When it comes to industrial cutting applications, the power and efficiency of fiber lasers are unparalleled. A common question among manufacturers and engineers is, "how thick can 6000W fiber laser cut?" This powerful piece of technology has revolutionized the manufacturing industry, enabling precise and swift cutting through various materials. The maximum cutting thickness of different materials for 6kw fiber laser cutting machine : carbon steel maximum thickness 25mm; stainless steel maximum thickness 25mm; aluminum material maximum thickness 25mm; yellow copper maximum thickness 12mm. In this article, we'll delve into the capabilities of a 6000W fiber laser, exploring the strong capability it can handle across different materials, and the factors that influence its cutting performance, etc.

What Are the Types of Laser Cutting

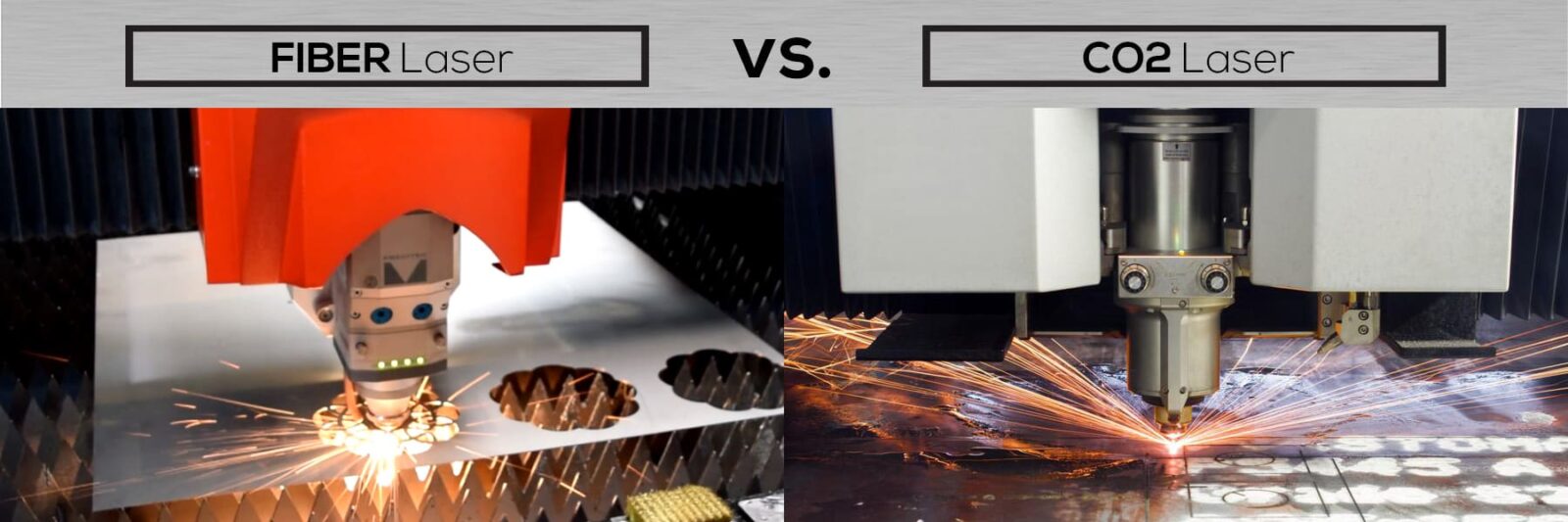

CO2 Lasers

A CO2 laser generates a light beam by running electricity through a gas-filled tube. This tube contains a mixture of gases, typically including carbon dioxide, nitrogen, hydrogen, and helium. The ends of the tube have mirrors, one fully reflective and the other partially reflective, allowing some light to pass through. CO2 lasers produce invisible light in the far infrared range of the spectrum, with typical industrial machines ranging from 25 to 100 watts and a wavelength of 10.6 micrometers.

CO2 lasers are highly effective for cutting non-metallic materials such as wood, paper, acrylic plastics, leather, and fabrics. They can also process certain foods, including cheese and chestnuts. While CO2 lasers can cut thin sheets of aluminum and other non-ferrous metals, their primary applications remain in non-metallic domains. Enhancing the CO2 beam’s power by increasing the oxygen content can improve cutting capabilities, but this approach requires caution and expertise.

Fiber Lasers

Fiber lasers are part of the solid-state laser family and utilize a seed laser, with amplification occurring through specially designed glass fibers energized by pump diodes. These lasers operate at a wavelength of 1.064 micrometers and are known for their extremely small focal diameters. Although they are typically the most expensive type of laser cutting machines, fiber lasers offer several advantages, including maintenance-free operation and a long service life of at least 25,000 laser hours.

Fiber lasers can achieve intensities 100 times greater than CO2 lasers with the same power output. They offer various beam settings, including continuous, quasi-, and pulsed, making them highly versatile. One notable subtype, the MOPA fiber laser, allows adjustable pulse durations for increased flexibility in applications. Fiber lasers excel at metal marking, engraving, and cutting, and can handle a wide range of materials, including metals, alloys, glass, wood, and plastics. They are particularly effective for cutting thin materials, although high-powered machines (over 6 kW) can cut materials exceeding 20 mm in thickness.

Nd:YAG/Nd:YVO Lasers

Crystal lasers, such as Nd (neodymium-doped yttrium aluminum garnet) and Nd (neodymium-doped yttrium ortho-vanadate), are known for their high cutting power. These lasers have a wavelength of 1.064 micrometers and are used in various fields, from medical and dental applications to military and manufacturing. Nd crystals offer higher pump absorption, broader bandwidth, and a broader wavelength range for pumping compared to Nd, although they have a shorter lifespan (8,000 to 15,000 hours) and higher costs.

These lasers can cut both coated and uncoated metals, non-metals, and some ceramics. Nd crystals are often combined with high NLO coefficient crystals (LBO, BBO, or KTP) to shift the output wavelength from near-infrared to green, blue, or even UV, enhancing their functionality. The ability to substitute yttrium, gadolinium, or lutetium ions with laser-active rare earth ions without significantly altering the lattice structure ensures high thermal conductivity and consistent performance.

Comparison Of Different Types Of Laser Cutting

1. CO2 Lasers

Benefits

- Can cut a wide range of thin materials

- Also useful for processing food like cheese and chestnuts

- Can cut through various thicknesses at the same (or lower) power

- Do not leave irregularities in material cuts

- Also suitable for boring and engraving

- Impressive energy efficiency

- High power output ratio

- Cost-effective

- Some CO2 lasers can deliver multiple kilowatts of power

- More oxygen can be added to the CO2 beam to strengthen it

Weakness

- Not suitable for cutting thick metal sheets

- Using it to cut metal might lead it to spark or catch fire

- Metal cutting jobs can damage the mirrors attached to the tube

- Typically limited to 25 to 100 watts of power

- Adding more oxygen to the CO2 beam can be risky

- This oxygen can potentially catch fire

2. Fiber Lasers

Benefits

- Capable of delivering consistently strong beams

- Can achieve extremely precise results compared to CO2 cutters

- Can cut more smoothly, quickly and flexibly than CO2 cutters

- Much more energy efficient than CO2 cutters

- Produce less waste than CO2 cutters

- Do not require any flow of gas

- Generally do not entail any maintenance

- Have a far longer service life than CO2 and crystal lasers

Weakness

- Usually the most expensive laser cutting machines

- Some fibre laser cutters can struggle to effectively cut materials thicker than 20mm

- Many fibre laser cutters come with various settings potentially confusing to people inexperienced at laser cutting

3. Direct Diode Lasers

Benefits

- Uses familiar (and so tried-and-trusted) laser cutting technology

- Already mainly used for cutting metal

- Some direct diode lasers can tap into multiple kilowatts of power

- Small size

- Long service life

- Acclaimed for their “high wall-plug efficiency”

Weakness

- Produce poorer laser beams in comparison to fibre lasers

- Are usually not as powerful as other models of laser cutting machine

- Typically only deliver about 10 watts of power

| Type of Laser | Key Features | Benefits | Weaknesses |

| CO2 Lasers | Uses carbon dioxide gas | Cost-effective, good for thin materials | Limited effectiveness on metals |

| Fiber Lasers | Uses optical fibers | High precision, efficient, low maintenance | Expensive initial cost, reflective metals can be challenging |

| Crystal Lasers | Uses crystals like Nd | High power, suitable for thick materials | High maintenance costs, shorter lifespan |

| Direct Diode Lasers | Uses diodes directly for lasing medium | Compact, energy-efficient, long lifespan | Limited power, not ideal for all materials |

Advantages Of Fiber Laser For Cutting

Before we delve further into the cutting capabilities of fiber laser cutting machines, let’s first take a look at the unique advantages of fiber lasers, which include the following seven points:

1. Highly Efficient Gain Medium

Fiber lasers distinguish themselves by using optical fibers doped with rare earth metal ions like ytterbium (Yb3+), neodymium (Nd3+), thulium (Tm3+), praseodymium (Pr3+), or erbium (Er3+). These ions absorb most of the pump light and emit photons at characteristic frequencies through stimulated emission. The flexible structure of fibers allows for much longer gain distances compared to other laser types, resulting in a high optical gain.

2. Smart Feedback Loop through Fiber Bragg Gratings

Instead of traditional dielectric mirrors, fiber lasers utilize fiber Bragg gratings for optical feedback. These gratings are made from glass fibers with varying refractive indices, arranged periodically to reflect the laser beam at specific wavelengths, forming the optical cavity. This means the optical cavity is integrated within the gain medium, enhancing efficiency and precision.

3. Robust Optical Cavity

Fiber lasers should not be confused with fiber-coupled diode lasers. In fiber-coupled diode lasers, optical fibers are used only for beam delivery, not for stimulated emission. Fiber lasers have an integrated optical cavity with the coiled fiber acting as the gain medium, providing a robust and stable optical cavity that enhances performance.

4. Compact Footprint

One of the significant advantages of fiber lasers is their compact design. Optical fibers are bendable and can be coiled into tight spaces, resulting in a much smaller footprint compared to other lasers with similar output powers. This flexibility allows for further customization of the optical path, making fiber lasers adaptable to various specific applications.

5. High Output Power

The thin and flexible nature of the gain medium in fiber lasers allows for several kilometers of optical fibers, achieving a high gain of the pumping light. The large surface area to volume ratio of optical fibers facilitates efficient heat dissipation, enabling fiber lasers to operate continuously at kilowatt levels without requiring complex cooling systems.

6. Excellent Beam Quality

Laser beam quality, often quantified by the M2 factor (with an ideal value of 1), measures how tightly the beam can be focused. Single-mode fibers in fiber lasers typically offer superior beam quality. This is advantageous in applications like laser cutting and welding, where high beam quality allows for a longer distance between the workpiece and the focusing object, protecting the optics from debris and fumes. The reduced beam diameter also enables finer structure manufacturing and the use of smaller, more cost-effective optical components.

7. High Reliability

Fiber lasers are highly reliable and nearly maintenance-free. The enclosed optical path within protective cladding layers makes the laser beam less susceptible to external disturbances. This results in excellent stability even in high-temperature and vibrational working conditions, making fiber lasers a dependable choice for industrial applications.

Introduction To IPG, Raycaus, Max Laser Source

IPG, MAX, and Raycus are all common-used brand names for laser sources, each with features that distinguish them from one another. A laser source is a critical element in a laser marking and cutting machine, and choosing the right one depends on properties such as cost, stability, and popularity. Here will explain the three laser sources and their differences so that you can select the right laser.

IPG laser sources are renowned for their high-quality engraving results, exceptional stability, and up to two years of warranty. These lasers are integral to laser markers used for marking jewelry and small electronic components. Machines equipped with IPG laser sources excel in carving materials that are challenging for other lasers. Additionally, they operate with a frequency range of 1 to 200kHz, ensuring versatility and precision in engraving.

Raycus laser sources, a Chinese brand, are popular in industries seeking affordable laser marking solutions. These Q-switch pulsed fiber lasers, while economical, deliver lower engraving quality and come with a shorter warranty compared to other laser sources. They operate within a frequency range of 20 to 80 kHz. Machines incorporating Raycus lasers are cost-effective due to their low price. Benefits of Raycus lasers include high electro-optic conversion efficiency, resistance to high temperatures, customizable output fiber lengths, and maintenance-free operation.

Max laser sources, a Chinese brand, are similarly affordable to Raycus lasers but offer better stability. Despite this, they share some of Raycus' drawbacks, such as sub-optimal engraving results and a low frequency range of 20 to 80 kHz. They are not ideal for high-quality plastic engraving and have shorter warranties. Advantages of Max laser sources include high reliability, good beam quality, a compact and sturdy design, a built-in cooling fan, and a dust-proof sealed unit, with a warranty of at least two years.

Below is a table showing the properties of each laser source.

| Laser source | IPG | MAX | JPT | Raycus |

| Cost | High | Low | Average | Low |

| Level of stability | Very high | Low | High | Low |

| Beam property | High | Good | Good | Fair |

| Engraving results | Excellent | Good | Good | Fair |

| Range of frequency | Very high | Low | High | Low |

| Metal materials | Great | Effective | Good | Effective |

| Plastic | Great | Poor | Effective | Poor |

| Warranty | Two years | One year | One year | One year |

Unlocking Cutting Capability of Fiber Lasers

Fiber lasers are among the latest advancements in laser technology that have a significant impact on the manufacturing industry. They are commonly used to engrave, mark, and perform various tasks. In this blog, we will discuss why having fiber lasers in the CNC machine shop will improve efficiency and will cover topics like speed and safety.

How Thick Can A Fiber Laser Cut

Fiber laser cutting machines have different cutting capabilities depending on their power, but almost all fiber laser machines can cut a sheet of metal that is up to 13mm thick. Higher powered fiber laser machines with 10kW of power can cut mild steel up to 2mm and stainless steel and aluminium up to 30mm.

| Material | Maximum Thickness (mm) |

| Carbon Steel | Up to 25 mm |

| Stainless Steel | Up to 20 mm |

| Aluminum | Up to 15 mm |

| Copper | Up to 10 mm |

| Brass | Up to 10 mm |

| Titanium | Up to 10 mm |

How Fast Can A Fiber Laser Cut

Fiber laser cutting speeds can vary depending on the power of the laser and the material being cut:

Power

A high-powered fiber laser cutter can be up to five times faster than a conventional CO2 laser. For example, an Accurl 10Kw Fiber Laser cutting machine can reach speeds of up to 180 m/min, while an Accurl 2Kw Fiber Laser cutting machine can reach speeds of up to 100 m/min.

Material

High-powered fiber lasers are most effective for cutting mid-range materials, such as 1/8" to ½" aluminum or mild steel, using air or nitrogen. For example, a 10kW fiber laser can cut 233% faster than a 4kW fiber laser when cutting a single 3/16" aluminum part. For steel, you'll need a minimum of 1.5 kW for material 1/4 inch thick or less, 2 kW for material 3/8 inch thick or less, and 3 kW for material ½ inch thick or less. For steel up to 1 inch thick, you can consider a laser cutter with 6 kW.

Cutting speed is measured in meters or feet per minute and is important for maintaining equipment longevity. A well-paced laser can reduce wear and tear on tools and parts, and can even cut down on power consumption. However, higher cutting speeds can also lead to cuts that are too shallow, as well as smoke and charred edges

| Material | Thickness (mm) | Cutting Speed (m/min) |

| Carbon Steel | 1 mm | Up to 25 |

| 5 mm | Up to 5 | |

| 10 mm | Up to 2 | |

| Stainless Steel | 1 mm | Up to 20 |

| 5 mm | Up to 3 | |

| 10 mm | Up to 1 | |

| Aluminum | 1 mm | Up to 18 |

| 5 mm | Up to 2 | |

| 10 mm | Up to 0.8 | |

| Copper | 1 mm | Up to 15 |

| 5 mm | Up to 1.5 | |

| 10 mm | Up to 0.5 | |

| Brass | 1 mm | Up to 12 |

| 5 mm | Up to 1 | |

| 10 mm | Up to 0.4 | |

| Titanium | 1 mm | Up to 15 |

| 5 mm | Up to 2 | |

| 10 mm | Up to 0.6 |

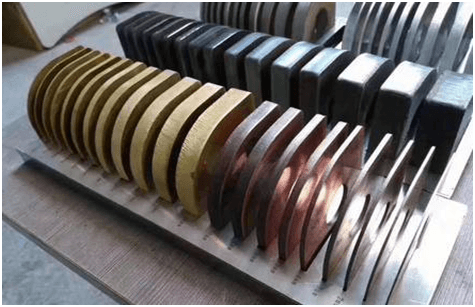

What Material Can A Fiber Laser Cut

A fiber laser cutting machine is highly effective for cutting various sheet metals such as carbon steel, stainless steel, copper, brass, aluminum, and titanium. Unlike CO2 lasers, fiber lasers excel at cutting reflective materials. Despite using some visible light, modern fiber lasers efficiently cut through brass, aluminum, and copper. This technology is vital in manufacturing, construction, and infrastructure, and is also gaining popularity in creative fields like metal art and sculpture, making metalworking much easier.

- Metals (e.g., steel, stainless steel, aluminum, copper, brass, titanium)

- Plastics (e.g., acrylic, polycarbonate, PVC, polyethylene)

- Wood (e.g., plywood, MDF)

- Ceramics

- Composites (e.g., carbon fiber, fiberglass)

- Fabrics and textiles

- Thin films and foils (e.g., aluminum, copper)

Applications of Fiber Laser Cutter

- Automotive Industry: Used for processing car parts such as doors, brakes, and exhaust pipes.

- Kitchenware Industry: Essential for crafting appliances from thin stainless steel sheets.

- Home Appliance Manufacturing: Enhances the quality and appearance of household appliances.

- Fitness Machine Manufacturing: Used in the production of gym equipment.

- Lighting Manufacturing: Shapes pipes for outdoor lamps.

- Decor & Metal Art Manufacturing: Creates custom designs and patterns in metal sheets for decorative purposes.

Uncovering the Capabilities of 6000W Fiber Laser Cutter

The advent of fiber laser technology has revolutionized the field of industrial cutting, offering unprecedented precision, speed, and versatility. Among the array of fiber laser systems available, the 6000W fiber laser cutter stands out as a powerhouse capable of tackling a wide range of materials with exceptional efficiency and accuracy.

How Thick Can 6000W Fiber Laser Cut

The maximum cutting thickness of different kinds of metals for a 6kw fiber laser cutter: 25mm carbon steel, 20mm stainless steel, 16mm aluminum, and 12mm brass.

Here is the detailed cutting parameters of 6000W fiber lasers.

Cutting parameters

| Thickness(mm) | Speed(m/min) | Focus position | Cutting height(mm) | Gas | Nozzle type | Pressure(bar) | |

|---|---|---|---|---|---|---|---|

| Carbon steel (Q235B) | 1 | 25-32 | 0 | 1 | N2 | Single: 1.5 | 12 |

| 2 | 20-27 | -1 | 1 | Single: 2.0 | 12 | ||

| 3 | 12-15 | -1.5 | 0.5 | Single: 2.0 | 14 | ||

| 4 | 7-8.5 | -2 | 0.5 | Single: 2.0 | 14 | ||

| 5 | 5.7-6.8 | -2.5 | 0.5 | Single: 3.0 | 16 | ||

| 3 | 3.6-4.2 | +5 | 0.8 | O2 | Double: 1.2 | 0.6 | |

| 4 | 3.3-3.8 | +5 | 0.8 | Double: 1.2 | 0.6 | ||

| 5 | 3-3.6 | +5 | 0.8 | Double: 1.2 | 0.6 | ||

| 6 | 2.7-3.2 | +5 | 0.8 | Double: 1.2 | 0.6 | ||

| 8 | 2.2-2.5 | +6 | 0.8 | Double: 1.2 | 0.6 | ||

| 10 | 2.0-2.3 | +7.5 | 0.8 | Double: 1.2 | 0.6 | ||

| 12 | 1.9-2.1 | +7.5 | 0.8 | Double: 1.2 | 0.6 | ||

| 14 | 1.4-1.7 | +9 | 1 | Double: 1.4 | 0.6 | ||

| 16 | 1.2-1.4 | +9 | 1 | Double: 1.4 | 0.6 | ||

| 18 | 0.7-0.8 | +12 | 0.3 | Single: 1.4 | 0.8 | ||

| 20 | 0.5-0.6 | +4 | 0.8 | Double: 5.0 | 0.6 | ||

| 20 | 0.6-0.7 | +13 | 0.3 | Single: 1.4 | 0.8 | ||

| 22 | 0.45-0.5 | +4 | 0.8 | Double: 5.0 | 0.6 | ||

| 22 | 0.5-0.6 | +13 | 0.3 | Single: 1.5 | 1 | ||

| 25 | 0.4-0.5 | +14 | 0.3 | Single: 1.5 | 1 | ||

| Stainless steel (SUS304) | 1 | 35-45 | 0 | 0.8 | N2 | Single: 1.5 | 10 |

| 2 | 23-32 | -1 | 0.5 | Single: 2.0 | 12 | ||

| 3 | 15-18 | -1.5 | 0.5 | Single: 2.5 | 12 | ||

| 4 | 9-13 | -2 | 0.5 | Single: 2.5 | 14 | ||

| 5 | 7-8.5 | -2.5 | 0.5 | Single: 3.0 | 14 | ||

| 6 | 4-5.5 | -3 | 0.5 | Single: 3.0 | 15 | ||

| 8 | 3-3.8 | -4 | 0.5 | Single: 3.0 | 15 | ||

| 10 | 1.8-2.1 | -6 | 0.5 | Single: 4.0 | 15 | ||

| 12 | 1-1.3 | -7.5 | 0.5 | Single: 5.0 | 16 | ||

| 14 | 0.85-1.1 | -9 | 0.5 | Single: 5.0 | 16 | ||

| 16 | 0.6 | -10.5 | 0.3 | Single: 5.0 | 18 | ||

| 18 | 0.5 | -12 | 0.3 | Single: 5.0 | 20 | ||

| 20 | 0.3 | -14 | 0.3 | Single: 6.0 | 20 | ||

| Aluminum (6061) | 1 | 30-37 | 0 | 1 | N2 | Single: 1.5 | 12 |

| 2 | 22-27 | -1 | 0.5 | Single: 2.0 | 12 | ||

| 3 | 13-18 | -1.5 | 0.5 | Single: 2.5 | 14 | ||

| 4 | 9-11 | -2 | 0.5 | Single: 2.5 | 14 | ||

| 5 | 5-6.5 | -3 | 0.5 | Single: 3.0 | 14 | ||

| 6 | 3.6-4.2 | -3 | 0.5 | Single: 3.0 | 16 | ||

| 8 | 1.8-2.1 | -4 | 0.5 | Single: 3.0 | 16 | ||

| 10 | 1-1.3 | -4.5 | 0.5 | Single: 3.5 | 18 | ||

| 12 | 0.7-1 | -5 | 0.5 | Single: 4.0 | 18 | ||

| 14 | 0.5 | -5 | 0.3 | Single: 4.0 | 18 | ||

| 16 | 0.4 | -8 | 0.3 | Single: 6.0 | 20 | ||

| Brass | 1 | 25-32 | 0 | 1 | N2 | Single: 1.5 | 12 |

| 2 | 17-21 | -1 | 0.5 | Single: 2.0 | 12 | ||

| 3 | 12-15 | -1 | 0.5 | Single: 2.5 | 14 | ||

| 4 | 8-9.3 | -1.5 | 0.5 | Single: 3.0 | 14 | ||

| 5 | 4.5-5.5 | -2 | 0.5 | Single: 3.0 | 14 | ||

| 6 | 3.2-4 | -3.5 | 0.5 | Single: 3.0 | 16 | ||

| 8 | 1.5-2 | -5 | 0.5 | Single: 3.5 | 16 | ||

| 10 | 1 | -6 | 0.5 | Single: 3.5 | 16 | ||

| 12 | 0.7 | -8 | 0.3 | Single: 4.0 | 18 | ||

| Copper | 1 | 20-27 | -0.5 | 1 | O2 | 2.0S | 8 |

| 2 | 10-13 | -1 | 0.5 | 2.0S | 8 | ||

| 3 | 7-9 | -2 | 0.5 | 2.0S | 8 | ||

| 4 | 4-5.2 | -2 | 0.5 | 2.0S | 8 | ||

| 5 | 3 | -3 | 0.5 | 2.5S | 8 | ||

| 6 | 2 | -4 | 0.5 | 2.5S | 8 |

Remark:

- In the cutting data, the core diameter of the 6000W laser output fiber is 50 microns;

- The cutting data adopts Jiaqiang cutting head with an optical ratio of 100/125 (collimation/focus lens focal length);

- Cutting auxiliary gas: liquid oxygen (purity 99.99%) liquid nitrogen (purity 99.999%);

- The air pressure in this cutting data specifically refers to the monitoring air pressure at the cutting head;

- Due to differences in the equipment configuration and cutting process (machine tool, water cooling, environment, cutting nozzle, gas pressure, etc.) used by different customers, this data is for reference only.

Key Factors For Influencing Laser Cutting Quality

1. Laser Output Power and Beam Mode

The laser's power output and beam mode significantly impact cutting quality. Higher power is often necessary for thicker materials, but beam mode distribution across the cross-section is equally vital. Optimal focus ensures higher power density, leading to superior cutting quality. However, maintaining consistent beam modes throughout the laser's lifespan requires attention to factors like optical element conditions and laser working gas mixture.

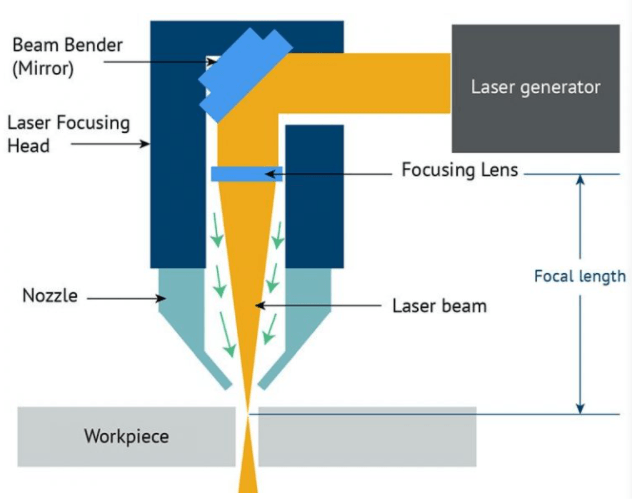

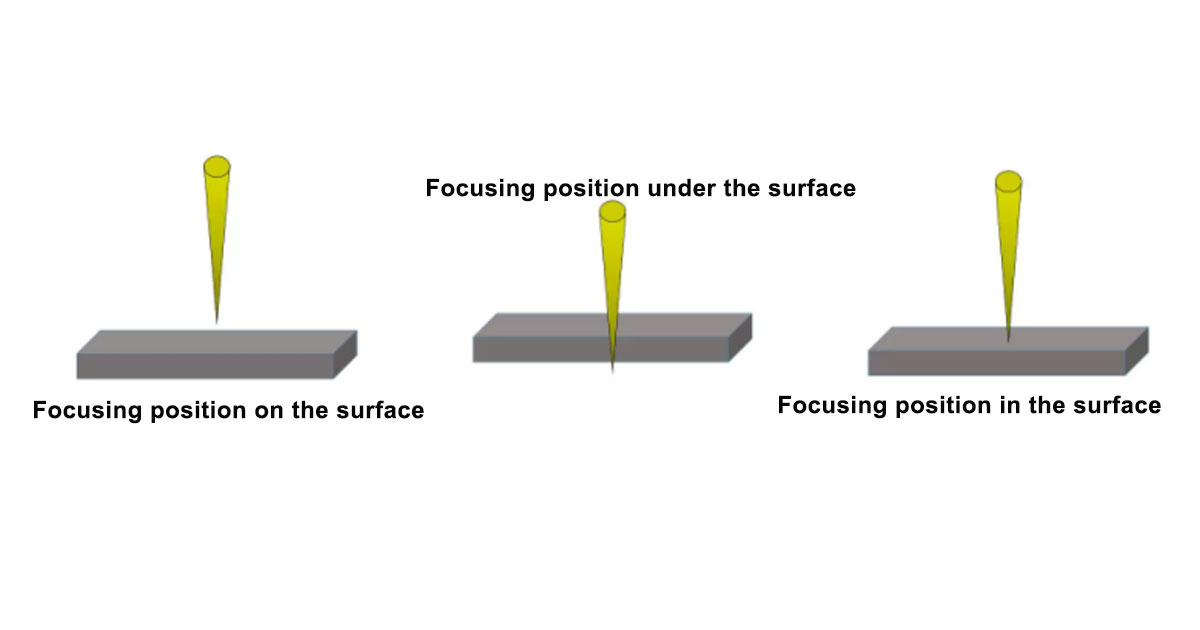

2. Focus Position Adjustment

Precise adjustment of the focus position relative to the workpiece surface is essential for achieving desired cutting quality. Maintaining a constant relative position ensures stable cutting performance. The ideal focus position results in smaller slits, higher efficiency, and improved cutting speed. Adjustments typically place the focus just under the nozzle, with the distance between the nozzle and workpiece surface typically around 1.5mm. Choosing the appropriate focal length lens is critical; shorter focal lengths are suitable for high-speed cutting of thin materials, while longer focal lengths are better for cutting thick workpieces.

3. Cutting Speed

Cutting speed directly correlates with laser power density. Increasing power density enhances cutting speed, although speed is inversely proportional to material density and thickness. Factors influencing cutting speed include power level, beam mode, focus spot size, material properties, and material thickness. Enhancing cutting speed requires increasing power within a certain range, optimizing beam mode, reducing focus spot size, and selecting materials with low density and initial evaporation energy.

4. Auxiliary Gas Pressure

Auxiliary gas pressure plays a vital role in laser cutting, particularly for protecting optics, removing debris, and enhancing cutting efficiency. The choice of gas (such as compressed air, inert gas, or active gas) depends on the material being cut. Active gases like oxygen facilitate oxidation reactions, increasing cutting speed. Higher gas pressure is necessary for preventing slag sticking during high-speed cutting of thin materials, while lower pressures are preferable for reducing plastic cutting edge frosting.

How To Find A Balance Between Power and Speed

Striking the perfect balance between speed and power can be a meticulous process. Even slight adjustments can dramatically impact the cut quality.Finding the best match requires careful test cuts, experimentation, and a keen eye for detail. It’s a continuous learning curve, as different materials and intricate geometries often demand unique settings.

1. Understand the Material

Different materials react differently to laser cutting. Factors such as thickness, density, and composition affect how power and speed should be adjusted.

- Thin materials generally require lower power and higher speed.

- Thick materials usually need higher power and slower speed.

2. Define Your Cutting Objectives

Identify what you aim to achieve with your cut:

- Precision: High power at a slow speed can provide a precise cut.

- Efficiency: Lower power at higher speed can be efficient for less intricate designs.

3. Experiment with Settings

Perform test cuts to find the optimal settings:

- Start with Manufacturer Recommendations: Begin with the settings suggested by the laser cutter’s manufacturer for the specific material.

- Adjust Incrementally: Make small adjustments to either power or speed, and observe the effects on the cut quality.

- Increasing Power: Results in deeper cuts but can cause burning or charring.

- Increasing Speed: Reduces cutting time but can lead to incomplete cuts.

4. Monitor the Quality of the Cut

Assess the results based on:

- Edge Quality: Look for clean, smooth edges without burns or melt.

- Depth of Cut: Ensure the laser cuts through the material completely.

- Kerf Width: Measure the width of the cut to ensure it meets your design specifications.

5. Utilize Software Tools

Modern laser cutters come with software that can help in adjusting settings:

- Automatic Optimization: Some software can automatically suggest optimal power and speed settings based on the material and desired outcome.

- Profiles and Presets: Save successful settings as profiles for future use.

6. Balance Power and Speed

Here are some general guidelines:

- For Thin Materials: Lower power (20-50%) and higher speed (70-100%).

- For Thick Materials: Higher power (60-100%) and lower speed (10-40%).

Example Workflow

- Choose Material: 3mm acrylic.

- Manufacturer Settings: Start with recommended settings (e.g., 50% power, 50% speed).

- Test Cut: Perform a small cut and evaluate.

- Adjust: If the edges are too burnt, reduce power to 40% and increase speed to 60%. If the cut isn’t complete, increase power to 60% and reduce speed to 40%.

- Repeat: Continue testing and adjusting until the cut meets your quality standards.

How To Find Your Best Power Solution For Laser Cutting

After discussion, we can know that the higher the fiber laser power, the thicker the metal cutting thickness. The most common cut metals are carbon steel, stainless steel, brass, and aluminum. And the most used fiber laser cutting power is from 1kw to 6kw. But if you want, Krrass can also provide you with higher laser power than 6kw, such as 10kw, 12kw, and even 20kw.

Whether fiber laser cutting machine or any other application, our team of experts has the right combination of industry knowledge and the latest tool to provide you with the best products and services in the market.