How to solve the large bending angle error of CNC press brake? Let's take a look at the specifics with the editor below.

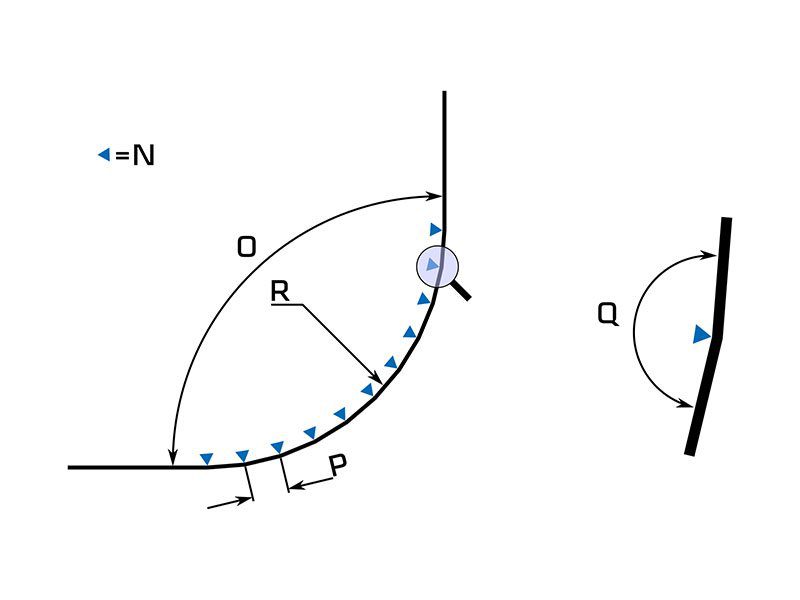

- Check whether the compensation deflection of the compensation cylinder of the bending machine is large, and the zero position cannot be completely restored

- Check whether the quick clamp of the press brake is loose

- Check whether the bottom dead center of the press brake changes every time you bend

- Check whether the bow plate installation of the press brake is standard, and whether the screw hole is dead

- Changes in the plate itself of the press brake (thickness, material, stress)

- Is the grating ruler of the CNC press brake loose?

- The positioning accuracy of the press brake is not accurate: whether the zero offset value of the proportional valve is appropriate, and the positioning cannot reach the bottom dead center so that it cannot return.

Learn more about our products, please visit and subscribe to our Youtube channel