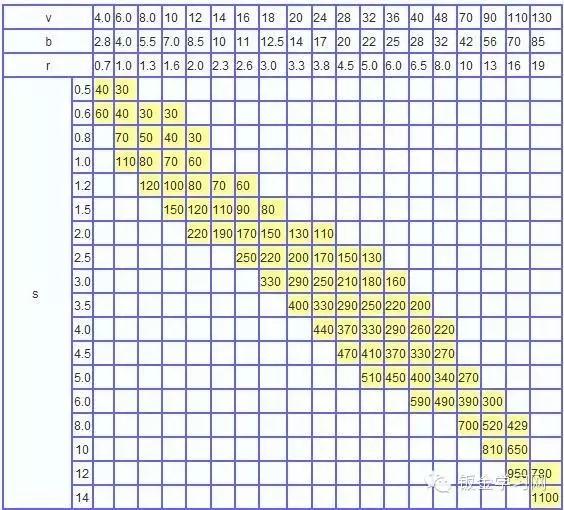

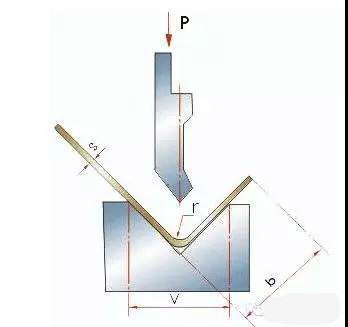

The influencing factors for determining the Hydraulic press brake working tonnage are: bending radius, bending method, die ratio, elbow length, thickness and strength of bending material, etc., as shown in Figure 1. Normally, the working tonnage can be selected in the following table and set in the processing parameters.

1. The value in the table is the bending pressure when the length of the sheet is one meter:

Example: S=4mm L=1000mm V=32mm

look up the table and get P=330kN

2. This table is calculated on the basis of materials with strength σb=450N/mm2. When bending other different materials, the bending pressure is the product of the data in the table and the following coefficients;

Bronze (soft): 0.5;

Stainless steel: 1.5;

Aluminum (soft): 0.5;

Chromium molybdenum steel: 2.0.

3. Approximate calculation formula for bending pressure:

P=650s2L/1000v, the unit of each parameter

P——kN

S——mm

L——mm

V——mm

bending pressure comparison table

Learn more about our products, please visit and subscribe to our Youtube channel