You need a good laser cutting machine for great metal work. CNC laser machines are special because they make clean cuts. They also give you very exact results every time. Most companies use fiber laser cutting machines. Fiber lasers are used in 60% of metal work jobs. Laser cutting technology has improved a lot recently. Better automation means you watch the process less. Real-time monitoring helps make cuts more accurate. You can now do hard laser engraving or cutting jobs easily. This saves you time and material. If you want a laser cutter for home or for a factory, choosing the right machine helps you work faster. It also makes your finished parts look better.

Table of Contents

Key Takeaways

- CNC laser machines make clean and exact cuts. They are very important for good metal work.

- Fiber laser cutting machines are the most popular. They do 60% of metal jobs because they are fast and work well.

- When picking a laser cutter, think about what materials you will use. Check how thick the metal is. Look at how exact you need the cuts. Think about how much you need to make.

- Top brands like Trumpf, AMADA, and KRRASS are trusted. They have new and smart features for laser cutting.

- The CNC laser machine market will grow a lot. People want faster and cleaner ways to cut metal.

- New laser cutting technology saves energy and makes less waste. This helps companies spend less money.

- It is important to take care of laser cutting machines often. This helps them last longer and work better.

- Safety comes first. Always wear safety gear. Make sure the air is clean when using laser cutting machines.

Best CNC Laser Machines Overview

Top Picks Summary

When you look for the best laser cutting machine for metal, you want to know which brands stand out. You see many options, but a few names always come up in every review. These brands lead the way in laser cutting and engraving. Here are the most popular choices you will find in the market:

- Trumpf: This company makes high-tech laser cutting machines. You get strong performance and reliable results. Trumpf is famous for its quality and innovation.

- AMADA: You see AMADA in many metal shops. Their laser cutters and laser engravers help you work faster and get clean cuts. AMADA is known for smart features and easy controls.

- KRRASS: If you want a laser cutting machine that handles many materials, KRRASS is a top pick. You get high precision and smooth finishes. KRRASS machines work well for both sheets and tubes.

- STYLECNC: This brand offers a wide range of laser engravers and laser cutters. STYLECNC helps you find the best at-home laser cutter or a machine for your workshop.

You can use these laser cutting machines for many metal projects. They work for automotive, aerospace, electronics, and more. You will see these brands in almost every review about laser cutting and engraving.

What Sets Them Apart

You want to know what makes one laser cutting machine better than another. Each brand offers something special. You should look at several criteria before you choose the best laser cutter for your needs. Here is a table that shows what you should check in your review:

| Criteria | Description |

|---|---|

| Material Types | You need to know what metal or other materials you will cut. Different lasers work best for different materials. |

| Thickness Range | You should check how thick your material is. Some laser cutting machines handle thick plates, while others work best for thin sheets. |

| Precision and Quality | You want high precision and smooth edges. The best laser engravers give you clean cuts and sharp details. |

| Production Volume | If you cut a lot of metal, you need a machine with fast cutting speed and high efficiency. |

| Power Output | You should match the power to your material and thickness. More power means faster cutting. |

| Cutting Speed | Fast cutting saves you time. You want a laser cutting machine that balances speed and quality. |

| Beam Quality | Good beam quality gives you smooth cuts and less waste. |

| Wavelength | The right wavelength helps you cut your main materials better. |

| Initial Investment | You need to compare prices and see what fits your budget. |

| Maintenance Costs | Some laser cutters need more care. You should check how much you will spend on upkeep. |

You see that the best laser cutter for metal is not just about power. You need to think about the type of laser, the materials you use, and your production goals. Some machines, like the KRRASS Fiber Laser Cutting Machine, give you automatic typesetting and high-speed cutting. Others focus on easy controls or special engraving features. You should read each review and look for machines that match your needs. If you want the best laser engravers for detailed work, you need high precision and smooth finishes. For big jobs, you want speed and efficiency. The right laser cutting machine helps you get better quality and saves you money in the long run.

CNC Laser Machines Market Trends

Growth in Metal Cutting

Metal cutting is changing a lot. More companies want faster and cleaner work. CNC laser machines help with this. The market for these machines grows every year. In 2022, metal fabrication was the biggest part. This is because fiber lasers are fast and accurate. People pick laser cutting machines for their speed and precision.

Here are some facts about the market:

- The CNC laser machine market could grow from $6.85 billion in 2024 to $12.09 billion by 2031.

- This means the market grows at 9.2% each year.

- The CNC fiber laser group is growing fastest. This is because of more automation and the need for exact metal parts.

- The CNC Laser Cutting Machines Market was worth $6.56 billion in 2023. It might reach $12.45 billion by 2031, with a CAGR of 8.12% from 2024 to 2031.

- The Global Laser Cutting Machines Market expects a CAGR of 7.40% from 2025 to 2035.

You can see the numbers in this table:

| Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2024 | 6.85 | N/A |

| 2025 | 7.49 | N/A |

| 2031 | 12.09 | 9.2 |

More factories and shops use laser cutting for metal. You get better quality and save time. The need for laser cutting machines keeps going up. People want clean cuts and less waste. There are also more laser engraving jobs in electronics and medical devices.

New Laser Cutting Technologies

Laser technology keeps getting better. Now, you find smarter and more energy-saving laser cutting machines. Fiber laser systems use only 1.5 to 2 kW each hour. CO2 lasers use much more, sometimes up to 5 kW. New machines can use 70% less power when not cutting. This saves money and helps the planet.

Smart manufacturing systems help you use up to 30% less raw material. They use special patterns to fit more parts on each sheet. AI now tells you when your machine needs fixing. This cuts downtime by 30% and lets you use 20% more material. You finish more work and spend less time on repairs.

Laser cutting machines now cut with a tolerance of ±0.01 mm. You need this for aerospace and medical metal parts. Laser engraving also looks better now. The newest laser cutting machines give you smooth edges and clean finishes. You get high quality every time.

Here’s a quick look at some new innovations:

| Innovation Type | Description |

|---|---|

| Energy Efficiency | Fiber laser systems use less power than older CO2 lasers. |

| Power Savings | New machines cut power use by up to 70% when not cutting. |

| Material Utilization | Smart systems save up to 30% of raw materials. |

| Predictive Maintenance | AI reduces downtime and boosts material usage. |

| Precision Cutting | Machines now reach tolerances of ±0.01 mm for top quality parts. |

Laser cutting keeps improving. You have more choices for metal cutting and engraving. The newest laser cutting machine helps you work faster and smarter. You can count on these machines for high quality and good results.

Types of Laser Cutting Machines

When you look at cnc laser machines, you find three main types. Each type works best for certain jobs. Let’s break down how they help with metal cutting and what makes them different.

Fiber Laser Cutters

Fiber laser cutters have changed the way you do metal cutting. You get fast, clean cuts and high efficiency. These machines use a fiber optic cable to deliver the laser beam. This makes them strong and reliable for many metal jobs.

Advantages for Metal Cutting

You will notice fiber laser cutters work well for sheet metal cutting. They handle thin and thick metals with ease. You can cut steel, aluminum, and stainless steel. The power ranges from 1000W to over 6000W, so you can pick what fits your needs.

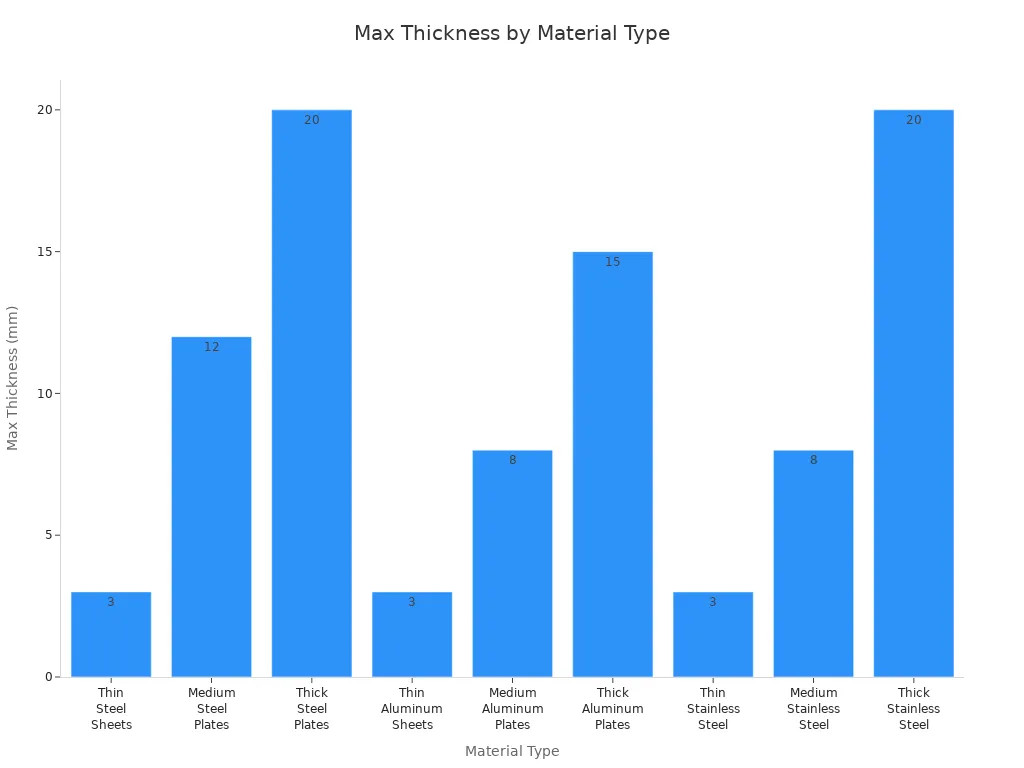

Here’s a quick look at what fiber laser cutters can handle:

| Material Type | Thickness Range | Power Required |

|---|---|---|

| Thin Steel Sheets | 0.5 mm – 3 mm | 1000W to 2000W |

| Medium Steel Plates | 4 mm – 12 mm | 2000W to 4000W |

| Thick Steel Plates | 13 mm – 20 mm | 4000W to 6000W |

| Thin Aluminum Sheets | 0.5 mm – 3 mm | 1000W to 2000W |

| Medium Aluminum | 4 mm – 8 mm | 2000W to 4000W |

| Thick Aluminum | 9 mm – 15 mm | 4000W or more |

| Thin Stainless Steel | 0.5 mm – 3 mm | 1000W to 2000W |

| Medium Stainless | 4 mm – 8 mm | 2000W to 4000W |

| Thick Stainless | 9 mm – 20 mm | 4000W to 6000W |

You get up to five times faster cutting speeds for thin metals compared to other machines. Fiber laser cutters use less energy, so you save money on power. They also last longer and need less maintenance. You can cut copper and brass without trouble. This makes fiber laser cutters a top choice for metal cutting.

Limitations

Fiber laser cutters work best for metals. If you want to cut wood or plastic, you may not get the best results. Some very thick metals may need extra power. For most metal jobs, though, fiber laser gives you speed, quality, and efficiency.

CO2 Laser Cutters

CO2 laser cutters use a gas tube to make the laser beam. You see these machines in many shops. They work well for non-metals and some metals.

Best Use Cases

You can use CO2 laser cutters for engraving, cutting wood, acrylic, and some thin metals. They are great for signs, crafts, and detailed designs. If you want to do both cutting and engraving, a CO2 laser can help.

Pros and Cons

Here’s how fiber laser and CO2 laser compare for metal cutting:

| Feature | Fiber Laser | CO2 Laser |

|---|---|---|

| Cutting Speed | Up to 5 times faster for materials < ¼” | Slower cutting speeds |

| Energy Efficiency | Lower power consumption, more efficient | Higher power consumption |

| Power Density | 5 times more at focal point | Less power density |

| Material Thickness Capability | Up to 1 inch thick | Limited thickness capability |

| Reflective Material Cutting | Effective for copper and brass | Struggles with reflective materials |

You will spend more on power with a CO2 laser. These machines turn only 10-15% of energy into laser output. You also need to replace parts more often. CO2 lasers need regular maintenance and use more gas. Fiber laser cutters use about a quarter of the energy and last three times longer.

Hybrid and Specialty Lasers

Hybrid and specialty lasers mix features from both fiber and CO2 machines. Some use special beams or combine cutting and engraving in one system.

Unique Features

You get machines that can cut 3D shapes or handle hard-to-machine metals. Some hybrid lasers let you switch between cutting and engraving without changing tools. This saves you time and boosts your workflow.

Applications

You see hybrid and specialty lasers in many industries:

- Automotive and transportation: You can cut body panels and make engine parts.

- Aerospace and defense: These lasers help you form tough metals and cut composites without damage.

- Architecture and home design: You create custom metal facades and structures.

- Electronics: You make tiny parts and engrave circuit boards.

- Military: You label gear and make strong parts for vehicles.

Tip: If you want to handle many jobs, hybrid and specialty lasers give you flexibility. You can switch between sheet metal cutting, engraving, and even 3D work.

With so many choices, you can find the right laser cutting machine for your metal project. Each type offers something special for your needs.

Top 10 Laser Cutter for Metal

KRRASS Fiber Laser Cutting Machine

Key Features

You want a machine that works well every time. The KRRASS Fiber Laser Cutting Machine is popular in reviews. It gives you very accurate cuts and works fast. The machine is built strong and lasts long. You can cut many metals like carbon steel, stainless steel, aluminum, and brass. You can pick power from 1.5kW up to 20kW. This helps you find the right laser cutter for your job.

Here’s a table that shows how KRRASS compares to other top models:

| Specification | KRRASS Fiber Laser Cutting Machine | Other Top Models |

|---|---|---|

| Precision | ±0.03 mm | Varies |

| Speed | Up to 100 m/min | Varies |

| Maintenance | Low | Higher |

| Energy Efficiency | Up to 35% | Lower |

| Versatility | High (handles reflective metals) | Varies |

| Quality of Cut | Cleaner edges, minimal damage | Varies |

| Build Quality | High-grade stainless steel | Varies |

| Customer Support | 24/7 assistance | Varies |

You get automatic typesetting and non-contact cutting. This means your workpiece gets less damage. The narrow kerf lets you use more material and waste less. You can cut sheets and tubes with this fiber laser machine.

Pros and Cons

You want to know why this machine is a good pick. Here are some points:

- The price is between $15,000 and $300,000, so you can choose what fits your budget.

- You get long warranties and help with maintenance, which saves you money.

- The machine works for many metal cutting and engraving jobs.

- You get very accurate cuts and smooth finishes every time.

Ideal Applications

You can use the KRRASS Fiber Laser Cutting Machine in many places. It works for cars, planes, electronics, and medical devices. If you have a small shop or a big factory, this machine fits your needs. You get good results for thick plates and small parts.

Tip: If you want a laser cutter for metal that makes clean cuts and saves time, KRRASS is a top choice in reviews.

Trumpf TruLaser 5030 Fiber

Key Features

You see the Trumpf TruLaser 5030 Fiber in many top shops. This fiber laser machine has smart features for perfect cuts. You get BrightLine Fiber, which changes the beam for smooth edges in thick carbon steel. The CoolLine feature sprays mist to keep the metal cool. This means less heat damage.

Here’s a table that shows what makes Trumpf special:

| Feature | Description |

|---|---|

| BrightLine Fiber | Adjusts beam mode for smooth, high-quality edges in thick carbon steel, previously achievable only with CO₂ lasers. |

| CoolLine | Sprays controlled mist to reduce heat-affected zone by up to 40%, preserving material properties in thick stainless steel cuts. |

| Ideal Applications | Aerospace, heavy machinery, and precision sheet metal industries where flawless cut quality is essential. |

You get fast cutting and great quality with every job. The machine works for both cutting and engraving.

Pros and Cons

You get smart features that help you cut thick metals easily. The machine gives you smooth edges and less heat damage. You pay more for these features, but you get top results and reliability.

Ideal Applications

You use the Trumpf TruLaser 5030 Fiber in planes, big machines, and sheet metal work. If you need perfect quality and accuracy, this machine is a strong pick. You see it in many lists for best laser cutters.

Bystronic BySmart Fiber 3015

Key Features

You want speed and accuracy for metal cutting. The Bystronic BySmart Fiber 3015 gives you both. This fiber laser machine cuts stainless steel and aluminum up to 1.18 inches thick. You get fast moving speeds and sharp edge detection.

Here’s a table with the main specs:

| Specification | Value |

|---|---|

| Max. Cutting Thickness Stainless | 1.18 inches |

| Max. Cutting Thickness Aluminum | 1.18 inches |

| Max. Positioning Speed (X/Y) | 3,937 IPM |

| Max. Simultaneous Positioning Speed | 5,511 IPM |

| Edge Detection Accuracy | ±0.019 inches |

You get steady performance for cutting and engraving. The machine works for many kinds of metal.

Pros and Cons

You get fast speeds and strong accuracy. The machine cuts thick metals and gives sharp edges. You may pay more for smart features, but you get great results for your money.

Ideal Applications

You use the Bystronic BySmart Fiber 3015 in metal shops, car work, and electronics. If you want a top laser cutter for fast and accurate jobs, this machine is a good choice. You see it in many lists for best fiber laser cutters.

Amada ENSIS-3015AJ

Key Features

If you need to make lots of metal parts, this machine helps you do it fast. The Amada ENSIS-3015AJ is known for saving time and money. You can pick how strong you want the laser to be: 3kW, 6kW, or 9kW. This means you can cut many types of metal quickly. The smart beam control changes the laser for thick or thin metal. You do not have to stop to change lenses. This saves you time and helps you make fewer mistakes.

Here’s why busy shops like the Amada ENSIS-3015AJ:

| Advantage | Description |

|---|---|

| High-speed cutting capabilities | You can pick from 3kW, 6kW, or 9kW for fast cutting. |

| Improved beam control technology | The laser changes itself for thick or thin metal. |

| Reduced production costs | You use less nitrogen gas and spend less cleaning up. |

| Enhanced quality | You get smoother cuts and better surfaces. |

You get cleaner cuts and smoother metal pieces. The machine uses less nitrogen gas, so you save money. You also have less mess to clean up after cutting.

Pros and Cons

Here’s what you get with the Amada ENSIS-3015AJ:

- You cut metal faster and spend less on gas.

- You get smooth edges and need less cleaning.

- You do not have to stop to change lenses.

- Your metal parts look better and more professional.

You might pay more at first, but you save money later. The machine works well for a long time.

Ideal Applications

You can use the Amada ENSIS-3015AJ in car shops, airplane factories, and big machine shops. If you have lots of metal to cut, this machine helps you keep up. You get great results when you need fast and clean cuts and want to spend less money.

Tip: If you need a fiber laser that cuts thick and thin metal easily, Amada ENSIS-3015AJ is a smart pick for busy shops.

Mazak Optiplex Series

Key Features

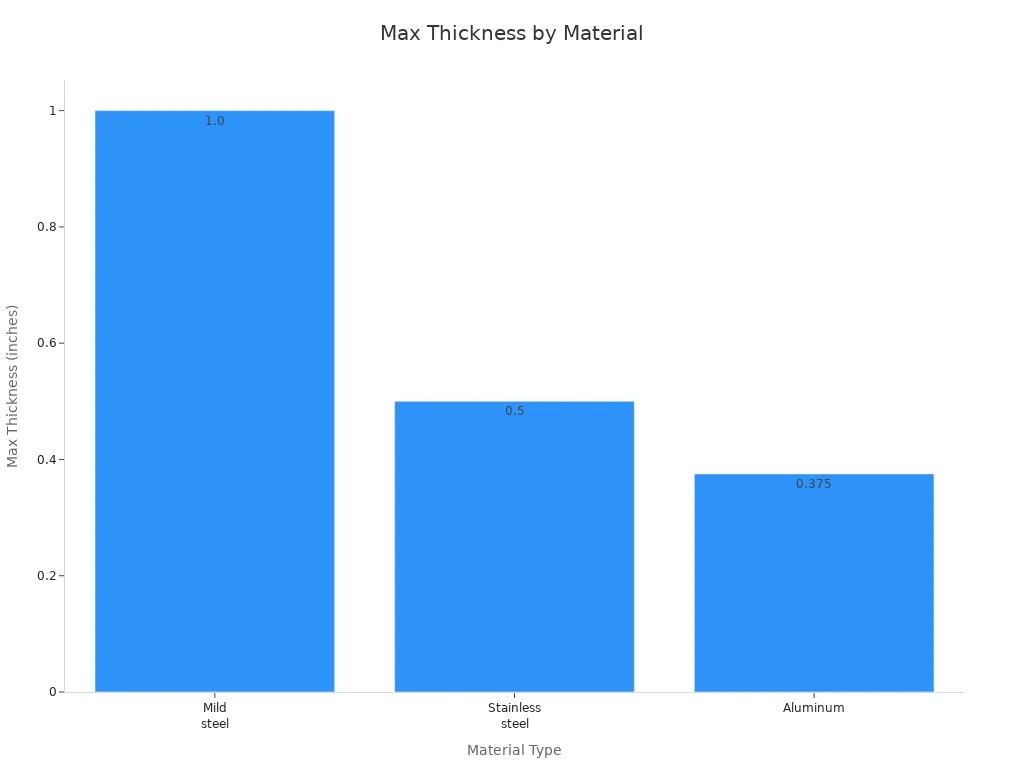

If you need to cut big metal sheets or thick plates, this machine is strong enough. The Mazak Optiplex Series can cut sheets up to 80.71 inches wide and 162.2 inches long. It cuts mild steel up to 1 inch thick, stainless steel up to 0.5 inch, and aluminum up to 0.375 inch. If you get the OPTIPLEX HP model, you can cut metal up to 2 inches thick.

Here’s a table that shows what you can cut:

| Material Type | Maximum Thickness |

|---|---|

| Mild steel | 1.00″ |

| Stainless steel | 0.500″ |

| Aluminum | 0.375″ |

The machine has smart features like automatic nozzle changing and sensors. These help you work faster and make fewer mistakes. The machine also cuts metal quickly, so you finish jobs fast.

Pros and Cons

Here’s what you get with the Mazak Optiplex Series:

- You can cut big sheets and thick plates easily.

- Automation helps you save time and avoid mistakes.

- The machine works well for many kinds of metal.

- You can upgrade it to cut even thicker metal.

You need a lot of space for this machine, but you get more speed and flexibility for big jobs.

Ideal Applications

You use the Mazak Optiplex Series in shipbuilding, building construction, and making heavy equipment. If you need to cut large or thick metal pieces, this machine gives you the power and accuracy you need. It is a good choice for shops that do big jobs and need a strong laser cutter.

Salvagnini L3 Fiber Laser

Key Features

If you want a fiber laser that does lots of work by itself, this machine is a good pick. The Salvagnini L3 Fiber Laser loads and stores metal sheets automatically. You do not have to move sheets by hand. TRADJUST and multi-interface features help you fix problems quickly and keep the machine running. Smart sensors and OPS software help you skip boring jobs and stop the machine from breaking down.

Here’s a table that shows the automation features:

| Automation Feature | Description |

|---|---|

| Storage and automatic loading/unloading | The machine loads and unloads sheets by itself, saving time and money. |

| TRADJUST and multi-interface | These features make it easy to solve problems and use the machine. |

| Cutting-edge sensors and OPS software | Sensors and software help you avoid slow jobs and keep the machine working. |

| TN manual sorting device | You can cut and sort metal at the same time, which saves time. |

| MCU automatic sorting device | The machine sorts metal fast, so you can start the next job quickly. |

| Automatic nozzle changer | The machine changes nozzles by itself, so you do not have to stop it. |

You can cut and sort metal at the same time, which makes your work faster. The automatic nozzle changer lets you run the machine all night without stopping.

Pros and Cons

Here’s what you get with the Salvagnini L3 Fiber Laser:

- You work faster because the machine does many jobs by itself.

- You spend less money on workers and avoid slowdowns.

- Smart sensors help the machine keep working.

- You can cut and sort metal at the same time.

Your team may need to learn how to use the new controls, but you get more speed and flexibility for big jobs.

Ideal Applications

You use the Salvagnini L3 Fiber Laser in factories that make lots of metal parts. If you want to automate your cutting and spend less money, this machine is a great choice. It works well for electronics, cars, and any job where you need fast and accurate cuts.

Note: If you want a fiber laser that works with little supervision and keeps your shop running smoothly, Salvagnini L3 is a top pick.

Han’s Laser Smart Series

Key Features

You want a laser cutter that helps your shop work well. Han’s Laser Smart Series has smart automation and cuts metal fast. This machine works with many metals like stainless steel, aluminum, and brass. You can switch jobs quickly because of its smart controls. Real-time monitoring lets you spot problems before they slow you down.

Look at how Han’s Laser Smart Series saves energy and needs less fixing:

| Feature | Benefit |

|---|---|

| Energy Efficiency | Cuts waste and makes work smoother |

| Maintenance Requirements | Needs less fixing because of new technology |

| Production Efficiency | Makes the whole process faster and better |

You can count on this machine for good quality and less stopping. The Smart Series lets you get help from far away if something breaks.

Pros and Cons

You get fast cutting and easy controls. The machine uses less power, so you save money. You do not spend much time fixing it because it tells you when there is a problem. You can change settings for different metals.

Some people say the software is hard to learn. Your team may need training to use it well.

Ideal Applications

You can use Han’s Laser Smart Series in car shops, electronics factories, and metal plants. If you want to make more parts and spend less, this machine is a good fit. It works well for both small and big metal pieces.

Tip: If you want a laser cutter that helps you work faster and smarter, Han’s Laser Smart Series is a great choice.

Bodor Laser Cutting Machine

Key Features

You want a laser cutter that keeps people safe. Bodor Laser Cutting Machine cuts steel, aluminum, copper, and more. It is easy to use and has smart features. The machine cuts fast and engraves with detail. Bodor lets you add new parts as your shop grows.

Bodor Laser Cutting Machine follows strict safety rules. Here are some safety facts:

- Bodor Laser Cutting Machine has CE and ETL safety certificates.

- It also follows NR12 and FDA rules.

- Bodor checks every machine to make sure it is safe and works well.

You can trust this machine to keep your team safe and give good results.

Pros and Cons

You get strong safety and steady work. The machine works with many metals and lets you change settings. You can upgrade it easily. Bodor checks each machine so it lasts longer.

Some people say setting up the machine takes time. You may need to change settings for each metal.

Ideal Applications

You can use Bodor Laser Cutting Machine in medical, electronics, and custom metal shops. If you need a safe and steady laser cutter, Bodor is a smart pick. You get good cuts and feel safe using it.

Note: Bodor’s focus on safety makes it a top pick for shops with strict rules.

ST-FC3015FM Sheet Metal Laser Cutter

Key Features

You want a machine that cuts sheet metal fast and well. ST-FC3015FM Sheet Metal Laser Cutter gives you quick cuts and sharp edges. You can cut thin or thick metal sheets. The frame is strong and the controls help you get clean cuts.

This machine uses a fiber laser, so it saves energy and needs little fixing. It loads and unloads metal by itself, so you finish jobs faster. You use a touchscreen to run it easily.

Pros and Cons

You set up the machine fast and the controls are simple. It works for small and big jobs. You do not fix it often because the fiber laser lasts long. The automatic parts help you save time.

Some people say the machine is big and needs lots of space. You may need to plan where to put it in your shop.

Ideal Applications

You can use ST-FC3015FM Sheet Metal Laser Cutter in building, car, and metal shops. If you need to cut big sheets fast, this machine is a good choice. It works well for jobs where you need to cut a lot of metal.

Tip: ST-FC3015FM is a good pick if you want to work faster and get clean cuts every time.

FORSUN CNC 1390M6

Key Features

If you want metal work to be simple, this machine can help. The FORSUN CNC 1390M6 is strong and works well for many jobs. It has a big cutting area, 1300mm by 900mm, so most metal sheets fit. The laser tube is high quality. This means your cuts are sharp and clean. You can change the power from 100W to 150W. This helps you cut different metals and thicknesses.

You use a touchscreen to control the FORSUN CNC 1390M6. The software is easy, so you set up jobs fast. You can upload designs and start cutting in just a few minutes. The frame is steady, so the machine does not shake much. This makes your cuts more accurate. You also get a honeycomb or blade table. These tables help hold metal sheets in place.

Some features you might like are:

- The cutting area is big for larger projects.

- You can change the laser power for different metals.

- The controls are easy, so setup is quick.

- The frame is steady, so cuts are precise.

- The honeycomb or blade table gives better support.

Tip: You can use the FORSUN CNC 1390M6 for cutting and engraving. This gives you more ways to use the machine in your shop.

Pros and Cons

You might wonder why this machine is a good pick. The FORSUN CNC 1390M6 has many good points, but there are some things to think about before buying.

Pros:

- You get very detailed cuts for metal work.

- The machine works with steel, aluminum, and brass.

- You can set up jobs fast with simple controls.

- The steady frame keeps your cuts sharp.

- You can switch between cutting and engraving.

Cons:

- The cutting area is not big enough for the largest sheets.

- You need to check the laser tube often to keep it working well.

Ideal Applications

You can use the FORSUN CNC 1390M6 in many places. This machine helps you make models, cut parts, and build displays. Shops that need fast and accurate metal cutting use it a lot.

Here is a table that shows where you can use the FORSUN CNC 1390M6:

| Industry Type | Applications |

|---|---|

| Mold Making | Making models, prototypes, and molds |

| Aerospace Component Manufacturing | Cutting parts for airplanes |

| Automotive Component Manufacturing | Making car parts |

| Exhibition Building Manufacturing | Cutting and shaping for display stands |

| Metal Fabrication | Cutting and shaping metal for projects |

You can use this machine for mold making, airplane parts, and car parts. It is also good for building displays and general metal work. If you want a laser cutter for many jobs, the FORSUN CNC 1390M6 is a smart choice.

Note: You get more out of the FORSUN CNC 1390M6 when you use it for both cutting and engraving. This helps you finish more jobs with just one machine.

Choosing the Best Laser Cutter

Material and Thickness

When you pick a laser cutting machine, you need to think about the type of metal and how thick it is. Different metals need different laser settings. Some metals, like stainless steel and aluminum, cut easily with fiber laser cutters. Others, like copper or brass, need more power. You want to match your laser to the job.

- Technology keeps improving, so you can cut thicker metal now than before.

- The maximum thickness you can cut depends on the quality of your metal and the laser configuration.

- Fiber laser cutters work best for both ferrous and non-ferrous metals. You get fast and precise metal cutting, even with thick materials.

- If you plan ahead and choose the right equipment, you can avoid problems with material thickness.

- Knowing the limits of your laser cutting machine helps you get better results and avoid mistakes.

If you want to do sheet metal cutting, check the specs for each machine. Some laser cutters handle thin sheets, while others work with thick plates. You should always review the machine’s capabilities before you buy.

Production Volume

Production volume matters when you choose a laser cutter for metal. If you make only a few parts, you might not need a high-end machine. If you make thousands of parts every month, a top laser cutting machine saves you time and money.

High-volume production means you make thousands or even hundreds of thousands of parts each year. When you reach this level, investing in a high-end laser cutting machine makes sense. For smaller jobs, like prototypes or custom pieces, you can use a basic machine.

Here’s a table to help you decide:

| Factor | Low-Volume (1–1,000 Units) | High-Volume (1,000+ Units) |

|---|---|---|

| Best For | Prototypes, custom parts, niche markets | Mass-market products, stable designs |

If you move from quick-turn prototyping to production machining, you usually cross the line at about 15 parts. As your volume grows, laser engravers and laser cutters become more cost-effective.

Budget and ROI

Your budget plays a big role in picking the best laser cutter. You want to get the most value for your money. Think about how much you will spend and how fast you will earn it back.

- High-end laser cutting machines cost more, but they save you money over time.

- You use less material and get faster metal cutting, which means lower costs.

- Laser engravers with smart features help you finish jobs quicker and with better quality.

- If you choose the best at-home laser cutter, you can start small and grow your business.

Look at the return on investment (ROI). If your laser cutting jobs bring in steady work, a bigger investment pays off. Review your needs and compare machines before you buy. Some machines, like fiber laser cutters, give you better ROI for metal cutting and sheet metal cutting.

Tip: Always review your production goals and budget before you pick a laser cutting machine. The right choice helps you grow and keeps your costs low.

Comparing Features

When you pick a laser cutting machine, look at the features that matter most. Some features help you more than others. Make a list of what you need for your work. Do you want faster cutting or sharper edges? Maybe you want easy controls or a machine for thick metal. Some people need high precision for detailed engraving.

Here’s an easy way to compare features:

| Feature | Why It Matters | What to Look For |

|---|---|---|

| Cutting Speed | Saves time on big jobs | Speed ratings in m/min or IPM |

| Precision | Makes edges clean and sharp | Tolerance levels (like ±0.01mm) |

| Material Compatibility | Lets you use more types of metal | List of supported materials |

| Automation | Makes work smoother and faster | Auto-loading, typesetting |

| Software Controls | Helps you set up jobs quickly | Touchscreen, easy interface |

| Safety Features | Keeps everyone safe | Certifications, sensors |

| Maintenance Needs | Cuts downtime and saves money | Service intervals, spare parts |

Read reviews and see which features match your needs. Some machines are fast, others are better for engraving. If you want high precision, look for smart software. Always check if the machine can cut the metal thickness you use.

Tip: Make a checklist before you shop. Write your top three features. Use this list to compare machines. This helps you pick the best one for your shop.

Support and Service

Buying a laser cutting machine is just the start. Support and service are very important. Good support helps your machine last longer. You save money and fix problems faster. People talk about service in every review.

Here’s why support matters:

- You get help with repairs and fixing problems.

- You can order spare parts quickly.

- Experts give advice when you need it.

- Your machine works better with less downtime.

The relationship with your supplier after you buy is very important. How fast and helpful the supplier is matters as much as the machine’s features.

Did you know after-sales service can make more profit than selling new machines? About 30% of a company’s profits come from spare parts and repairs. Companies work hard to help you succeed.

When you pick a machine, ask about service and warranties. Find out how fast they fix problems. Look for suppliers who offer training and regular check-ups. Good support helps your machine last longer.

Note: Pick a supplier with strong support. You will worry less and get more work done.

Laser Cutting Process & Safety

Step-by-Step Process

You may wonder how a CNC laser machine makes your design into a metal part. The steps are simple and easy to follow. Here is what happens when you use a laser cutter for metal fabrication:

- Drawing & CAM Preparation

First, you make your design with CAD software. Next, you get the file ready for the machine using CAM software. - Machine Programming

You upload your file to the machine. Then, you set the cutting settings. This tells the machine what to do. - Material Loading

You put your metal sheet or tube on the machine bed. Make sure it is flat and does not move. - Piercing

The laser makes a small hole in the metal. This helps the machine start the cut in the right spot. - Cutting in Action

The laser moves along the path you set. It cuts through the metal fast and with care. - Final QC & Post-Cut Processing

You check the finished part to see if it looks good. Sometimes, you clean or smooth the edges for a better finish.

Tip: Always check your design and machine settings before you start. This helps you save time and materials.

Safety Tips

Laser cutting machines are fast and powerful, but you must be careful. Here are some safety tips to follow every time you use a CNC laser cutter:

- Keep your work area clean. A tidy space helps stop accidents.

- Make sure the room has good airflow. This gets rid of bad fumes from cutting metal.

- Wear PPE like gloves and safety goggles.

- Keep fire extinguishers close by. Make sure everyone knows how to use them.

- Check your machine and wires often. This helps you find problems early.

- Use strong ventilation systems. These help remove harmful gases and dust.

⚠️ Safety first! Never forget your safety gear or skip safety checks. Your health and your team’s safety are most important.

Maintenance Essentials

If you want your laser cutter to work well for a long time, you need to take care of it. Here is a simple table to help you remember what to do and when:

| Maintenance Interval | Tasks |

|---|---|

| Daily | Clean and check parts, look for dust and slag, wipe surfaces. |

| Weekly | Clean the head shell, oil the guide rail surface. |

| Monthly | Check and clean the countertop blade, look at the oil system. |

| Bi-Monthly | Clean the center tube, change water cooling filters. |

| Quarterly | Rinse the oil container, clean the oil filter. |

| Every 500 hours | Oil X, Y-Axis guide rails and Z-Axis lead screw. |

| Annually | Change gas system filters, check all electrical parts. |

Note: Set reminders for these jobs. Regular care keeps your machine working well and helps you avoid big repairs.

You can keep your CNC laser machine safe, accurate, and working well by following these steps. Stay careful, follow your routine, and your laser cutter will last for years.

When you choose a CNC laser machine, you want the right motor power for your jobs. You should look for suppliers who offer strong after-sale services and help with maintenance. Always negotiate for a fair price and good warranty terms. Think about your shop’s needs, your budget, and how many parts you plan to make. Stay safe by following regular maintenance routines. If you feel unsure, talk to an expert for advice.

Picking the best machine helps you work smarter and safer every day.

FAQ

How do you choose the right CNC laser machine for metal?

You look at your material type, thickness, and how many parts you need. Check the machine’s power, speed, and features. Compare support and warranty options before you buy.

Can you cut both sheets and tubes with one laser cutter?

Yes, many fiber laser machines let you cut sheets and tubes. You switch settings or use special attachments. This gives you more flexibility for different jobs.

What metals can you cut with a fiber laser machine?

You can cut carbon steel, stainless steel, aluminum, brass, and copper. Some machines handle other metals too. Always check the specs for your model.

How often should you maintain your CNC laser cutter?

You clean and check your machine daily. Oil and inspect parts weekly. Change filters and check systems every few months. Regular care keeps your machine working well.

Is laser cutting safe for beginners?

Laser cutting is safe if you follow rules. Wear safety gear, keep your area clean, and use good ventilation. Read the manual and get training before you start.

What is the difference between fiber and CO2 laser cutters?

Fiber lasers work best for metals. They cut faster and use less energy. CO2 lasers handle non-metals and thin metals. Fiber lasers last longer and need less maintenance.

How do you get help if your machine breaks down?

You contact your supplier’s support team. Many companies offer 24/7 help, spare parts, and training. Good support gets you back to work quickly.

Can you use a CNC laser cutter for engraving?

Yes, you can engrave with most CNC laser cutters. You upload your design and set the engraving depth. This lets you add logos, text, or patterns to metal parts.