You use the bending process to shape sheet metal. This helps make parts for manufacturing. Bending helps you build strong and useful parts. These parts are used in cars, buildings, and electronics. CNC press brake machines have changed how you work. They make jobs faster and more exact. You can see output go up by 30%. Accuracy can get better by 20%. KRRASS is a leader in new ideas. They help you handle hard jobs with advanced press brake solutions.

| Impact Area | Improvement Percentage |

|---|---|

| Output Increase | Up to 30% |

| Precision Enhancement | Up to 20% |

Table of Contents

Key Takeaways

- Bending changes flat metal into parts for cars, buildings, and electronics.

- CNC press brake machines can make more parts, up to 30% more, and make them 20% more accurate.

- It is important to know about bend radius, how the material acts, and springback for good bending.

- There are different ways to bend, like V-bending and rotary bending, and each way helps with different projects.

- Quality control is very important. Using sensors and checking often makes sure every part is good.

- Picking the right material, like aluminum or copper, can make bending easier and the final part better.

- Manual bending works well for small jobs. CNC bending is better for making lots of parts or hard shapes.

- KRRASS machines have special features that save time, cut down on waste, and make results better.

Bending Process Overview

What Is Bending?

You use the bending process to change flat sheet metal into shapes you need for many products. You push or press the metal so it bends at a certain angle. This step is important in sheet metal fabrication. You can make strong parts for cars, buildings, and electronics. When you use advanced machines like KRRASS CNC press brakes, you get better precision and faster results. You see how a simple metal sheet becomes a useful part. You control the shape and size by choosing the right tools and settings.

Key Principles

You need to understand some basic rules when you work with sheet metal bending. These rules help you get the best results and avoid mistakes. Here are the main principles:

- Bend radius matters. If you make the bend too tight, the metal can break.

- Material behavior changes during bending. You must know how strong the metal is and how it stretches.

- Springback happens after you bend the metal. The metal tries to go back to its old shape. You must adjust your process to fix this.

- Bend allowance affects the final size. You need to measure and plan so your part fits right.

You use different techniques for sheet metal bending. Each method has its own benefits and challenges. The table below shows some common techniques and what you should think about:

| Bending Technique | Description | Key Considerations |

|---|---|---|

| V-bending | You press the metal between a punch and a V-shaped die to make a V shape. | Match the inside bend radius to the sheet thickness to stop cracks. |

| U-bending | You use a U-shaped die to form a U shape, often with a hydraulic press. | Use precise tools and check the curl radius. |

| Coining | You use high force to make sharp bends by going past the metal’s yield strength. | This method uses more energy and is less flexible. |

| Rotary Bending | You use rotating dies to bend metal for steady patterns. | This method is not good for tight bends and may need more setup time. |

| Air Bending | You float the sheet above the die and bend only at the contact point. | This method adapts well but is less precise because of springback. |

You can choose the best method for your job. KRRASS machines help you control these principles with advanced features. You get accurate bends and save time.

Industrial Applications

You see sheet metal bending in many industries. You use it to make parts that must be strong and fit well. Here are some common applications:

| Sector | Applications |

|---|---|

| Automotive | Frames, exhaust systems, protective structures |

| Aerospace | Airframe parts, wing ribs, internal bracing |

| Construction | Beams, columns, custom facade elements |

| Consumer Electronics | Electronics enclosures, computer chassis, appliance frames |

| Telecommunications | Antenna mounts, protective housings |

| HVAC | Ductwork and ventilation systems |

- Automotive: You make chassis parts, brackets, and body panels with sheet metal bending. These parts need strength and exact fit.

- Construction: You use custom-bent metal for building facades, handrails, and supports.

- Electronics: You create enclosures and frames with tight bends to protect devices.

- HVAC: You shape ductwork and vents for good airflow and easy installation.

You see how KRRASS leads in industry innovation. Their machines help you handle tough jobs in these sectors. You get reliable results and high precision every time.

Sheet Metal Bending Methods

Press Brake Bending (KRRASS)

You use press brake bending when you want high precision and speed in sheet metal bending. This method shapes metal by pressing it between a punch and a die. You can make many different angles and forms. When you use a press brake machine, you get strong, repeatable results. You see this method in many factories because it works well for both small and large batches.

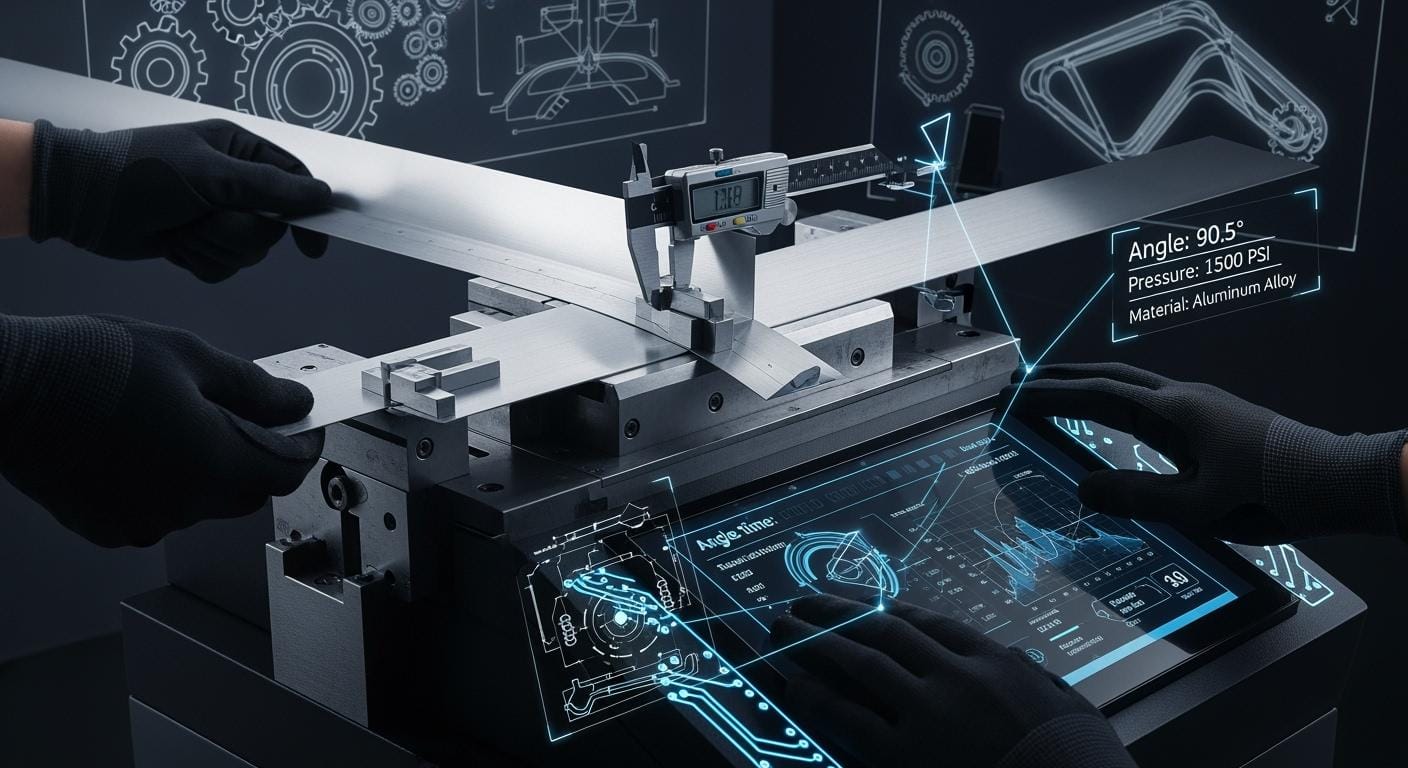

KRRASS stands out in this area. The CNC Press Brake MB8-250T3200 4+1 Axis gives you advanced control. You can set exact angles and lengths. The DELEM DA-53T controller helps you work faster and with fewer mistakes. You get uniform bends across the whole sheet. The electric crowning system keeps your results accurate, even with thick or long sheets. You can handle heavy-duty jobs and complex shapes with ease.

Here is a table that shows how press brake bending compares to other sheet metal bending methods:

| Feature | Press Brake | Other Bending Methods |

|---|---|---|

| Precision | High | Varies depending on method |

| Speed | Fast | Slower for manual methods |

| Repeatability | Excellent | Limited for manual methods |

| Versatility | High | Limited to specific shapes |

| Tonnage Capacity | High | Lower for hand bending |

| Automation | Yes | Limited or none |

You see that press brake bending gives you the best mix of speed, accuracy, and flexibility. You can use it for many sheet metal bending jobs in sheet metal fabrication. KRRASS machines help you save time and reduce waste. You get more parts done right the first time.

Roll Bending

You use roll bending when you need to make curves or cylinders from flat metal sheets. This method uses three rollers to shape the metal. You feed the sheet between the rollers. The rollers turn and bend the metal into a smooth curve. You can make pipes, tanks, and round frames with this method.

Roll bending works well for large parts and long sheets. You can adjust the rollers to change the curve. You get good results with many types of metal. The tolerances for roll bending are tight. You can achieve cross-section dimensions within ± 1/64 inch and angles within ± 1° to 2°. For special jobs, you can get even closer, up to ± .005 inch.

| Tolerance Type | Value |

|---|---|

| Cross-section dimensions | ± 1/64” |

| Angles | ± 1° to 2° |

| Closer tolerances | ± .005” |

You need to watch for some factors that can change your results:

- Variations in strip thickness

- Hardness changes in coils

- Roll pressure adjustments

- Lubricant or temperature changes

- Camber

You can use roll bending for many projects, but it works best for round or curved shapes. You may not get sharp angles or small parts with this method. You see roll bending in industries that need tanks, pipes, and curved beams.

Rotary Draw Bending

You use rotary draw bending when you want to make precise bends in tubes or pipes. This method uses a rotating die to pull the metal around a fixed shape. You get smooth, tight bends without wrinkles or flattening. You can control the angle and radius very well.

Rotary draw bending works best for round or square tubes. You see it in the machine and parts industry. You also use it for piping in many fields. This method helps you make frames, handles, and custom pipe shapes.

- Machine and parts industry

- Piping

You choose rotary draw bending when you need high accuracy and clean bends. You can make complex shapes that fit together well. You see this method in automotive, furniture, and construction projects.

You have many options for sheet metal bending. Each method gives you different results. You pick the one that fits your job best. KRRASS helps you with advanced press brake solutions, so you get the most from your sheet metal bending process.

Manual vs. CNC Bending

You face a choice between manual and CNC bending when you work with sheet metal bending. Both methods help you shape metal, but they offer different results and suit different needs. You should know how each method works so you can pick the best one for your project.

Manual bending uses simple tools like hand brakes, hammers, and vises. You control the process with your hands and eyes. You measure, mark, and bend the metal yourself. This method works well for small jobs or custom pieces. You can make quick changes and fix mistakes easily. You do not need expensive machines for manual sheet metal bending. You use your skills to get the shape you want.

CNC bending uses computer-controlled machines. You program the machine to bend the metal at exact angles and positions. The CNC Press Brake MB8-250T3200 4+1 Axis from KRRASS gives you advanced control. You set the parameters, and the machine does the work. You get high precision and repeatability. You can handle large batches and complex shapes with CNC sheet metal bending. You save time and reduce errors.

Let’s look at the main differences between manual and CNC bending:

- Manual bending gives you flexibility for small jobs.

- CNC bending offers speed and accuracy for big projects.

- Manual bending relies on your skill and experience.

- CNC bending uses technology to ensure consistent results.

- You spend less money on manual sheet metal bending tools.

- You invest more in CNC machines, but you get better output.

Tip: You should use manual bending for prototypes or repairs. You should choose CNC bending for production runs and tight tolerances.

You need to think about cost when you pick a method for sheet metal bending. Manual bending costs less for small batches. CNC bending costs more upfront, but it saves money for large jobs. Here is a table that shows the cost range for each method:

| Production Volume | Bending Method | Cost Range |

|---|---|---|

| ≤50 bends/month | Manual | Ideal for <$1K |

| ≥1000 bends/month | CNC | Starting around $20K |

You see that manual sheet metal bending works best for low-volume jobs. CNC bending becomes cost-effective when you need to make many parts each month. You should match your method to your production needs.

You also need to think about quality. Manual bending can lead to mistakes if you do not measure carefully. You may see uneven bends or cracks. CNC bending gives you uniform results every time. The KRRASS CNC Press Brake MB8-250T3200 4+1 Axis helps you avoid errors. You get smooth bends and tight angles. You can trust the machine to follow your design.

You use manual sheet metal bending for simple shapes and quick fixes. You use CNC bending for complex parts and high-volume production. You see both methods in sheet metal fabrication shops. You pick the one that fits your job, budget, and quality needs.

Here is a quick comparison to help you decide:

| Feature | Manual Bending | CNC Bending |

|---|---|---|

| Precision | Depends on skill | High, machine-controlled |

| Speed | Slower | Fast, automated |

| Repeatability | Low | High |

| Cost | Low for small jobs | Better for large batches |

| Flexibility | Good for custom | Good for complex designs |

| Labor | Hands-on | Minimal, operator setup |

You should remember that both manual and CNC sheet metal bending have a place in manufacturing. You use manual bending for art, repair, and prototypes. You use CNC bending for mass production and advanced designs. KRRASS gives you the tools to succeed with both methods. You can improve your workflow and get better results with the right choice.

Bending Process Steps

Preparation

You start the bending process with careful preparation. Good preparation helps you get accurate results and avoid mistakes later. Here are the main steps you follow:

- Design and Planning: You choose the right material and thickness for your project. You decide on the bend angles and select the best bending method for your needs.

- Material Preparation: You cut the sheet metal to the correct size. You mark the bend lines clearly so you know where to bend.

- Review Drawings: You check your technical drawings and make sure all measurements match your plan.

- Check Equipment: You inspect your tools and machines to make sure they work well. You clean the work area to prevent any problems during bending.

Tip: Careful planning at this stage saves you time and reduces waste during production.

Tool Setup

You move to tool setup after you finish preparation. This step is important for getting the right bend and keeping your parts consistent. Here’s what you do:

- Select the Right Tools: You pick the punch and die that match your material and desired bend angle.

- Install Tools: You place the punch and die into the press brake. You secure them tightly to prevent movement.

- Adjust Settings: You set the machine for the correct bend length, angle, and pressure. If you use a KRRASS CNC press brake, you enter these values into the controller.

- Test Run: You run a test piece to check alignment and accuracy. You make small adjustments if needed.

KRRASS machines help you with quick tool changes and easy setup. The DELEM DA-53T controller lets you program settings fast, which increases your efficiency.

Execution

You now perform the actual bending. This is where you shape the metal into the form you need. Follow these steps:

- Position the Sheet: You place the metal sheet on the worktable, aligning it with the marked bend lines.

- Start the Machine: You activate the press brake. The punch moves down and presses the sheet into the die, creating the bend.

- Monitor the Process: You watch the bend as it happens. You check for any signs of cracking or misalignment.

- Adjust for Springback: You may need to overbend slightly to account for springback, which is when the metal tries to return to its original shape.

- Remove and Inspect: You take out the bent part and check it against your measurements.

KRRASS press brakes give you high precision and repeatability during execution. The electric crowning system and advanced sensors help you get the same results every time, even for complex shapes. This makes your manufacturing process smoother and more reliable.

Quality Control

You need good quality control to make sure each part is right. Quality control helps you find mistakes early. This keeps your products safe and reliable. KRRASS CNC press brakes have smart features. These features make checking parts faster and easier.

First, you set clear rules for every part. You pick the exact size, allowed errors, and how the surface should look. You write these rules down so everyone knows what to check. You use these rules when you inspect parts.

You watch the bending process with sensors and machines. These tools check things like bend angle, pressure, and position. You see live data on the machine’s screen. If something is wrong, you can stop and fix it before making more parts.

You check your equipment often. Calibration keeps your press brake working well. You look at the machine’s settings and change them if needed. The DELEM DA-53T controller on KRRASS machines helps you do this quickly. This step stops mistakes from old tools or wrong settings.

You use special inspection methods to check finished parts. Laser scanning measures bend angle and length very closely. Ultrasonic testing finds hidden cracks inside the metal. These methods help you make sure every part matches your rules.

You teach your team to find problems and follow quality steps. You show them how to use inspection tools and read drawings. You ask them to report issues and share ideas. Skilled workers help you catch mistakes early and keep things running well.

You study production data with statistical process control (SPC). You collect numbers from each batch and look for patterns. If you see too much change, you find out why and fix it. SPC helps you keep your process steady and easy to predict.

You set up feedback loops to keep getting better. You look at inspection results and listen to customers. You use this info to improve your process and update your rules. You make small changes over time for better results.

Here is a summary of good quality control steps:

- Set clear rules for size, errors, and finish.

- Watch the bending process with sensors and machines.

- Check equipment often to keep it accurate.

- Use special inspection methods like laser scanning and ultrasonic testing.

- Teach and help workers find and fix problems.

- Use SPC to study production data.

- Set up feedback loops to keep improving.

Tip: KRRASS CNC press brakes help you automate many quality control jobs. You get quick measurements, fast calibration, and easy data tracking. This makes your work more reliable and smooth.

You use these quality control steps to make sure every part is right. You find mistakes early, waste less, and give better products to your customers.

Materials for Bending

Metals

You pick metals for bending because they are strong and flexible. Some metals bend easily and stay in shape. Others need more force or special tools to bend. You should check things like ductility, malleability, and tensile strength before you start.

Here is a table that shows how common metals act during bending:

| Metal | Ductility | Malleability | Tensile Strength | Thermal Conductivity |

|---|---|---|---|---|

| Copper | High | High | Moderate | High |

| Aluminum | High | Moderate | Moderate | High |

| Gold | Moderate | High | Low | Moderate |

| Silver | Moderate | High | Low | Moderate |

| Stainless Steel | Low | Low | High | Low |

Copper and aluminum are good for bending with high precision. You can make complex shapes with them and not get cracks. Stainless steel is very strong, but you need more force and must be careful. Gold and silver bend easily, but you do not use them much for big jobs.

Plastics & Composites

You sometimes bend plastics or composite materials. These materials do not act like metals. You have to watch out for some special problems.

- Delamination can happen. Layers might come apart if you use too much force.

- Matrix cracking and microcracking can show up. Fast changes in heat or pressure can make tiny cracks.

- Fiber pull-out and fuzzing can happen. The edges may get rough if your tools are dull or the angle is wrong.

- Composite burrs can form. Bundles of fibers may stick out and make the surface uneven.

- Thermal effects are important. High heat can make the resin soft or burn it, which makes the part weak.

You need sharp tools and must control the temperature. You should check the material often while bending. Plastics and composites need more care than metals.

Suitability Factors

You have to think about a few things before you pick a material for bending. These things help you get the best results.

- Ductility lets you stretch the material without breaking it. Ductile metals can bend into many shapes. Brittle metals might break if you bend them too much.

- The K-factor is about thickness. It helps you know how the material will move when you bend it. You use this to plan your bends and not make mistakes.

- Thin materials and tight bends move the neutral axis closer to the inside of the bend. This changes the final shape and can make it weaker.

Tip: Always test a small piece before you start a big project. This helps you see how the material acts and lets you change your process if you need to.

You can pick the right material and method by thinking about these things. This helps you make strong and accurate parts every time.

Bending Process: Pros & Cons

Advantages

Cost Savings

You can save money by using modern bending machines. Many companies say they spend less on workers and finish jobs faster with automated systems. For example, car makers now pay 40% less for labor and make parts 30% faster. Aerospace suppliers cut labor costs in half and make 25% more parts. Construction companies finish jobs 35% quicker and use 25% less material. These savings happen because setup is faster, there is less waste, and fewer mistakes are made.

Design Flexibility

You get more design choices with new bending technology. CNC press brakes let you change setups fast. You can work on many small orders without trouble. You can make tricky shapes and special features. Automation lets you switch jobs quickly. You can make many kinds of parts without buying costly stamping tools. This flexibility helps you meet customer needs and try new projects.

- Change jobs quickly for different orders

- Bend detailed and tricky shapes

- Make special parts for custom orders

- Use robots to speed up production

Product Quality

You make better products with precise bending machines. CNC press brakes help you get exact bends every time. You waste less material and make fewer mistakes. Optical sensors and lasers check if things line up and spot problems. You get smooth bends and neat edges. Every part matches your plans, so you have fewer bad parts and happier customers.

Tip: KRRASS CNC press brakes use smart controllers and sensors to help you get high accuracy and steady quality.

Challenges

Material Springback

You deal with springback when you bend metal. The metal tries to go back to its old shape after bending. This can make parts not fit right and mess up assembly. You need to bend the metal a little more than needed to fix this. KRRASS machines help you adjust for springback with special controls and live feedback.

| Challenge | Description | Solution |

|---|---|---|

| Material Springback | Metal returns toward its original shape after bending. | Bend past the needed angle; use CNC control. |

Tool Maintenance

You must keep your tools clean and working well for good bending. Clean and oil them often to stop damage and blockages. Check moving parts, make sure tools line up, and look at safety features. Clean the lower mold slot before you start the machine. Doing these things helps your tools last longer and work better.

- Check moving parts for damage.

- Oil with the right oils.

- Adjust tools to line up.

- Clean the machine frame.

- Look at safety features.

Precision Issues

You need very exact bends for many jobs. Bad bends can cause problems when putting parts together and waste materials. Manual bending often gives uneven results. KRRASS CNC press brakes fix this by changing tools automatically, cutting down on mistakes, and making sure every bend is just right. Optical sensors and lasers find and fix errors, so you get the same good results every time.

- Get the same results for big jobs

- Work with many types of materials

- Make tricky parts quickly

- Keep every bend very exact

Note: KRRASS automated systems help you solve common bending problems and give you steady, good results.

Real-World Applications

Automotive

You see bending play a big role in the automotive industry. You use this process to shape metal parts for cars and trucks. Many frames, brackets, and body panels come from bent sheet metal. You rely on bending to make strong and lightweight components that fit together well. You need these parts to build safe vehicles that last a long time.

- About 25-30% of automotive parts are made using bent sheet metal.

- You use bending to create door frames, seat supports, and exhaust systems.

- You need precise bends for crash protection and smooth finishes.

You use a press brake machine to get the right angles and shapes. This helps you keep up with high production demands. You make sure every part matches the design and fits with other components. You see how bending helps you build cars that meet safety standards and look good.

Construction

You use bending in construction to shape beams, columns, and custom metal pieces. You need these parts for buildings, bridges, and other structures. Bending lets you create strong supports and unique designs. You choose different methods based on the job and the material.

| Bending Method | Description |

|---|---|

| Ram Bending | You use a hydraulic ram to push at the middle and get the curve you want. |

| Gag Pressing | You apply force at certain spots for large bends, often for cambering beams. |

| Hot Bending | You heat the metal to make it bend easier and reduce its strength. |

| Incremental Step Bending | You bend the metal at many close spots using hydraulic rams. |

| Induction Bending | You heat a narrow band before bending for smooth curves. |

| Rotary Draw Bending | You clamp the metal and draw it around a die for cold bending. |

You use these methods to shape steel for building frames and architectural features. You need accurate bends to make sure everything fits and stays strong. You see bending help you create curved facades, handrails, and custom supports. You use these techniques to finish projects faster and with less waste.

Electronics

You use bending to make enclosures and frames for electronic devices. You need custom shapes to fit circuit boards, screens, and connectors. You use a press brake machine to form the metal with a punch and die. You plan the design so each bend matches the size of the components inside.

You choose the right material and bend radius to make sure everything fits. You need smooth edges and tight corners for safety and performance. You see bending help you protect sensitive electronics and keep them working well. You rely on this process for strong cases that last through daily use.

When you design enclosures, you think about how the bends affect strength and durability. You match the internal bend radius to the external radius of the parts. You make sure every piece fits together without gaps or stress. You use bending to create reliable products for computers, phones, and appliances.

You see how bending supports many applications in modern manufacturing. You use this process to meet high production goals and deliver quality parts in every industry.

KRRASS Solutions

You want to make your work better and get good results. KRRASS gives you machines that help with this. The CNC Press Brake MB8-250T3200 4+1 Axis is a popular choice for many factories. You use this press brake to do hard jobs and keep your work exact.

This machine has many smart features. The DELEM DA-53T controller helps you set up jobs fast and bend metal very accurately. The electric crowning system makes sure every bend is the same, even with big or thick sheets. The Siemens motor is quiet and gives steady power. The Rexroth hydraulic valve lets you control the machine easily. Quick clamping helps you change tools fast, so you do not waste time.

Here is a table that shows how these features help you:

| Feature | Benefit for You |

|---|---|

| DELEM DA-53T Controller | Easy setup, high precision |

| Electric Crowning | Consistent bending accuracy |

| Siemens Motor | Quiet, reliable performance |

| Rexroth Valve | Stable hydraulic control |

| Quick Clamping | Fast tool changes |

You see these features help in many jobs. In car making, you finish work 25% faster and make 15% more parts. Electronics makers use KRRASS to get better bends and waste less metal. Builders use these machines to do more work and handle different shapes with robots and automatic lines.

You also save money and energy. Many users say they work 35% faster and waste 20% less material. You pay 25% less for energy and get your money back in 18 months.

You can trust KRRASS to help with smart technology. The machine’s CNC controls and automation help you work quicker and make fewer mistakes. You get special solutions for your business. Safety features keep your team safe while working.

Tip: If you pick KRRASS, you get more than a machine. You get a partner that helps your business grow and face new problems.

You see how KRRASS machines help in real factories. You make better products, save time, and earn more money with each job.

You can see how bending helps make things today. Machines like KRRASS CNC press brakes let you work faster. You make better parts with these machines. You save time and use less material.

| Key Advantage | Description |

|---|---|

| Faster Production Times | You finish work quickly and meet your goals. |

| More Precise Production | You get exact bends for each job. |

| Efficient Use of Materials | You waste less and save money. |

- You can look at KRRASS for new bending ideas.

- You should buy smart tools and use robots to get better results.

FAQ

What is a press brake?

You use a press brake to bend sheet metal. The machine pushes the metal between a punch and a die. You control the angle and shape with settings on the machine.

How does CNC bending improve accuracy?

CNC bending uses computer controls. You enter your bend angles and measurements. The machine follows your instructions exactly. You get precise and repeatable results every time.

What materials can you bend with a press brake?

You can bend steel, aluminum, copper, and stainless steel. Some machines also handle plastics and composites. Always check the material’s thickness and strength before you start.

Why does springback happen during bending?

Springback happens because metal tries to return to its original shape after bending. You fix this by bending the metal a little more than needed. CNC machines help you adjust for springback.

How do you choose the right bending method?

You look at your part’s shape, size, and material. For simple bends, you use manual tools. For complex or large jobs, you use CNC press brakes. You pick the method that fits your needs.

What safety steps should you follow when using a press brake?

You wear safety glasses and gloves. You keep hands away from moving parts. You check the machine before starting. You follow all safety signs and instructions.

How does KRRASS help you with bending jobs?

KRRASS gives you advanced press brakes with smart controls. You set up jobs quickly and get accurate bends. The machines help you save time and reduce mistakes.

Can you bend thick metal sheets with a CNC press brake?

You can bend thick sheets with a CNC press brake. You choose the right punch and die. The machine uses strong force to shape the metal. Always check the machine’s capacity before you start.