Fiber laser cutting machines have become a cornerstone in the manufacturing and metalworking industries due to their precision, efficiency, and versatility. These machines utilize high-powered fiber lasers to cut through a variety of materials with remarkable accuracy, making them indispensable tools for businesses ranging from small workshops to large industrial operations. However, understanding the fiber laser cutting machine price is crucial for businesses looking to make informed investment decisions.

The cost of acquiring and operating a fiber laser cutting machine can vary significantly based on several factors. This article aims to provide a comprehensive guide to the factors influencing the price of fiber laser cutting machines, helping potential buyers navigate their options and choose the best machine for their needs and budget.

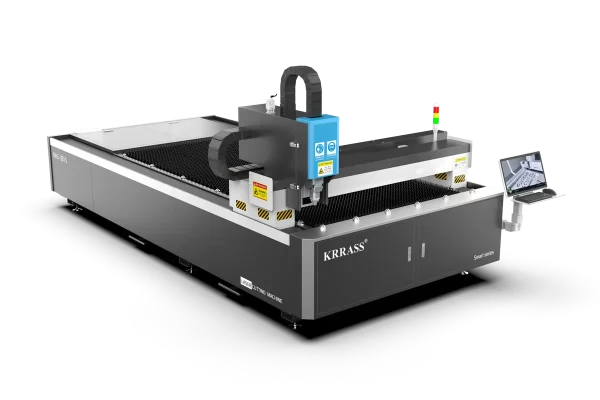

What Is A Fiber Laser Cutting Machine

A fiber laser cutting machine uses a fiber laser to cut materials. The laser beam is generated by a series of diodes and then channeled through a fiber optic cable, which amplifies the beam before it reaches the cutting head. Key components include the laser source, fiber optic cable, cutting head, and control system. Compared to CO2 and crystal lasers, fiber lasers are more efficient, require less maintenance, and have a longer operational life. essential tools for a wide range of applications. This article provides an in-depth look at fiber laser cutting machines, their benefits, applications, key features, and factors to consider when purchasing one.

Main Components of Fiber Laser Cutting Machine

Fiber Laser Source

Fiber lasers use a fiber doped fiber optic cable as the laser source. There are many different types of rare earth materials available for doping. This leads to multiple options for fiber laser source. Ytterbium-doped fiber lasers are among the most common types of laser source among fiber lasers. Different doping materials produce laser of different wavelength.

Cutting Head

The cutting head is the part that outputs the laser from the system and focuses it on the workpiece. It c a focus consists of a lens, a nozzle, and a focus tracking system. This is a movable part of the fiber laser cutting machine. The movement is according to the direction of the cut. The height of the cutting head from the workpiece is also adjustable.

Servo Motor

Servo motor is the part responsible for the movement of the optics and mechanical parts of the laser cutting machine. Modern laser cutting machines have precise servo motors capable of minute movements of the optical components. The speed of the servo motor is also highly controlled. The precision of the laser cutting is largely dependent on the movement of the servo motor.

Cooling System

Laser machine parts generate a high amount of heat. Therefore, it requires a cooling system to ensure the internal components are not damaged. This job is done by the water chillers. Water chillers can drop the temperature of the entire fiber laser cutter very quickly.

Worktable

The worktable is the area for mounting the workpiece. The worktable, bed, and beam are collectively called the host. The host contains various servomotors for the relative movement in the z-axis.

CNC Controller

One of the benefits of a fiber laser cutting machine is its ability to be automated through a CNC control system. The CNC controller interprets the program instructions and passes it along to the various parts of the machine. The CNC controller moves the cutting head in the X, Y, and Z axis accordingly.

Types of Fiber Laser Cutting Machine

- Fiber Laser Sheet Cutting Machine:

- Designed for cutting flat sheet materials such as metal sheets, plates, and panels.

- Ideal for applications in industries like manufacturing, automotive, aerospace, and construction.

- Offers high cutting speeds, accuracy, and the ability to process a variety of metals including steel, aluminum, brass, and copper.

- Fiber Laser Tube Cutting Machine:

- Specifically designed for cutting tubular and cylindrical metal components such as pipes, tubes, and profiles.

- Suitable for industries like furniture, automotive, architecture, and agriculture.

- Offers precise and clean cuts on a wide range of tube diameters and lengths.

- Fiber Laser Pipe Cutting Machine:

- Similar to tube cutting machines but optimized for cutting pipes and cylindrical components with larger diameters.

- Commonly used in industries such as oil and gas, plumbing, and construction.

- Provides high-speed cutting of pipes with complex geometries, bevels, and contours.

- Fiber Laser 3D Cutting Machine:

- Capable of cutting three-dimensional shapes and contours on various metal components.

- Utilizes advanced motion control systems and multi-axis configurations for precise and complex cutting tasks.

- Ideal for applications in industries like automotive, aerospace, medical, and electronics.

- Fiber Laser Marking and Engraving Machine (Optional):

- Some fiber laser cutting machines may also include marking and engraving capabilities.

- Used for adding identification marks, serial numbers, logos, and other graphics on metal surfaces.

- Offers high-speed, high-precision marking and engraving on a wide range of materials.

Advantages of Fiber Laser Cutting

- The most recent and technologically advanced form of laser cutting

- Has the ability to adjust from one industry need to another smoothly

- Can be used on a versatile range of metals

- Can adapt to different wavelengths, ranges and even speeds

- Works at a faster speed than CO2 lasers, increasing overall efficiency

- Increased efficiency with reduced set-up and down times

- High power output and beam quality, which creates a cleaner cutting edge

- Lower power consumption keeps running costs low

- The machine does not pose a heat risk despite its power

Fibre laser cutting offers unrivalled performance in metal fabrication, and its precision and accuracy result in optimal output figures. When compared to other types of laser cutting available, fiber lasers achieved high quality results at a faster rate and at a lower rate of materials consumption.

Understanding the Core - Fiber Laser Resonator

Fiber lasers have revolutionized the field of laser cutting, significantly enhancing the capabilities and performance of laser cutting machines. And fiber laser also affect price of laser cutter.

Importance of Fiber Lasers for Laser Cutting Machines

1. Enhanced Efficiency and Power Conversion

Fiber lasers boast a higher electrical-to-optical efficiency compared to other types of lasers. This means they convert a larger portion of the input electrical energy into useful laser light, reducing energy consumption and operational costs. The high efficiency also allows for more compact designs, which can be integrated into various industrial applications.

2. Superior Cutting Speed and Quality

The beam quality of fiber lasers is excellent, providing a smaller and more focused spot size. This results in higher intensity and more precise cutting capabilities. Fiber lasers can cut through materials at higher speeds with smoother edges and minimal thermal distortion. This precision is particularly important for industries that require high accuracy and clean cuts, such as aerospace and medical device manufacturing.

3. Versatility in Material Cutting

Fiber lasers are highly versatile and can effectively cut a wide range of materials, including metals (steel, aluminum, copper, brass), plastics, and even reflective materials. Their ability to cut reflective metals without the risk of back reflections damaging the laser source is a significant advantage over CO2 lasers.

4. Lower Maintenance and Operating Costs

One of the standout benefits of fiber lasers is their low maintenance requirements. Unlike CO2 lasers, which require regular replacement of gas and maintenance of mirrors and lenses, fiber lasers have fewer moving parts and a solid-state construction. This robustness translates to reduced downtime and lower maintenance costs over the machine's lifetime.

5. Longevity and Reliability

Fiber lasers are known for their long operational life. The solid-state nature of the fiber laser medium contributes to its durability and reliability, ensuring consistent performance over extended periods. This longevity is a critical factor for businesses looking to minimize machine replacement costs and disruptions.

6. Environmental Benefits

Fiber lasers are more environmentally friendly compared to traditional laser types. Their higher efficiency reduces energy consumption, and their solid-state nature means they do not rely on hazardous gases or materials. This aligns with the growing emphasis on sustainable manufacturing practices.

7. Compact and Flexible Design

The design of fiber lasers allows for a more compact and flexible setup. They can be easily integrated into existing production lines and configured for various cutting applications. This flexibility is crucial for manufacturers who need to adapt to different production requirements and material types.

8. Technological Advancements and Integration

Fiber lasers are at the forefront of technological advancements in laser cutting. They can be integrated with modern automation systems and advanced software for enhanced control and precision. This integration facilitates smart manufacturing processes, such as Industry 4.0, where machines communicate and optimize production autonomously.

How Lasers Influence the Fiber Laser Cutting Machine Price

1. Initial Purchase Cost

High-Quality Laser Source:

- Fiber lasers are known for their superior beam quality, efficiency, and durability. The high-quality components and advanced technology used in fiber lasers make them more expensive to produce and integrate into laser cutting machines compared to other types of lasers like CO2 or crystal lasers.

Power and Specifications:

- The power rating of the fiber laser (measured in watts) significantly affects the price. Higher power lasers can cut thicker and harder materials but come with a higher price tag. Machines with advanced specifications and features, such as auto-focus capabilities and precision control, further increase the cost.

2. Operational Efficiency and Cost Savings

Energy Efficiency:

- Fiber lasers are more energy-efficient than other types of lasers. They convert a higher percentage of electrical energy into laser light, which reduces operational costs in the long run. This efficiency can offset the higher initial purchase cost, making fiber lasers a cost-effective option over time.

Low Maintenance Requirements:

- The solid-state design of fiber lasers means fewer moving parts and less frequent maintenance. Unlike CO2 lasers that require regular gas refills and maintenance of mirrors and lenses, fiber lasers have lower ongoing maintenance costs. This can result in significant savings over the machine’s lifespan.

3. Longevity and Reliability

Durability:

- Fiber lasers have a longer operational lifespan, reducing the need for frequent replacements. This longevity ensures a higher return on investment (ROI) for businesses, justifying the higher upfront cost.

Consistent Performance:

- The reliability of fiber lasers in providing consistent, high-quality cuts reduces downtime and improves productivity. This reliability is a valuable feature that influences the price positively, as businesses are willing to pay more for machines that enhance operational efficiency and minimize disruptions.

4. Market Demand and Brand Reputation

Market Trends:

- As the demand for fiber laser technology grows, driven by its advantages over traditional laser types, the market price reflects this trend. High demand can lead to higher prices, especially for top-tier machines with the latest advancements.

Brand and Support:

- Machines from reputable brands that offer excellent customer support and after-sales service tend to be priced higher. The assurance of reliable performance and support adds value to the investment, influencing the overall cost of the machine.

Well-known Laser Source Brands

- IPG PhotonicsA globally recognized manufacturer of laser technology machines with 30 years of experience. IPG is the world's largest fiber laser manufacturer and their products are known for quality.

- RaycusA world-renowned manufacturer of laser equipment that provides industry solutions for laser equipment users. Raycus fiber laser sources are known for their lower cost, stable performance, and high product reliability.

- JPTA leading company in the laser industry that produces laser sources for applications such as marking, cutting, welding, cleaning, and 3D printing.

- MaxA trusted name in the fiber laser industry that offers reliable and high-performance laser sources. Max fiber laser sources are known for their excellent beam quality and stable operation.

- LaseraxA leading company that was founded in 2010 and was the first to develop inline laser solutions for major smelting plants.

| Brand | Features | Country | Price Range |

| IPG Photonics | Globally recognized, 30 years of experience, high-quality products | USA | High |

| Raycus | Renowned for lower cost, stable performance, high reliability | China | Moderate to High |

| JPT | Leading producer for various laser applications, versatile | China | Varies |

| Max | Trusted name, excellent beam quality, stable operation | China | Moderate to High |

| Laserax | Pioneer in inline laser solutions for smelting plants | Canada | Varies |

For laser source manual, you can click below to read.

1500W Fiber Laser Source Manual

2000W 3000W Fiber Laser Source Manual

12000W Fiber Laser Source Manual

The quality of the laser cutting machine itself determines the price; lasers, cutting heads, machine tools, etc. are all important parts of the laser cutting machine, especially the laser, which is like the heart of the laser cutting machine, and its quality directly determines the cutting process. Therefore, when buying products, merchants must collect relevant information on the Internet and check the information about these core components of the laser cutting machine.

Factors Influencing Fiber Laser Cutting Machine Price

1. Components and Accessories

Different components, such as the laser, motor, laser lens, and control system, significantly impact the price of laser cutting machines. For instance:

- Motor Quality: Precision motors from renowned brands can increase machine accuracy but come at a higher cost.

- Laser Lens: Variations in quality and power of laser lenses affect cutting performance and longevity.

- Laser Tube: The brand and quality of the laser tube determine its lifespan and cutting efficiency.

2. Machine Specifications

Diverse machine models with varying power levels and cutting formats lead to different prices. Users should select the most suitable power and format to maximize cutting efficiency and business profitability.

3. Equipment Variations

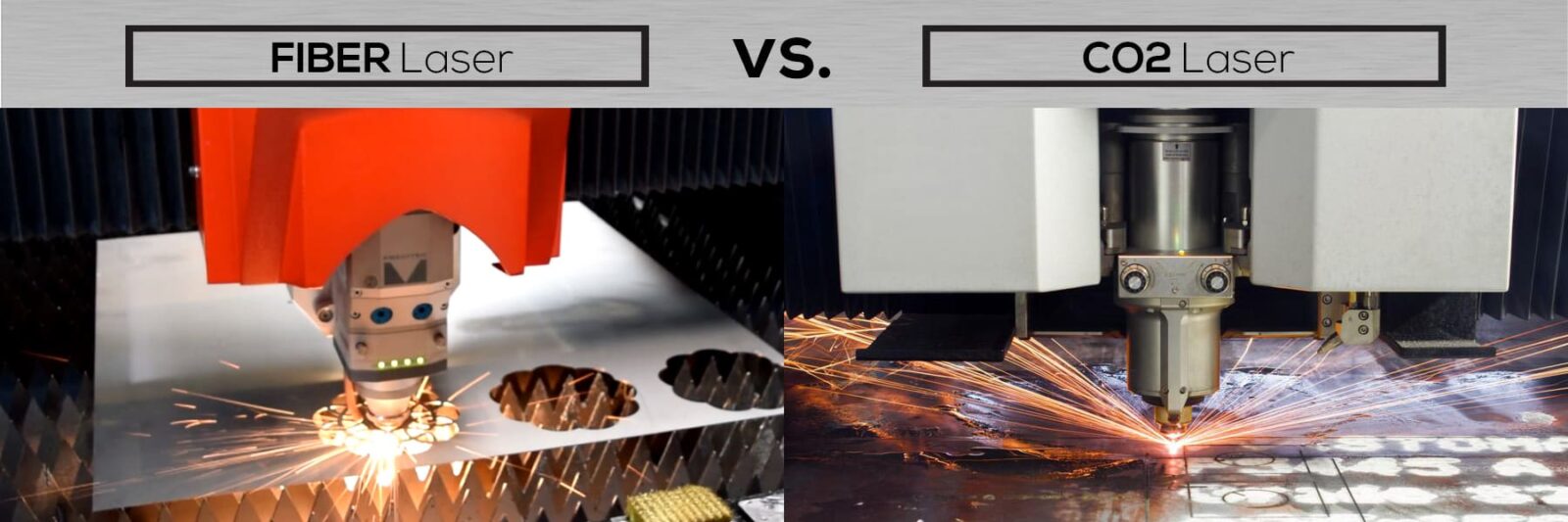

The cutting quality and speed differ among fiber laser, YAG laser, and CO2 laser cutting machines, influencing their respective prices.

4. After-Sales Support

Comprehensive after-sales service is crucial for ensuring equipment safety and timely maintenance. Manufacturers' capabilities in providing timely replacement of consumables like laser tubes and reflectors affect prices.

5. Build Quality

Manufacturing materials and construction affect long-term performance. Some manufacturers may use lower-quality materials to cut costs, leading to issues like rack deformation over time.

6. Functionality

The inclusion of various features and upgrades affects pricing. Users should prioritize cost-effective configurations that meet their specific cutting needs rather than opting for overly complex machines.

Fiber Laser Cutting Machine - 2024 Price Analysis

Key Factors Affecting Price

Laser cutting machines come in various configurations, each catering to specific needs and budgets. Here's a breakdown of the key factors influencing their price:

- Type of Laser:

- CO2 Lasers: Generally more affordable due to their mature technology and readily available parts.

- Fiber Lasers: Advanced technology and superior performance for cutting metals typically lead to a higher price tag.

- Diode Lasers: Compact and affordable, ideal for engraving and cutting thin materials.

- Rough Price Estimates by Type:

| Type of Laser Machine | Price Range |

|---|---|

| Fiber Laser | $20,000 - $600,000 |

| CO2 Laser | $1,000 - $100,000 |

| Diode Laser | $500 - $2,500 |

- Laser Power: Higher power enables cutting thicker materials and faster speeds, but also increases the cost.

- Material Compatibility: Machines that handle diverse materials often require more advanced components, impacting the cost.

- Cutting Ability: Machines excelling at both cutting and engraving typically come at a premium.

- Working Size: Larger working areas (beds) require more materials, translating into a higher price.

- Cutting Speed: Faster cutting speeds often necessitate powerful motors, adding to the cost.

- Add-On Features: Integrated cameras, cooling systems, and fire extinguishers can significantly increase the price.

The cost of a fiber laser can vary significantly depending on various factors. Entry-level diode lasers may start from as low as $500, while high-powered industrial fiber lasers can reach staggering prices of up to $600,000.

Types of Laser Cutting Machines with Different Price

- Metal Laser Cutting Machine: Primarily fiber lasers due to their efficiency with metals. Prices start from $20,000 and go up.

- Acrylic Laser Cutting Machine: Typically CO2 lasers, costing from $1,000 to $5,000 (diode lasers can also be used for some acrylics).

- Wood Laser Cutting Machine: CO2 and diode lasers are suitable, costing from $1,000 to $4,000 (CO2) and $1,000 to $2,000 (diode).

- Plastic Laser Cutting Machine: Diode lasers or lower-power CO2 lasers, costing from $500 to $5,000 (industrial CO2 machines can go beyond $100,000).

- Paper Laser Cutting Machine: Dio

Rough Price Estimates by Material:

| Material | Type of Laser Machine | Price Range |

|---|---|---|

| Metal | Fiber/CO2 Laser | $20,000 - $600,000/$10,000 - $100,000 |

| Acrylic | CO2/Diode Laser | $1,000 - $5,000/$500 - $2,000 |

| Wood | CO2/Diode Laser | $1,000 - $5,000/$500 - $2,000 |

| Plastic | CO2/Diode Laser | $500 - $5,000 |

Rough Price Estimates by Power:

| Laser Power | Price Range |

| Up to 1 kW | $20,000 - $50,000 |

| 1 kW - 2 kW | $50,000 - $100,000 |

| 2 kW - 3 kW | $100,000 - $200,000 |

| 3 kW - 4 kW | $150,000 - $300,000 |

| 4 kW - 6 kW | $200,000 - $400,000 |

| 6 kW - 8 kW | $300,000 - $600,000 |

| 8 kW and above | $400,000 - $1,000,000+ |

Is It Worth Investing In A High-power Laser Cutting Machine?

High-wattage laser cutting machines typically come at a premium compared to entry-level units. Prices can range from $4,000 to $15,000 for various laser cutter models. At Krrass, our team can assist you in finding the ideal price point tailored to your specific needs. Prices vary widely for each Krrass cutting machine model, with factors such as wattage, work-surface size, laser type, and additional features influencing costs.

When estimating the cost of a particular Krrass model, consider wattage and work-surface size as key factors. Generally, machines with higher wattage and larger work surfaces command higher prices.

For a detailed price estimate, contact us to discuss the additional add-ons you require for your laser machine model. Add-ons typically range from $2,000 to $5,000, depending on the attachments and features you choose. Our team can provide an itemized price breakdown tailored to your specifications.

CO2 and Fiber Lasers: Price Difference Analysis

You may be curious about the cost disparities between CO2 laser machines and fiber lasers. Fiber laser cutting offers heightened energy efficiency and precision, making it particularly suited for upscale industries.

Fiber laser machines deliver exceptionally precise cuts compared to conventional CO2 lasers and boast extended lifespans. However, they often come with a higher price tag. Fiber lasers typically range from $20,000 to $45,000.

But don't feel pressured to opt for a costly fiber laser machine. Instead, consider a CO2 machine, which from our selection, is likely to meet or even surpass the requirements of your next wood, metal, glass, or acrylic project. The price of laser cutting machines for sale represents a significant investment for your business.

CO2 vs Fiber Lasers: Evaluating Cost Difference

Comparing the operational costs of older CO2 laser cutting machines to today's fiber laser cutting machines reveals significant advantages in productivity and cost-efficiency. With fiber laser technology, which offers less than half the operating costs and more than double the speed compared to CO2 lasers, it's evident why fiber lasers have gained such popularity.

Technology Contributions to Operating Costs:

The focused beam of a 2 kW fiber laser possesses significantly higher power density and absorption compared to a 4 kW CO2 laser, resulting in higher feed rates and up to five times more parts produced per unit of time. This increased productivity reduces the time and cost per part. Additionally, fiber lasers consume almost three times less electrical energy than CO2 lasers of the same power output, further reducing operational costs. Eliminating maintenance on beam delivery optics, beam path bellows, and purge systems, as well as the vacuum pump, adds to the cost-saving benefits of fiber lasers.

Fixed and Variable Cost Comparisons:

While there may be sentimental attachment to older equipment, the decision to replace it should be based on objective analysis rather than subjective factors. Repair and maintenance costs, a significant variable cost factor for older equipment, should be evaluated on a rolling basis over time. Excessive repair costs and downtime significantly impact profitability and the cost per part.

Actual 'Cost per Part' Factors:

Comparing the cost per part of current equipment to that of a new fiber laser machine reveals substantial cost savings. Fiber lasers enable the production of three to five times more parts at half the operating costs, resulting in a lower overall cost per part. Analysis of cost trends and lost bids helps determine when increasing costs become a trigger for considering new equipment.

Justifying the Fiber Laser Investment:

After evaluating the potential of fiber laser technology, it becomes clear that the ability to produce more parts at lower costs and win more competitive bids justifies the investment in fiber lasers. The increased productivity and cost-efficiency enable businesses to expand capacity, increase revenue, and maintain competitiveness in the market.

Experience Unrivaled Accuracy with KRRASS Laser Cutters

KRRASS laser cutting machines represent the pinnacle of precision engineering and advanced technology in the realm of metal fabrication. Renowned for their unparalleled accuracy, efficiency, and reliability, KRRASS machines empower businesses to achieve outstanding results in their cutting applications. So make a instant call for more surprise!