Are you trying to find the best sheet metal bender for your small workshop in 2025? You have many good choices. Some are KRRASS, TruBend 7000, Amada HG-1003, Bystronic Xpert 150, Baileigh, and LVD Strippit PEB 5020. These machines are strong and bend metal well. They have smart controls and save energy. Here is how they compare:

| Model | Key Feature |

|---|---|

| KRRASS | Advanced CNC press brake, energy efficient |

| TruBend 7000 | Ergonomic, compact, fast setup |

| Amada HG-1003 | Precision, automation, robust performance |

| Bystronic Xpert 150 | Hybrid drive, optical tool detection |

| Baileigh | Space-saving, easy operation |

| LVD Strippit PEB 5020 | User-friendly, quality results |

You need the right sheet metal press brake for better work. It helps with safety and saves money. Think about your workshop size. Think about what metal you bend. Also, think about how much you can spend. More people want these machines now. The market was worth USD 988.1 million in 2024. It is expected to grow by 5.5% each year.

Table of Contents

Key Takeaways

- Think about your workshop’s size and shape before picking a sheet metal bender. Make sure the machine fits well and lets you move safely.

- Check what kind of metal you want to bend. Some presses work better with certain metals, so pick one that fits your needs.

- Try to find machines that use less energy. Machines like KRRASS can save up to 78% on power. This helps lower your costs.

- Put safety first. New presses have things like light curtains and emergency stop buttons. These keep you safe while you work.

- Think about machines that can work by themselves. CNC controls help save time and cut down on mistakes. They are good for jobs you do over and over.

- Look at the warranty and support you get. A strong warranty keeps your money safe. Good customer support helps you fix problems fast.

- Read what other users say about the machine. Reviews from other shop owners can help you choose the right one.

- Think about what you might need later. Pick a press that can add things like automation or energy-saving parts as your shop grows.

Sheet Metal Bender Basics

What Is a Sheet Metal Bender

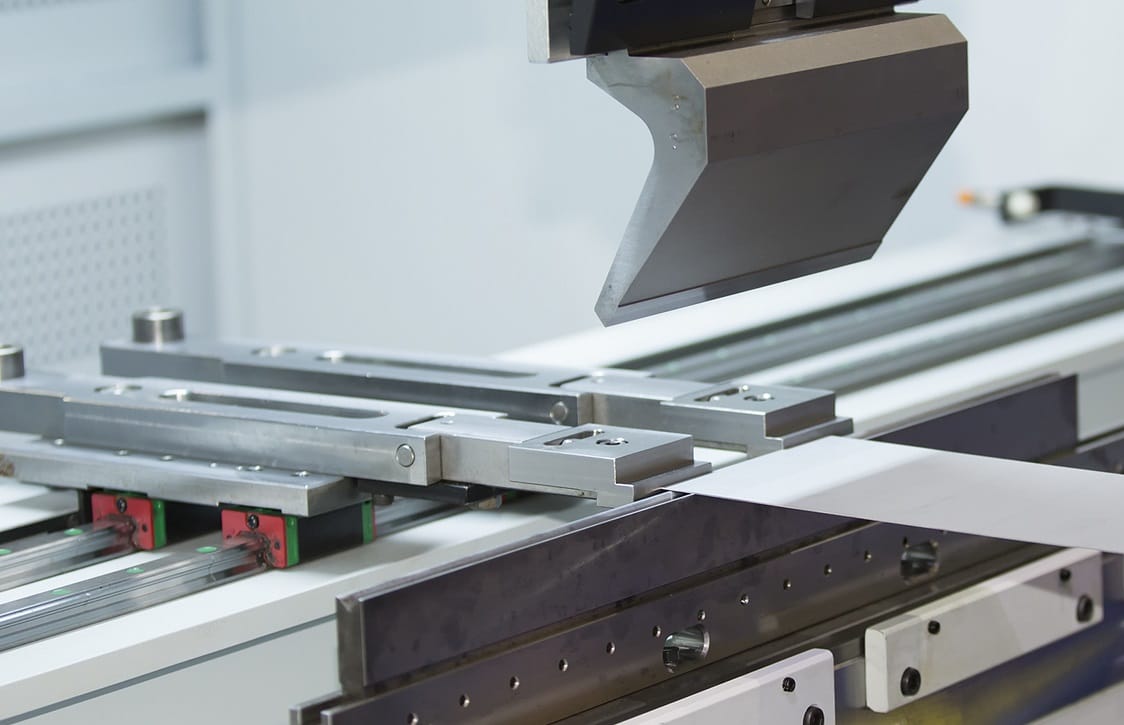

A sheet metal bender helps you shape metal sheets. People also call it a press brake. It is important for making metal parts. You put metal on the press. The machine pushes down hard using a hydraulic system. Hydraulic oil moves a piston. The piston bends the metal. You can change the angle and pressure. This lets you get the bend you want. That is why many shops need a sheet metal bender.

Types of Sheet Metal Benders

There are different machines for bending metal. Each one works best for certain jobs and has special features.

Manual

Manual presses use your hands to work. You pull a lever or turn a wheel to bend metal. These are good for small jobs or thin metal. They are simple and cost less. You need to use more effort with them.

Hydraulic

Hydraulic press brakes use liquid pressure for strong force. They bend thick or tough metal. These have more features than manual presses. You can adjust pressure and use safety systems. Many small workshops pick hydraulic press brakes. They do many jobs and last a long time.

Electric

Electric presses use motors instead of hydraulics. They are quiet and easy to take care of. You get exact bends and quick work. Some have energy-saving press brakes technology. This helps you use less power.

CNC

CNC press brakes use computer controls. You tell the machine what bends to make. These have advanced features like automatic angle adjustment. They remember jobs for later. CNC press brakes save time and lower mistakes. They are great for making many parts that look the same.

Why Small Workshops Need One

A sheet metal bender helps your workshop in many ways. Here are the main reasons:

| Reason | Description |

|---|---|

| Increased Production Efficiency | You make bends fast and finish more jobs. |

| Versatility | You bend many kinds of metal for projects. |

| Complex Bending Operations | You make detailed shapes and bends easily. |

| Safety | New machines have features to keep you safe. |

Tip: If you get a sheet metal bender, you can do more projects and help customers. You also stay safer and waste less material.

Hydraulic press brakes and CNC press brakes are very reliable. They help you do simple and hard bending jobs. If you want your business to grow, getting the right sheet metal bender is important.

Best Sheet Metal Benderes 2025

KRRASS Press Brake

Features

This machine works well in small workshops. It gives strong performance like big machines. KRRASS press brakes help you bend metal the same way every time. They work well and do not break down often. Safety is important, so there are light curtains and emergency stop buttons. The clamping system comes from Europe and helps you bend metal better. The control units are easy to use and make setup simple. You can pick from different models, like cnc press brakes or hydraulic press brakes. These machines use less energy and can save up to 78% on power. If you need help, there are service centers in many countries. KRRASS uses green technology. You save money and help the planet too.

Pros

- These press brakes work well for many jobs.

- They use less energy, so you pay less for power.

- You can choose cnc press brakes or hydraulic press brakes.

- Safety features help keep you safe at work.

- You get help fast if you need parts or service.

- The machines are made with good technology.

Cons

- Some features are hard for new users and need training.

TruBend 7000

Features

TruBend 7000 is great for small workshops. It is small and bends metal quickly. It does not take up much space. The On-Demand Drive only uses energy when you need it. The ACB laser checks your bends and helps you stay safe. You can add a gripper module to move parts faster and safer. You can set up jobs quickly. The design lets you work for a long time without getting tired.

Pros

- The machine is small and fits in tight spaces.

- You can set up and bend metal fast.

- The drive saves energy and lowers your bills.

- Safety features protect you while you work.

- Automation helps you finish more jobs.

Cons

- It cannot bend very thick metal.

Amada HG-1003

Features

Amada HG-1003 has lots of automation and is very accurate. It can do hard bending jobs easily. It has a robot with seven axes to load, bend, and unload metal. Other machines do not have as much automation. This machine sets up jobs three or four times faster than others. The tool changer works by itself and makes setup quick. Other machines need you to change tools by hand. Amada HG-1003 uses less energy, so you save money. It makes very exact bends and can adjust itself. Other machines are not as precise. You can do many jobs without stopping to change tools. The robot arm and tool changer keep you working.

Pros

- It does a lot of work by itself.

- Tool changes are fast and save time.

- It uses less energy, so you spend less money.

- Every bend is high quality.

- It can bend hard shapes and do the same job many times.

Cons

- It costs more than simple machines.

Bystronic Xpert 150

Features

The Bystronic Xpert 150 bends metal with a lot of power. It uses a hydraulic drive, so it works strong and fast. Adaptive bending technology helps you make each bend just right. You can check on the machine from far away. This means you can watch your jobs from anywhere. Here are the main features:

| Feature | Description |

|---|---|

| Hydraulic Drive | Gives you strong and efficient bending. |

| Adaptive Bending Technology | Lets you bend with high precision and flexibility. |

| Remote Monitoring | Helps you oversee and manage jobs from a distance. |

You can use this press for many types of work. The features help you get good results and keep your shop working well.

Pros

- It bends thick and thin metal with lots of power.

- Adaptive technology helps you make bends that are exact.

- You can watch your jobs from far away.

- The machine is good for tough press brakes jobs.

- It works for easy and hard bending tasks.

Cons

- You might need to learn more to use all the features.

- It costs more than simple hydraulic press brakes.

Baileigh Compact Press

Features

The Baileigh Compact Press fits in small places. Its small size is good for tight workshops. Even though it is small, it still works strong. You can use it for work or for fun projects. The controls are easy, so you can start bending fast. It is simple to take care of, which saves you time. These features make it easy to use and keep working.

The design lets you bend metal well without using much space. You can trust this press to work the same every time. It can help you with many different bending jobs.

Pros

- The small size is good for little workshops.

- The controls are simple for quick bending.

- You do not need much time for care.

- It works for many kinds of bending.

- You get good bends every time.

Cons

- It costs more than some basic presses.

- It may not have special cnc press brakes features.

LVD Strippit PEB 5020

Features

The LVD Strippit PEB 5020 bends metal quietly and smoothly. The electric servo drive keeps it quiet and steady. You can change tools fast with the quick-change mold system. This saves you time when you switch jobs. The advanced cnc press brakes controller saves your programs. You can find jobs fast and make bends that are right. The touchscreen is easy to use for setup and checking progress. Here are the main features:

| Feature | Description |

|---|---|

| Electric Servo Drive | Quiet and smooth bending operation. |

| Quick-Change Mold System | Fast tool changes for less downtime. |

| Advanced CNC Controller | Stores programs for easy access and accurate bends. |

| Touchscreen Interface | Simple job setup and progress monitoring. |

You can use this press for many jobs in your shop. The features help you make good bends and keep your work moving fast.

Pros

- It is quiet, so your shop is nicer to work in.

- You can change tools quickly and save time.

- The cnc press brakes controller helps you with jobs.

- The touchscreen makes setup easy.

- You get good and even bends every time.

Cons

- It may cost more than simple hydraulic press brakes.

- You might need to learn new controls for some features.

Press Brake Bending Machine Comparison

Comparison Table

You might want to know how each press brake bending machine compares. The table below shows the main sizes, power, and features for each model. This makes it easier to choose the best metal fabrication equipment for your shop.

| Model | Size (L x W x H) | Power Source | Max Bending Force | Features | Price Range |

|---|---|---|---|---|---|

| KRRASS Press Brake | 8′ x 3′ x 6′ | Electric/Hybrid | 80-150 tons | Smart automation, energy saving, global support | $$$ |

| TruBend 7000 | 7′ x 2.5′ x 6′ | Electric | 50-80 tons | Ergonomic, fast setup, ACB laser, automation | $$$ |

| Amada HG-1003 | 9′ x 3′ x 7′ | Hydraulic | 100 tons | Hydraulic crowning, auto tool changer, precision | $$$$$ |

| Bystronic Xpert 150 | 8.5′ x 3′ x 6.5′ | Hydraulic | 150 tons | Adaptive bending, remote monitoring, hybrid drive | $$$$$ |

| Baileigh Compact Press | 5′ x 2′ x 4′ | Electric | 40 tons | Space-saving, easy controls, reliable performance | $$ |

| LVD Strippit PEB 5020 | 7.5′ x 2.5′ x 6′ | Electric | 50 tons | Servo drive, quick-change mold, CNC controller | $$$ |

Tip: If you want more automation and to save energy, KRRASS is a good pick. TruBend 7000 and Baileigh Compact Press are great for fast setup and simple controls. Amada and Bystronic are best for advanced bending and high accuracy.

Quick Reference

You may wonder which press brake bending machine is right for you. Here is a short guide to help you choose:

- KRRASS Press Brake: This machine has smart automation and saves energy. It bends metal with accuracy. You also get help from support centers around the world.

- TruBend 7000: This model is small and sets up fast. The ACB laser system helps you get the right angle. Automation lets you finish jobs quickly.

- Amada HG-1003: This machine has hydraulic crowning and automatic tool changers. These features save you time and make your work better. It bends metal with high accuracy.

- Bystronic Xpert 150: This model has adaptive bending and remote monitoring. The hybrid drive gives strong performance. You can do hard jobs with this machine.

- Baileigh Compact Press: This press is good for small shops. It saves space and bends metal well. The controls are easy to use.

- LVD Strippit PEB 5020: This machine is quiet and uses a servo drive. You can change molds fast and use the CNC controller to work quicker. You get the same good results every time.

Note: Each press brake bending machine has special features. Think about your shop size, what kind of bending you do, and how much automation you want. If you care about quality and performance, these models are strong choices.

This comparison helps you find the best metal fabrication equipment for your needs. Picking the right machine helps you make better bends, save time, and get better results in your shop.

Choosing a Sheet Metal Bender

Space Needs

You want your workshop to feel open and safe. Before you pick a press brake bending machine, look at your space. Some presses take up more room than you think. Here are a few things to check:

- Footprint of the press: Measure the size of the machine and see if it fits in your workshop.

- Workbench capacity: Make sure your workbench can hold the weight and handle the vibrations from the press.

- Overall space available: Think about the total area you have. Leave enough room to move around the machine and work safely.

If you plan ahead, you will avoid problems later. You can keep your shop organized and easy to use.

Power & Capacity

You need a press that matches your bending jobs. If you pick a machine that is too weak, you will not get good results. If you pick one that is too strong, you might waste money and space. Here is how you can figure out what you need:

- Calculate the tonnage you need. Look at the thickest metal and longest bends you plan to make. Add a safety margin of 20-30% to make sure you have enough power.

- Think about the future. You might want to bend new materials or make bigger parts later. Choose a press with extra capacity for growth.

- Check the machine specs. Look at throat depth, daylight opening, stroke length, and control system. These details affect how fast and easy you can work.

When you match the power and capacity to your needs, you get better quality and save time.

Material Compatibility

You want your press to work with the materials you use most. Some presses handle small parts better than others. Ball-screw-driven electric presses give you high positioning accuracy and speed. This helps when you form small pieces. Even a small mistake can ruin a part. Fast acceleration and deceleration let you adjust quickly and keep your work moving. You get better quality and more control over your bending jobs.

Ball-screw-driven electric press brakes are particularly effective for small-piece forming due to their positioning accuracy and speed. The precision in positioning is crucial for small parts, as even slight overtravel can disrupt the forming process. Additionally, the rapid acceleration and deceleration of the ram allow for efficient processing of small materials, maintaining minimal open heights for quick adjustments.

If you know your materials, you can choose a press that gives you the best performance and quality.

Safety

You want to keep your workshop safe. Sheet metal benders can be dangerous if you do not follow safety steps. Here are some things you should always do:

- Wear protective gear like safety glasses, cut-resistant gloves, and steel-toe shoes.

- Use earplugs and a hard hat if your shop is noisy or if there is a risk of falling objects.

- Keep your work area clean and organized. A tidy space helps you avoid slips and falls.

- Make sure you have good lighting and clear emergency exits.

Modern presses come with built-in safety features. Look for these when you choose a machine:

- Light curtains stop the press if your hand or any object enters the danger zone.

- Two-hand controls make you use both hands to start the machine, keeping your hands away from moving parts.

- Emergency stop buttons let you shut down the machine fast if something goes wrong.

Tip: Always follow the safety rules from the machine’s manual. Never remove or change safety devices. These features protect you and everyone in your shop.

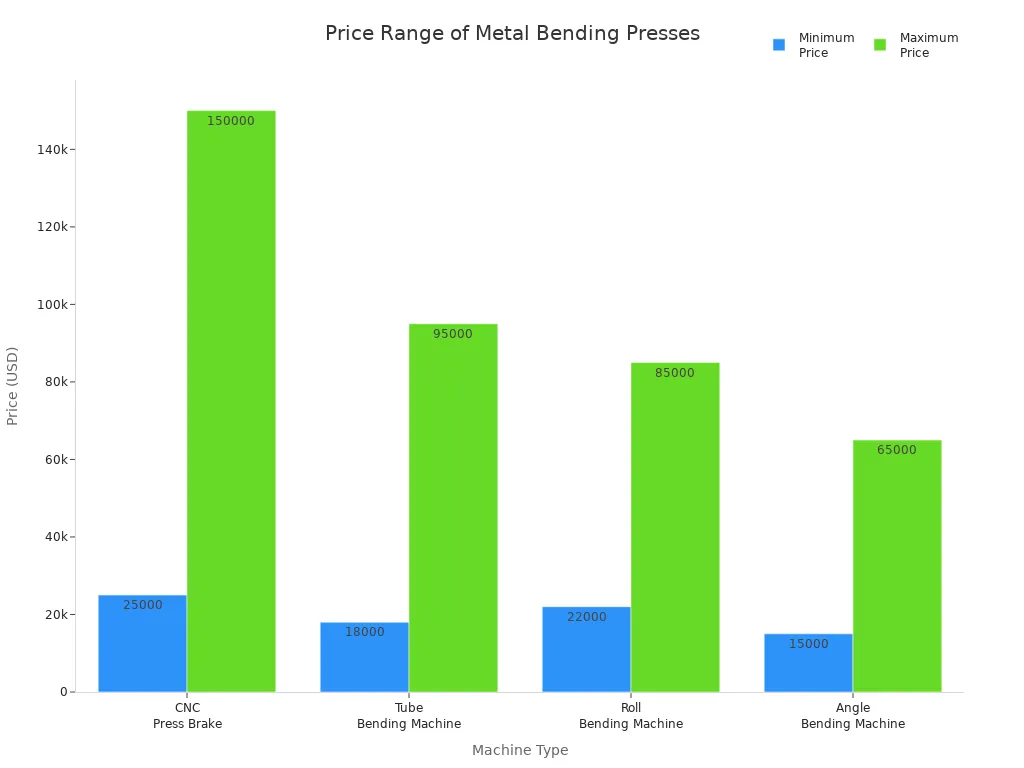

Budget

You need to plan your budget before you buy a sheet metal bender. Prices can change a lot depending on the type and features. Here is a table to help you see the typical price range for presses in 2025:

| Machine Type | Price Range ($) |

|---|---|

| CNC Press Brake | 25,000-150,000 |

| Tube Bending Machine | 18,000-95,000 |

| Roll Bending Machine | 22,000-85,000 |

| Angle Bending Machine | 15,000-65,000 |

Think about what you need now and what you might need later. A more expensive machine may save you money over time if it works faster or lasts longer. Set a budget that fits your shop and your goals.

Ease of Use

You want a press that is easy to use. Some machines need more training than others. For example, many small shops use Baileigh’s manual press. Workers learn to use it quickly and get good results. Simple controls help you start working right away. If you choose a machine that matches your skill level, you will spend less time learning and more time getting work done.

Note: Pick a press that fits your experience. Easy-to-use machines help you avoid mistakes and finish jobs faster.

Buying Factors

Brand & Support

The brand you pick is important when buying a press brake bending machine. A trusted brand makes you feel safe about your choice. You want a company that helps you if you have problems. Some brands have made strong machines for many years. They also help you if something breaks or if you have questions.

Here is a quick list of top brands and what they give you:

| Brand | Features |

|---|---|

| Amada | Cutting-edge technology, superior craftsmanship, advanced AMNC controls, precise hydraulics. |

| Trumpf | Advanced laser monitoring systems, consistent bend angles, high productivity. |

| LVD | EasyForm Laser, Touch-B interface, optimized setup times, enhanced bending quality. |

| Bystronic | Patented bending angle control system, exceptional accuracy for intricate shapes. |

| Prima Power | Wide range of capacities, advanced software, automation solutions for increased productivity. |

Check if the brand has a service center close to you. Fast help can save you time and money. Some brands teach you how to use the machine. This training helps you do better work. If you pick a famous brand, you often get better help and can find spare parts easily.

Tip: Choose a brand with good customer support and a strong reputation.

Warranty

A warranty keeps you safe if your machine breaks or does not work right. You should know what the warranty covers before you buy. Most companies have different warranties. Some cover parts, and some cover labor. You can also get a longer warranty for more protection.

Here is a table to show what is common:

| Warranty Type | Duration | Coverage | Exclusions |

|---|---|---|---|

| Parts Warranty | 5 years | Main hydraulic cylinder, drive components, motors | Damages from rigging, transportation, incorrect use |

| Labor Warranty | Limited | Onsite labor if troubleshooting is exhausted | Improper use or tampering |

| Extended Warranty | 7 years | Extended parts warranty | N/A |

Always read the warranty rules. Some things, like damage from moving the machine or using it wrong, are not covered. If you want extra safety, ask about a longer warranty.

User Reviews

User reviews show how a machine works in real shops. People who use these machines every day know what is good and what is not. You can learn a lot from their stories.

- Haas DT Series Press Brake gets good reviews for its price, reliability, and easy use. Many small shops like it because it works well.

- Accurpress is known for being strong and working well in tough jobs. Users say it is good for custom work too.

When you read reviews, look for comments about how strong the machine is, how good the support is, and if it is easy to use. This helps you pick a machine that fits your needs and gives you good quality.

Note: Always read reviews from people who have shops like yours. Their advice can help you avoid problems and make a smart choice.

Upgrade Options

When you buy a sheet metal bender, you want it to last. Your workshop might grow. Your jobs might change. You do not need to buy a new machine every time. Many presses let you add upgrades. These upgrades help your press do more work and keep up with new needs.

You can look at these common upgrade options:

- Energy-Efficient Presses

You can switch to energy-saving systems. Some presses let you add hybrid or electric drives. These upgrades use less power. You save money on your electric bill. You also help the environment. If you care about green technology, this upgrade makes sense. - Automation

You can add automation to your press. This means you can use robots or automatic feeders. These tools move metal for you. You finish jobs faster. You also make fewer mistakes. Automation helps you do more work with less effort. Some presses let you add these features later. You do not need to buy them right away. - Smart/Data Monitoring Technology

You can add smart controls to your press. These systems watch your machine. They tell you how much you bend, how long jobs take, and when you need to fix something. You see this data on a screen. You can use this information to plan your work. You also spot problems before they get big. Smart technology helps you run your shop better.

Tip: If you plan to grow your workshop, pick a press that lets you add upgrades. This way, your machine grows with you.

You might also want to look at other upgrades:

- Tooling Upgrades

You can buy new dies and punches. These tools let you bend new shapes. You can take on more jobs. - Safety Features

You can add light curtains or guards. These upgrades keep you safe. You work with more confidence. - Software Updates

Some presses let you update the software. New software can make your press faster or easier to use.

You do not need to buy all upgrades at once. Start with what you need now. Add more as your shop grows. This way, you spend money only when you need to. Your press stays useful for many years.

Note: Always check if your press supports upgrades before you buy. Some machines work better with upgrades than others.

Choosing the right upgrade options helps you get more from your press. You work faster, save money, and keep your shop ready for new jobs.

You need a good sheet metal bender for your shop. The machine should fit your space and budget. It must also handle the jobs you do. The table below shows what to think about when picking a press:

| Factor | Description |

|---|---|

| Accuracy and Repeatability | Choose controls that help you make the same bend each time. |

| Functions and Modes | Make sure the machine can do the bends you need. |

| User Interface | Pick a simple screen so you can learn quickly. |

| Programming Functions | Look for both manual and automatic ways to set up jobs. |

| Automation Functions | Find features that help you finish work faster. |

| Diagnosis and Maintenance | Pick a system that checks itself so you have less downtime. |

| Upgradeability | Choose a press that lets you add new tech in the future. |

You can talk to companies or go to showrooms to see presses. Try the controls and ask questions before you buy.

FAQ

What is a press brake?

A press brake bends sheet metal. You place the metal on the machine. The press pushes down and shapes the metal. You can make many shapes with it.

How do I choose the right press brake for my shop?

First, measure your space. Next, check what metal you use most. Look at the power you need. Think about your budget. Pick a machine that matches your jobs.

Can I use a press brake for different metals?

Yes, you can bend steel, aluminum, and copper. Always check the machine’s specs. Some presses work better with certain metals.

Do I need special training to use a press brake?

You should learn how to use the controls and safety features. Many brands offer training. Always read the manual before you start.

How often should I maintain my press brake?

Check your machine every week. Clean it and look for worn parts. Oil moving parts as needed. Regular care keeps your press working well.

What safety gear should I wear when using a press brake?

Wear safety glasses, gloves, and steel-toe shoes. Use earplugs if it is loud. Always follow safety rules in your shop.

Can I upgrade my press brake later?

Many presses let you add new tools or features. You can add automation, safety devices, or software updates. Check with your brand for upgrade options.

How long does a press brake last?

With good care, a press brake can last many years. Clean it, check for damage, and fix problems quickly. This helps your machine work longer.