Fiber laser machines have revolutionized the manufacturing and engraving industries with their precision and efficiency. Whether you’re a small business or a large industrial operation, understanding the fiber laser machine cost is crucial for making an informed investment. This article delves into the factors that influence the cost of fiber laser machines, providing a comprehensive guide to help you navigate your purchase decision.

Factors Affecting Fiber Laser Machine Cost

Laser Power

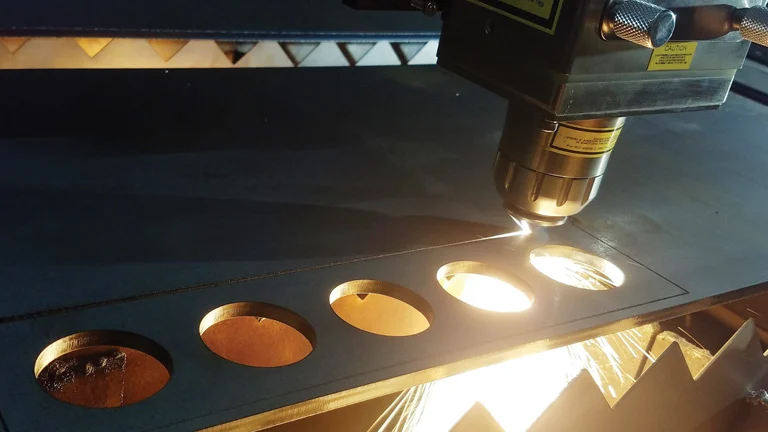

- Explanation of Power Levels: Fiber laser machines come in various power levels, typically ranging from hundreds of watts to thousands of watts or more. Lower power machines are generally used for precision tasks such as engraving and marking, while higher power machines are suitable for cutting through thicker materials and handling more demanding industrial applications.

- Impact on Cost: Higher power machines are more expensive due to their increased capability and the more robust components required to handle higher energy output. For instance, a 6000W machine will cost significantly more than a 2000W machine, but it will also offer greater versatility and productivity, making it a better investment for certain applications.

Brand and Manufacturer

- Comparison of Well-Known Brands vs. Lesser-Known or Emerging Brands: Established brands such as IPG Photonics, Trumpf, and Coherent are well-known for their quality and reliability. They often come with a higher price tag due to their reputation and proven track record. Lesser-known or emerging brands, particularly those from countries with lower manufacturing costs, like China, may offer more competitive prices but can vary widely in quality.

- How Reputation and Country of Origin Affect Pricing: Brands with a strong reputation for durability, customer service, and technological innovation can command higher prices. Additionally, machines manufactured in countries with stringent quality control standards (e.g., Germany, Japan) tend to be more expensive compared to those from countries where production costs are lower.

Machine Specifications

- Key Features that Affect Cost: The specifications of a fiber laser machine, such as cutting speed, precision, and versatility, play a significant role in its cost. High-speed machines that can cut through materials quickly reduce production time and increase efficiency, which justifies a higher price.

- Additional Functionalities: Features such as automated systems (e.g., auto-focusing, dual-head systems), enhanced cooling systems, and advanced safety features add to the machine’s cost. These functionalities improve ease of use, safety, and performance, making them worthwhile investments for certain users.

Software and Integration

- Importance of Quality Software and Its Impact on Cost: The software that controls the fiber laser machine is crucial for its operation. High-quality software that offers intuitive user interfaces, advanced features, and reliable performance can significantly increase the machine's cost.

- Ease of Integration with Other Systems and Advanced Software Features: Machines that integrate seamlessly with other production systems and offer features such as remote operation, diagnostics, and customization options tend to be more expensive. These capabilities can enhance productivity and reduce downtime, making them valuable for complex manufacturing environments.

Support and Warranty

- Value of Comprehensive Support and Extensive Warranties: Machines that come with extensive warranties and comprehensive support packages tend to be more expensive upfront. However, the value of these services can outweigh the initial cost by ensuring quick resolution of issues, reducing downtime, and extending the machine's operational life.

- Long-Term Benefits vs. Initial Cost: Investing in a machine with robust support and a strong warranty can lead to long-term savings. Reliable after-sales service, easy access to spare parts, and professional technical support contribute to smoother operations and lower total cost of ownership.

Operational Cost of Fiber Laser Cutting Machine

When evaluating the fiber laser machine cost, it's crucial not to stop at the initial purchase price. It's equally important to consider the ongoing operational costs that accumulate day-to-day. Below, we will analyze the key factors that constitute these operational expenses.

Energy Consumption

- Electricity Usage: Fiber laser cutting machines require a significant amount of electrical power to operate, especially those with higher wattage. The cost of electricity can vary depending on the machine’s power level and the duration of its use.

- Efficiency: More energy-efficient models might have a higher upfront cost but can save money over time through reduced electricity bills.

Maintenance and Upkeep

- Regular Maintenance: Routine maintenance is essential to keep the machine operating efficiently and to prevent breakdowns. This includes cleaning optics, checking alignment, and replacing consumables like nozzles and lenses.

- Repairs and Parts Replacement: Unexpected repairs can add to operational costs. High-quality machines from reputable brands may have fewer breakdowns, but when they do occur, the cost of parts and labor can be significant.

Consumables

- Gases: Some fiber laser machines require assist gases (e.g., nitrogen, oxygen) to cut different materials. The cost of these gases can add up, particularly in high-volume production environments.

- Lenses and Mirrors: These components wear out over time and need to be replaced periodically. The frequency of replacement depends on the intensity of use and the materials being processed.

Labor Costs

- Operator Training: Proper training for operators is crucial for maximizing efficiency and ensuring safety. This may involve initial training sessions, ongoing education, and potentially higher wages for skilled operators.

- Operation Time: The labor cost is also influenced by the machine’s operational time. Efficient machines that require less manual intervention can reduce labor costs.

Software and Updates

- Software Licensing: Some machines come with proprietary software that may require periodic updates or subscriptions. Ensuring the software is up-to-date can prevent compatibility issues and improve efficiency.

- Software Maintenance: Regular updates and maintenance of the software are essential to ensure optimal performance and security, which can incur additional

Downtime

- Production Halts: Any downtime due to maintenance, repairs, or software issues can result in production halts. The cost of downtime can be substantial, especially in high-output manufacturing environments where every minute of operational time is valuable.

- Preventive Measures: Investing in preventive maintenance can help reduce unplanned downtime, but this also adds to the operational costs.

Facility Requirements

- Environmental Controls: Maintaining a stable environment, including temperature and humidity control, is important for the optimal performance of fiber laser machines. The cost of HVAC systems and their operation can be significant.

- Space Requirements: Adequate space for the machine, including considerations for safety and operational efficiency, may require modifications to existing facilities or new infrastructure investments.

By considering these operational costs, businesses can gain a more comprehensive understanding of the total fiber laser machine cost. This thorough evaluation helps in making an informed decision that aligns with both budgetary constraints and operational needs.

What Is The Fiber Laser Machine Cost

The cost of a laser cutting machine is a crucial consideration when budgeting for equipment. However, it's equally important to factor in the differences among manufacturers. For professionals seeking reliability and tailored solutions, opting for a reputable manufacturer specializing in CNC laser cutting machines is advisable. These companies, with their extensive market experience, understand the specific needs of operators and often provide reasonable offers tailored to those needs.

Nevertheless, it's essential to note that the quality of laser engraving and cutting machines can vary based on specifications like laser power, type, tube, lens, and mirror configurations. As a professional manufacturer of CNC and fiber laser cutting machines, CNC prioritizes providing 24/7 person-to-person free service and support to ensure customer satisfaction and understanding of their requirements.

Regarding pricing, the range for laser engraving and cutting machines typically spans from $3,000 to $300,000, encompassing both CO2 and fiber laser machines. This wide range reflects variations in configuration and customer requirements.

Let's delve into the pricing of commonly used fiber laser cutting machines:

1KW Fiber Laser Cutting Machine: Priced at $17,300, this machine can cut up to 10mm carbon steel and 5mm stainless steel. For processing highly reflective materials like aluminum and copper, opting for an IPG fiber laser cutting machine, priced at $26,000, ensures cutting precision and reduces damage to the laser generator.

High-Power Fiber Laser Cutting Machine: With a maximum power of 12KW, this machine, costing about $100,000, is capable of cutting up to 40mm carbon steel and 30mm stainless steel plates. Suitable for thick metal projects such as building materials and industrial pipes, this high-power machine is chosen based on the thickness of the metal and cutting speed requirements.

Customization Options: Additional configurations, such as adding a rotary axis unit for cutting both metal plates and pipes or integrating a second worktable for enhanced productivity, can increase the overall cost. While these additions may incur extra expenses, they offer greater versatility and efficiency for specific production needs.

Safety Features: Machines equipped with large enclosure structures ensure user safety during operation. This design, fully enclosed during cutting, allows users to monitor the process through an external display screen, eliminating direct exposure to the laser and sparks.

As technology continues to evolve and accessory costs decline, the price of fiber laser cutting machines is expected to trend downwards. However, advanced technology will always command a premium, offering greater benefits and positioning fiber laser machines as indispensable equipment in the metal cutting market's future.

Fiber Laser Machine: Evaluate Cost and Performance

Incorporating operational and annual maintenance expenses into the overall costs of laser equipment provides a precise assessment of the final system cost. This approach offers a clearer understanding of whether investing in a fiber laser system aligns with your production goals while optimizing costs. With a grasp of your shop's production expenses for specific products, your evaluation, though detailed, becomes grounded in relevant data. The accuracy of this evaluation is further enhanced when your fiber laser machine provider possesses the expertise and experience to assist you in making informed decisions.

As you explore your options in laser cutting machines, consider these two primary factors influencing fiber laser machine cost:

Cutting Speed

Operating costs vary, but industry data suggests that the average cost to operate a 4kW CO2 laser cutter is approximately $12.73 per hour. In contrast, a 4kW fiber laser system typically incurs an average hourly cost of $6.24. This significant difference underscores why the latter may present a more cost-effective solution for certain facilities. Additionally, fiber laser systems offer the versatility to cut a diverse range of materials across various thicknesses with higher precision, employing a contactless process that ensures repeatability.

Operating Cost

Fiber lasers offer distinct advantages in cutting speed. Unlike traditional cutting systems, which may require up to 10 minutes for startup, fiber lasers eliminate lengthy setup times and warm-up periods. This immediate operational readiness translates into time savings. During the cutting process, fiber laser machines can achieve cutting speeds up to five times faster than conventional CO2 lasers. Beyond reducing production time, fiber laser systems may also deliver cost savings on maintenance. Their solid-state design entails fewer moving parts, resulting in lower maintenance requirements. In essence, the superior cutting speeds of fiber lasers contribute to reduced operational costs.

Why Fiber Laser Cost More?

Several factors contribute to the higher price tag of fiber lasers compared to other laser engraving technologies like CO2 lasers:

- Advanced Technology: Fiber lasers utilize sophisticated technology with complex components, leading to higher production costs.

- Superior Performance: Fiber lasers offer unparalleled speed, precision, and marking capability on various materials, justifying their premium price point.

- Durability and Reliability: These lasers boast exceptional lifespans exceeding 100,000 hours, making them a long-term investment.

- Compact Design: Despite their power, fiber lasers are known for their compact size, often requiring specialized engineering and materials, contributing to the cost.

Real Cost Of Owning A Fiber Laser Cutter

Purchasing and operating a laser cutter really worth it? Between the initial investment and additional costs of labor and maintenance, owning a laser cutter is no small undertaking. While the initial investment may seem significant, the long-term benefits in terms of precision, efficiency, versatility, cost savings, and competitive advantage outweigh the upfront costs.

Initial investment

The initial investment for a high quality, high-power, precision laser cutter can be daunting. For most industrial-grade laser cutters, the cost can range from $250k for a small footprint, low power (1kW – 3kW) machine, to more than $1 million. High power fiber laser cutters with state of the art technology that can easily cut 1” thick steel can cost well over $2 million, before you even add on cool options like automation.

CO2 lasers that are powerful enough to cut plastics, wood and even thin metals start at about $15,000 and scale upwards based on a number of factors, including size and power.

The initial investment costs for any laser cutter depends on the laser technology and capabilities, as well as your machine shop’s needs regarding capacity, level of power, and degree of automation.

Cost of staff and reaching ROI

Small CO2 lasers, which are limited on both size and available materials, can easily be run by just one operator. A larger, high power fiber laser could potentially be run by one operator, but is ideally run by a team of 2-3 staff made up of one operator, one materials handler, and oftentimes one parts handler. Lasers are fast machines that need to be fed material constantly in order to achieve a positive ROI.

High powered fiber lasers should be run as close as possible to 24 hours a day to maximize its efficiency and ROI. Ideally, all the parts cut on this laser are eligible for automatic loading and unloading. However, since this can’t always be the case (job shops), your shop should be prepared to have 2-3 shifts of several people each working around the clock to load and unload the material.

Materials and storage costs

The cost of materials is as much a part of the cost of the laser cutter as it is the cost of the parts you’re cutting. Depending on the part geometry and how the parts are nested in programming, anywhere from 10% to 50% of the raw material is wasted and has to be recycled. This can be partially mitigated by efficient sheet utilization, but if you aren’t also running the laser often enough to utilize all of the raw material, the amount and cost of scrapped material will be high.

If you don’t have enough parts to utilize all the raw material when laser cutting, you will also probably face issues with price scaling as it’s often significantly cheaper to order material in large quantities. However, if you can order large quantities of material and can justify it with the near constant use of the laser cutter, you will eventually need to address a rather glaring storage problem. This can be expensive for smaller machine shops who may have to store the material for an extended period of time before it’s all used.

The most efficient material sizes may be sheets of 4’x4’, 4×10’, or even 5’x12’. Storing and handling materials of those sizes requires a lot of space, specialized equipment (forklifts, cranes, etc.), and unique training for laser operators. Since it may be difficult for shops to find the space for such storage and equipment, they will have to turn to renting additional space on top of ordering the larger sheets in large quantities. As you can see, materials costs are not as cut and dry as they may appear.

Maintenance needs and consumables

High power fiber lasers require a significant amount of maintenance which will play into the cost of daily operation.

- Lens and nozzle alignment (daily)

- Lens savers (protective lens cover): $10-$20 each, (daily)

- Emptying scrap bins/dust collection units (daily)

- Replacing sacrificial slats for work tables: $1-1.50 per pound, plus cutting time (every 2-3 days to once a month, depending on production levels)

- Lubrication (daily/weekly/monthly depending on machine and use)

- Replacing air/gas filters: $2,000 – $4,000, (semi-annually)

- Cleaning/replacing dust collector filters (depends on materials being cut and level of machine use): $800 – $2,000, (every 6 months)

- Large amounts of assist gas – typically liquid nitrogen or N2 generated from atmosphere using specialized equipment: $3,000 – $30,000 per month, depending on volume

CO2 lasers require less maintenance and consumables, but what they make up for in convenience, they lose in power, available materials, and capacity.

- Changing distilled water in the chiller every 100 hours of cutting

- Lubricating X/Y axis points

- Adjusting alignment (daily)

- Replacing laser tube: $700-$4,000 each, (every 2,000-5,000 hours, depending on power output)

Is It Worth Investing A Fiber Laser Cutter?

In today's rapidly evolving manufacturing industry, businesses are constantly seeking ways to improve efficiency, increase productivity, and enhance the quality of their products. One technology that has gained significant popularity is fiber laser cutting machines. These advanced machines offer precise and efficient cutting capabilities, making them a tempting investment for many companies. However, before making such a significant purchase, it's crucial to evaluate whether investing in a fiber laser cutting machine is truly worthwhile.

1. Cost and Financial Considerations

The cost of purchasing a fiber laser cutting machine is a major consideration. Prices for these laser cutters can range from tens of thousands to hundreds of thousands of dollars, depending on the features and capabilities. Conducting a detailed cost-benefit analysis is essential to evaluate whether the anticipated benefits outweigh the initial investment. Consider the predicted return on investment, cost savings from enhanced efficiency, material waste reduction, and future revenue growth.

- Return on Investment (ROI): Perform a comprehensive analysis to establish the expected ROI of purchasing a fiber laser cutting machine. Consider factors like increased production, reduced material waste, and potential income growth. Determine how long it will take to pay off the investment and whether it aligns with your company's financial objectives.

- Cost Savings: Fiber laser cutters provide significant cost-saving advantages compared to traditional cutting methods. Their efficiency reduces production time and labor costs, while their precision cutting capabilities minimize material waste, leading to substantial savings in raw material costs.

- Maintenance and Operating Costs: While fiber laser cutting machines require less maintenance than other cutting processes, ongoing operational costs must be considered. Examine the costs of power use, gas supply, and routine maintenance to ensure they fit within your budget and financial expectations.

- Scalability and Future Growth: Consider your company's long-term potential and growth trajectory. Ensure the fiber laser cutting equipment will meet your future requirements by examining whether the machine's capabilities align with your anticipated growth.

2. Increased Efficiency and Productivity

Fiber laser cutting machines offer remarkable cutting precision and speed, allowing for faster production cycles and increased efficiency. Compared to traditional cutting methods, these machines can significantly reduce the time required to complete jobs, resulting in enhanced production. Additionally, the automated features and extensive software capabilities of fiber laser cutting machines allow for seamless integration with other manufacturing processes, further increasing overall efficiency.

- Speed and Precision: Fiber laser cutting machines can cut materials at high speeds while maintaining precision. They handle a variety of materials with excellent accuracy and consistency, resulting in faster and more efficient manufacturing processes.

- Minimal Material Waste: Fiber laser cutters are highly efficient, resulting in minimal material waste. Their precise cutting capabilities ensure accurate cuts, avoiding the need for extra cuts or finishing work, leading to significant cost savings in raw material expenses and reduced environmental impact.

- Reduced Labor Costs: The advanced automation features of fiber laser cutting machines reduce the need for manual labor, resulting in lower labor costs. These machines can operate continuously with minimal operator intervention, freeing up employees to focus on other critical tasks.

- Increased Output: The increased speed and precision of fiber laser cutting machines allow for faster production times and higher output. This increased output can lead to higher revenue and growth opportunities for businesses.

3. Versatility and Flexibility

The versatility of fiber laser cutting machines is another significant advantage. These machines can cut a variety of materials such as carbon steel, stainless steel, aluminum, and more. This adaptability enables businesses to diversify their product offerings and reach a larger customer base. Furthermore, fiber laser cutters can easily handle intricate designs and complex shapes, providing businesses with the flexibility to meet a variety of consumer requests.

- Material Compatibility: Fiber laser cutting machines can efficiently cut through various materials, including metals and even reflective materials like brass and copper. This adaptability allows organizations to meet diverse customer requests and expand their product offerings.

- Wide Range of Applications: Fiber laser cutting machines can be utilized in numerous industries, including metal fabrication, automotive production, aerospace, electronics, signage, and architecture. This versatility enables businesses to adapt to changing market demands and pursue new opportunities.

- Customization and Complex Designs: The precise cutting capabilities of fiber laser equipment allow for the fabrication of intricate and complex designs with high accuracy, opening the door to customization and personalized products, which can provide a competitive advantage in markets that value originality and customization.

- Cutting Thick Materials: Fiber laser cutters excel at cutting thick materials, which is particularly useful in industries requiring thick metal cutting, such as shipbuilding, construction, and heavy machinery production. Efficiently handling thick materials can lead to cost savings and enhanced production processes.

4. Enhanced Product Quality

Investing in a fiber laser cutting machine can significantly enhance the quality of the final product. The accurate and clean cuts produced by these machines result in less material distortion and reduced post-processing requirements, improving both the aesthetic appeal and functional integrity of the products.

- Clean and Precise Cuts: Fiber laser cutting machines produce narrow and precise cuts, avoiding the need for secondary finishing processes like deburring or polishing. The clean cuts ensure smooth edges and accurate measurements, enhancing the overall quality of the finished product.

- Minimal Material Distortion: Fiber laser cutting equipment produce few heat-affected zones, reducing the risk of material distortion. This is particularly beneficial in industries requiring high precision and dimensional accuracy, such as aerospace or medical equipment manufacturing.

- Improved Consistency: Fiber laser cutting machines provide consistent cutting results, ensuring uniformity across multiple pieces or batches. The precise control and automation capabilities of these machines reduce variation in the cutting process, resulting in products with standardized dimensions and quality.

- Complex Geometries and Intricate Designs: The high precision and versatility of fiber laser cutting machines enable the creation of intricate and complex designs with ease, allowing businesses to meet customer demands for unique and aesthetically pleasing products.

- Quality Control and Traceability: Advanced monitoring systems and quality control features are often included with fiber laser cutting machines, ensuring that only high-quality products are produced. The ability to monitor and trace each cut piece provides valuable data for quality control and compliance with standards and regulations.

5. Long-term Cost Savings:

While the initial cost of a fiber laser cutting machine may appear high, it is essential to consider the long-term cost savings it can provide. Compared to traditional cutting methods, these machines are highly efficient and require less maintenance. Additionally, reduced material waste and optimized production processes can result in significant cost savings over time.

- Less Material Waste: Fiber laser cutting equipment provide precise and accurate cuts, resulting in minimal material waste. The ability to cut intricate designs and optimize material usage ensures that raw materials are used efficiently, lowering overall material costs. The clean cuts produced by fiber lasers reduce the need for secondary finishing processes, further decreasing material waste and associated costs.

- Lower Labor Costs: The advanced automation features of fiber laser cutting machines reduce the need for manual labor, leading to lower labor costs. The reduced reliance on manual intervention also eliminates the possibility of human error, resulting in consistent and high-quality cuts.

- Increased Production Output: The high speed and precision of fiber laser cutting machines significantly boost production output. These machines can cut through materials at a faster rate than traditional methods, allowing businesses to fulfill orders more quickly and take on additional projects, leading to increased revenue.

Overall, investing in a fiber laser cutting machine can provide significant long-term cost savings. The reduced material waste, lower labor costs, increased output, and enhanced efficiency contribute to improved profitability and a stronger bottom line. Businesses can allocate resources more effectively and achieve long-term growth by optimizing operational efficiency and reducing costs.

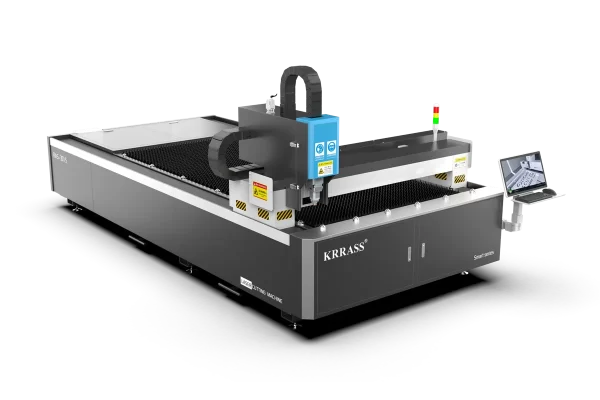

Krrass Fiber Laser Machine - Your Cost-saving choice

Krrass laser cutting machines have become the preferred choice in various industrial applications due to their exceptional performance and economic benefits. Here are some notable features of Krrass laser cutting machines that highlight their high quality and cost-saving advantages:

High-Quality Cutting Performance

- High Precision: Krrass laser cutting machines utilize advanced laser technology to achieve high-precision cutting, ensuring smooth, burr-free edges.

- Strong Stability: With a robust machine structure, equipped with high-performance servo motors and guide rails, these machines ensure stability and reliability over long-term use.

- Intelligent Control System: Equipped with an advanced CNC control system, Krrass machines support quick programming and precise cutting of complex patterns, enhancing production efficiency.

Significant Cost Efficiency

- High Material Utilization: By optimizing cutting paths and compact layout design, Krrass machines reduce material waste, improving material utilization and lowering production costs.

- Low Energy Consumption: Utilizing efficient laser sources, these machines have high energy conversion efficiency, reducing the cost per unit of cutting.

- Low Maintenance Costs: With a rational design and durable core components, Krrass laser cutting machines have long maintenance intervals and low maintenance costs, further saving on operational expenses.

Wide Range of Applications

- Suitable for Various Materials: Capable of cutting stainless steel, carbon steel, aluminum alloys, copper, and other metals, meeting the needs of different industries.

- High Flexibility: Suitable for both mass production and small-batch customization, widely used in automotive manufacturing, aerospace, electronics, advertising, and other fields.

With their high-quality cutting performance and significant cost-saving benefits, Krrass laser cutting machines help enterprises improve production efficiency and market competitiveness, making them an ideal choice in industrial manufacturing.