Description

The CNC press brake uses the equipped mold (general or special mold) to bend the cold metal sheet into various geometric cross-sectional shapes. The bending machine generally uses a special CNC system, and the coordinate axis has been changed from a single axis,Developed to 12-axis, the numerical control system can automatically realize the sliding depth control, the left and right tilt adjustment of the sliding block, the front and back adjustment of the rear stopper, the left and right adjustment, the pressure tonnage adjustment and the slider approaching speed adjustment. The CNC bending machine can easily realize the actions of slide down, jog, continuous, pressure holding, return and halfway stop, and complete multiple bends of the same angle or different angles in one feeding.

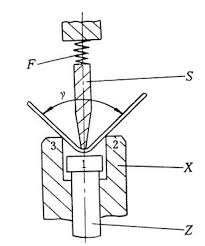

Working Principle

The CNC press brake machine mold includes a bracket, a workbench and a clamping plate. When in use, the coil is energized by the wire, and the pressure plate is gravitational after being energized, so as to realize the clamping of the thin plate between the pressure plate and the base. Due to the electromagnetic clamping, the pressing plate can be made into a variety of workpiece requirements, and the workpiece with side walls can be processed, and the operation is very simple.

Composition of NC press brake

Slider: It adopts hydraulic transmission. The slider part is composed of a slider, an oil cylinder and a mechanical stopper fine-tuning structure. The left and right oil cylinders are fixed on the frame, the piston (rod) drives the slider to move up and down through hydraulic pressure, and the mechanical stop is controlled by the numerical control system to adjust the value.

Workbench: Operated by the button box, the motor drives the stopper to move back and forth, and the distance of the movement is controlled by the numerical control system. The minimum reading is 0.01 mm (the front and rear positions have travel switch limits).

Synchronous system: Different from ordinary bending machines, this machine uses servo valves and grating rulers and other hydraulic devices to form a closed loop circuit to accurately control various actions of the bending machine.

Stopper mechanism: The stopper is driven by a motor, and the two screw rods are driven to move synchronously through a chain operation. The CNC system controls the size of the stopper.

Operation method of CNC bending machine

- First, turn on the power, turn on the switch on the control panel, and then start the oil pump, so that you can hear the rotating sound of the oil pump, but the machine does not perform any action at this time.

- The stroke adjustment, you must pay attention to the adjustment stroke when using, and be sure to test before bending. When the upper mold descends to the bottom, there must be a gap of plate thickness, otherwise it will cause damage to the mold machine, and the stroke adjustment is also electric quick adjustment.

- For the selection of bending notches, a notch with a width of 8 times the thickness of the plate is generally selected. If you bend a 4mm sheet, you need to choose a slot of about 32.

- Backgauge adjustment generally has electric quick adjustment and manual fine adjustment, the method is the same as the shearing machine.

- Step on the foot switch to start bending. The CNC bending machine mold is different from the shearing machine. It can be released at any time, and it will stop when you release the foot.

Precision of CNC bending machine

The repeatability of the slider of the CNC press brake is ±0.0004 inches, and the precise angle of forming must use such precision and a good mold. The repeatability of the slide block of the manual bending machine is ±0.002 inches, and the deviation of ±2~3° is generally generated under the condition of using a suitable mold. In addition, the CNC bending machine is ready for rapid mold assembly. When you need to bend many small batches of parts, this is an indisputable reason for consideration.

Learn more about our products, please visit and subscribe to our Youtube channel