Hydraulic Ironworker Machine

Hydraulic Ironworker Machine

This Hydraulic ironworker is designed with multi-functions to save labor, time, energy, and cost. This versatile aspect allows the machine to meet the diversified needs of the metal fabricating industry. Currently, KRRASS has the highest reviews of any ironworker machine brand on the market today.

Top performances allow to accurately and cost-efficiently cut pieces in high volumes.

We has entirely designed the proportional oil hydraulic circuit. It is optimized for every guillotine shear size, with high-quality and reliable parts.

Hydraulic ironworker machine is available in a wide range of models and powers. Ironworker machines can customize parameters to the highest levels in the category.

Standard Equipment

- Electrics: Schneider Electric - France

- Main Motor: Siemens Motor - Germany

- Foot Switch: KACON - South Korea

- Hydraulic System: Bosch Rexroth - Germany

- Oil pump: First/Sunny - USA

- Sealing Ring: PARKER - America

Features of Hydraulic ironworker

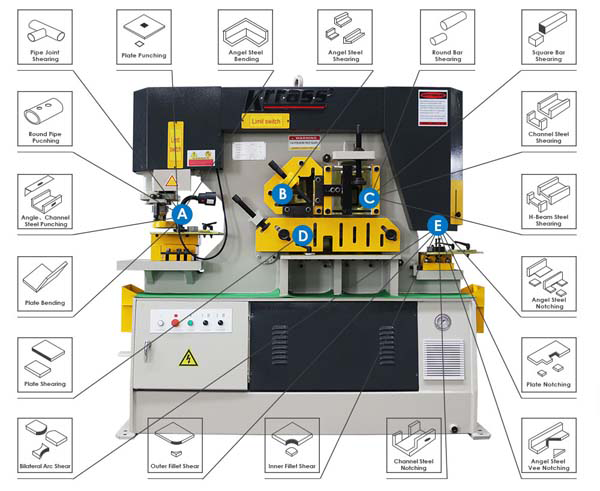

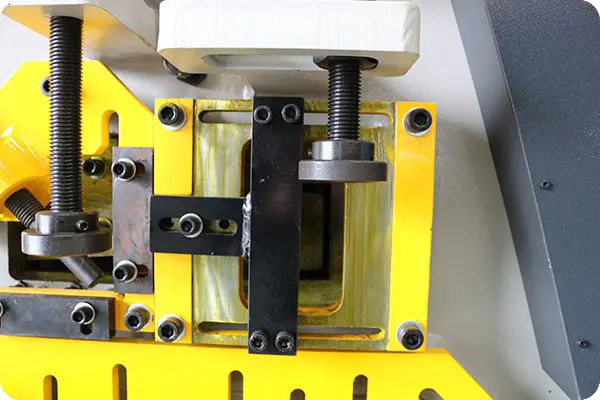

Punching station

All metal punching operations of the ironworker machine are processed using hydraulic power, thus allowing the machine to punch very efficiently and silently. Punching is silent, powerful, and efficient. The device can either be used to hit thick metal or thin materials layered together. The waste materials come off together and in layers. The punching table consists of two parts: the first is the punching flange, and the second is the holder. There are different holders for different materials. The holder is a device that prevents the fabric from coming back with the punch after cutting.

Flat bars shearing station

The metal shear station of the ironworker machine has been equipped with simple and sturdy fixing mechanisms. Depending on the machine’s cutting capacity, You can adjust it for any steel thickness. The shearing capacity can go up to 17.71 inches in the flat bar or the cutting of corner profiles. The shearing blades, built for mass production, can be used on both sides (the upper blade has two cutting edges, and the lower blade has four cutting edges); this ensures a clean cut with minimal warping, from the total capacity to a thickness of only 1/8 inch.

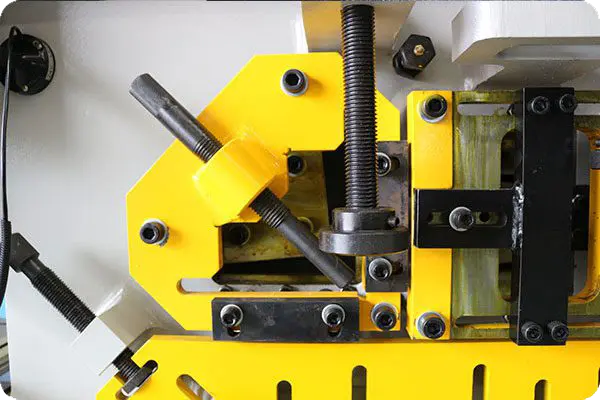

Bars cutting station

Standard machines are equipped with blades for cutting U-sections. The edges are held by efficient jaws, ensuring the equipment can be arranged easily at the device without any additional adjustment. Thanks to other equipment, cutting I-section profiles, T-sections, and round and square metal bars is possible.

Notching station of ironworker machine

High Adaptability: With QBH, QCS, and other optical fiber interfaces, it can be adapted to various mainstream laser devices.

Excellent Design: Optimized optical configuration and smooth and efficient airflow design significantly improve cutting quality and efficiency.

Angle shearing station

This station enables the cutting of large angles with a capacity ranging from 17 3/4 inches to 35 1/2 inches.

Optional Equipment

- Angle steel, channel steel, round steel automatic positioning shear

- Shear plate automatic hydraulic clamping

- Angle steel shear automatic clamping

- Laser positioning

- Louver punching

- Bending

More Details of Ironworker Machine

Technical Parameters of Ironworker Machine

| Technical Specification | Q35Y-12 | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | Q35Y-50 | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Punching Pressure(T) | 35T | 60T | 90T | 120T | 160T | 200T | 250T | |||

| Depth of throat(mm) | 115 | 300 | 355 | 400 | 600 | 600s | 600 | |||

| Standard Die | Punching | Dia.X Max.Thickness | mm | 25X12 | 25X16 | 30X20 | 35X25 | 38X26 | 40X35 | 40X40 |

| Dia.X Thickness | mm | 25X12 | 25X16 | 30X20 | 35X25 | 38X26 | 40X35 | 40X40 | ||

| Max.Diameter | mm | 12 | 25 | 30 | 35 | 38 | 40 | 40 | ||

| Travel | mm | 35 | 80 | 80 | 80 | 80 | 80 | 80 | ||

| Working Travel | mm | X18 | X20 | X25 | X25 | X30 | X35 | X40 | ||

| Throat Depth | mm | 115 | 300 | 355 | 400 | 600 | 600 | 600 | ||

| Steel Bar | Round | mm | 35 | 45 | 50 | 60 | 65 | 70 | 80 | |

| Square | mm | 30X30 | 40X40 | 50X50 | 50X50 | 55X55 | 60X60 | 65X65 | ||

| Steel Angle | Angle Size | mm | 86X86X8 | 125X125X12 | 140X140X12 | 160X1160X14 | 180X180X16 | 200X200X18 | 200X200X20 | |

| Cutting Angle | ° | 50X50X5 | 50X50X5 | 50X50X5 | 60X60X6 | 60X60X6 | 100X100X10 | 120X120X10 | ||

| Angle Section | mm | 5.5 | 5.5 | 6.5 | 9 | 11.5 | 12 | 12 | ||

| Slotting | Thickness | mm | 100 | 126 | 160 | 210 | 280 | 300 | 320 | |

| Width | mm | 30 | 53 | 60 | 75 | 86 | 89 | 92 | ||

| Depth | mm | |||||||||

| Optional Die | U-I Shaped Profile | mm | 100X100X8 | 125X125X12 | 140X140X12 | 160X160X14 | 180X180X16 | 160X160X14 | 180X180X16 | |

| T-shaped Profile | mm | 40X40X6 | 60X60X8 | 70X70X10 | 80X80X10 | 80X80X10 | 80X80X10 | 80X80X10 | ||

| I-Beam | mm | 40X60X4 | 126X74X5 | 160X86X6 | 200X102X9 | 280X124X10.5 | 300X126X11 | 320X130X10 | ||

| V-Bending | Length | mm | 600 | 600 | 600 | 600 | 600 | 600 | 600 | |

| V-Bending | Thickness | mm | 4 | 10 | 15 | 20 | 26 | 33 | 40 | |

| Voltage | Kn | 350 | 600 | 900 | 1200 | 1600 | 2000 | 2500 | ||

| Motor Power | kw | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 18.5 | ||

| Weight | Kg | 1600 | 1800 | 2400 | 4200 | 6800 | 7600 | 13500 | ||

| Outline Dimension (LXWXH) | mm | 950X950X1800 | 1640X730X1770 | 1860X800X1990 | 2355X960X2090 | 2680X1040X2300 | 2970X1240X2350 | 3000X1440X2450 | ||

Use case of ironworker machine

Reviewed by 21 users

I used KRRASS Iornworker Q35Y-25 to cut my angle steel, realy helpful for my jobs, Thanks

Me sorprendió gratamente el rendimiento de la máquina cortadora de hierro KRRASS. Realiza la mayor parte de mi trabajo con facilidad.

Incrível! Gosto da máquina da China, bom preço e boa qualidade.

My 120ton metal ironwoker is great! I like it.

I like my ironworker 120Ton. It could cut most of my profiles. Great!