1. Motion control card initialization failed' when open TubePro

- In windows'Device Manager' execute'Scan for hardware changes'. If found BMC1805 motion control card in Device Manager, re-start TubePro software.

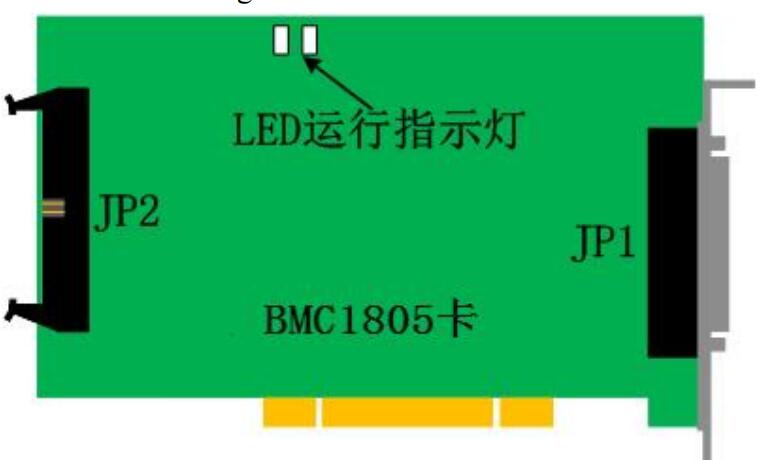

- Watch 2 LED lights flashing status (LED7 and LED8) on BMC1805 control card. The position of the LED lights shown below:

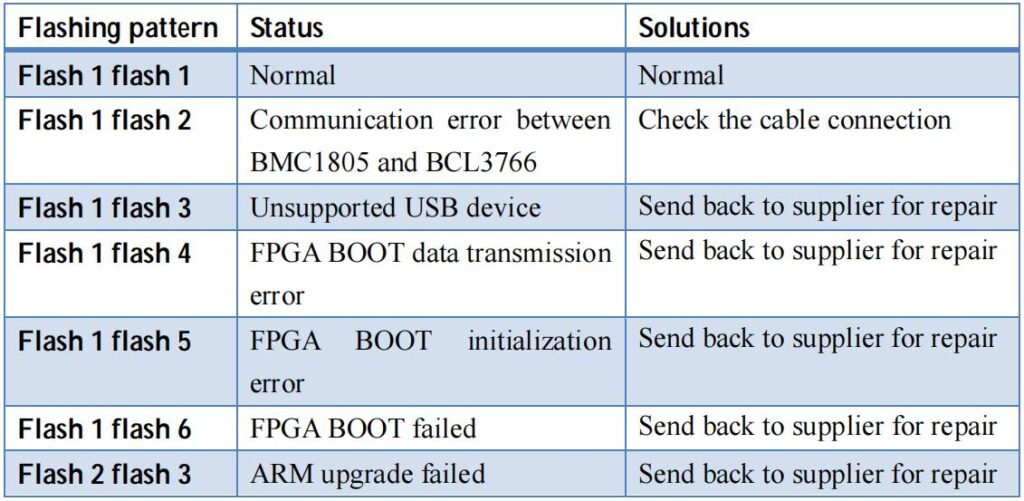

LED flashing patterns indicates the following status:

LED flashing patterns indicates the following status:

- If LED lights are in flash 1 flash 1 pattern it means BMC1805 card works normally. PCI socket might in bad contact. It recommended that cut off computer power and re-insert PCI card or replace PCI socket.

2. Pulse Equivalent

Pulse equivalent is moving distance of load or rotation degree of rotary axis corresponding to one pulse sent by CNC controller.

The maximum pulse frequency system supports is 3Mpps. If the highest running speed of the machine is 1000mm/s. Then the pulse equivalent of each axis should not exceed 3Mpps/1000 = 3000 Pulse/mm.

It suggested that set the pulse equivalent within 1mm corresponds 1000~2000 pulses. It better not set pulse equivalent under 200Pulse/mm.

Set similar pulse equivalent to X and Y axes to reduce the tr

3. Machining speed is too slow or not smooth with pauses

- Check if set improper delay or misread the unit, for example set 200s while it should be 200ms.

- If there are pauses in Z axis lifting motion, please check the BCS100 firmware version. If BCS100 is V2.0, please update to V1112 and above.

- If it takes a long interval after gassing finished then laser starts emitting, check the laser serial communication.

4. Corner Burning

- Rise the corner precision parameter to smooth the corner path.

- Edit power-speed curve, lower the power at low speed area.

- Add cooling point to the corner.

5. No laser emission

Check the laser configuration

- Check the laser configuration in config tool (IPG YLS series contain American version and Germany version).

- If using serial communication or network communication check if communication port set correctly.

- Check if using DA control laser peak power and if select correct DA port in config tool.

- Check if PWM and laser enable port are set correctly.

Check PWM and DA output

- In TubePro-Tool-Card monitor set DA and PWM output value. Measure the voltage value on DA and PWM port on BCL3766 board by multimeter.

- If PWM or DA port output voltage too low or even no output, change to the other PWM and DA port.

- You can contact our technicians for hardware malfunctions.

Check the wiring

- Check the wiring of PWM, DA, serial cable and laser control cables.

- Serial port cable must have shielded layer.Pin2 and pin3 must be crossed.

Check laser unit

- Examine the laser emitting by laser software check if laser works properly.

- When use serial communication, not allowed to open more than one laser software to communicate with laser unit.

- If serial communication failed, enable debug mode in config tool check the command and feedback message from laser in log window of TubePro main program.

Learn more about our products, please visit and subscribe to our Youtube channel

LED flashing patterns indicates the following status:

LED flashing patterns indicates the following status: