When investing in an electric press brake, understanding the electric press brake price is crucial for making an informed decision. Electric press brakes offer precision, efficiency, and energy savings, but their prices can vary widely based on several factors. Whether you're a small workshop or a large manufacturing facility, knowing what influences the cost of these machines can help you budget effectively and choose the best option for your needs.

Introduction

Brief Overview of Electric Press Brakes

Electric press brakes are advanced machines used in sheet metal fabrication to bend and shape metal with precision and efficiency. Unlike hydraulic press brakes, electric press brakes use electric motors for their operation, providing benefits such as energy efficiency, precise control, and lower maintenance requirements. They are highly regarded in the industry for their ability to deliver consistent, high-quality bends, making them a popular choice for various manufacturing applications.

Importance of Understanding Pricing

Understanding the electric press brake price is crucial for making an informed purchasing decision. The price of these machines can vary significantly based on factors such as size, tonnage capacity, technological features, and brand reputation. For businesses, especially small to medium-sized enterprises, making a substantial investment in an electric press brake requires careful consideration of the cost implications. By comprehending what influences the pricing, you can better assess your budget, evaluate the return on investment, and select a press brake that aligns with your specific production needs and financial constraints. This knowledge ensures you get the best value for your money, optimizing both performance and cost-efficiency in your operations.

Basic Undertanding Of Electric Press Brake

Before discussing the price of electric press brakes, let's have a basic understanding of this type of bending machine. As a typical category of bending machines, press brake machines becoming more and more popular?

What Is A Electric Press Brake

Electric press brakes, use an electric motor to generate the force needed to bend metal sheets into desired shapes. These press brake machines are more energy-efficient than hydraulic systems, making them a cost-effective option for those who are looking to reduce their energy costs. Electric press brakes are also much easier to control and operate than hydraulic systems, making them ideal for smaller metalworking shops or those who are just starting out in the metalworking industry.

Electric Press Brake: A Leap in Metal Fabrication Technology

The electric press brake marks a significant advancement in metal fabrication technology, distinguished by its innovative working principle compared to traditional press brakes. Grasping its operational mechanism is essential to appreciate its efficiency and precision.

Working Principle

At its core, an electric press brake operates using electrically powered components, diverging from the hydraulic systems of traditional press brakes. This fundamental shift results in a different mode of operation, emphasizing precision and control.

Key Components and Operation

Electric Servo Motors:

- The operation of an electric press brake begins with the electric servo motors, which control the movement of the ram. When a bending task is initiated, these motors precisely manage the downward movement of the ram to form the metal sheet. The control level provided by these motors is unmatched, ensuring highly accurate bends.

Backgauge System:

- Simultaneously, the backgauge system positions the metal sheet. Powered by electric motors, the backgauge moves the sheet to the exact required position for each bend. This precise positioning is crucial for achieving the desired bend angles and dimensions.

Synchronization and Control Systems:

- A crucial aspect of the electric press brake's working principle is the synchronization between the ram’s movement and the backgauge positioning. Advanced control systems facilitate this synchronization, ensuring that every bend is executed with precision and consistency.

Software Integration:

- The role of software in an electric press brake is pivotal. Modern electric press brakes are equipped with sophisticated software that allows for the programming of complex bending sequences, storage of job data, and real-time monitoring of operations. This integration of hardware and software results in a highly efficient, accurate, and user-friendly bending process.

What Are the Types of Electric Press Brake

- Servo-Electric Press Brake

- Electro-Hydraulic Press Brake

- Hybrid Press Brake

- Direct Drive Electric Press Brake

What Are the Applications of Electric Press Brake

- Automotive Industry

- Aerospace Sector

- Construction Industry

- Furniture Manufacturing

- Electronics Industry

- General Manufacturing

- Appliance Production

Advantages of Electric Press Brakes over Other Types of Press Brakes

Electric press brakes have revolutionized the metal fabrication industry with their advanced technology and efficient operation. Here’s a detailed look at the key advantages of electric press brakes over other types of press brakes, such as hydraulic and mechanical models:

1. Precision and Accuracy

- Electric Press Brakes: Electric press brakes utilize servo motors and advanced control systems to achieve precise control over the bending process. This results in highly accurate bends with minimal variation, which is crucial for applications requiring tight tolerances.

- Hydraulic Press Brakes: While hydraulic press brakes can also offer precision, they often depend on the consistency of hydraulic fluid, which can be affected by temperature and wear.

- Mechanical Press Brakes: These are generally less precise due to their reliance on mechanical linkages and less sophisticated control systems.

2. Energy Efficiency

- Electric Press Brakes: These machines are significantly more energy-efficient because they consume power only during the bending operation. This leads to lower energy costs and a smaller environmental footprint.

- Hydraulic Press Brakes: Hydraulic systems require continuous operation of hydraulic pumps, leading to higher energy consumption.

- Mechanical Press Brakes: Although mechanical presses can be efficient in certain high-speed applications, they generally lack the energy-saving benefits of electric systems.

3. Lower Maintenance Costs

- Electric Press Brakes: With fewer moving parts and no hydraulic fluid, electric press brakes require less maintenance. There’s no need for regular fluid changes or checks for leaks, reducing downtime and maintenance costs.

- Hydraulic Press Brakes: Maintenance is more intensive due to the need for regular inspection and replacement of hydraulic fluids and seals.

- Mechanical Press Brakes: These also require regular maintenance of mechanical components, which can wear out and need replacement over time.

4. Operational Speed and Flexibility

- Electric Press Brakes: They offer faster response times and quicker setup changes. The ability to store and recall multiple bending programs through CNC controls enhances their flexibility and efficiency in changing tasks quickly.

- Hydraulic Press Brakes: While they can handle large loads effectively, they typically have slower cycle times and longer setup durations.

- Mechanical Press Brakes: They can be very fast in specific repetitive tasks but lack the flexibility and ease of programming found in electric models.

5. Environmental Impact

- Electric Press Brakes: Their energy-efficient operation and lack of hydraulic fluids contribute to a lower environmental impact, making them a more sustainable choice.

- Hydraulic Press Brakes: Potential for hydraulic fluid leaks and higher energy consumption make them less environmentally friendly.

- Mechanical Press Brakes: They can be relatively efficient but still generate significant wear-and-tear waste and may not meet modern sustainability standards.

6. Consistency and Repeatability

- Electric Press Brakes: Advanced CNC systems ensure that each bend is performed consistently, providing excellent repeatability which is essential for high-volume production.

- Hydraulic Press Brakes: They can be consistent but may suffer from slight variations due to hydraulic fluid dynamics.

- Mechanical Press Brakes: These can be less consistent due to mechanical wear and tear over time.

7. Noise and Vibration

- Electric Press Brakes: Operate more quietly and with less vibration compared to hydraulic and mechanical press brakes, leading to a better working environment.

- Hydraulic Press Brakes: Typically generate more noise due to the hydraulic pumps and fluid dynamics.

- Mechanical Press Brakes: Can be quite noisy and prone to significant vibration during operation.

2024 Electric Press Brake Price Guide

Are you considering investing in an electric press brake but unsure about the costs involved? In this comprehensive guide, we'll explore everything you need to know about electric press brake pricing, factors affecting costs, and how to make an informed decision for your business.

Factors Affecting Electric Press Brake Prices

1. Size and Tonnage Capacity

- Size: Larger press brakes capable of handling bigger workpieces generally come at a higher price point due to their increased material and structural requirements.

- Tonnage Capacity: The tonnage capacity of the press brake, which indicates its bending force, directly affects the price. Higher tonnage capacities for bending thicker and tougher materials often result in higher costs.

2. Technology and Features

- CNC Controls: The sophistication of the CNC control system can significantly impact the price. Advanced controls offer features like multi-axis control, automatic bending sequences, and programming capabilities, which contribute to higher costs.

- Backgauge Systems: Press brakes with advanced backgauge systems, such as motorized or CNC-controlled backgauges, tend to be more expensive but offer precise positioning and automation capabilities.

- Safety Features: Enhanced safety features such as light curtains, safety mats, and interlocks may increase the price but ensure compliance with safety standards and regulations.

3. Brand and Manufacturer

- Reputation and Quality: Well-known brands with a reputation for quality and reliability often command higher prices. These brands may offer better build quality, customer support, and longer warranties.

- Innovations and R&D: Manufacturers investing in research and development to introduce new technologies and innovations may price their machines higher to reflect the added value.

4. Material and Build Quality

- Construction Materials: Press brakes constructed from high-quality materials such as heavy-duty steel are more durable and may have higher upfront costs.

- Precision Components: Machines equipped with precision components such as ball screws, linear guides, and high-quality bearings may have higher initial prices but offer better performance and accuracy.

5. Additional Considerations

- Accessories and Tooling: Additional accessories like specialized tooling, safety equipment, and software upgrades can add to the overall cost of the press brake.

- Installation and Training: Costs associated with installation, training, and setup should also be considered when budgeting for an electric press brake.

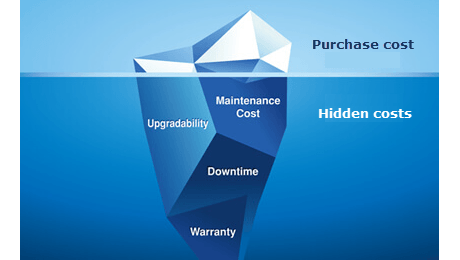

Cost Breakdown of Electric Press Brake Ownership

When considering the purchase of an electric press brake, it's essential to understand the various costs involved beyond just the initial purchase price. Here's a breakdown of the costs associated with owning an electric press brake:

1. Initial Purchase Price

- Machine Cost: The initial purchase price of the electric press brake itself is a significant factor. It includes the base cost of the machine and any standard features included.

- Optional Features: Additional features or upgrades such as advanced CNC controls, backgauge systems, safety features, and tooling may incur extra costs.

2. Installation Costs

- Shipping and Handling: Costs associated with transporting the press brake to your facility should be considered.

- Installation: Hiring technicians for machine installation, setup, and calibration is an additional expense.

- Electrical Requirements: If modifications or upgrades to electrical systems are needed to accommodate the press brake, there may be additional costs.

3. Operating Costs

- Electricity: The power consumption of the electric press brake during operation contributes to ongoing operating costs. Electric press brakes are generally more energy-efficient than hydraulic models but still consume electricity.

- Tooling and Consumables: Costs for tooling, such as punches and dies, as well as other consumables like lubricants and protective coatings, should be factored in.

- Maintenance: Regular maintenance to keep the press brake in optimal condition involves costs for inspections, lubrication, and potential repairs.

- Operator Labor: Labor costs associated with operating the machine should also be considered.

4. Long-term Investment

- Productivity and Efficiency: Consider how the electric press brake contributes to productivity and efficiency in your operation. Higher productivity may justify a higher initial investment.

- Reliability and Durability: Investing in a higher-quality press brake may result in lower long-term maintenance and repair costs, making it a more cost-effective option over time.

- Resale Value: Resale or trade-in value should be considered if you plan to upgrade or replace the machine in the future.

- Total Cost of Ownership (TCO): Assessing the TCO involves considering all costs over the machine's lifespan, including purchase price, operating costs, maintenance, and potential downtime.

Comparison of Electric Press Brake Price

1. Entry-Level Models

- Price Range: Entry-level electric press brakes typically range from $50,000 to $100,000, depending on size, features, and brand.

- Features:

- Basic CNC controls with limited programming capabilities.

- Manual or basic backgauge systems.

- Standard safety features.

- Suitable for small workshops or low-volume production.

- Build Quality:

- Basic construction with standard materials and components.

- Limited customization options.

- Applications:

- Ideal for small businesses or workshops with occasional bending needs.

- Suitable for simple bending tasks and low-volume production requirements.

2. Mid-Range Models

- Price Range: Mid-range electric press brakes typically range from $100,000 to $200,000, depending on size, features, and brand.

- Features:

- Advanced CNC controls with more programming capabilities and user-friendly interfaces.

- Motorized or CNC-controlled backgauge systems for precise positioning.

- Enhanced safety features such as light curtains or safety mats.

- Build Quality:

- Better construction quality with higher-grade materials and components.

- More customization options available.

- Applications:

- Suitable for medium-sized fabrication shops or manufacturers with moderate production requirements.

- Offers a balance between price and features for versatile bending tasks.

3. High-End Models

- Price Range: High-end electric press brakes can range from $200,000 to $500,000 or more, depending on size, features, and brand.

- Features:

- Advanced CNC controls with extensive programming capabilities, 3D simulation, and networking options.

- Fully automated backgauge systems with multi-axis control for complex bending sequences.

- Comprehensive safety features including laser safety systems and automatic tool changers.

- Build Quality:

- Top-of-the-line construction with premium materials and precision engineering.

- Highly customizable with advanced options for specific production needs.

- Applications:

- Suitable for large manufacturing facilities or high-volume production environments.

- Offers the highest level of precision, automation, and efficiency for demanding bending applications.

Tips for Budgeting and Purchasing an Electric Press Brake

1. Setting a Realistic Budget

- Assess Your Needs: Evaluate your production requirements, anticipated workload, and the features you need. Set a budget based on your requirements and available funds.

- Consider Total Cost of Ownership (TCO): Factor in not only the initial purchase price but also installation, operating costs, maintenance, and potential downtime over the machine's lifespan.

- Account for Additional Costs: Remember to include costs for accessories, tooling, installation, training, and ongoing maintenance in your budget.

2. Exploring Financing Options

- Equipment Financing: Research financing options such as equipment loans or leases offered by banks or specialized equipment financing companies. These can help spread out the cost over time.

- Manufacturer Financing Programs: Some manufacturers offer financing or leasing programs for their equipment, providing flexible payment options.

- Consider Tax Incentives: Explore potential tax incentives or deductions available for equipment purchases in your region, which can help reduce the overall cost.

3. Where to Buy

- Authorized Dealers: Purchase from authorized dealers or directly from the manufacturer to ensure quality, warranty coverage, and access to support services.

- Online Marketplaces: Consider reputable online marketplaces where new or used equipment is available. Ensure the seller has a good reputation and offers warranties or guarantees.

- Attend Trade Shows: Visit trade shows or industry events where you can see different models in person, discuss options with experts, and negotiate deals.

4. Negotiating Price

- Research Prices: Research prices from multiple suppliers to understand the market range for the equipment you need.

- Bundle Deals: Inquire about bundle deals or package discounts if you plan to purchase additional accessories or equipment along with the press brake.

- Ask About Discounts: Don't hesitate to ask for discounts, especially if you're purchasing multiple machines or during promotional periods.

- Consider Used Equipment: If your budget is tight, consider purchasing a certified pre-owned or used electric press brake, but ensure it's in good condition and comes with a warranty.

Recommended Electric Press Brake Manufacturers

When considering electric press brake manufacturers, it's essential to look for companies known for quality, innovation, and reliability. Here are some recommended manufacturers:

1. Amada

Amada is a leading global manufacturer of sheet metal processing equipment, including high-quality electric press brakes. Their products are known for precision, efficiency, and advanced technology.

2. Bystronic

Bystronic is a Swiss company known for its innovative solutions in the field of sheet metal processing. Their electric press brakes are renowned for their accuracy, energy efficiency, and user-friendly interfaces.

3. Trumpf

Trumpf, a German company, offers a range of advanced sheet metal fabrication equipment. Their electric press brakes are recognized for their robustness, precision, and advanced software integration.

4. LVD

LVD is a Belgian manufacturer that provides high-quality electric press brakes. They are known for their precision, reliability, and advanced control systems that enhance productivity and ease of use.

5. Salvagnini

Salvagnini, an Italian company, specializes in flexible automation and sheet metal processing solutions. Their electric press brakes are praised for their innovative design, efficiency, and adaptability.

6. Durma

Durma, based in Turkey, offers a wide range of sheet metal processing equipment. Their electric press brakes are known for their affordability, quality, and advanced technological features.

7. Cincinnati

Cincinnati Incorporated, a U.S. company, is a reputable manufacturer of metal fabrication equipment. Their electric press brakes are valued for their durability, precision, and advanced control systems.

8. Accurpress

Accurpress, based in Canada, provides a range of press brakes, including electric models. They are known for their reliability, user-friendly design, and robust construction.

9. SafanDarley

SafanDarley, a Dutch manufacturer, is recognized for its innovative electric press brakes that offer energy efficiency, precision, and ease of use with advanced control interfaces.

10. Krrass Machinery

Krrass, a Chinese company, specializes in sheet metal processing technology. Their electric press brakes are known for their cutting-edge technology, precision, and energy efficiency.

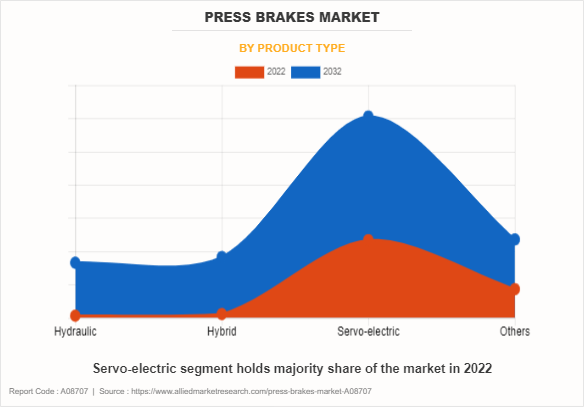

Electric Press Brake Price Trend

Which Regions Are Leading the Electric Press Brakes Market?

- North America (United States, Canada and Mexico)

- Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

- Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

- South America (Brazil, Argentina, Columbia etc.)

- Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

Current Price Trend Overview (2023-2024)

Steady Increase:

The prices of electric press brakes have been steadily increasing over recent years. This trend is largely attributed to rising material costs, inflation, and advancements in technology. Manufacturers are incorporating more sophisticated features into their machines, which enhances their capabilities but also drives up costs.

Post-Pandemic Adjustments:

The aftermath of the COVID-19 pandemic continues to affect the market. Disruptions in supply chains have led to increased costs for raw materials and components, which manufacturers are passing on to buyers. This adjustment period has contributed to the overall rise in prices.

Energy Efficiency and Automation:

There is a growing trend towards more energy-efficient and automated solutions in the industry. Companies are increasingly willing to invest in more expensive technology that promises long-term cost savings and improved efficiency. This shift towards sustainability and automation is a significant factor in the rising prices of electric press brakes.

Digitalization and Smart Manufacturing:

The integration of Industry 4.0 and smart manufacturing solutions is becoming more prevalent. These advancements, which include improved digital controls and connectivity, add significant value to the machines but also increase their cost. The push for digitalization is a driving force behind the upward price trend.

Geopolitical and Economic Factors:

Global geopolitical and economic conditions are also influencing prices. Tariffs, trade restrictions, and economic policies in major manufacturing regions such as the US, EU, and China have a considerable impact. These factors can lead to increased costs for manufacturers, which are then reflected in the prices of electric press brakes.

Future Price Trend Summary

- Short-Term Outlook: Prices may see a moderate increase due to the integration of advanced technologies, increased automation, and initial costs associated with energy efficiency and sustainability initiatives.

- Medium-Term Outlook: As these technologies become standardized and production processes are optimized, prices may stabilize. Competition and economies of scale may also contribute to more stable or slightly reduced prices.

- Long-Term Outlook: Long-term trends point towards potentially lower prices as technological advancements become more cost-effective, supply chains stabilize, and market competition drives efficiency. However, ongoing regulatory changes and economic factors will continue to play a significant role in determining the overall price trajectory.

Get Best Electric Press Brake Price at Krrass

Krrass electric press brakes are an excellent choice for manufacturers seeking efficient, precise, and eco-friendly bending solutions. With advanced control systems, robust build quality, and a focus on energy efficiency, these machines help enhance productivity while minimizing operational costs. For more detailed information and pricing, you can visit the Krrass official website or contact their sales team.