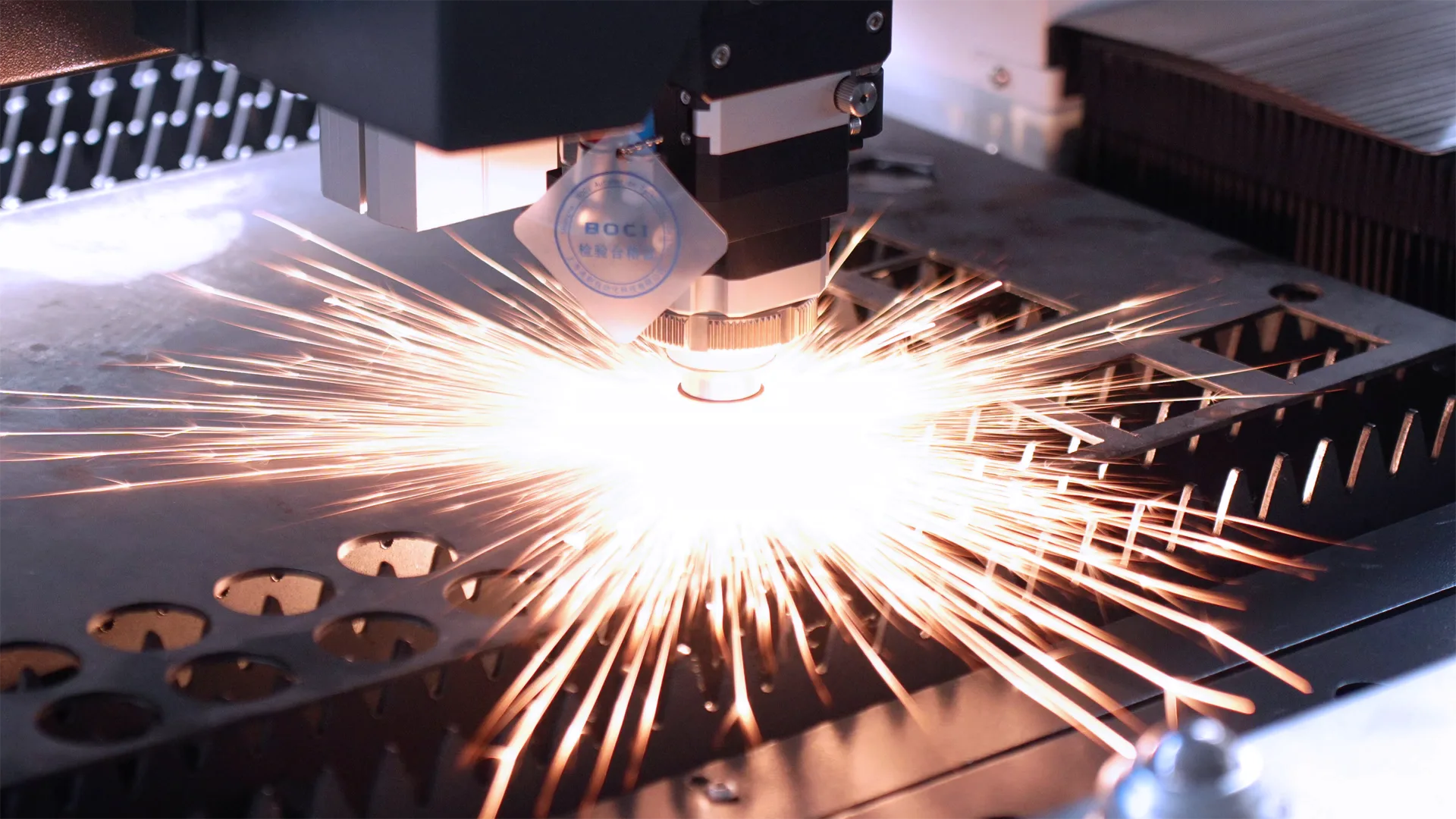

The Fiber Laser source the core power component of the sheet cutting equipment. Its function is to generate and output laser beams with specific wavelengths, powers and modes. Through the focusing system, the laser energy is concentrated on the surface of the sheet, and the high energy density of the laser is utilized to melt, vaporize or decompose the metal or non-metal sheets, thereby completing the cutting operation. In simple terms, it is the “energy source” of the entire cutting equipment, directly determining the core performance such as the efficiency, accuracy and material adaptability of the cutting.

Table of Contents

I. Basic Components of Fiber Laser source

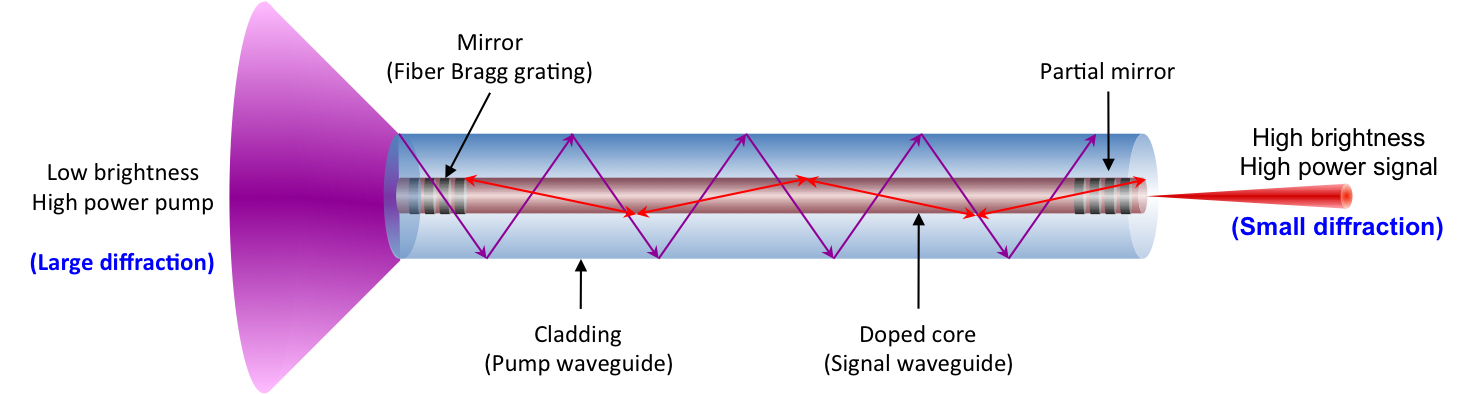

- Working substance: This is the core material for generating laser. It can be classified into several types such as solids (e.g. ruby, neodymium glass, YAG crystal), liquids (e.g. dye solutions), gases (e.g. helium-neon mixture, carbon dioxide gas), and semiconductors (e.g. gallium arsenide). The working substance needs to achieve particle number inversion, that is, the number of high-energy level particles should be greater than that of low-energy level particles, providing the basis for stimulated emission.

- Excitation source: It is used to provide energy to the working substance to achieve particle number inversion. Different working substances require different excitation methods. For example, solid working substances are usually excited by flash lamps or semiconductor lasers, gas working substances mostly use electrical excitation, and semiconductor working substances are excited by current injection.

- Resonant cavity: It consists of two mirrors placed opposite to each other (one is a total reflection mirror, and the other is a partial reflection mirror). Its function is to make the stimulated emission light generated in the working substance reflect back and forth in the cavity, continuously being amplified, and finally forming a laser with sufficient intensity, good directionality and coherence, and then output through the partial reflection mirror.

II. Working Principle of Fiber Laser Source

- Pumping: The excitation source supplies energy to the working substance, causing the atoms, molecules or ions in the working substance to absorb energy and transition from the ground state to a higher energy level, achieving particle number inversion.

- Stimulated emission: At the high energy levels, the particles are unstable and will spontaneously transition to the lower energy levels and release photons. When these photons pass through the working substance in a particle number inversion state, they will trigger stimulated emission from higher energy particles, releasing photons with the same frequency, phase and direction as the incident photons, doubling the photon quantity and forming a strong laser.

- Resonant amplification: The photons generated by stimulated emission are constantly reflected in the resonant cavity. Each reflection passes through the working substance, promoting the generation of stimulated emission from more particles, resulting in a rapid increase in the photon quantity and forming a strong laser.

- Laser output: When the laser intensity reaches a certain level, some of the laser passes through the partial reflecting mirrors of the resonant cavity and is emitted to form a laser beam.

III. Classification of Fiber Laser source

- Solid Fiber Laser Source: Utilizing solid materials as the working substance, such as Ruby Fiber Laser Source, Neodymium Glass Fiber Laser Source, YAG Fiber Laser Source, etc. These emitters feature small size, high power, and pulsed output, and are commonly used in industrial processing (such as cutting, welding), medical surgeries, etc.

- Gas Fiber Laser Source: The working substance is gas. Common examples include Helium-Neon Fiber Laser Source, Carbon Dioxide Fiber Laser Source, Argon Ion Fiber Laser Source, etc. The Helium-Neon Fiber Laser Source emits red light and has good directionality, and is often used for alignment, measurement; the Carbon Dioxide Fiber Laser Source emits infrared light, has high power, and is widely used in material processing, laser marking, etc.

- Liquid Fiber Laser Source: Using liquid as the working substance, mainly including Dye Fiber Laser Source. Its wavelength can be tuned within a certain range, and is suitable for spectroscopy analysis, medical diagnosis, etc.

- Semiconductor Fiber Laser Source: The working substance is semiconductor materials, featuring small size, light weight, high efficiency, and long lifespan, and is widely used in optical fiber communication, optical disc storage, laser indicators, etc.

- Low-power Fiber Laser Source: The output power is usually in the milliwatt range, such as Fiber Laser Source in laser pens and CD players, mainly used for indication, information reading, etc.

- Medium-power Fiber Laser Source: Power ranges from watt level to several tens of watts, suitable for laser welding, laser engraving, etc.

- High-power Fiber Laser Source: Power can reach several hundred watts or even higher, mostly used in industrial cutting, laser weapon research, etc.

- Continuous Fiber Laser Source: Capable of continuously outputting laser, such as Helium-Neon Fiber Laser Source, Continuous Wave Carbon Dioxide Fiber Laser Source, suitable for occasions requiring a stable laser source, such as laser communication, precise measurement.

- Pulsed Fiber Laser Source: Outputs laser in a pulsed form, with extremely high peak power, such as Ruby Fiber Laser Source, Q-switched Fiber Laser Source, often used for laser ranging, material impact treatment, etc.

IV.Four. What is the price range of the Fiber Laser Source?

The price of a fiber laser source varies significantly depending on factors such as the type of laser, power, brand, and technical parameters. The approximate price ranges for different types of laser emitters are as follows:

Fiber laser souce: For medium and low power (500W – 3000W) domestic fiber laser transmitters, the price is generally between 30,000 yuan and 200,000 yuan. For example, some medium and low power laser transmitters from Chuangxin Laser may have a price range of 50,000 yuan to 150,000 yuan. High power (such as 10,000W and above) fiber laser transmitters have higher prices, with domestic ones possibly costing over 500,000 yuan, and imported brands may have even higher prices, such as IPG, whose high-power fiber laser transmitters may cost over 1 million yuan.

CO₂ laser souce: For low power (such as 30W – 100W) CO₂ laser transmitters, the price is usually between 6,000 yuan and 30,000 yuan. For example, the 30W CO₂ laser generator from CRD LASER costs 6,000 yuan – 31,200 yuan. For medium and high power (such as 200W – 1000W) CO₂ laser transmitters, the price may be between 30,000 yuan and 100,000 yuan or more. Imported high-power CO₂ laser transmitters are even more expensive.

Ultraviolet laser transmitter: Due to the high technical threshold, ultraviolet laser transmitters are relatively expensive. Low power (such as 500mW – 1W) ultraviolet laser transmitters may cost between 10,000 yuan and 50,000 yuan. For example, the 375nm 500mw ultraviolet fiber coupled laser from Blueyu Laser costs 14,000 yuan. Higher power or better-performing ultraviolet laser transmitters may cost over 100,000 yuan.

V. Application Areas of Fiber Laser Source

- Industrial field: Laser cutting (can cut various materials such as metals and non-metals, with high precision and fast speed), laser welding (welding quality is good, with small heat affected zone), laser marking (marking permanent identification on the product surface), laser heat treatment (changing the surface properties of the material, improving wear resistance, hardness, etc.).

- Medical field: Laser surgery (such as laser myopia correction surgery in ophthalmology, laser skin whitening and acne removal in dermatology), laser treatment (used for treating tumors, stones, etc. diseases), laser diagnosis (using laser spectroscopy analysis for disease detection).

- Communication field: Fiber optic communication uses laser as the carrier, with advantages such as large transmission capacity, long distance, strong anti-interference ability, and is an important means of modern communication.

- Research field: In atomic physics, quantum mechanics, and nuclear fusion research, Fiber Laser Source is used as an important experimental tool, which can be used to excite atoms, create high-temperature and high-pressure environments, etc.

- Military field: Laser distance meters (accurately measuring target distance), laser-guided weapons (improving weapon hit rate), laser weapons (using high-power laser to destroy targets) etc.

- Daily life: Fiber Laser Source is used in devices such as laser printers, barcode scanners, laser mice, laser indicators, etc. in daily life.

VI. Precautions for Using Fiber Laser Source

- Safety protection: Laser has potential harm to the eyes and skin. The degree of harm varies with different laser powers. When using, appropriate laser protective glasses should be worn to avoid direct exposure to the laser beam. At the same time, a safety warning area should be set up to prevent irrelevant personnel from coming into contact.

- Environmental requirements: Some Fiber Laser Sources have certain requirements for the temperature, humidity, and dust in the working environment. The environment must be kept clean and stable to ensure the normal operation of the equipment and extend its service life.

- Standard operation: Operators should undergo professional training and be familiar with the performance and operation procedures of the equipment. They should use it strictly in accordance with the operating procedures to avoid equipment damage or safety accidents due to improper operation.

VII. Which brands of Fiber Laser Sources are available for selection?

- Chuangxin Laser / MAX: Established in 2004, it is one of the first domestic manufacturers of fiber lasers and also one of the first national high-tech enterprises in China that has independently owned intellectual property rights in core technologies such as fiber lasers and optical components and has carried out vertical integration.

- Ruike Laser / Raycus: Wuhan Ruike Fiber Laser Technology Co., Ltd. is a national high-tech enterprise under the Torch Program, specializing in the research, development, production and sales of fiber lasers and their key components and materials. It has the vertical integration capability from materials, components to complete machines.

- IPG Apache: Founded in 1990, it is a research and development center and manufacturing company with international leading level for high-power fiber lasers. Its efficient fiber lasers, fiber amplifiers and Raman lasers have led the world in technology and are widely used in material processing, detection and measurement, scientific research and other fields.

- Trumpf / TRUMPF: Founded in 1923 in Germany, it is a world-leading high-tech company and a well-known large multinational enterprise group. It holds a leading position in the world’s machine tool manufacturing field and is also one of the well-known enterprises in the global manufacturing technology field.

- Coherent / COHERENT: Founded in 1971 in the United States, it is one of the global leaders in materials, networks and laser fields. It aims to produce materials and optical components for industrial fiber lasers and provide various products ranging from laser measurement and control products to precision optics and laser systems.

- Feibo Laser / FEIBO: Established in 2012, it specializes in the technical development, transfer, consultation and production and sales services of fiber lasers, optical components and laser detection equipment. It independently develops a number of high-end fiber laser products, covering medium and high-power continuous, large-energy pulsed, point-ring energy adjustable, MOPA pulse, green light, high-power narrow linewidth, linear polarization and other series of fiber lasers.

- Guangwei Laser / GW: Established in 2015, it is a global supplier of high-brightness fiber lasers and integrated solution for application tools. It is a leader in the 10-watt level fiber laser field and has released 2kW-4kW single-mode fiber lasers and 6kW-50kW multi-mode laser modules, with nearly 100 patents.

- JPT / JPT: Established in 2006, it is a national high-tech enterprise founded by returned overseas students, specializing in the research, production and sales of laser light sources, laser intelligent equipment and optical components. It is also the first commercial manufacturer of pulse-adjustable high-power fiber lasers in China.

- nLIGHT / nLIGHT: Founded in 2000 in the United States, it is a well-known fiber laser brand. It is committed to developing and promoting laser technology and its diode fiber lasers are well-known. It provides innovative laser solutions for customers.

VIII. What parameters should be considered when purchasing Fiber Laser Source?

1.When choosing a sheet cutting machine, several factors need to be considered comprehensively. Here are some key points:

Fiber laser: It has advantages such as high electro-optical conversion rate (above 30%) and simple maintenance, and is suitable for medium and thin sheet metal processing (0.5 – 20mm). It is currently the mainstream choice for metal sheet cutting.

CO2 laser: It performs better for non-metallic materials and metal cutting of 8mm and above, has strong thick plate cutting capabilities, but has relatively higher maintenance costs, and efficiency is lower than that of fiber lasers.

Low power (500W – 1000W): Suitable for cutting thin sheets of 1 – 3mm, such as stainless steel, carbon steel, etc., and is suitable for small batch production and occasions with high precision requirements.

Medium power (1000W – 3000W): Can be used for cutting medium-thick sheets of 3 – 10mm, meeting the production needs of medium scale, and achieving a good balance between cutting speed and quality.

High power (above 3000W): Mainly used for cutting thick sheets of 10mm and above, suitable for large-scale production and high-speed cutting, but the equipment cost and operating cost are also relatively higher.

Beam quality: Beam quality directly affects the cutting accuracy and the quality of the cutting surface. The M² factor is commonly used to measure it. The closer the M² value is to 1, the better the beam quality is, and the higher the focusing accuracy and energy concentration are. It is particularly important for precise cutting and thin sheet cutting.

Brand: Choose well-known brands of laser equipment, such as IPG, Ruike, Chuangxin, etc. These brands have more guaranteed quality control, technological research and development, and stability.

After-sales: Good after-sales service is an important guarantee for the normal operation of the equipment, including technical support, maintenance services, spare parts supply, etc. It is necessary to understand the after-sales capabilities and response speed of the supplier.

Cutting head compatibility: The cutting head is an important accessory of the laser equipment and should be selected to be compatible with the power and type of the laser. For example, high-power equipment can use cutting heads from brands like Prestat, which have better cutting effects; for medium-low power equipment, cost-effective cutting heads from brands like Wanshunxing can be chosen.

Safety performance: The emitter of the sheet cutting machine should have complete safety protection measures, such as laser protection covers, emergency stop buttons, safety interlock devices, etc., to ensure the safety of operators. At the same time, it is necessary to understand the safety level of the laser, and the safety level of general industrial sheet cutting machine emitters should be Class IV.

2.What are the differences in performance between imported brand and domestic panel cutting machine emitters?

The differences in performance between imported brand and domestic panel cutting machine emitters mainly lie in aspects such as technical accumulation, core indicators, stability, and adaptability to application scenarios. Specific analysis can be conducted from the following dimensions:

Fiber Lasers: Domestic fiber lasers (such as Ruike and Chuangxin) have achieved significant breakthroughs in the high-end market. By 2025, their market share will reach 55%, and they will introduce a 200kW ultra-high power model, with a cutting speed for 80mm thick steel plates leading globally. However, imported brands (such as IPG and Trumpf) still have technical advantages in the high-power field. For instance, IPG achieved 10kW single-mode output as early as 2009, while domestic watt-level lasers (such as Daokexin’s M² = 1.36) have only reached international standards in recent years.

Power Coverage and Beam Quality: Domestic medium and low-power (500W – 3000W) equipment has outstanding cost performance. While imported brands excel in ultra-high power (such as Trumpf’s 20kW) and precision micro-processing (such as semiconductor wafer inspection). For example, the 10kW laser developed by National University of Defense Technology has an M² of 1.92, approaching IPG’s level, but imported equipment has better power stability under complex conditions. Domestic lasers (such as Changfei Guangfang with M² = 1.2) have approached the international standard, but there is still a gap in mode stability at high power. For instance, Trumpf’s BrightLine technology can optimize the beam focusing accuracy during the cutting of highly reflective materials, while the M² consistency fluctuation of domestic equipment is relatively large during batch production.

Long-term operation performance and adaptability to extreme environments: The average mean time between failures (MTBF) of imported equipment is generally over 10,000 hours, while the failure rate of domestic equipment is slightly higher in complex environments (such as high temperature and high humidity). For example, the 24-hour power fluctuation of Xingyan Tong 35W green laser is less than 0.5%, but some domestic equipment still has power drift problems during continuous operation. Domestic equipment (such as Ruike IP66 protection level) can operate in harsh environments, but imported brands (such as Mazak) have more mature anti-vibration and anti-interference designs, especially suitable for high-demand scenarios such as aerospace.

Cutting efficiency and processing accuracy: The TruLaser series of TruLaser from KUKA can cut 20mm stainless steel plates at a speed of 0.8 minutes per meter, while domestic equipment (such as Daqin Laser G6020) has a speed about 15% lower at the same thickness. However, domestic equipment (such as Qingzhao Laser) has efficiency close to that of imported equipment in medium-thin plate cutting (such as 3-10mm carbon steel). Imported equipment (such as TruLaser) has a positioning accuracy of ±0.01mm in precision part cutting, while domestic equipment (such as Qingzhao Laser) has a cutting edge roughness Ra < 1.6μm in thin plate cutting, but the edge consistency of complex graphics processing still needs to be improved.

Operational economy and after-sales response: The maintenance cost of domestic equipment is low (no working gas, fiber transmission), with an annual maintenance cost of approximately 1/3 of that of imported equipment. For example, the cost of replacing optical lenses for domestic equipment is about 2,000 yuan per time, while that for imported equipment is more than 500 yuan. Domestic manufacturers can provide 24-hour on-site service, while imported brands need to allocate spare parts from overseas, and the repair cycle is usually extended by 3-5 days. However, the technical support of imported brands is more professional, especially in complex process debugging (such as optimizing cutting parameters for aerospace materials), where they have a significant advantage.

3.Match the thickness of your board according to the cutting power.

- 1500W Laser Souce Cutting parameters Max cuting 12mm

- 2000W Laser Souce Cutting parameters Max cuting 16mm

- 3000W Laser Souce Cutting parameters Max cuting 20mm

- 6000W Laser Souce Cutting parameters Max cuting 22mm

- 12000W Laser Souce Cutting parameters Max cuting 25mm

- 20000W Laser Souce Cutting parameters Max cuting 50mm

X. How to choose the suitable sheet cutting machine launcher for yourself?

Cutting thickness and speed: Power is the key indicator determining the cutting thickness – the higher the power, the thicker materials can be cut.

Example: A 500W fiber laser can cut carbon steel with a thickness of ≤3mm; a 3000W laser can cut carbon steel with a thickness of ≤12mm; and a 12000W laser can cut carbon steel with a thickness of ≤30mm (the specific cutting thickness depends on the material type). High-power lasers cut the same thickness of material faster (but balance accuracy is necessary). If the production requirement is “massive rapid cutting of thin plates”, focus on medium to high power; if “a small amount of fine cutting of thick plates” is needed, balance the power and beam quality.

Cutting accuracy requirements: The beam quality (measured by M² value, the closer to 1 the better) directly affects the accuracy:

High beam quality (M²≤1.2): Suitable for precision parts, fine seam cutting (such as electronic components, mold accessories), and requires an optical fiber laser or ultraviolet laser. General beam quality (M²≥1.5): Suitable for ordinary sheet material cutting, rough processing (such as metal shell, advertising board), CO₂ lasers or medium-low beam quality optical fiber lasers can meet the requirements.

Cutting accuracy requirements: The beam quality (measured by M² value, the closer to 1 the better) directly affects the accuracy: High beam quality (M²≤1.2): Suitable for precision parts, fine seam cutting (such as electronic components, mold accessories), and requires an optical fiber laser or ultraviolet laser. General beam quality (M²≥1.5): Suitable for ordinary sheet material cutting, rough processing (such as metal shell, advertising board), CO₂ lasers or medium-low beam quality optical fiber lasers can meet the requirements.

Budget: Medium and low power (500W – 3000W): Domestic optical fiber lasers have higher cost-effectiveness (30,000 – 200,000 yuan), suitable for users with limited budgets and small batch production. High power (10000W+) or precision scenarios (such as ultraviolet laser): Imported brands (such as IPG, Coherent) have better stability, but the price is 1.5 – 3 times that of domestic products (over 100,000 yuan), suitable for large-scale production or scenarios with extremely high stability requirements (such as automotive manufacturing, aerospace).

Energy consumption: CO₂ lasers have higher energy consumption than optical fiber lasers (under the same power, CO₂ energy consumption is approximately 2 – 3 times that of optical fiber). Long-term use requires calculating the “electricity bill”.

Optical fiber laser: Core components have a long lifespan (over 100,000 hours), maintenance is simple (mainly replacing coolant), and the annual maintenance cost is low.

CO₂ laser: The lifespan of the glass tube is shorter (domestic about 1500 – 3000 hours, imported about 8000 – 15000 hours), regular replacement is required, and the long-term cost is higher.

Imported equipment: The price of accessories is high (such as imported optical fiber modules are more than 50% higher than domestic), but the failure rate is low; domestic equipment has cheaper accessories, but may require more frequent minor repairs.

XI. Summary

Imported brands have advantages in technical accumulation, reliability in extreme environments, and adaptability to high-end scenarios, and are particularly suitable for fields with extremely high requirements for precision and stability. Domestic equipment, on the other hand, takes the lead in the general processing market due to its high cost-effectiveness, rapid service response, and performance close to international standards at medium and low power levels. With the breakthroughs made by domestic enterprises (such as Ruike and DaZui) in the ultra-high power and ultra-fast laser fields, the gap between the two is gradually narrowing. However, in core components (such as high-power ultraviolet modules) and complex processes (such as 3D curved surface cutting), they still need to catch up. When making a choice, it is necessary to comprehensively consider factors such as processing materials, precision requirements, and budget cycle. For high-end demands, imported products can be prioritized, while for large-scale production, domestic equipment can be given preference. If you need more detailed information about Fiber Laser Source, please contact us.