Compared with other industrial cutting solutions, the 6000w high power sheet metal Fiber Laser Cutting Machine with changing tray has faster-cutting speed and higher power laser source (e.g.1000w, 2000w, 3000w, 4000w, 6000w, 12000w ), the best 6000w high power sheet metal laser cutting machine for sale now at an affordable price.

Machine video:

Machine introduction:

The 6000w high-power Fiber Laser Metal Cutting Machine has fast cutting speed, high power laser source (e.g.1000w, 2000w, 3000w, 4000w, 6000w, 12000w), and higher quality cutting results compared to other cutting solutions. It adopts the most advanced IPG laser, combined with CNC machinery designed by our company and a high-strength welded body, after standard heat treatment and process processing of a large CNC milling machine.

6000W laser cutting machine transmitter brand choice?

- Chinese brands: MAX, RAYCUS

- American brands: IPG, GW

The choice of the brand is based on the customer's budget. If there is enough budget, we recommend buying IPG because IPG is very stable in cutting, and the cutting surface is beautiful. When your funding is insufficient, it is recommended to buy MAX. MAX laser transmitters are cheap and have a low failure rate.

Advantages of 6000w high-power Fiber Laser Metal Cutting Machine:

- Compact structure, small footprint.

- Stability and reliability of optical path system and control system.

- High performance and low operating cost, the famous IPG fiber laser has a service life of more than 100,000 hours.

- Higher cutting quality and efficiency, the cutting speed can reach 40 m/min, beautiful appearance, and cutting edge.

- High-precision servo motors, screw rods, and guide rails use well-known brands to ensure efficiency and precision and increase stability and reliability.

6KW IPG Laser Souce technical parameters:

| Thickness(mm) | Speed(m/min) | Focus position | Cutting height(mm) | Gas | Nozzle type | Pressure(bar) | |

|---|---|---|---|---|---|---|---|

| Carbon steel (Q235B) | 1 | 25-32 | 0 | 1 | N2 | Single: 1.5 | 12 |

| 2 | 20-27 | -1 | 1 | Single: 2.0 | 12 | ||

| 3 | 12-15 | -1.5 | 0.5 | Single: 2.0 | 14 | ||

| 4 | 7-8.5 | -2 | 0.5 | Single: 2.0 | 14 | ||

| 5 | 5.7-6.8 | -2.5 | 0.5 | Single: 3.0 | 16 | ||

| 3 | 3.6-4.2 | +5 | 0.8 | O2 | Double: 1.2 | 0.6 | |

| 4 | 3.3-3.8 | +5 | 0.8 | Double: 1.2 | 0.6 | ||

| 5 | 3-3.6 | +5 | 0.8 | Double: 1.2 | 0.6 | ||

| 6 | 2.7-3.2 | +5 | 0.8 | Double: 1.2 | 0.6 | ||

| 8 | 2.2-2.5 | +6 | 0.8 | Double: 1.2 | 0.6 | ||

| 10 | 2.0-2.3 | +7.5 | 0.8 | Double: 1.2 | 0.6 | ||

| 12 | 1.9-2.1 | +7.5 | 0.8 | Double: 1.2 | 0.6 | ||

| 14 | 1.4-1.7 | +9 | 1 | Double: 1.4 | 0.6 | ||

| 16 | 1.2-1.4 | +9 | 1 | Double: 1.4 | 0.6 | ||

| 18 | 0.7-0.8 | +12 | 0.3 | Single: 1.4 | 0.8 | ||

| 20 | 0.5-0.6 | +4 | 0.8 | Double: 5.0 | 0.6 | ||

| 20 | 0.6-0.7 | +13 | 0.3 | Single: 1.4 | 0.8 | ||

| 22 | 0.45-0.5 | +4 | 0.8 | Double: 5.0 | 0.6 | ||

| 22 | 0.5-0.6 | +13 | 0.3 | Single: 1.5 | 1 | ||

| 25 | 0.4-0.5 | +14 | 0.3 | Single: 1.5 | 1 | ||

| Stainless steel (SUS304) | 1 | 35-45 | 0 | 0.8 | N2 | Single: 1.5 | 10 |

| 2 | 23-32 | -1 | 0.5 | Single: 2.0 | 12 | ||

| 3 | 15-18 | -1.5 | 0.5 | Single: 2.5 | 12 | ||

| 4 | 9-13 | -2 | 0.5 | Single: 2.5 | 14 | ||

| 5 | 7-8.5 | -2.5 | 0.5 | Single: 3.0 | 14 | ||

| 6 | 4-5.5 | -3 | 0.5 | Single: 3.0 | 15 | ||

| 8 | 3-3.8 | -4 | 0.5 | Single: 3.0 | 15 | ||

| 10 | 1.8-2.1 | -6 | 0.5 | Single: 4.0 | 15 | ||

| 12 | 1-1.3 | -7.5 | 0.5 | Single: 5.0 | 16 | ||

| 14 | 0.85-1.1 | -9 | 0.5 | Single: 5.0 | 16 | ||

| 16 | 0.6 | -10.5 | 0.3 | Single: 5.0 | 18 | ||

| 18 | 0.5 | -12 | 0.3 | Single: 5.0 | 20 | ||

| 20 | 0.3 | -14 | 0.3 | Single: 6.0 | 20 | ||

| Aluminum (6061) | 1 | 30-37 | 0 | 1 | N2 | Single: 1.5 | 12 |

| 2 | 22-27 | -1 | 0.5 | Single: 2.0 | 12 | ||

| 3 | 13-18 | -1.5 | 0.5 | Single: 2.5 | 14 | ||

| 4 | 9-11 | -2 | 0.5 | Single: 2.5 | 14 | ||

| 5 | 5-6.5 | -3 | 0.5 | Single: 3.0 | 14 | ||

| 6 | 3.6-4.2 | -3 | 0.5 | Single: 3.0 | 16 | ||

| 8 | 1.8-2.1 | -4 | 0.5 | Single: 3.0 | 16 | ||

| 10 | 1-1.3 | -4.5 | 0.5 | Single: 3.5 | 18 | ||

| 12 | 0.7-1 | -5 | 0.5 | Single: 4.0 | 18 | ||

| 14 | 0.5 | -5 | 0.3 | Single: 4.0 | 18 | ||

| 16 | 0.4 | -8 | 0.3 | Single: 6.0 | 20 | ||

| Brass | 1 | 25-32 | 0 | 1 | N2 | Single: 1.5 | 12 |

| 2 | 17-21 | -1 | 0.5 | Single: 2.0 | 12 | ||

| 3 | 12-15 | -1 | 0.5 | Single: 2.5 | 14 | ||

| 4 | 8-9.3 | -1.5 | 0.5 | Single: 3.0 | 14 | ||

| 5 | 4.5-5.5 | -2 | 0.5 | Single: 3.0 | 14 | ||

| 6 | 3.2-4 | -3.5 | 0.5 | Single: 3.0 | 16 | ||

| 8 | 1.5-2 | -5 | 0.5 | Single: 3.5 | 16 | ||

| 10 | 1 | -6 | 0.5 | Single: 3.5 | 16 | ||

| 12 | 0.7 | -8 | 0.3 | Single: 4.0 | 18 | ||

| Copper | 1 | 20-27 | -0.5 | 1 | O2 | 2.0S | 8 |

| 2 | 10-13 | -1 | 0.5 | 2.0S | 8 | ||

| 3 | 7-9 | -2 | 0.5 | 2.0S | 8 | ||

| 4 | 4-5.2 | -2 | 0.5 | 2.0S | 8 | ||

| 5 | 3 | -3 | 0.5 | 2.5S | 8 | ||

| 6 | 2 | -4 | 0.5 | 2.5S | 8 |

Parameter of 6KW high-power fiber laser cutting machine

| Model | RAS-3015T/RAS-4015T/RAS-4020T/RAS-6015T/RAS-6020T metal laser cutting machine |

|---|---|

| Working Area | 3050*1525/4050*1525/4050*2020/6050*1525/6050*2020 |

| Laser Power(kw) | 1/1.5/2/3/4 |

| Maximum Speed(m/min) | 80 |

| Maximum acceleration(g) | 0.8 |

| X/Y Axis positioning accuracy(mm/m) | ±0.05 |

| X/Y Axis repeated positioning accuracy(mm) | ± 0.02 |

6000W high-power fiber laser cutting machine features:

- Equipped with a high-power fiber laser generator, it can cut any graphics.

- Good stability and strong deformation resistance. Aging process technology ensures machine durability and precision.

- Automatic focus device to realize dynamic focus and continuous cutting of materials with different thicknesses.

- The workbench is equipped with universal wheels and a pneumatic feeding device (optional), which saves labor, avoids damage to the metal sheet, and ensures good cutting quality.

- Independent digital operating table and remote control, easy to operate. There are various data transmission methods, such as U disk data copy, USB cable data transmission, network connection, etc.

- Automatic nesting software is standard, and automatic identification and cutting are optional, saving materials and improving work efficiency.

- The machine can be equipped with an integrated or separate rotary device to perform fixed-point punching, slotting, and cutting metal pipes.

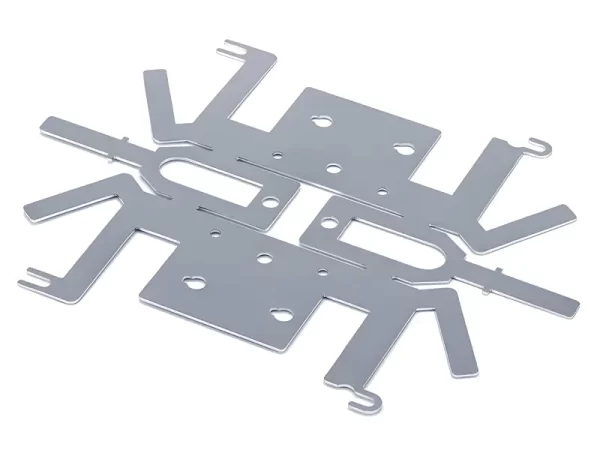

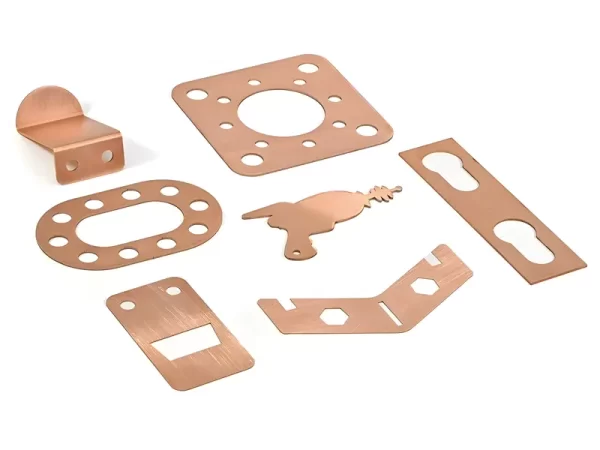

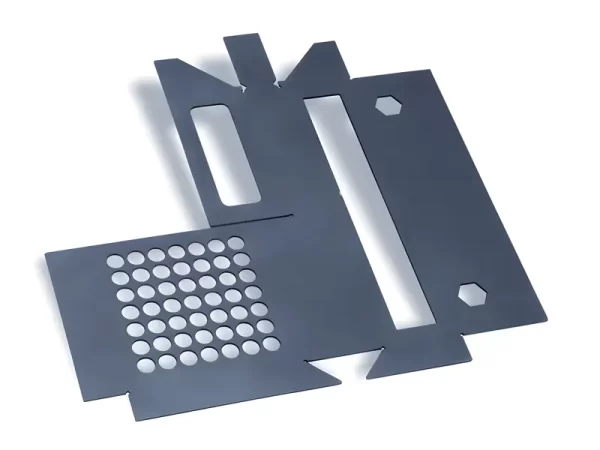

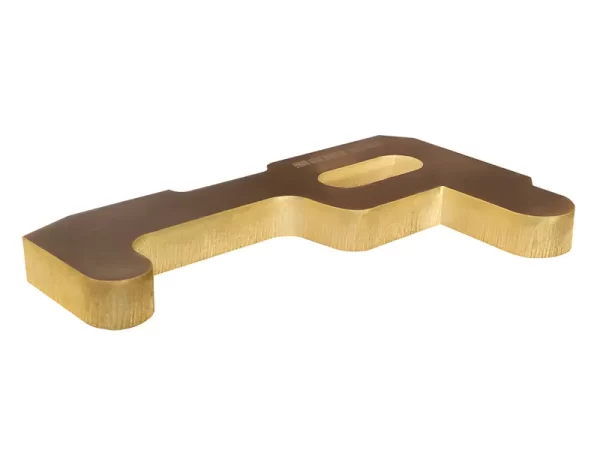

6000W fiber laser cutting machine application materials:

The application field of fiber laser cutting machines includes but is not limited to the manufacture of billboards, advertisements, signs, signs, metal letters, LED letters, kitchen utensils, advertising letters, sheet metal processing, metal parts, hardware, chassis, rack and cabinet processing, metal crafts, Metal crafts, elevator panel cutting, hardware, auto parts, glasses frames, electronic parts, nameplates, etc.

- With a cantilever mechanical structure, one machine is multi-purpose for plates and pipes, and the workbench is easy to replace. It can not only cut round pipes and square pipes but also make holes in the molding box.

- Cut wires and holes of different diameters from different directions.

- Cut the sloped section at the end of the pipe.

- Cut the branch pipe intersecting with the main line.

- Open square, waist-shaped, and round holes on the pipe.

- Cut various graphics on the surface of the square tube.

- Cut metal plates of different sizes.

- Drill holes in the modeling box.

6000W fiber laser cutting machine product display:

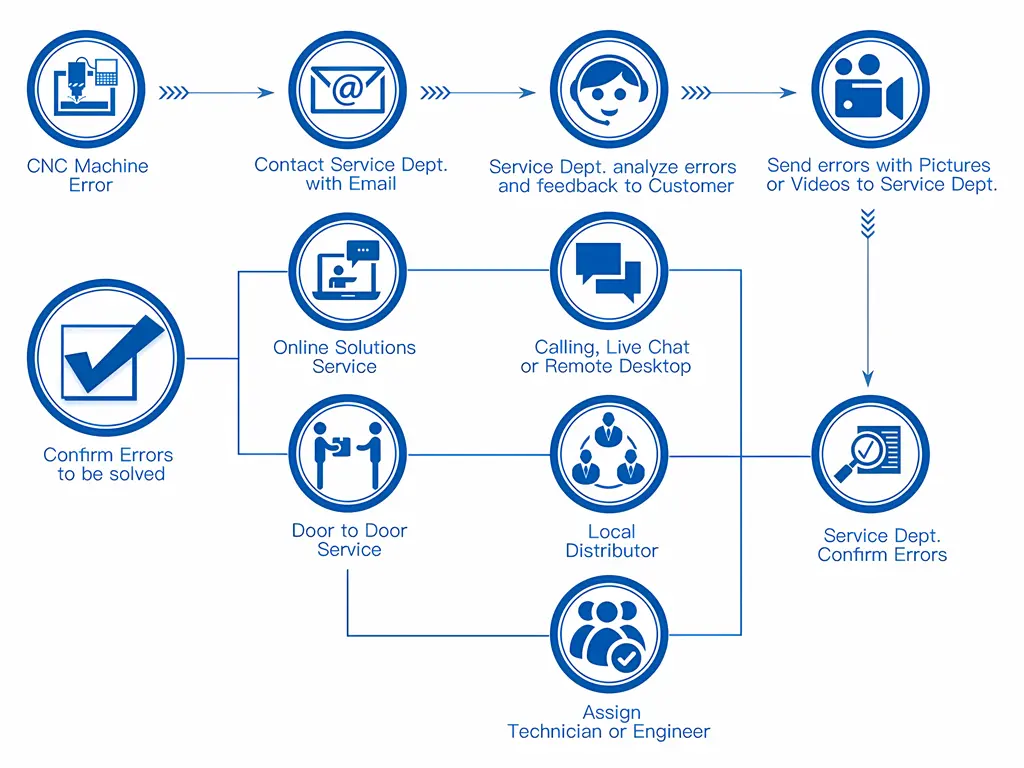

After-sales service of KRRASS 6000w high-power fiber laser cutting machine:

- We will provide a training video and English user manual for the laser machine for installation, operation, maintenance, and troubleshooting, and provide technical guidance through remote, such as TeamViewer, Email, telephone, mobile phone, Whatsapp, Skype, 24/7 online chat, etc. when you have installation, operation or adjustment problems. (more recommended)

- You can come to our factory for laser machine operation training, and we will provide professional guidance. Direct and practical face-to-face training. We have assembled equipment, various tools, and testing facilities here. Training time: 3~5 days (recommended if possible)

- Our engineers will conduct on-site guidance and training services at your local site. Please help us handle visa procedures and prepay travel and accommodation expenses before dispatch. It would be best to have a translator for our engineers during training (if English is not spoken).

Customer photo:

Warranty of KRRASS high-power 6000w fiber laser cutting machine:

- Two years for the whole machine, three months for the laser, one month for the chiller, and no warranty for the lens/mirror/nozzle.

- The after-sales department will provide 24/7 English online support for long-term maintenance.

- Besides manufactured damage, we are responsible for providing free accessories during the warranty period.

- The buyer only needs to pay maintenance after the warranty expires.

- Certificate support: CE, FDA, SGS.

If you have an idea of getting a free quotation for a high-power fiber laser cutting machine, please answer the following questions and tell us by email so that we can directly recommend the most suitable laser machine and quote you an affordable price.

- Do you need to cut metal sheet/plate, metal pipe/pipe, or both?

- If you need to cut the pipe, what are your pipe length, diameter, and maximum thickness?

- What is the maximum working area required for cutting sheet metal?

- What is the use of the processed material? (application)

- Which seaport is closest to you?

- Have you experience using a high-power fiber laser cutting machine?

- What is your online chat tool? Examples include Skype and Whatsapp.

- Are you an end user or a distributor?

KRRASS: the best choice for

all sheet metal processing manufacturers

When considering the overall costs of purchasing, maintaining, and operating a sheet metal equipment setup, a sheet metal fabrication service: KRRASS brand is your best choice. KRRASS has a tremendous reputation in the market due to its focus on consistency and quality at the most competitive price. Whether it's high power sheet metal fiber laser cutting machine or any other application equipment, our team of experts has the right combination of industry knowledge and the latest tool to provide you with the best products and services on the market. Moreover, we set ourselves apart with our advanced system that is completely online. Just let us know what your product needs, request a quote, and start the process.

Make a request and Get Started Today

Get Instant Quote

Learn more about our products, please visit and subscribe to our Youtube channel

Reviewed by 2 users

Laser machine

Very good laser cutting machine

6kw fiber laser cutting machine

La máquina de corte del laser de KRRASS es muy excelente, compramos muchas unidades para vender en agenyan,