Hydraulic CNC Bending Machine, also called CNC forming, is the process whereby sheet metal is reshaped from a flat form. Using Hydraulic CNC Bending Machine technology you can produce almost any component design. A basic example of this would be the creation of a 90 degree bend transforming a flat piece of metal into an ‘L’ shaped bracket.

Hydraulic CNC stands for ‘computer numerically controlled’. This means that computer software translates your design into code or numbers and it’s this code which controls the bending machinery.

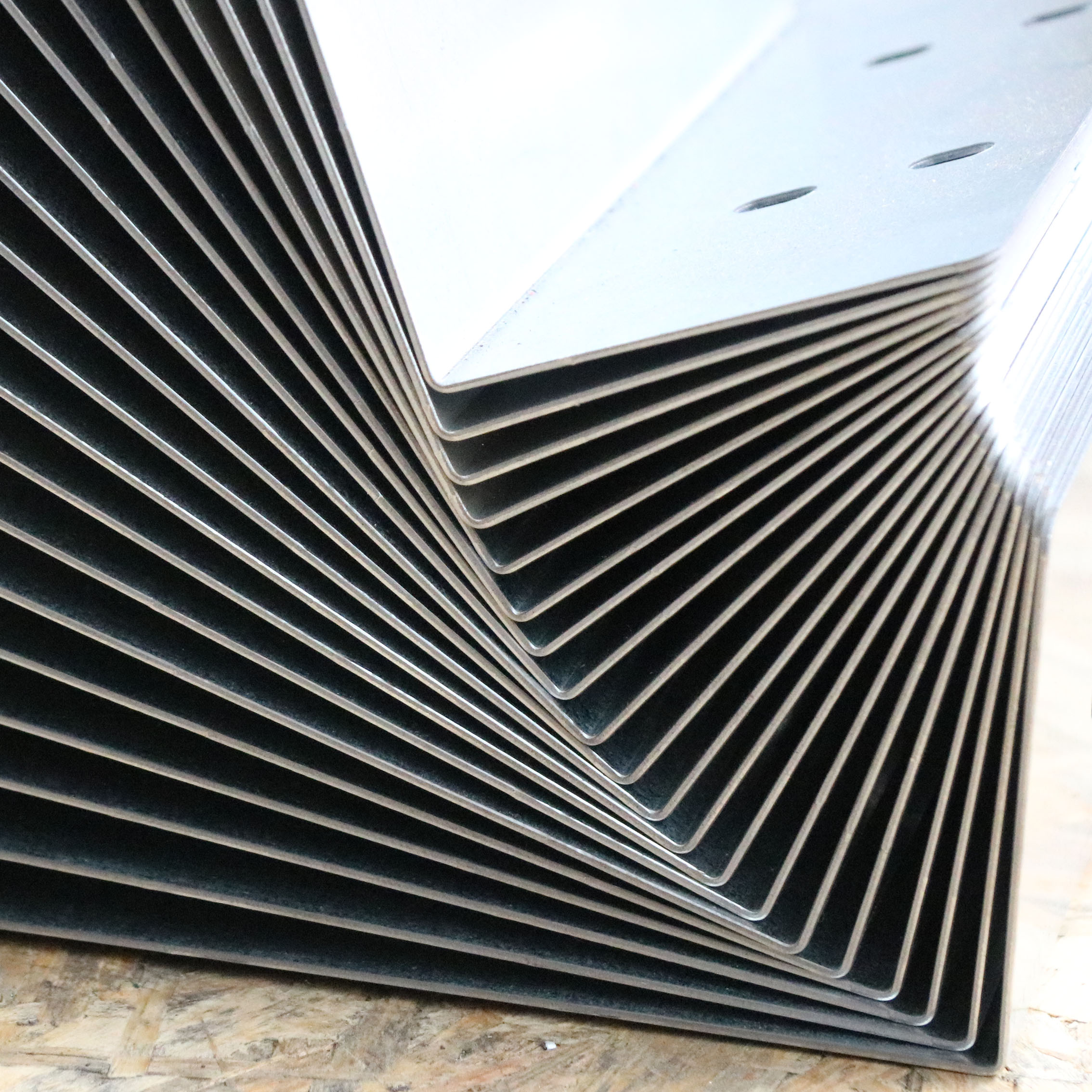

The machines used for CNC bending are called CNC press brakes (or brake presses). They can transform sheet metal ranging in size from a few millimetres to several metres long.

What’s involved in the Hydraulic CNC Bending Machine?

The press brake is made up of a bottom bed and a top rail or beam. A vee (or die) sits on the bottom bed and a punch tool sits on the top rail. The size and angle of the vee and the punch are determined by the thickness of the sheet metal to be used and the geometry of the desired bend. Once the machine is operating, the punch forces the metal into the vee and creates a shape.

Modern machines commonly have a fixed bottom bed and a down-stroking top rail, although some are constructed in the opposite manner where the bottom bed moves in an up-stroking direction. Either way, you can achieve the same results.

A CNC press brake has a programmable console into which the data (numbers) are entered. This controls the position of a back stop which in turn, controls the height and length of each bend. It can also quickly alter the height between the bottom bed and top rail, allowing you to easily remove parts once formed. The beauty of this technology is that once the console is programmed, you can repeatedly form multiple bends accurately (with a tolerance of a few microns).

What machinery does KRRASS use for CNC bending?

At KRRASS, we have three CNC press brakes, with bed sizes ranging from 1200mm to 2500mm. This gives us the capability and capacity to produce your components at cost effective rates and lead times to suit your requirements.

What are our forming capabilities?

With our largest press brake, a 7 axis 2500mm bed Amada, and universal tooling, we can bend lengths of up to 2.5 metres in various thicknesses.

We also use radius tooling and swan neck tooling. These allow us to create a range of internal bend radiuses and produce special channel forms.

What are the benefits of Hydraulic CNC Bending Machine technology?

Prior to the introduction of CNC bending technology, producing sheet metal components with several bends was a manual and laborious task. The back stop, which predetermines the height and length of a bend, was operated by a technician. He would manually fix it into the correct position, but this meant that he could only produce single bends at any one time. Once the first bend was complete, the operator would move the back stop into a new position for the next bend, and so on and so on. This meant it was necessary to handle the same component several times until all the bends were completed. It’s not difficult to imagine how long this process would take from start to finish.

With technology advancements creating automation that once could only be dreamed of, a CNC bending machine can now create multiple bends quickly and accurately. Programmable back stops can traverse in seconds meaning intricate components with multiple bends can be produced in minutes, speeding up production times and reducing costs.

Learn more about our products, please visit and subscribe to our Youtube channel