The hydraulic control system of the press brake is composed of hydraulic control and sensors. The hydraulic control and energy conversion part usually refers to hydraulic control valves, hydraulic pumps, etc. Hydraulic control technology is an important branch of automatic control system. The hydraulic control system has many obvious features and many advantages, and it plays an important role in the bending machine system.

Hydraulic control technology is a typical electro-hydraulic hybrid technology. For example, the electric industry hybrid system is based on the power system, which combines mechanical systems, electronic systems and hydraulic systems. At present, hydraulic control systems are widely used in equipment manufacturing, automobile industry, aerospace, metallurgy and other industries.

This article will specifically introduce the electro-hydraulic control system in the bending machine, which can be divided into an open-loop control system and a closed-loop control system. The beam of the bending machine is the main control part of the system.

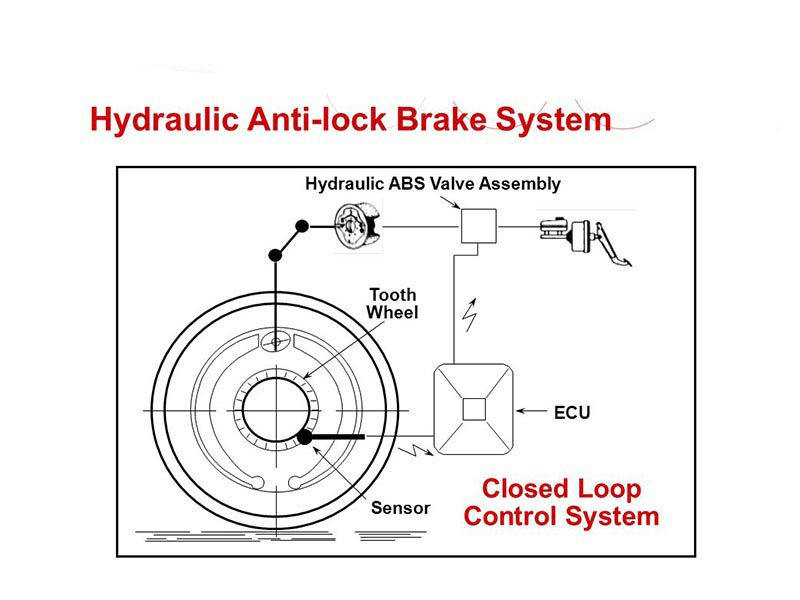

1. Closed loop

Hydraulic Press Brake Closed loop is also called a feedback control system. The system compares the measured value of the system output with the expected given value to generate a deviation signal, and then uses the signal deviation to control and adjust, so that the output value can be close to the desired value.

For example, when driving, people first have a preliminary perception of the driving direction of the car in the brain. During the driving process, people observe the driving direction of the car with eyes, and compare the driving direction of the car with the expected direction. In this process, the direction is continuously adjusted, and finally the driving direction of the car is continuously approached to the target direction, thereby forming a closed-loop control.

Closed-loop control is based on the operating conditions of each part of the machine tool, with high accuracy and response speed. Since the closed-loop control system involves many elements, compared with the open-loop system, the structure of the whole system is more complicated and the price is higher.

2. Open loop

Hydraulic Press Brake Open loop is compared to closed loop, that is, open loop control does not feed back the current system control result. For example, throw things. Once something is thrown out, people cannot control what is thrown out. Because once things leave the hands of people, people's control over things stops immediately.

Therefore, in the open loop system of the bending machine, the accuracy of bending depends on the accuracy of each part of the machine tool. The system cannot control and compensate for the parameter changes produced during the bending process, resulting in low bending accuracy. Once the outside of the machine tool is disturbed, the internal parameters of the machine tool will change.

However, in terms of system design, the open-loop design is simpler and more stable. Whether it is the installation of the machine tool in the early stage or the maintenance of the subsequent machine tool, it is easier.

To sum up, when buying a bending machine, if the buyer has higher requirements for bending accuracy and sufficient purchase funds, our company recommends that you buy a bending machine with a closed-loop system; if the bending accuracy is not high, choose Bending machine with open loop system.

Learn more about our products, please visit and subscribe to our Youtube channel