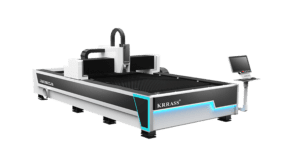

A fiber laser cutter is a type of automatic CNC laser metal cutting system with high quality, high speed, high precision and high efficiency, which is designed for all types of metal fabrication, as well as your good metal working partner. It is equipped with different laser powers (1000W to 20000W) to cut sheet metals and metal tubes made of carbon steel, stainless steel, electrical steel, tool steel, galvanized steel, mild steel, aluminum zinc plate, aluminum alloy, aluminum, titanium alloy, brass, copper, iron, and more metals with different thicknesses.

Why choose RAS series?

- Simple and efficient

RAS series is a perfect standard plane fiber laser cutting machine, which is popular in the industry. It has the highest speedamong those with the same level and may cut 400 small circles per minute. With the maximum speed of 140m and maximum acceleration of 1.5G, it has the highest accuracy among those with the same level and may cut the bicycle with the size of 1/5 of coin. - Success points

1. Pioneered simple and integrated integration design all over the world.

2. The cast-aluminum beam is die-cast and molded with 10t of steel mould for the first time in the industry, with good rigidity and high strength, whose weight is 1/2 of that of the traditional welded iron beam.

Technical Parameters And Specification

[wptm id=114]

Machine Capacity

[wptm id=115]

Description Of Main Configuration

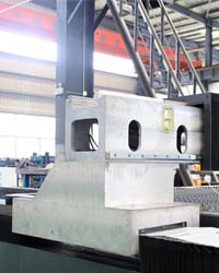

1.Body

Gantry machine body, designed and manufactured for the high speed movement. Twice of aging treatment of reinforcement welding machine body to ensure the precision and stability of the long running. The rigidity is good, the higher acceleration can be accepted, the main body adopts the precise welding of steel structure, the stress failure treatment, the gantry milling of The heavy frame structure.

The main body frame is welded with the carbon dioxide protection welding, with such advantages as stable welding process, free internal defect, minimum splash, etc. At present, such welding becomes the most important welding for the black metal material.

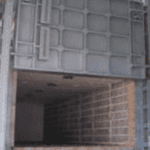

The material stress resulting from welding is eliminated. A very large fuel heating annealing furnace is used to perform stress annealing for several body frames at 600℃ at the same time. With stable furnace temperature and uniform electronic monitoring, the welding stress is thoroughly removed,with guaranteed quality. Annealing of one small non-common electric furnace with non-uniform temperature cannot guarantee to thoroughly eliminate the stress.

The material stress resulting from welding is eliminated. A very large fuel heating annealing furnace is used to perform stress annealing for several body frames at 600℃ at the same time. With stable furnace temperature and uniform electronic monitoring, the welding stress is thoroughly removed,with guaranteed quality. Annealing of one small non-common electric furnace with non-uniform temperature cannot guarantee to thoroughly eliminate the stress.

Rough machining is designed to quickly cut the workblank margin. When rough machining is performed, the large load and cutting depth as much as possible shall be chosen, so as to cut the cuttings as much as possible within a short period of time.

Rough machining is designed to quickly cut the workblank margin. When rough machining is performed, the large load and cutting depth as much as possible shall be chosen, so as to cut the cuttings as much as possible within a short period of time.

Another method to eliminate the internal residual internal stress is as follows: When the vector sum of the residual internal stress in the workpiece and additional vibration stress reaches or exceeds the yield strength of the material, the material has a minor plastic deformation, so that the internal stress in the material is loosened and relieved.

Another method to eliminate the internal residual internal stress is as follows: When the vector sum of the residual internal stress in the workpiece and additional vibration stress reaches or exceeds the yield strength of the material, the material has a minor plastic deformation, so that the internal stress in the material is loosened and relieved.

Place the body outdoors for more than one month. Eliminate the repetitive temperature stress caused for several times to relieve the residual stress, obtain the stable dimension accuracy,enhance the rigidity and enhance the deformation resistant capacity, so as to ensure the dimension stability of the body.

Place the body outdoors for more than one month. Eliminate the repetitive temperature stress caused for several times to relieve the residual stress, obtain the stable dimension accuracy,enhance the rigidity and enhance the deformation resistant capacity, so as to ensure the dimension stability of the body.

The CNC pentahedral machining center is used to machine the guide rail, rack, etc. which have high precision requirements to obtain the high quality installation base plane, so as to ensure the cutting accuracy of the tool.

The CNC pentahedral machining center is used to machine the guide rail, rack, etc. which have high precision requirements to obtain the high quality installation base plane, so as to ensure the cutting accuracy of the tool.

2.Beam

The heavy-duty steel mold pressure casting is used.

The heavy-duty steel mold pressure casting is used.

- The mold cost is high and its service life is long;

- The liquid aluminum has good mobility,uniform density and high strength;

- Such casting defects as sand hole, etc. Are eliminated;

- The surface roughness is good and it isunnecessary to machine the non-mounting surface.The machining cost is low and the protective casting surface has high strength;

- The pressure casting wall thickness may reach 10mm, which does not impact the strength.Theweight is light, inertia is small and the dynamic performance is good.

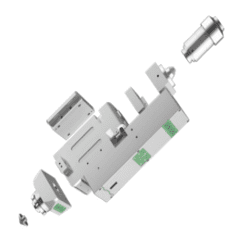

3.Cutting Head

Characteristic:

Characteristic:

- Light and precise focusing

- Simple installation of cutting nozzle and edge piece

- Built-in dual water system cooling system

- The one-usage possibility accords with the individual lens type, provided Optimum cutting effect for the parameters.

4. Fuji (Japan)

It was a leader in industrial manufacture and modern electrical systems.

It was a leader in industrial manufacture and modern electrical systems.

All electrical equipment meets world quality standards with a high reliability and safety.

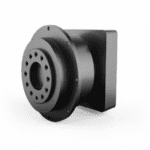

5.Reducer Motoreducer (France)

France Motoreducer was founded in 1946,which provides advanced cross-border technology solutions,apply for industrial transmission hubs all over the world.

France Motoreducer was founded in 1946,which provides advanced cross-border technology solutions,apply for industrial transmission hubs all over the world.

The France Motoreducer Reducer has high precision, high efficiency, wide application and so on.

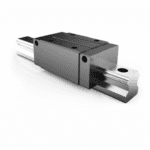

6.Linear guide (Taiwan)

HIWIN is a Taiwanese company responsible for the production and development of linear guide.

HIWIN is a Taiwanese company responsible for the production and development of linear guide.

Characteristic:

- High accurate

- High hardness

- Long-term operation without technical maintenance

- Fast speed

- Working efficiently

- Low noise displacement

7. Gear Rack YYC, SMG(Taiwan/Japan)

Characteristic:

Characteristic:

- Enhanced carrier capability

- Low operating noise

- Stability strongly

- High speed operation

- High accurate

- Large meshing area

8. Automatic Lubrication System

Characteristic:

Characteristic:

- It reduces manual lubrication time and improves machine production efficiency.

The whole machine part lubricant, every certain time automatic lubrication. - Lubrication time can be set according to the actual situation.

- Eliminate artificial lubrication, dust adsorption on the grease, resulting in the smoothness of the slide.

9. Water Chiller

HanLi Industrial water chiller, which is made cooling equipment for laser cutting machine.

HanLi Industrial water chiller, which is made cooling equipment for laser cutting machine.

Characteristic:

Dual temperature control mode, suitable for different occasions, with a variety of Settings and fault display functions, equipped with ion adsorption filter and detection, compressor delay protection, compressor overcurrent protection, water flow alarm, ultra-high/low temperature alarm.

10. Control Panel

Characteristic:

Characteristic:

Humanized design, integrated operation platform, reduce on-site installation trouble and damage to the line.

11. wireless controller

Give you a chance to control it. It has a convenient magnetic holder.

Give you a chance to control it. It has a convenient magnetic holder.

Characteristic:

- Stable seamless coupling

- Anti-interference algorithm

- Wide range of functions

- Operating instructions

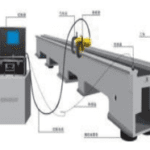

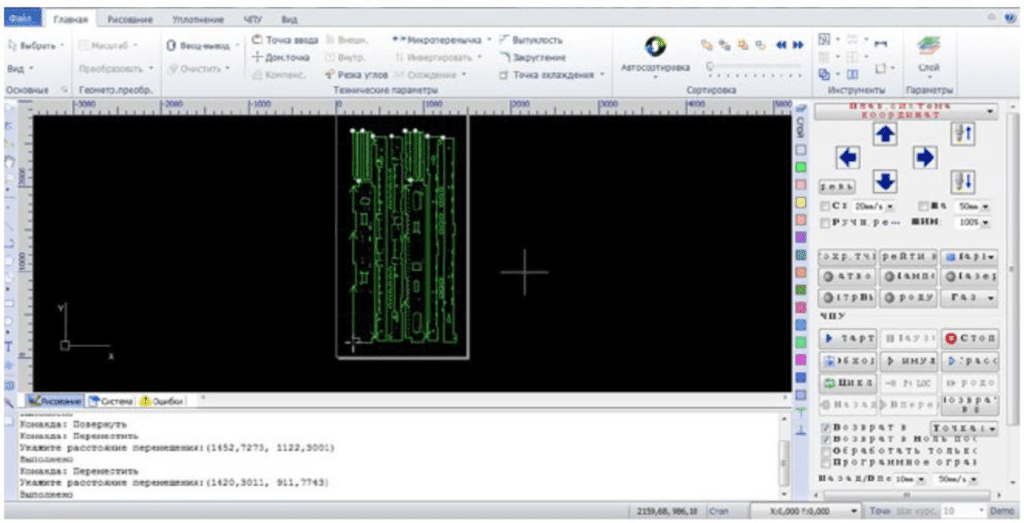

CypCut Software

KRRASS RAS-Series is controlled by the CypCut 2000 system.

In the PC database under Windows operating system.A Cutting system controls the laser source, cutting and motion processes.

CypCut is the best cutting system designed specifically for cutting so far.

The management system is easy to use and that is a completely unmarked interface.

Database CypCut includes standard cutting parameters for common materials (carbon) steel, stainless steel, aluminum, etc. Moreover, these standard values can easily improve the quality and save the cutting parameters.

Support available graphic file formats: DXF, DWG, Al, automotive CAD, etc

Powerful tools are embedded in this project. Collect data about the workings of machines and systems.

Realize remote diagnosis function.

Technical Control

KRRASS provides a complete cycle with strict checks at all stages. Before sending the machine to the customer, the factory engineer needs to perform multi-level diagnostic and matching checks on all laser equipment.

Previous

Next

Learn more about our products, please visit and subscribe to our Youtube channel