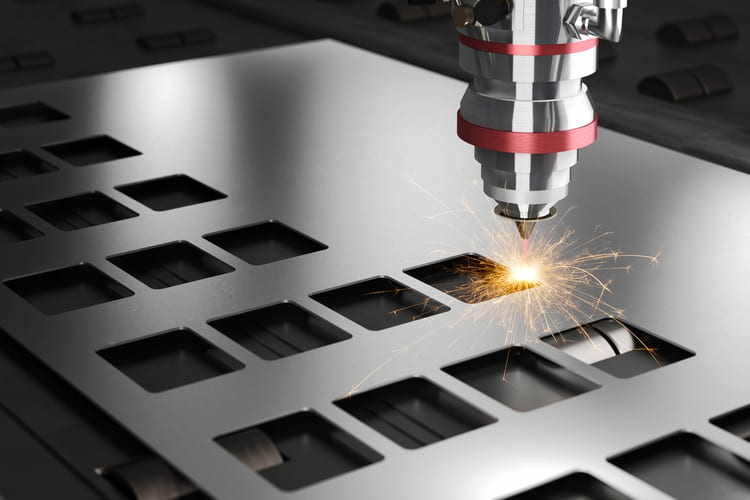

In the production of materials, in order to meet the production needs of products, the need to cut different materials into a certain size, so that they can be put into the next production process, so in these production and processing industries need to pay attention to the selection of cutting equipment, cutting equipment selection directly affects the quality of material processing, the selection of equipment products if not meet the prescribed standards will not be able to achieve the ideal application effect, so in recent years the demand for fiber laser cutters is constantly improving. Also let the application of optical fiber laser cutters for the development of the industry to provide more convenient conditions.

How to cut efficiency in fiber laser cutters:

- the use of common edge cutting layout: not only greatly reduce the trip of the fiber laser cutter, but also save cutting supplies, only use one perforation, on the completion of multiple parts of continuous cutting, improve production efficiency at the same time, greater saving material.

- the use of oxygen-assisted gas: the principle of fiber laser cutter is the use of high-energy laser beam will be sheet metal surface melting, to achieve the effect of cutting. If oxygen-assisted gas is used, the processing sheet metal oxidation can be increased to achieve a molten state, thus improving cutting efficiency.

- the use of parts of the bridge and continuous cutting programming mode: the programming method is more focused on improving cutting speed and cutting efficiency, this programming mode is the traditional cutting methodcant. Through the special computer software drawing, the cutting path of multiple parts is connected together, so that the fiber laser cutter in the work, only through the hole can complete the whole plate cutting.

The use of fiber laser cutters for material production and processing can also achieve higher stability, now the introduction of fiber laser cutter using advanced and reliable production technology, which not only makes the application of fiber laser cutter better, but also let the equipment in the processing of materials more stable, not vulnerable to environmental impact, but also can reach a higher production standards.

Now the function of fiber laser cutter is also more abundant, can provide more convenient conditions for the development of production work, so that the production work is more simple and convenient.

Because of its high precision, fast speed, high cost-effective and other significant characteristics, optical fiber laser cutter is more and more widely used in industrial production, compared with traditional cutting equipment, optical fiber laser cutter also has their incomparable cutting efficiency. Therefore, China's laser cutter continues to rise, laser cutting machine industry continues to be in a period of high-speed development, laser equipment has become an advantage of the industry.

Learn more about our products, please visit and subscribe to our Youtube channel