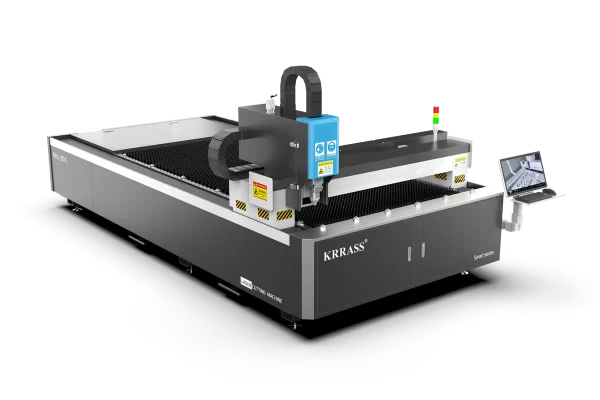

Fiber laser cutting machines have revolutionized the manufacturing and fabrication industries, offering precise and efficient cutting of various materials such as metal, plastic, and composites.

https://www.youtube.com/watch?v=BigPoBJBjhs&list=PLhHaChREghbI0XS8i7wMqDScjkmP__KH0However, like any sophisticated equipment, fiber laser cutting machines can encounter common issues that may affect their performance and productivity. In this article, we'll delve into several common faults of fiber laser cutting machines and provide practical solutions to optimize their operation and minimize downtime.

Beam Quality Degradation

Identifying Signs of Beam Quality Degradation:

- Poor cutting quality: Irregularities in cut edges, rough surfaces, or inconsistent cuts.

- Reduced cutting speed: Slower cutting speeds than usual to achieve the desired results.

- Unstable laser output: Fluctuations in laser power or beam intensity during operation.

Strategies to Address Beam Quality Degradation:

- Regular Maintenance: Implement a scheduled maintenance routine to clean optical components and inspect beam delivery systems for alignment issues.

- Laser Source Replacement: Consider replacing aging laser sources or upgrading to newer models to maintain optimal beam quality.

- Calibration and Adjustment: Regular maintenance and calibration are essential for sustaining cutting quality and machine longevity. Monitoring the condition of consumables such as nozzles, lenses, and filters, and replacing them when necessary, ensures consistent performance.

| Maintenance Task | Frequency | Impact on Efficiency |

| Nozzle Replacement | Every 500 hours | High |

| Lens Cleaning | Weekly | Medium |

| Filter Inspection | Monthly | Low |

Nozzle Clogging and Damage

Nozzle clogging and damage can significantly disrupt the cutting process and lead to poor cutting quality and increased downtime. These issues often arise due to the accumulation of debris, splatter, or wear on the nozzle components.

Recognizing Signs of Nozzle Clogging and Damage:

- Erratic cutting behavior: Inconsistent cutting patterns, intermittent pauses, or unexpected stops during operation.

- Excessive spatter: Increased spatter formation around the cutting area or nozzle.

- Reduced cutting efficiency: Longer cutting times or difficulty piercing through material due to nozzle obstructions.

Material Warping and Distortion

Material warping and distortion can occur during the cutting process, particularly when working with thin or heat-sensitive materials. This issue can result from excessive heat input, improper cutting parameters, or inadequate support structures.

Identifying Signs of Material Warping and Distortion:

- Bent or warped cut edges: Curvature or deformation along the edges of cut parts.

- Dimensional inaccuracies: Deviations from the intended dimensions or geometric shapes of cut parts.

- Surface irregularities: Uneven or wavy surfaces on cut parts due to material deformation.

Preventive Measures to Reduce Material Warping and Distortion:

- Optimal Cutting Parameters: Fine-tuning cutting parameters such as laser power, speed and frequency can significantly impact efficiency. By conducting experiments and analyzing data, operators can determine the ideal settings for different materials and thicknesses.

| Material | Power (%) | Speed (m/min) | Frequency (Hz) |

| Stainless Steel | 80-90 | 30-40 | 2000-3000 |

| Aluminum | 70-80 | 40-50 | 3000-4000 |

| Mild Steel | 90-100 | 20-30 | 1500-2000 |

| Brass | 80-90 | 15-25 | 2500-3500 |

- Material Preparation: Ensure that materials are properly secured and supported during cutting to prevent warping or shifting during the process.

| Material | Thickness Range (mm) | Speed (m/min) | Accuracy (mm) |

| Stainless Steel | 0.5 - 25 | 25 - 40 | ±0.05 |

| Aluminum | 0.5 - 12 | 30 - 50 | ±0.03 |

| Mild Steel | 0.5 - 25 | 20 - 35 | ±0.08 |

| Brass | 0.5 - 6 | 15 - 25 | ±0.05 |

- Cooling and Annealing: Implement post-cutting cooling or annealing processes for heat-sensitive materials to relieve internal stresses and minimize distortion.

Software and Control System Issues

Software and control system issues can hinder the operation of fiber laser cutting machines, leading to delays, errors, or malfunctions in cutting programs and machine control.

Signs of Software and Control System Issues:

- Program errors: Inaccurate or incomplete cutting paths, unexpected tool movements, or program crashes during cutting operations.

- Control interface glitches: Unresponsive controls, display errors, or communication failures between the control system and machine components.

- Inconsistent performance: Variability in cutting results or machine behavior across different cutting programs or operating conditions.

Strategies to Address Software and Control System Issues:

- Software Updates: Keep cutting software and control system firmware up-to-date with the latest patches and enhancements to ensure compatibility and stability.

- Operator Training: Provide comprehensive training to machine operators on software operation, programming, and troubleshooting procedures to address common issues.

- Technical Support: Establish a reliable technical support channel with software vendors and equipment manufacturers to seek assistance and guidance in resolving complex software-related issues.

Conclusion

By implementing efficient operational strategies and proactive maintenance practices provided by Krrass, manufacturers can optimize the performance and reliability of fiber laser cutting machines, ensuring smooth operation and high-quality cutting results. Krrass focuses on providing a full range of technical support and services, including scheduled maintenance, remote monitoring and fault diagnosis, to ensure that customers' equipment operates in optimal conditions. Their professional team can respond and solve any problems that may arise in a timely manner, maximizing the uptime and productivity of fiber laser cutting systems, thereby improving operational efficiency and profitability. Contact us today to learn more about our laser machines and how they can help you optimize your business operations. Let us help you choose the correct laser wattage to take your business to the next level.