I. Introduction

In the modern industrial processing field where intelligent manufacturing is accelerating its upgrade, metal forming equipment is continuously evolving along the path of “mechanical bending machine , hydraulic press brake, electro-hydraulic servo bending machine”. Nowadays, Electric Press Brake has become a core and mainstream choice in the metal forming field. Its performance directly affects product accuracy, production efficiency and manufacturing costs, while its distinct feature of “low carbon and energy conservation” responds to the global green development trend. Currently, enterprises have put forward higher requirements for the accuracy, energy consumption control and process adaptability of equipment. Blind purchasing not only leads to resource waste but also may affect product quality due to the mismatch between equipment performance and production needs. Therefore, mastering a scientific and precise purchasing method, fully understanding the working principle of Electric Press Brake from its basic principles, confirming the key components of Electric Press Brake to better choose its configuration, and screening whether it fully meets the processing needs through the specific application scope of Electric Press Brake are all essential.

This guide will focus on the core points of Electric Press Brake purchasing, highlighting its advantages and limitations in detail, helping enterprises accurately lock in the ideal equipment that suits their production needs in the complex product market, and achieving the dual goals of efficient production and sustainable development.

II.The basic principle of the Electric Press Brake

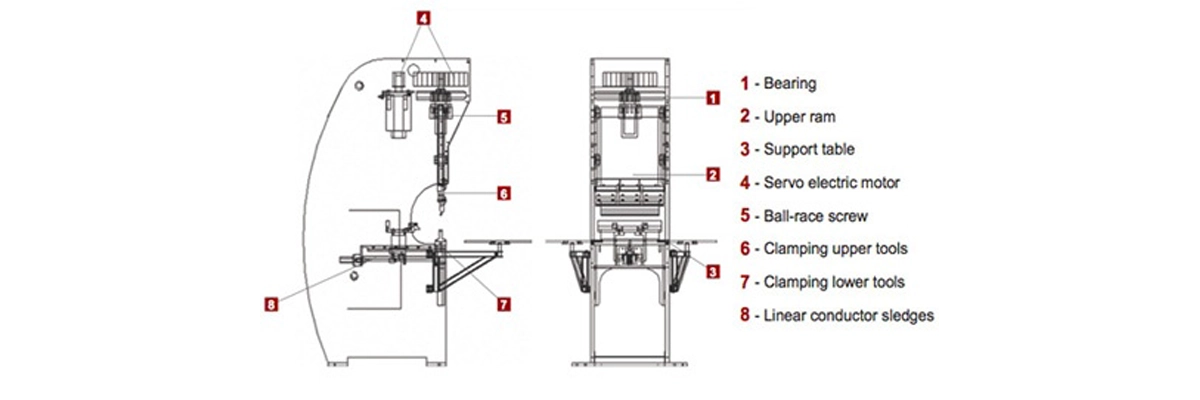

1.Definition: An Electric Press Brake is a metal sheet bending processing equipment that adopts fully electric drive and control technology. Its core feature is to replace the hydraulic components of traditional hydraulic bending machines (such as hydraulic pumps, cylinders, and hydraulic valve groups) with mechanical transmission components like servo motors, ball screws (or synchronous belts), etc., to achieve the motion control (including speed, position, and pressure) of the bending slider, thereby completing the plastic deformation (bending formation) of the metal sheet.

2.Working Principle: The numerical control system (CNC) sends electrical signals to precisely control the operation of the servo motor. The servo motor then drives the ball screw or gear rack, converting rotational motion into linear motion, which in turn drives the slider to move up and down, applying pressure to the sheet metal parts placed on the workbench, thereby achieving the bending processing.

3.Body Structure: The body is the main load-bearing component of the Electric Press Brake. It is usually constructed with an integral welding structure, and the materials commonly used are high-strength cast iron or steel. After welding, it undergoes aging treatment (such as natural aging or artificial aging) to eliminate internal stress, ensuring that the body does not deform under long-term high-intensity operation. The rigidity of the body directly affects the bending accuracy. Generally, the deflection should be controlled within ≤0.5mm/m, so as to provide a stable support platform for other components during the bending process.

4.Slider Component: The slider is the key component that drives the upper mold to move. Its structural design must ensure the smoothness and accuracy of the movement. The slider is connected to the body through a guide rail. The guide rails mostly use high-precision linear guides to reduce the friction resistance during the slider’s movement and improve the movement accuracy. Inside the slider, there are usually components connected to the transmission mechanism to convert the force and motion transmitted by the transmission mechanism into up-and-down reciprocating motion, thereby achieving the bending of the sheet material.

5.Workbench: The workbench is located at the lower part of the machine body and is used to place the lower die and the materials to be processed. The surface of the workbench has undergone precise processing to ensure the accuracy of the flatness, ensuring that the materials can be placed stably. Some workbenches also have deflection compensation function, which can be adjusted slightly through mechanical or hydraulic means to counteract the deflection caused by force during the bending process, thereby further improving the bending accuracy.

6.Transmission mechanism: The transmission mechanism is the core power transmission component of the Electric Press Brake. It is mainly composed of ball screws, synchronous belts or rack and pinion gears. Among them, ball screws are the most widely used. They consist of a screw and a nut. When the servo motor drives the screw to rotate, the nut will move linearly along the screw, thereby driving the slider to move up and down. Ball screws have the advantages of high transmission efficiency, high positioning accuracy, and good rigidity. They can ensure the accuracy and stability of the slider’s movement.

7.Die: The mold consists of an upper die and a lower die, and is the component that directly contacts the sheet material and realizes the bending forming process. The upper die is usually a convex die, and the lower die is a concave die. Their shapes are designed according to the bending requirements. The material of the mold needs to be selected based on the characteristics of the processing material. For example, high-speed steel molds are suitable for materials with high hardness such as stainless steel, while hard alloy molds are suitable for difficult-to-machine materials such as high-strength steel. At the same time, the precision of the mold is extremely high, and the general precision needs to reach ±0.01mm to ensure the dimensional accuracy and surface quality of the sheet material after bending,Learn more about Press Brake die.

III.The key components of the Electric Press Brake

The key components of the Electric Press Brake work together to jointly determine the bending force, accuracy, speed and stability of the Electric Press Brake. Among them, the servo drive system, transmission system, numerical control system, cooling system, detection device and safety protection device are the most technologically advanced core parts of the Electric Press Brake and also the main sources of performance differences in the equipment.

1.Control System

Core Function: As the “brain” of the Electric Press Brake, it is responsible for receiving the bending parameters input by the user (such as plate thickness, material, bending angle, speed, etc.), generating motion trajectories through built-in algorithms, and sending instructions to the servo drive system.

Key Function: Supports multi-axis coordinated control (such as slider, rear stopper, side pusher, etc.), ensuring the accuracy of the bending process. Integrates a bending process database, which can automatically match the bending parameters of different materials (such as compensation amount, pressure threshold), reducing the operational difficulty. It has real-time monitoring and fault diagnosis functions, which can display the equipment operation status (such as motor load, screw rod position), and give an alarm in case of abnormalities.

Main Brands: DELEM from the Netherlands, CYBELEC from Switzerland, and Chao Hong from Taiwan, etc. The computing speed and compatibility of their systems directly affect the response speed and processing accuracy of the equipment.Understand the controller of the press brake

2.Servo drive system

Core Function: Connects the numerical control system with the actuating components (servo motors), converting the digital instructions from the numerical control system into actual movements (rotational speed, torque) of the motors, serving as the “bridge” for power transmission.

Composition and Function: Includes a servo driver and a servo motor: The driver receives numerical control instructions and regulates the current and voltage of the motor; the servo motor (mostly permanent magnet synchronous motors) converts electrical energy into mechanical energy, providing power for the transmission system.

Supports Closed-loop Control: Through the built-in encoder of the motor, real-time feedback of rotational speed and position is provided, and the driver dynamically adjusts the output based on the feedback signal to ensure motion accuracy (such as rotational speed error ≤ 0.1%).

Fast Response Characteristics: During bending start-up, emergency stop, or speed change, torque adjustments can be completed within milliseconds, avoiding deformation or wrinkling of the sheet material due to impact.

Technical Requirements: Needs to match the tonnage requirements of the bending machine. For example, equipment of the 100-ton level usually is equipped with a servo motor group with a total power of 15-20kW to ensure stable output torque.

3.Transmission System (Screw)

Core Function: Converts the rotational motion of the servo motor into the linear motion of the slider, which is the key mechanical structure for transmitting power and achieving the output of bending pressure.

Main Types and Characteristics: Ball screw: The preferred choice for Electric Press Brake. It transmits force through the rolling friction between balls, screws, and nuts, with an efficiency of up to 90%-95% (much higher than the 30%-50% of ordinary screws), and has low wear and strong precision retention.

Structural Design: Usually adopts “symmetrical arrangement of two screws”, ensuring uniform force on the slider and avoiding workpiece skewing due to unilateral load during bending. The screw accuracy grades are mostly C3-C5 (positioning error ≤ 0.01mm/m), which directly affects the consistency of the bending angle.

Maintenance Points: Regularly add special lubricating grease (such as lithium-based lubricating grease) to prevent dust from entering the screw nut pair. Otherwise, it may cause jamming or a decrease in precision.

4.Cooling System

Core Function: To cool the heat generated during the operation of the equipment (mainly from the friction of servo motors, drivers and lead screws), preventing performance degradation or component damage due to overheating.

Cooling Methods and Applicable Scenarios:

Air Cooling: Forced ventilation of the heat dissipation plates of the motor and driver through cooling fans, suitable for small-tonnage (≤100 tons) and low-load operating equipment, with a simple structure and low cost.

Water Cooling: Heat is removed by circulating cooling water, with a cooling efficiency of 3-5 times that of air cooling. Suitable for large-tonnage (≥200 tons) or continuously high-intensity operating equipment, capable of keeping the motor temperature within 60°C (over 80°C may trigger overheating protection).

Additional Function: Some high-end models are equipped with temperature sensors to monitor the temperature of core components in real time, automatically adjusting the cooling intensity (such as fan speed, water flow rate), balancing the cooling effect and energy consumption.

5.Detection and Feedback Device

Core Function: Real-time collection of equipment operation status data (such as position, pressure, angle), feedback to the numerical control system, forming a closed-loop control to ensure bending accuracy.

Key Components:

Tachogenerator: Installed on the slider or worktable, with an accuracy of ±0.001mm, it provides real-time feedback on the slider position and serves as the “scale” to ensure positioning accuracy.

Pressure Sensor: Installed at the connection point of the screw rod or slider, monitoring the actual pressure during the bending process, avoiding overload (such as automatic shutdown when the material suddenly becomes harder).

Angle Sensor: Available in some models (such as laser angle meter), directly detecting the angle of the workpiece after bending, comparing with the target value and automatically compensating to further improve accuracy (angle error can be controlled within ±0.1°).

6.Safety protection device

Core function: Ensures the safety of operators and equipment, in line with industrial safety standards (such as EU CE, Chinese GB standards).

Safety light curtain: Installed on both sides of the workbench, forming an infrared protective net. When a human body (such as hands) enters the bending area, the equipment immediately stops operating, with a response time of ≤ 20ms.

Emergency stop button: Distributed at positions such as the operation console and the body, pressing it immediately cuts off the power source, ensuring rapid shutdown in emergency situations.

Guardrail and interlock device: A guardrail is set up in the sliding block movement area, and it is interlocked with the equipment operation (the equipment cannot start when the guardrail is open), preventing accidental contact.

Overload protection: The numerical control system continuously monitors the motor current and the pressure of the screw rod. When it exceeds the safety threshold, it automatically stops, preventing damage to mechanical components.

IV.The application of Electric Press Brake

The Electric Press Brake, with its advantages of high precision, high efficiency, low energy consumption and environmental friendliness, has been widely applied in various industries that require metal sheet bending processing. Its application scenarios cover both traditional manufacturing industries and emerging fields, as follows:

1.The sheet metal processing industry (core application field)

Sheet metal processing is the primary application scenario of Electric Press Brake, covering the bending and forming of various metal thin plates (with a thickness usually ranging from 0.1 to 16mm, and some large-tonnage models can handle even thicker plates).

General sheet metal parts: The shells and internal frames of distribution boxes and control cabinets (requiring multiple precise bends to ensure sealing and assembly accuracy), the evaporator shells of air conditioners / refrigerators, the metal frames of washing machines, etc.

Customized sheet metal parts: Special-shaped bent parts processed according to customer requirements, such as metal supports for medical devices, guide rails for industrial assembly lines, metal connectors for stage equipment, etc.

The high precision (bending angle error can be controlled within ±0.5°) and programmability of Electric Press Brake can meet the flexible production needs of “small batch, multiple varieties” for sheet metal parts, especially suitable for customized orders.

2.Automobile and component manufacturing

In the field of new energy vehicles: battery shells (mostly made of aluminum alloy or high-strength steel, requiring no burrs and high-precision bending to avoid leakage), motor housings, metal components of charging guns, etc. have extremely high requirements for bending accuracy and surface quality. The low-impact characteristic of Electric Press Brake can reduce plate deformation and surface scratches.

Traditional automotive parts: door frames, seat frames, dashboard brackets, etc. Some high-end models use lightweight materials (such as magnesium alloy), and the flexible pressure control of Electric Press Brake can avoid material cracking.

Automotive customization industry: customized body panels, guardrails, etc., require rapid switching of bending programs. The efficient mold changing and programming capabilities of Electric Press Brake can improve production efficiency.

3.Precision instruments and electronics industry

Instrumentation: The metal casings of precision equipment such as oscilloscopes and spectrometers need to be bent to ensure that the dimensional tolerance is within ±0.1mm, and the appearance should be smooth without deformation. The micron-level positioning accuracy of the Electric Press Brake can meet the requirements.

Electronic equipment: The metal frames of server cabinets and communication base stations, as well as internal structural components (such as circuit board fixing brackets), need to undergo multiple bends and ensure uniform assembly gaps for each component. The numerical control system of the Electric Press Brake can store multiple bending programs to achieve automated production.

4.Medical device manufacturing

Medical devices have strict requirements for the precision, cleanliness and stability of metal components. The application of Electric Press Brake includes:

Surgical instruments: Bending and forming of stainless steel surgical forceps and forceps (requiring symmetry and accuracy of opening and closing angles).

Medical equipment structural components: Metal protective shells of CT machines and nuclear magnetic resonance equipment, bed lifting frames, etc. Some use anti-radiation alloy materials. The precise pressure control of Electric Press Brake can prevent damage to material properties.

Rehabilitation equipment: Wheelchair frames, prosthetic connection pieces, etc. Need to balance strength and lightweight. Electric Press Brake can be adapted for bending processes of aluminum, titanium alloys, etc.

5.Aerospace and Rail Transportation

Aerospace: Metal decorative parts inside aircraft cabins, seat brackets, and drone fuselage frames (mostly made of titanium alloy or high-strength aluminum alloy), require no stress concentration after bending. The smooth drive of the Electric Press Brake can reduce internal damage to the materials.

Rail transportation: Interior metal parts of high-speed rail / subway (such as handrail brackets, luggage racks), and door sealing frames, need to ensure sealing and safety with other components after bending. The repetitive positioning accuracy of the Electric Press Brake (usually ≤ ±0.02mm) can meet the assembly requirements.

6.The construction and decoration industry

Building hardware: The frames of aluminum alloy doors and windows, and the main beams of curtain walls (which need to be bent into specific angles to fit the architectural design), can be processed by Electric Press Brake. This machine can handle long-sized plates (some models have worktables over 6 meters in length) and ensures extremely small straightness errors.

Metal decorative parts: The metal ceiling designs for shopping malls and hotels, as well as the bent parts for stair handrails, need to balance precision and aesthetics. The oil-free drive feature of Electric Press Brake can prevent oil contamination on the workpiece surface.

V. The Main Advantages and Limitations of the Electric Press Brake

1.Core Advantage:

Higher bending accuracy: Using servo motors for direct drive (or through precise ball screws, synchronous belts, etc. for transmission), combined with precision detection components such as grating scales, it can achieve micron-level position control. The bending angle error is usually ≤ ±0.1°, and the dimensional tolerance of the workpiece can be controlled within ±0.05mm, far superior to hydraulic presses (with a general error of ±0.5° or more). In the bending of the battery shell of new energy vehicles, it can avoid the problem of poor sealing caused by insufficient accuracy.

Precise repeat positioning: The servo system has a fast response speed (at the millisecond level), and there is no “creeping” or “lagging” phenomenon of the hydraulic system. The repeat positioning accuracy can reach ≤ ±0.02mm, ensuring the consistency of each batch of workpieces in mass production.

Flexible pressure control: By precisely adjusting the bending pressure through the numerical control system (with a minimum pressure adjustment unit of up to 1N), it can adapt to different thicknesses and materials of plates (such as aluminum, titanium alloys, etc., which are easily deformed), reducing the cracking of the workpiece due to overpressure or the rebound due to insufficient pressure.

Significantly reduced energy consumption: No need for continuous operation of hydraulic pumps, only consuming electrical energy during the bending action. The energy consumption is only 30%-50% of the hydraulic press of the same tonnage.

For a 100-ton model, working 8 hours a day, the annual electricity cost can be saved by tens of thousands of yuan.

Higher production efficiency: The travel speed (the rapid movement of the slider) is more than 50% faster than that of the hydraulic press (up to 150-200mm/s), and the change of molds and programming time is short (by one-click calling the stored bending program through the numerical control system), when producing small batches and multiple varieties, the overall efficiency can be increased by more than 30%.

Lower maintenance costs: There are no easy-to-damage parts such as hydraulic oil, sealing rings, etc., reducing the work of oil replacement and leakage repair. The annual maintenance cost is only 1/5-1/3 of the hydraulic press.

No pollutant emissions: No need for hydraulic oil, completely avoiding the pollution of the workshop caused by oil leakage and the oil contamination of the workpiece (especially suitable for medical, food machinery, etc., which have high cleanliness requirements), and no need to handle waste oil, in line with environmental protection regulations (such as EU RoHS, domestic “carbon neutrality” policies).

Low noise operation: The noise of the servo motor and mechanical transmission is usually ≤ 75 decibels, much lower than that of the hydraulic press (85-95 decibels), improving the working environment of the workshop and reducing the impact of noise pollution on workers’ health.

Operation is safer: There is no risk of burst of high-pressure hydraulic pipelines, and the numerical control system can integrate multiple safety protections (such as laser guards, emergency stop linkage), reducing the probability of work-related injuries.

Easy programming and debugging: Equipped with high-end numerical control systems (such as DELEM, Cybelec, etc.), supporting 3D simulation bending, automatic calculation of bending steps, operators can quickly program without complex experience. For irregular parts, they can be directly imported into the program, shortening the trial-and-error time.

Adapt to multi-variety production: It can store hundreds of sets of bending programs, and when changing production types, there is no need to adjust the mechanical parameters again, just a one-click switch, suitable for “small batch, multiple varieties” flexible manufacturing needs (such as custom sheet metal, precision instrument processing).

Easy integration of automation systems: Supports linkage with robots, automatic feeding machines, material storage, etc., forming an automated production line. For example: Through industrial Ethernet and MES system connection, realize real-time monitoring of production data, meeting the needs of intelligent manufacturing factories.

Summary: Advantage Comparison Table

| Comparison dimension | Electric Press Brake | Hydraulic Press Brake |

| Bending accuracy | ±0.1°or less, with micrometer-level positioning | ±0.5°or more, with millimeter-level positioning |

| Energy consumption | Low (30%-50% of hydraulic machine energy consumption) | High (continuous energy consumption of hydraulic pump) |

| Environmental friendliness | No oil pollution, low noise; | Oil leakage risk, high noise |

| Maintenance cost | Low (no hydraulic system wear) | High (requires regular oil replacement and repair of leaks) |

| Flexible production capacity | Strong (rapid programming, multiple program storage) | Weak (complex production changeover and debugging) |

2.Limitations

Although Electric Press Brake has significant advantages in terms of precision, efficiency and environmental protection, it still has some limitations due to its technical principles and current development level. These limitations mainly manifest in the following aspects:

Lower output capacity limit: Electric Press Brake relies on servo motors + ball screws (or synchronous belts) for transmission. Due to the limitations of motor power, screw strength and mechanical structure rigidity, the tonnage of mainstream models is mostly below 300 tons. For ultra-thick plates (such as high-strength steel plates with a thickness of more than 20mm) or large-sized workpieces (such as large steel structures longer than 6 meters), equipment of 500 tons or even thousand-ton level is required. At this time, the manufacturing cost of pure motor type will increase sharply (requiring multiple motor linkage and strengthening the structure), and the operational stability is not as good as hydraulic bending machines (the hydraulic system can output larger tonnage more uniformly through multi-cylinder linkage), as the bending speed slows down and the positioning accuracy decreases.

The energy-saving advantage decreases at higher tonnage: The energy consumption of Electric Press Brake with a tonnage of less than 100 tons is only 30%-50% of that of hydraulic machines. However, when the tonnage exceeds 300 tons, pure motor type requires multiple servo motors to work simultaneously, and the energy loss in mechanical transmission (such as screw friction) increases, reducing the energy-saving advantage to only be 10%-20% lower than that of hydraulic machines, and even approaching that of hydraulic machines during frequent full-load operation.

The low-temperature sensitivity of servo motors and lubricating grease: In low-temperature environments (such as below -10℃), the winding resistance of servo motors will increase, and the output power will decrease; at the same time, the viscosity of the lubricating grease of the ball screws increases, and the mechanical transmission resistance increases, resulting in slower bending speed and decreased positioning accuracy.

Hydraulic bending machines can maintain viscosity by heating the hydraulic oil, and have stronger adaptability in low-temperature environments (especially in outdoor or non-constant-temperature workshop scenarios).

VI.Operation, daily maintenance and common fault resolution of Electric Press Brake

1.Practical operation

(1) Parameter Settings (NC System Operation): First, input the sheet thickness, material type (the system has a built-in database that supports common materials such as Q235, 304 stainless steel), target bending angle, and bending length in the NC system interface. The system will automatically generate the initial bending depth (slider travel) and pressure value. Make minor adjustments based on experience: for example, stainless steel has high hardness, so the pressure can be appropriately increased by 10%-15%. For thin sheets (≤1mm), the bending speed needs to be reduced to avoid deformation. Set the clamping position: control the clamping shaft through the NC system to ensure that the edge of the sheet is in contact with the clamping device. The positioning accuracy can reach ±0.05mm. If it is batch processing, the parameters can be saved in the system and reused later when called, reducing the time for repeated settings.

(2) Test bending and accuracy calibration: During a single test bend, place the sheet material on the workbench, step on the foot pedal switch (or press the start button), and the equipment will complete one bending process according to the set parameters. Pay attention to whether the slider movement is smooth and if there are any abnormal noises. Use a caliper to measure the edge length of the workpiece after bending, and use an angle gauge to detect the bending angle. If there is an error (such as a larger angle), adjust it through the “angle compensation” function of the numerical control system: for example, an angle error of + 0.5° can increase the slider travel by 0.1-0.2mm (the specific value needs to be combined with the sheet thickness). For high-precision workpieces (such as an angle error of ≤ ±0.1°), repeat the test bend 2-3 times until the parameters are stable.

(3) Batch processing: After confirming that the trial folding is qualified, place the sheet materials one by one in the positioning area. Through a foot pedal switch or an automatic feeding device (for high-end models), continuous processing is carried out. During the processing, it is necessary to observe the area through the safety light curtain to avoid hands entering the bending range; if there is any sheet material deviation, immediately press the emergency stop button.

2.Daily Maintenance

The maintenance of Electric Press Brake is crucial for ensuring its accuracy and extending its service life. Through regular daily maintenance, the service life of Electric Press Brake can be extended to 8-10 years, and it can maintain a bending accuracy of ±0.1° for a long time, significantly reducing production downtime. Due to its core drive being a servo motor + screw rod transmission (without hydraulic system), the maintenance focus is significantly different from that of traditional hydraulic bending machines. Specific operations need to be carried out in accordance with the characteristics of the electric system. The following are the detailed key maintenance steps:

(1) Daily Maintenance: Basic Checks and Cleaning of Power Supply and Control System: Before starting the machine, check if the power cord and data cable connectors are loose to prevent poor contact and potential errors from the servo driver (such as “overcurrent” or “communication failure”). Clean the display screen and operation panel of the numerical control system to prevent oil and dust from entering the key gaps and affecting the operational sensitivity.

Transmission and Moving Components: Check if there are any metal debris or oil stains on the surfaces of the screw rod and guide rail. After wiping with a clean cotton cloth, apply the dedicated guide rail lubricant (such as ISO VG32 model) to ensure smooth movement (重点: the contact area between the screw nut and the guide rail slider). Observe the temperature of the servo motor during operation (use an infrared thermometer to detect, normal should be ≤ 60℃). If overheating occurs, check if the cooling fan is blocked.

Safety Devices: Test if the emergency stop button can immediately cut off the power supply, and if the safety curtain is triggered to stop the machine when it is blocked (use a piece of paper to block the edge of the curtain to verify).

(2) Weekly Maintenance: Precision Calibration and Component Tightening – Post-Stop Positioning Accuracy Calibration: Use a dial indicator to measure the actual position of the post-stop device within the 0-500mm travel range. If the error exceeds ±0.05mm, use the “axis compensation” function of the numerical control system to correct it (enter the system maintenance interface and input the deviation between the measured value and the theoretical value).

Parallelism Check of Slides: Place equal-height blocks (such as 100mm height) at the left, middle, and right points of the worktable. Use a feeler gauge to measure the gap when the slide descends to the equal-height blocks. Ensure that the difference in gap at the three points is ≤0.1mm. Otherwise, adjust the locking nuts at both ends of the screw rod.

Fastener Inspection: Tighten the mold installation bolts and the fixing screws for the screw rod support (it is recommended to use a torque wrench and tighten according to the torque values specified in the equipment manual, such as M12 bolts corresponding to 35-40N·m).

(3) Monthly Maintenance: Deep Cleaning and System Inspection – Servo System Maintenance: Check if the servo motor encoder cables are worn out, and whether the plugs are oxidized (a small amount of electronic cleaner can be sprayed for treatment). Prevent signal loss that may cause inaccurate positioning. Check the operation log on the servo driver panel and record abnormal alarm codes (such as “overload” “under-voltage”), and analyze whether frequent heavy-load processing has caused motor fatigue.

Screw Rod and Guide Rail Maintenance: If the equipment is used in an environment with a lot of dust, the anti-dust cover of the screw rod needs to be removed, and the screw rod should be rinsed with a special cleaning agent, and lithium-based lubricating grease should be re-added (the filling amount is 1/3 – 1/2 of the volume of the screw rod nut). Check if the guide rail protective cover is damaged, and if there are cracks, it should be replaced in time to avoid iron filings entering the guide rail and causing scratches.

NC System Backup: Back up the bending parameters, mold library, and compensation values saved in the system to a USB drive to prevent data loss caused by sudden system failures.

(4) Long-term Maintenance Notes Environmental Control: The Electric Press Brake has high requirements for the environment and should not be used in places with a humidity of over 85% or high dust concentration (a workshop dehumidifier and dust cover can be installed).

Load Management: Long-term processing beyond the specifications (such as plate thickness exceeding the equipment’s rated value by 20%) is prohibited. Otherwise, it will cause the screw rod to deform and the servo motor to overheat and age.

Professional Maintenance: For the repair of core components (such as servo drives and high-precision screw rods), it is recommended to contact the original equipment manufacturer or authorized service providers to avoid secondary damage caused by non-professional operations.

3.Common Fault Resolution (with Solutions)

(1)Precision anomaly type failure

| Fault phenomenon | Possible causes | Exclusion methods |

| Bending angle instability (fluctuation of more than±1°) | 1. Insufficient lubrication of the screw rod, uneven movement resistance; 2. Excessive thickness error of the sheet (more than±0.1mm); 3. Loose rear stop sensor. | 1. Clean the screw rod and add lubricating grease; 2. Select the sheet, re-measure the thickness and correct the compensation value; 3. Tighten the sensor bracket and calibrate the zero point. |

| Post-stop positioning deviation | 1. Loose servo motor belt (for some models); 2. Dirty Grating Ruler reading head. | 1. Adjust the belt tension (flexure controlled within 5-8mm); 2. Wipe the Grating Ruler surface with anhydrous alcohol. |

(2) Abnormal operation faults of the equipment

Sliding block operation is sluggish / there is abnormal noise: Check if there is any foreign object stuck in the screw rod (such as iron filings entangled), remove it and manually rotate the screw rod to confirm there is no obstruction; If the abnormal noise comes from the motor, it might be due to bearing wear, and you need to contact the manufacturer to replace the servo motor bearings (it is recommended to replace them every 20,000 hours).

Servo system alarm (such as “AL001 Overcurrent”): Immediately stop the machine and check if it is due to incorrect parameter settings (such as the bending pressure being far beyond the rated load of the motor); Measure whether the power supply voltage is stable (normal 380V ± 10%), low voltage may cause the driver to protect; If there are frequent alarms, check the insulation of the motor winding (use a multimeter to measure the insulation resistance, it should be ≥ 1MΩ), and eliminate the risk of short circuit.

(3) Faults in the safety and control systems

Safety curtain failure: Check if the curtain emitter and receiver are aligned (an optical calibrator can be used for assistance), clean the lens dust; if the cable is damaged, replace it with a dedicated shielded cable (to avoid electromagnetic interference).

NC system black screen / freeze: Check the output voltage of the power module (such as DC24V is stable), replace the damaged fuse; if the system still freezes after restarting, it may be a system program error, import the previously backed-up system image to restore.

VII. Summary

This article conducts a comprehensive analysis of Electric Press Brake, starting from the working principle of the fully electric drive and control technology. The article elaborates in detail on how the core key components (servo drive system, transmission system, numerical control system, cooling system, detection device and safety protection device) work together to achieve bending force, accuracy, speed and stability.

Electric Press Brake, as an innovative equipment in the field of sheet metal processing, has achieved remarkable advantages such as energy saving, high efficiency, environmental protection, high precision, low maintenance cost and intelligent and convenient operation. It has been widely applied in numerous industries including medical devices, automotive and component manufacturing, precision instruments, aerospace and others, and shows a promising market prospect. With continuous technological innovation and the continuous growth of market demand, Electric Press Brake will play a more important role in the future sheet metal processing industry, promoting the entire industry to develop to a higher level.

For enterprises, actively introducing Electric Press Brake not only helps to improve production efficiency and product quality, reduce operating costs, but also conforms to the environmental trend and enhances the competitiveness of the enterprise, seizing the initiative in the fierce market competition. Only by precisely matching the technology selection with the business can the unlimited potential of Electric Press Brake be exerted, achieving the dual goals of efficient production and sustainable development. To ensure that you make the right choice, you can contact us and our technical experts will provide you with guidance services throughout the process.The core of pure electric press brake selection is described in detail in the article on pure electric bending machine lead screw and motor.