The Delem DAC 360s controller provides a user-friendly and versatile solution for shearing machines. It controls back gauge axes, cutting angle, stroke length and gap and automatically calculates the required setting for the cutting angle and gap depending on material properties and thickness. 100 shearing programms of 25 cuts can be memorized in the Delem DAC 360s controller. The stroke length is optimized based on the required cutting length, increasing productivity. The back gauge control supports servo control, 2-speed AC control as well as inverter control. Depending on the application you can select either two-side positioning or single side positioning with spindle correction. The numerical programming is user-friendly and guides the operator through all programming possibilities.

Featuring

- Panel based housing

- Bright LCD screen

- Back/front gauge control

- Retract function

- Cutting angle and gap control

- Stroke length limitation

- Manual movement of axes

- Force control

- Sheet thickness measurement

- Automatique and manual mode

How to operate Delem DAC 360s controller

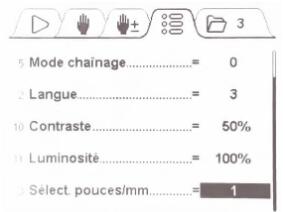

Set label:

- Brightness and contrast settings

- Choice of language and measurement system-1 / inch-2 / mm

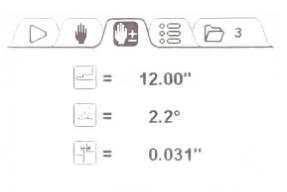

Manually locate the label:

- Position the back gauge

- Angle positioning

- Distance between positioning knives

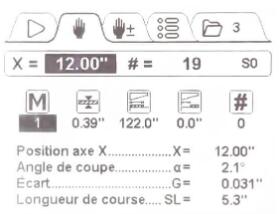

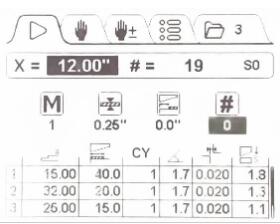

Manual mode:

- Cutting metal number-1 / steel-2 / aluminum-3 / stainless steel

- Metal thickness

- Cutting length (In order to obtain speed, the cutting will be done at the specified length instead of the length of the shearing machine)

- Space between swing arm and material

- Number of pieces

- Automatically calculate the cutting angle, distance and stroke length according to the specified parameters

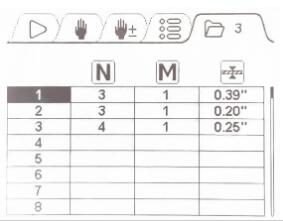

Automatic mode:

We find the same parameters as the manual mode, but can create a cutting sequence.

Each line represents a part, you point out the distance to be cut, the length of the cut and the number of repetitions of the line in the upper right corner, we can see the corresponding program number.

Program:

List of registered automatic programs, up to 100 programs can be registered.

- To create a new program, select a blank line and press "Enter".

- To edit the program, select the program line and press "Enter".

Learn more about our products, please visit and subscribe to our Youtube channel