Understanding the maximum thickness your fiber laser can cut with a certain power is crucial, especially when dealing with high-powered lasers like a 3kW machine. Guesswork in determining cutting capabilities can lead to inefficiencies and poor results. So, if you're struggling to find the optimal cutting thickness for your laser machine, keep reading. In this article, we’ll explore how thick a 3kW laser can cut and discuss the various factors that affect its cutting performance. This will help you achieve the best results with your laser cutting equipment.

What Is Fiber Laser Cutting

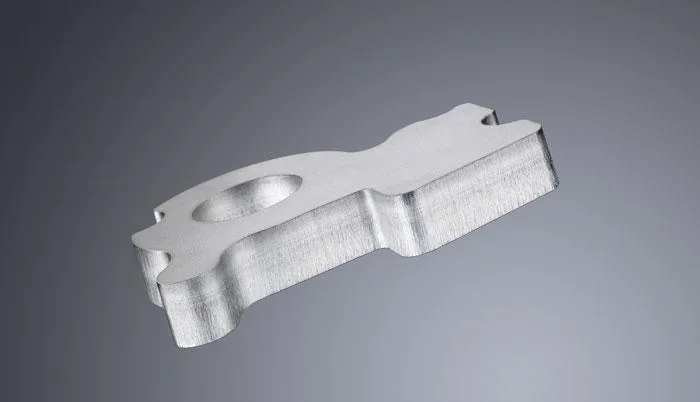

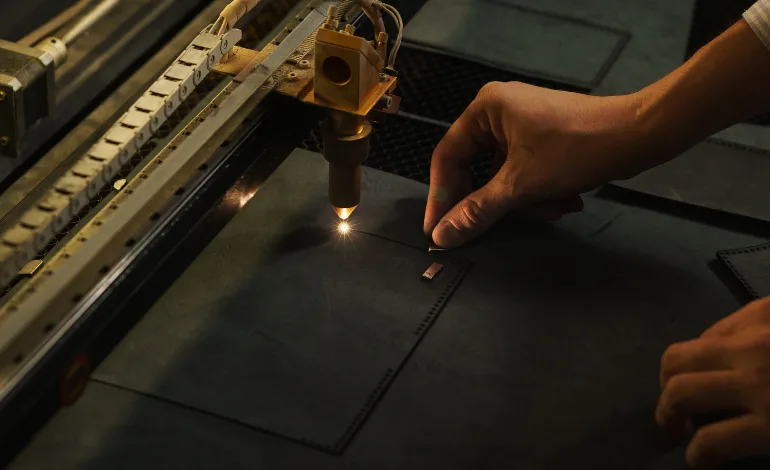

Fiber laser cutting is a precise and efficient laser cutting technology that utilizes a high-intensity laser beam to cut through various materials. This technology is renowned for its ability to deliver high-quality cuts with minimal waste. Fiber laser cutters are equipped with a fiber laser source, which generates a focused laser beam that can handle a wide range of materials, including metals like stainless steel and carbon steel.

What is Fiber Laser Cutting?

Fiber laser cutting is a precise and efficient laser cutting technology that utilizes a high-intensity laser beam to cut through various materials. This technology is renowned for its ability to deliver high-quality cuts with minimal waste. Fiber laser cutters are equipped with a fiber laser source, which generates a focused laser beam that can handle a wide range of materials, including metals like stainless steel and carbon steel.

How Thick Can Fiber Lasers Cut?

The most powerful fiber laser cutting machines can achieve a maximum thickness of up to 50 mm for certain metals.

Fiber laser cutting machines are capable of cutting a variety of materials to impressive thicknesses. The cutting thickness depends on the power of the laser and the material being cut. For example, high-power fiber laser cutters can handle stainless steel and carbon steel with ease, making them ideal for metal fabrication and other industrial applications. The cutting process is optimized by adjusting factors such as laser cutting speed and laser beam quality to achieve the desired thickness

Metal Laser Cutting Machine Cutting Depth

For example, a 1000w fiber laser cutting machine can cut carbon steel plates of about 10mm. It is more difficult to cut stainless steel. To increase the cutting thickness, edge effects and speed can be sacrificed.

Carbon steel 36mm (steel plate quality is good, speed can reach 650mm/min). If the 36mm steel plate is made of high-quality materials, the machine performance is good, the graphics are not complicated, and the cutting quality is still very good.

The key is that the speed is not fast, and it is more reasonable to use a plasma cutting machine or a flame cutting machine. 25mm stainless steel (when using high-pressure nitrogen as auxiliary gas, the speed is about 400mm/min);

Chinese users usually target laser cutting, with mild steel below 25mm and stainless steel below 16mm.

The laser cutting thickness limit of the higher power 60kw is as high as 200mm-300mm. The higher the power, the higher the laser cutter cutting depth.

How Thick Can a 3KW Laser Cut?

The maximum cutting thickness of different materials with a 3000W fiber laser cutting machine is as follows: the maximum thickness of carbon steel is 25 mm; the maximum thickness of stainless steel is 10 mm; the maximum thickness of aluminum is 8 mm; the maximum thickness of copper is 5 mm. More information for all materials and various thicknesses will be provided below.

| Fiber Laser Power (W) | Material | Maximum Cutting Thickness (mm) |

|---|---|---|

| 3000 | Carbon Steel | 25 |

| 3000 | Stainless Steel | 10 |

| 3000 | Aluminum | 8 |

| 3000 | Copper | 5 |

| 3000 | Brass | 5 |

| 3000 | Plastic | 6 |

| 3000 | Composites | 6 |

| 3000 | Ceramics | 6 |

| 3000 | Wood | 6 |

Range of Materials That 3KW Fiber Laser Can Cut

Fiber laser cutting machine belongs to the category of metal cutting machine and is good at processing different types of metals, but it is not a good choice for non-metallic materials such as PVC. Which materials cannot be cut by a fiber laser cutting machine?

Sheet metal cutting is one of the largest cutting applications in the manufacturing, construction, and infrastructure industries, and fiber laser cutting can cut all types of metals from carbon steel, stainless steel, non-ferrous metals, and more. Metalworking just got easier with a fiber laser cutting machine. You’d better know the characteristics of each material in advance, and pay special attention to the state of some materials when cutting.

Carbon steel

Carbon steel contains carbon, which does not reflect light strongly but absorbs light well. Therefore, cutting carbon steel with fiber laser works best among all metal materials. The maximum cutting thickness of the Krrass Laser fiber laser cutting machine can reach 120MM. The incision of carbon steel can be controlled within a satisfactory width range, and the incision of the thin plate can be as narrow as about 0.1MM.

stainless steel

Under the condition of strictly controlling the heat input of laser cutting, the width of the heat-affected zone of the cutting edge can be limited, to ensure the good corrosion resistance of stainless steel. Moreover, nitrogen gas is generally used for cutting stainless steel sheet metal, which can prevent oxidation, has no burrs on the edges, and can be directly welded with almost no post-processing. According to the characteristics of the stainless steel material, the fluidity of the liquid can be accelerated, so that the cutting efficiency is higher and the speed is faster.

Alloy steel

Most alloy structural and tool steels can be laser-cut with good edge quality. The cut edges are slightly oxidized when oxygen is used as the process gas. For sheets up to 4mm thick, high-pressure cutting can be performed using nitrogen as the process gas. In this case, the cut edge will not be oxidized.

For high-strength steel, as long as the process parameters are properly controlled, straight and slag-free cutting edges can be obtained. However, for high-speed tool steel and hot forging die steel, corrosion, and sticky slag are prone to occur during laser cutting.

Aluminum and its alloys

For laser cutting of aluminum and its alloys, the auxiliary gas is mainly used to blow the molten product away from the cutting area to obtain better-cutting quality. For some aluminum alloys, care should be taken during the cutting process to prevent micro-cracks on the surface of the cutting seam. When oxygen is used, the cut surface is rough and hard; when nitrogen is used, the cut surface is smooth. Pure aluminum is difficult to cut and can only be cut with a “reflection absorber” device installed on the system, otherwise, reflections can damage the optics.

Copper and its alloys

The reflectance of copper is too high, and basically cannot be cut with fiber laser beams. Cutting brass should use high laser power and use compressed air or nitrogen as auxiliary gases, which can cut thinner plates. Bronze with a thickness of less than 1mm can be cut with nitrogen; copper with a thickness of less than 2mm can be cut, and the processing gas must be oxygen. (Delete) Only the “reflex absorber” device installed on the system can cut pure copper and brass, otherwise, the reflection will damage the optical element.

Materials That Fiber Laser Can Cut

CO2 Lasers: Carbon dioxide (CO2) lasers are commonly used for cutting non-metallic materials such as plastics, woods, fabrics, and composites. These lasers operate at wavelengths suited for efficient absorption by organic materials.

Fiber Lasers: While primarily used for metal cutting, fiber lasers can also process some non-metallic materials, particularly ceramics, thanks to their high power density and precision.

UV Lasers: Ultraviolet (UV) lasers are suitable for precise cutting of materials like certain polymers, ceramics, semiconductor materials, and more, due to their shorter wavelengths and minimal thermal effects on the surrounding material.

What Factors Affect the Laser Cutting Thickness

Material Type and Properties:

Different materials have varying absorption coefficients and thermal conductivities, affecting their suitability for laser cutting and the achievable thicknesses.

Laser Power:

Higher laser powers allow for cutting through thicker materials. The power requirement varies depending on the material’s properties, such as reflectivity and thermal conductivity.

Beam Focus and Quality:

The quality of the laser beam and its focus influence the precision and efficiency of cutting. A tightly focused beam enables cleaner cuts and better penetration through thicker materials.

Assist Gasses:

The type and flow rate of assist gasses (such as oxygen, nitrogen, or air) affect the cutting process by aiding in material removal and preventing excessive heat buildup.

Cutting Speed:

The speed at which the laser beam moves across the material surface affects the heat input and the overall cutting efficiency, especially for thicker materials.

Capabilities of Fiber Lasers Cutting by Material Thickness

Fiber laser cutting machines offer versatile applications across different materials, allowing precise cuts from thin sheets to thicker metal plates. This capability is due to the advanced technology in fiber lasers, which uses a highly concentrated laser beam to cut through materials efficiently.

Metals

Fiber laser cutters are widely used for cutting metals like steel, aluminum, and copper. The cutting process involves directing a high-power laser beam at the material, melting or vaporizing it along a path. This results in clean and accurate cuts with minimal waste. Here are the specific parameters for various metals:

Steel

- Minimum Thickness: Approximately 0.5 mm

- Maximum Thickness: Up to 25 mm

- Notes: Steel, including alloy steel and carbon steel, is a common application for fiber lasers. The high power levels of fiber laser cutting machines ensure efficient cutting with excellent surface cutting quality. Proper settings like laser cutting speed and auxiliary gas type can enhance the cutting ability and reduce burrs.

Aluminum

- Minimum Thickness: As low as 0.5 mm

- Maximum Thickness: Up to 30 mm with very high-power lasers

- Notes: Aluminum is another material where fiber lasers excel. The aluminum plate’s reflective properties require careful adjustment of the laser beam focus and power. Using a fiber laser cutting machine, you can achieve smooth edges on aluminum alloy sheets.

Stainless Steel

- Minimum Thickness: About 0.5 mm

- Maximum Thickness: Up to 20 mm

- Notes: Stainless steel is popular in industries for its durability and resistance to corrosion. Fiber lasers provide a high-quality cutting process for stainless steel, ensuring precision parts with minimal post-processing required.

Copper and Brass

- Minimum Thickness: Around 0.5 mm

- Maximum Thickness: Up to 10 mm

- Notes: Cutting copper and brass can be challenging due to their reflective nature. Fiber laser cutters equipped with specific settings can handle these materials efficiently, producing quality cutting results without compromising on speed.

Non-Metals: Plastics and Composites

Fiber lasers are not limited to metals; they also cut non-metallic materials such as plastics and composites. The ability to adjust laser power and speed makes fiber lasers suitable for these materials.

Plastics

- Minimum Thickness: Typically around 1 mm

- Maximum Thickness: Up to 10 mm

- Notes: When cutting plastics, fiber lasers provide clean edges without melting or warping. The precise control over the laser beam allows for detailed cuts in various plastic types.

Composites

- Minimum Thickness: Around 1 mm

- Maximum Thickness: Up to 20 mm for some composite materials

- Notes: Composite materials can vary widely in composition and thickness. Fiber lasers offer a flexible solution, adapting to the unique characteristics of each material for optimal cutting quality.

What is The Minimum Cutting Thickness Achievable with Fiber Lasers?

Fiber lasers can efficiently cut extremely thin materials, such as metal sheets and films that are less than 1mm thick. These include stainless steel, aluminum plate, and copper plate, achieving minimal kerf (the width of the cut). This precision makes fiber lasers ideal for industries requiring intricate designs, such as electronics and medical devices. Additionally, the efficiency of fiber lasers in handling thin materials reduces production costs and improves output quality.

What is The Maximum Cutting Thickness Achievable with Fiber Lasers?

For a 40000W fiber laser cutting machine, the maximum cutting thickness for various materials is as follows:

- Carbon steel: up to 6mm

- Stainless steel: up to 3mm

- Aluminum plate: up to 2mm

- Copper plate: up to 2mm

These specifications enable fiber lasers to manage a broad range of cutting tasks, with specific performance depending on the material and thickness.

Applicationtions of 3KW Fiber Laser

A 3kW fiber laser is a versatile tool used in various industrial and manufacturing applications due to its high precision, efficiency, and ability to cut a wide range of materials. Here are some common applications:

Sheet Metal Cutting: Ideal for cutting thin to medium-thickness sheets of metal, including steel, stainless steel, aluminum, and brass. It provides high-speed and accurate cuts with minimal distortion.

Tube and Pipe Cutting: Suitable for cutting various diameters of tubes and pipes. It’s used in industries like automotive, aerospace, and construction for creating precise cuts and intricate shapes.

Structural Steel Processing: Used for cutting structural steel beams and sections in construction and infrastructure projects. It can handle complex profiles and precise dimensions.

Signage and Graphics: Excellent for cutting and engraving materials used in signage, including acrylic, aluminum, and other non-metal materials.

Prototyping and Custom Parts: Commonly used in prototyping and manufacturing custom parts for industries such as aerospace, automotive, and electronics. It allows for quick adjustments and precise manufacturing of intricate designs.

Sheet Metal Fabrication: Used in various fabrications, including HVAC components, brackets, enclosures, and panels, due to its precision and ability to handle complex geometries.

Jewelry and Decorative Items: Useful for cutting and engraving delicate and detailed designs on metals used in jewelry and decorative items.

Medical Device Manufacturing: Employed in cutting and shaping components for medical devices, requiring high precision and cleanliness.

Automotive Parts: Used in the automotive industry for cutting and shaping parts, including components for engines, chassis, and body panels.

Aerospace Components: Suitable for cutting high-strength materials used in aerospace components, offering the precision required for high-performance applications.

The 3kW fiber laser offers a good balance between power and versatility, making it a popular choice for a wide range of applications across different industries.

Optimizing Cutting Performance with a 3kW Fiber Laser

Tips for Achieving the Best Cutting Quality

To achieve the best cutting quality, optimize the cutting speed and power settings based on the material and thickness. Adjust the cutting speed to match the material type and thickness—higher speeds are suitable for thinner materials, while slower speeds are better for thicker materials.

Similarly, set the laser power to be sufficient for the material thickness; insufficient power can lead to incomplete cuts, while excessive power may cause burn marks or distortion.

Use the appropriate assist gas, such as oxygen for steel or nitrogen for non-ferrous metals, to enhance cutting efficiency and edge quality. Maintain a clean lens by inspecting and cleaning it regularly to prevent interference with the laser beam, ensuring consistent cut quality.

Importance of Proper Machine Maintenance

Proper machine maintenance is vital for preventing unexpected downtime and costly repairs, which helps maintain continuous operation and productivity. Routine checks and maintenance extend the life of your fiber laser machine, protecting your investment and ensuring long-term performance. Regular upkeep also ensures that all components, including mirrors, lenses, and mechanical parts, are functioning correctly, which is essential for maintaining cutting accuracy and quality.

Additionally, addressing potential issues through regular maintenance improves safety by identifying and resolving problems before they escalate.

Adjusting Settings for Different Materials and Thicknesses

Adjust cutting settings based on the material type and thickness for optimal results. For steel, configure higher power and speed settings for thicker sheets, and use oxygen as the assist gas for faster cutting. When working with aluminum, use nitrogen as the assist gas and adjust settings to prevent oxidation and ensure clean cuts.

For stainless steel, similar to steel, use oxygen but be mindful of potential oxidation. For thin materials, higher cutting speeds and lower power settings are generally effective, while thicker materials require slower speeds and higher power settings. Ensure the material surface is clean, as contaminants can affect cut quality.

Conclusion

Now, I think you have got basic understanding of how thick can a 3kw laser cut. A 3kW fiber laser is a versatile tool capable of cutting a range of materials with varying thicknesses. Typically, a 3kW laser can efficiently cut up to 20mm (0.79 inches) of mild steel, around 15mm (0.59 inches) of stainless steel, and approximately 12mm (0.47 inches) of aluminum. These capabilities make it suitable for medium to heavy-duty applications in industries such as automotive, aerospace, and manufacturing.

When selecting a laser cutting system, it's essential to consider not only the cutting capacity but also the brand and its features. KRRASS, known for its high-performance laser cutting machines, offers advanced technology and support that can optimize your cutting processes. Their 3kW laser models are designed to deliver precise cuts across various materials and thicknesses, providing both efficiency and quality.

Investing in a KRRASS 3kW laser ensures you are equipped with a reliable tool that meets your cutting needs and enhances your operational capabilities. For businesses seeking to maximize their cutting performance, considering KRRASS as a choice provides not just a machine but a comprehensive solution that aligns with industry standards and requirements.