In today's rapidly evolving industrial landscape, the demand for advanced manufacturing technologies in the USA is growing exponentially. Companies across various sectors are seeking innovative solutions to enhance precision, efficiency, and productivity in their operations. One such innovation that has significantly impacted the manufacturing industry is the fiber laser cutting machine.

Fiber laser cutting machine in USA have revolutionized the way industries approach cutting and fabrication processes. Known for their exceptional precision, speed, and versatility, these machines utilize advanced fiber laser technology to cut through a wide range of materials with remarkable accuracy. This article will explore the basics of fiber laser cutting technology, introduce some of the leading manufacturers in the USA, and highlight the diverse applications of these cutting-edge machines. Furthermore, we will discuss important considerations when choosing a fiber laser cutting machine and examine emerging trends in this dynamic field.

Overview of Fiber Laser Cutting Machine in USA

Fiber laser cutting machines utilize a fiber laser, which is generated using a seed laser and amplified within a glass fiber. This technology is renowned for its high efficiency, precision, and ability to cut through various materials including metals, plastics, and composites. Compared to traditional CO2 lasers, fiber lasers offer improved beam quality and energy efficiency, making them a popular choice in modern manufacturing.

Features of Fiber Laser Cutting Machine in USA

1. High Precision and Accuracy

- Beam Quality: Fiber lasers provide superior beam quality, resulting in precise and clean cuts. This is essential for industries requiring high precision, such as aerospace and medical device manufacturing.

- Fine Cutting Capabilities: These machines can cut intricate designs and small features with high accuracy, making them ideal for detailed fabrication work.

2. Speed and Efficiency

- High Cutting Speeds: Fiber lasers operate at high speeds, significantly reducing cutting time compared to traditional methods. This boosts overall productivity in manufacturing processes.

- Quick Setup Times: Modern fiber laser machines are designed for quick setup and minimal downtime, further enhancing efficiency.

3. Versatility in Material Processing

- Wide Range of Materials: Fiber laser cutting machines can cut various materials including stainless steel, aluminum, brass, copper, and plastics. This versatility makes them suitable for diverse industrial applications.

- Thick and Thin Materials: These machines can handle both thick and thin materials, offering flexibility for different cutting requirements.

4. Advanced Automation and Software Integration

- CNC Control Systems: Equipped with advanced CNC (Computer Numerical Control) systems, fiber laser machines offer precise control over the cutting process, ensuring consistent quality.

- User-Friendly Interfaces: Modern fiber laser machines come with intuitive software interfaces that allow easy programming and operation, reducing the learning curve for operators.

5. Energy Efficiency

- Lower Power Consumption: Fiber lasers are more energy-efficient compared to CO2 lasers, resulting in lower operational costs and reduced environmental impact.

- High Electrical Efficiency: The high electrical efficiency of fiber lasers translates to more energy being converted into laser light, enhancing cutting performance.

6. Durability and Low Maintenance

- Robust Design: Fiber laser cutting machines are built with durable components that ensure long operational life and reliability.

- Minimal Maintenance: Due to fewer moving parts and the solid-state nature of fiber lasers, these machines require less maintenance, reducing downtime and maintenance costs.

7. Safety Features

- Enclosed Cutting Areas: Many fiber laser cutting machines feature enclosed cutting areas to protect operators from laser exposure and reduce the risk of accidents.

- Safety Sensors: Advanced safety sensors and automatic shutdown features ensure safe operation and compliance with industry safety standards.

8. Customizable Options

- Power Options: Fiber laser machines are available in various power ratings, allowing customization based on specific cutting needs (e.g., 2 kW, 4 kW, 6 kW, etc.).

- Additional Accessories: Options for additional accessories such as rotary attachments for tube cutting, automatic loaders, and unloaders enhance the versatility and automation capabilities of the machines.

9. Support and Service

- Technical Support: Leading manufacturers in the USA offer robust technical support and customer service, ensuring that any issues are quickly addressed.

- Training and Resources: Many companies provide comprehensive training programs and resources to help operators get the most out of their fiber laser cutting machines.

These features make fiber laser cutting machines a valuable asset for various industries in the USA, driving advancements in manufacturing efficiency, precision, and versatility.

Leading Fiber Laser Cutting Machine Manufacturers in USA

1. Bodor Laser

- Overview: Bodor Laser is known for its state-of-the-art laser cutting solutions. The company offers a wide range of fiber laser cutting machines that cater to various industrial applications.

- Key Features: Bodor machines are recognized for their precision, speed, and reliability. They come with advanced features such as automatic loading and unloading systems, high-power laser sources, and user-friendly interfaces.

- Presence in the USA: Bodor Laser has a significant presence in the USA with a subsidiary in Chicago, Illinois, ensuring excellent customer service and technical support.

2. HSG Laser

- Overview: HSG Laser provides comprehensive laser cutting solutions, known for their affordability and high performance. The company’s product range includes machines suitable for small to large-scale operations.

- Key Features: HSG machines are appreciated for their efficiency, energy savings, and versatility in cutting different materials. They offer various models tailored to specific industry needs (HSG Laser USA).

- Presence in the USA: HSG Laser has a facility in Casa Grande, Arizona, supporting customers with sales, service, and training.

3. AMADA America

- Overview: AMADA America is a leader in the laser cutting industry, offering advanced machines like the VENTIS and REGIUS series. The company has a long-standing reputation for innovation and quality.

- Key Features: AMADA’s fiber laser cutting machines are known for their high cutting speeds, precision, and automation capabilities. They feature advanced CNC control systems and are designed for heavy-duty industrial use (Amada).

- Presence in the USA: AMADA operates multiple facilities across the USA, including locations in Schaumburg, Illinois, and High Point, North Carolina, providing extensive customer support and training services.

4. TRUMPF

- Overview: TRUMPF is a globally recognized name in laser technology, offering a range of fiber laser cutting machines known for their compact design and high efficiency.

- Key Features: TRUMPF machines feature excellent beam quality, flexible control options, and long service life. They are suitable for a wide range of applications, from automotive to aerospace industries (TRUMPF the solutions provider).

- Presence in the USA: TRUMPF has a strong presence in the USA, with facilities that offer sales, service, and technical support to ensure customers get the most out of their machines.

5. MC Machinery Systems

- Overview: MC Machinery Systems, a subsidiary of Mitsubishi Corporation, provides high-power and high-speed fiber laser cutting machines. The company is well-regarded for its robust engineering and customer service.

- Key Features: Their machines are designed to handle tough materials and thick cuts with precision and speed. They are equipped with advanced automation features and reliable CNC systems (Thomasnet).

- Presence in the USA: Based in Elk Grove Village, Illinois, MC Machinery Systems supports customers with comprehensive service and maintenance programs.

These manufacturers represent the forefront of fiber laser cutting technology in the USA, offering machines that cater to diverse industrial needs. Their commitment to innovation, quality, and customer support makes them leaders in the market, driving advancements in precision manufacturing and efficiency.

Comparison of Leading Manufactures

Here's a comparison of leading fiber laser cutting machine manufacturers in the USA presented in a table format:

| Manufacturer | Key Features | Product Range | Presence in the USA | Industries Served |

| Bodor Laser | High precision, automatic loading/unloading, high-power laser sources, user-friendly interfaces | Wide range of fiber laser cutting machines | Subsidiary in Chicago, Illinois | Automotive, aerospace, metal fabrication |

| HSG Laser | Affordable, high performance, energy efficient, versatile in cutting different materials | Comprehensive lineup for small to large operations | Facility in Casa Grande, Arizona | General manufacturing, custom fabrication |

| AMADA America | High cutting speeds, precision, advanced CNC systems, heavy-duty design, automation capabilities | VENTIS, REGIUS series | Facilities in Schaumburg, Illinois and High Point, North Carolina | Automotive, aerospace, medical devices |

| TRUMPF | Compact design, high efficiency, excellent beam quality, flexible control options, long service life | Various fiber laser models | Strong presence with multiple facilities | Automotive, aerospace, electronics |

| MC Machinery Systems | High-power and high-speed cutting, reliable CNC systems, advanced automation features, robust engineering | Range includes high-power models | Based in Elk Grove Village, Illinois | Aerospace, automotive, heavy industry |

Fiber Laser Cutting Machine Price In USA

When considering the price of fiber laser cutting machines in the USA, several factors influence the cost, including the machine's power, brand, features, and intended use. Here’s an overview of the price ranges for these machines based on recent data:

- Entry-Level Fiber Laser Cutting Machines:

- These machines are typically geared towards hobbyists and small businesses. The price for entry-level models starts at around $14,000 and can go up to approximately $32,000. They usually have lower power outputs, suitable for light-duty tasks and less demanding materials.

- Mid-Range Fiber Laser Cutting Machines:

- Suitable for small to medium-sized businesses, these machines offer more power and advanced features. Prices in this category range from $32,000 to around $150,000. They can handle a broader range of materials and thicknesses, providing better precision and speed for more demanding applications.

- High-End Industrial Fiber Laser Cutting Machines:

- These machines are designed for heavy-duty industrial applications, capable of cutting thick and tough materials with high precision and speed. Prices for high-end models can start around $150,000 and go up to $1,000,000, depending on the power (up to 60kW) and additional features like automation and advanced software integration.

- Specific Examples:

- Boss Laser FC-6012 Elite: This machine, designed for more demanding metal cutting applications, offers a robust frame and power options ranging from 1kW to 2kW, with prices reflecting its enhanced capabilities and build quality.

- OMTech FC-105C: Featuring a 1.5kW IPG power source, this machine is marketed as a cost-effective solution for light metal fabrication, priced competitively within its class and including comprehensive support and warranty.

Future Trend of Fiber Laser Cutting Machine Technology

Fiber laser cutting technology is reshaping the landscape of metal cutting, heralding a new era of precision and efficiency. In the USA, the surge in demand for CNC fiber laser cutting machines underscores their transformative potential across industries. These cutting-edge machines offer unparalleled accuracy and versatility, making them the preferred choice for a wide array of manufacturing needs.

The burgeoning popularity of fiber lasers has spurred remarkable innovations in the American market. Today, there exists a multitude of fiber laser cutting machine options tailored to meet diverse manufacturing demands. From enhanced productivity to superior cutting precision, these machines are revolutionizing metal fabrication processes nationwide.

1. Advancements in Fiber Laser Cutting Technology

As the demand for fiber laser cutting machines in the USA continues to rise, the future of laser cutting technology is poised for significant breakthroughs. One key area of development is the improvement of power and energy efficiency. Future systems are expected to deliver higher power levels while maintaining or enhancing energy efficiency, enabling faster and more precise cutting of thicker materials. This enhancement will expand the range of applications for fiber laser cutting machines across various industries.

2. Integration of Artificial Intelligence for Enhanced Precision

The fusion of laser cutting technology with artificial intelligence (AI) marks a revolutionary trend in the industry. AI-driven systems optimize cutting parameters, predict maintenance needs, and adapt to changing workpieces in real-time. In the USA, this integration ensures maximum efficiency and accuracy, while machine learning algorithms predict and prevent problems, minimizing downtime and waste. This integration of AI is set to redefine the capabilities of fiber laser cutting machines, making them indispensable assets in modern manufacturing processes.

3. Diversification and Adaptation for Future Challenges

In the dynamic landscape of laser cutting technology, diversification and adaptation are key to meeting future challenges. Emerging trends such as hybrid laser cutting, quantum laser cutting, and augmented reality (AR) assistance are reshaping the industry. Hybrid systems combine laser cutting with other processing methods for greater versatility, while quantum technology promises unparalleled precision. AR assistance enhances operator accuracy, simplifying complex cutting tasks. Furthermore, the integration of laser cutting with additive manufacturing and the enhancement of connectivity and network security underline the industry's commitment to innovation and sustainability. These advancements position fiber laser cutting machines as indispensable tools in driving forward the future of manufacturing in the USA and beyond.

Fiber Laser Cutting Machines in USA vs. China

When comparing fiber laser cutting machines in the USA and China, several factors come into play, including technology, quality, pricing, and support services. Here's a breakdown of the comparison:

1. Technology and Innovation

USA: The USA is known for its advanced technology and innovation in manufacturing. Fiber laser cutting machines produced in the USA often incorporate cutting-edge advancements in laser technology, automation, and software integration.

China: China has made significant strides in the development of fiber laser cutting technology. Chinese manufacturers produce a wide range of machines, from entry-level to high-end models, incorporating both domestic and imported components.

2. Quality and Precision

USA: Fiber laser cutting machines manufactured in the USA are renowned for their high quality, precision, and reliability. Rigorous quality control measures ensure consistent performance and accuracy, making them preferred choices for precision manufacturing applications.

China: Chinese fiber laser cutting machines vary in quality depending on the manufacturer. While some Chinese brands offer competitive quality and precision comparable to international standards, others may have inconsistent quality control and reliability issues.

3. Pricing

USA: Fiber laser cutting machines from US manufacturers typically come with higher price tags due to factors such as labor costs, quality standards, and technology innovation. However, they often justify the higher cost with superior performance and reliability.

China: Chinese fiber laser cutting machines are generally more affordable compared to their US counterparts. Lower labor and manufacturing costs contribute to competitive pricing, making them attractive options for budget-conscious buyers.

4. Support and Service

USA: US-based manufacturers provide comprehensive support and service networks, including technical assistance, training, and spare parts availability. This ensures timely support and maintenance, minimizing downtime and optimizing machine uptime.

China: Chinese manufacturers may offer varying levels of support and service, depending on the brand and distributor. While some companies provide robust support networks, others may have limited service capabilities, especially for international customers.

Both the USA and China offer a wide range of fiber laser cutting machines catering to different market segments. US machines are known for their advanced technology, quality, and reliability but come with higher price tags. On the other hand, Chinese machines are more affordable but may vary in quality and support. Ultimately, the choice between a US or Chinese fiber laser cutting machine depends on specific requirements, budget considerations, and the importance of factors such as technology innovation and after-sales support.

How To Choose A Fiber Laser Cutting Machine in USA

Choosing the right fiber laser cutting machine in the USA requires careful consideration of various factors to ensure it meets your specific needs and provides optimal performance. Here's a step-by-step guide:

1. Define Your Requirements:

- Determine your cutting requirements, including material type, thickness, and desired cutting speed.

- Consider any specific features or capabilities you need, such as automatic focusing, integrated cooling systems, or advanced motion control.

2. Research Available Options:

- Explore different manufacturers and models available in the USA market. Consider factors such as reputation, reviews, and customer feedback.

- Look for manufacturers with a strong track record of producing high-quality fiber laser cutting machines and providing reliable customer support.

3. Evaluate Machine Specifications:

- Compare the specifications of different machines, including laser power, cutting area, cutting speed, and accuracy.

- Ensure that the machine's specifications align with your cutting requirements and production goals.

4. Consider Quality and Reliability:

- Prioritize machines known for their quality construction, durability, and reliability. Look for features such as robust frame designs, high-quality components, and advanced laser sources.

- Research the manufacturer's reputation for product quality, reliability, and customer satisfaction.

5. Assess After-Sales Support:

- Evaluate the manufacturer's after-sales support and service offerings. Consider factors such as technical assistance, training, spare parts availability, and warranty coverage.

- Choose a manufacturer with a strong support network in the USA, ensuring timely assistance and maintenance when needed.

6. Request Demonstrations and Samples:

- If possible, request demonstrations or samples from potential suppliers to evaluate the machine's performance firsthand.

- Test the machine's cutting quality, speed, and accuracy to ensure it meets your expectations and requirements.

7. Consider Total Cost of Ownership:

- Take into account the total cost of ownership, including initial purchase price, operating costs, maintenance expenses, and potential downtime.

- Balance upfront costs with long-term benefits and consider the machine's return on investment (ROI) over its lifespan.

8. Seek Recommendations and References:

- Consult with industry peers, colleagues, or experts for recommendations and references on reputable manufacturers and models.

- Learn from others' experiences and insights to make informed decisions.

9. Make a Decision and Purchase:

- Once you've thoroughly evaluated your options and considered all relevant factors, make a decision and proceed with purchasing the fiber laser cutting machine that best fits your needs and budget.

- Ensure clear communication with the manufacturer or supplier regarding delivery, installation, training, and ongoing support arrangements.

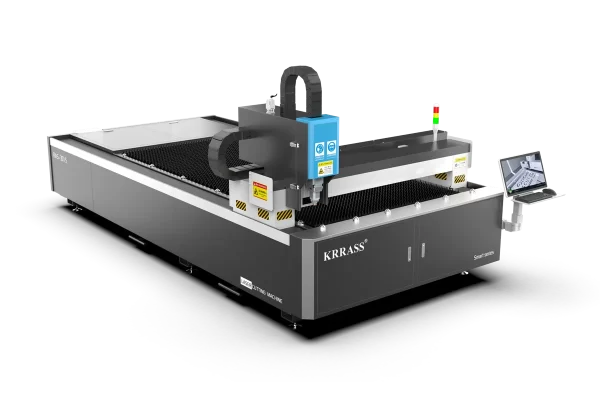

Fiber Laser Cutting Machine From Krrass

Krrass is a renowned manufacturer of high-quality fiber laser cutting machines, offering a comprehensive range of solutions tailored to meet diverse metal fabrication needs. With a commitment to innovation, precision, and reliability, Krrass has established itself as a trusted name in the industry.

Whether you're a small workshop or a large-scale manufacturing facility, Krrass offers a range of fiber laser cutting machines to suit your specific requirements and budget. With Krrass, you can expect cutting-edge technology, superior performance, and unmatched reliability to drive your metal fabrication operations to new heights.