Hydraulic Press Brake mold includes a bracket, a table, and a clamping plate. The coil is energized by a wire when in use, and the platen is attracted by the current after being energized, thereby clamping the thin plate between the platen and the base. Due to the use of electromagnetic force clamping, the pressure plate can be made into a variety of workpiece requirements, and workpieces with side walls can be processed, and the operation is very simple. Brief introduction to processing Q235 sheet according to common Hydraulic Press Brake mold:

1. First, turn on the power, turn on the switch on the control panel, and then start the oil pump, so you can hear the sound of the oil pump turning (at this time the machine does not move).

Preparation before starting

1. Rails, back gauges and other moving parts with centralized oil supply should be refueled regularly;

2. Check the cleanliness and damage of the mold, and deal with it in time if any abnormality is found;

3. Check the parallelism of the back gauge and the tension of the driving belt.

Hydraulic Press Brake boot step tutorial

1. Follow the operation steps to operate the machine correctly;

2. When the machine tool is running, if the abnormal situation occurs, stop the inspection immediately, and refer to the relevant troubleshooting methods in the Training Manual for troubleshooting;

3. If the machine stops when an alarm occurs, it should be treated differently, not blindly to avoid damage to the machine;

4. The newly executed program, the first workpiece must be checked according to the drawing to avoid batch errors;

5.During the bending process, if abnormal conditions are found in the mold, the machine should be shut down and inspected in time;

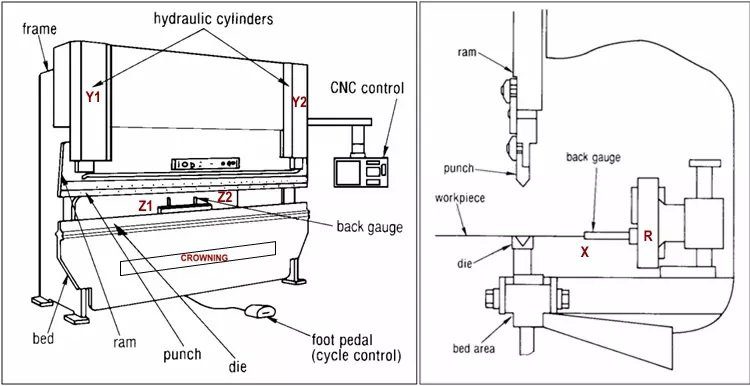

6. Frequently check whether the actual position of the X axis and the detected value match, and adjust in time if there is a deviation.

2, stroke adjustment, use must pay attention to adjust the stroke, be sure to test before bending. Its upper die must ensure a gap of plate thickness when it descends to the bottom. Otherwise it will cause damage to the mold machine. The adjustment of the stroke is also electric fast adjustment.

3, the choice of bending notches, generally choose the slot thickness of 8 times the thickness. If you bend a 4mm sheet, you need to choose a notch of about 32.

4. The backgauge adjustment generally has electric quick adjustment and manual fine adjustment, the method is the same as that of the shearing machine.

5. Press the foot switch to start bending. The Hydraulic Press Brake mold is different from the shears. It can be released at any time. When you release the foot, it stops and continues to step down. Plastic Hydraulic Press Brake mold, plastic edge bending machine, plastic plate Hydraulic Press Brake mold, plastic sheet bending, plastic sheet bending directly, no splicing, no slotting, no welding rod is required, its corner appearance is not beautiful Leakage, it transforms manual welding into fully automatic machine operation, which improves quality, improves labor efficiency, reduces labor costs, and greatly shortens the production cycle of the product.