When it comes to establishing a successful metalwork shop, it is vital you buy the best tools for this job. Metalworking companies use various types of industrial tools to make parts that have desired shapes. Several hundred and one thousand years ago machines evolved allowing it to be incredibly complex and more effective. Several manufacturing techniques have led to many inventions and developments for various machines.

In metal processing manufacturing, although we will use: forming tools, sheet metal working tools, cutting tools, welding tools and many other tools and process methods, in general, the types of tools that can be used may be nothing more than the following 10 types:

Milling machine

The mill is a metal tool whose cutter uses rotation to take apart unwanted materials. The work piece is securely attached to an adjustable work surface. The two major operations performed on milling machines are face grinding and peripheral grinding. For face milling, the operator grinds a flat surface at an angle to rotate the cutter while the cutter is pressed parallel to the cutting tool. They can serve different purposes such as simply cutting and complicated shaping and cutting. Due to this versatility milling machinery are common in most metalworking shops.

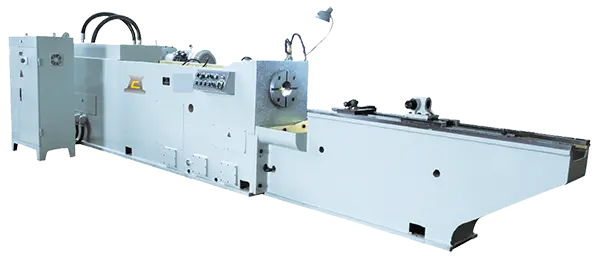

Broaching machine

Sanding machines cut various material forms and shapes. The technique involves the removal of material using toothpicks and broach tools. The process is linear and rotary. The most widespread is linear broaching where machine is placed along work surface. However, rotative broaches involve rotating the broche to apply its force to the material on a surface of the work. Brochures are regarded as versatile tools which have many applications across various industry sectors. They provide various products to industry workers who are involved in metal working tasks.

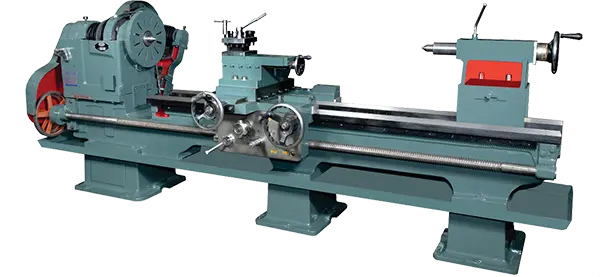

Lathe machine

A rotary lathe is a metal working machine that rotates the working piece for machining operations. Latheses are used for making parts of metals including steel, plastics and wood. These multipurpose machines are used for a range of tasks like cutting or grinding. It comes in various shapes and has several accessories. A lathe was invented by ancients and is largely utilized for the precise working process. These products are available at factories producing light machinery parts and machines and metalworking stores that use heavy machines.

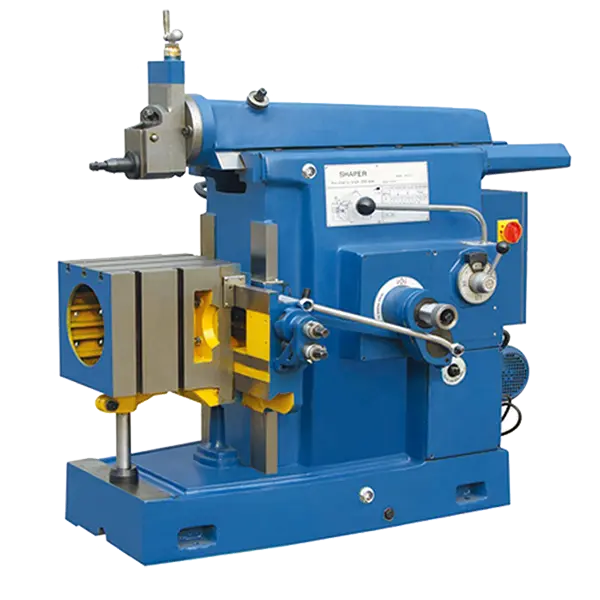

Shaper machine

Shaper machines use the same one-point tool for the cutting of a material in linear motion. Its simple mechanisms make it simple to operate. The mills are used for cutting and molding metal into the required form. It is usually mounted to an arranged table to allow for easy and quick access of the materials. Among the types of work pieces which benefit from such machines is sheet metal because they are capable of making complex shapes with only a few passes. It seems that they are quite frequently used in various industries in general.

Grinding machine

With a grind machine the abrasives are rotated at relatively high speeds. This rotating wheel helps in removing a relatively tiny portion of the surface to make it smoother. Grinders are available for a number of uses: shaping, sizing a piece of material or lathe that was cut with a different tool such as a saw. Abrasive materials can even be used in removing rust or painting parts to be repainted or replaced. Grinding equipment provides a flexible and accurate tooling solution for the entire manufacturing operation of the metals.

Hobbing Machine

Hobbing machines in metalworking greatly enhance quality and productivity. They are a variant of milling machines using specialized types of cutting tools to manufacture high-precision shafts, gears, segments, and splines that are used in a range of applications. Usually a metal factory has several workers on site to meet customer requirements. It's relatively inexpensive and usually requires a handful of employees in operation and produces a large quantity of parts every day for a small business.

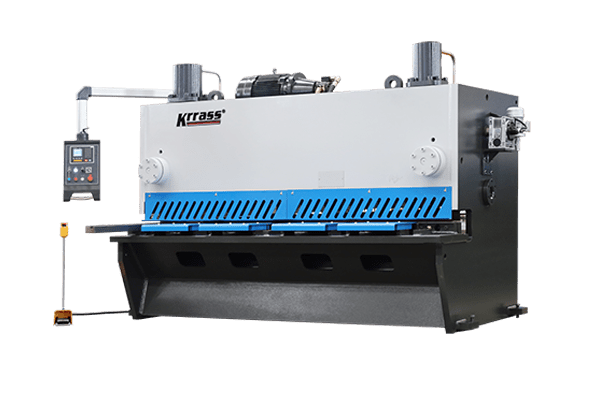

Shearing Machine - sheet metal tools

Shearing machines are commonly used sheet metal tools, used by the machine to assemble sheet metal, the most widely used of these is hydraulic guillotine shears. The main difference with this metalworking equipment used in the industry shop is the shearing process doesn't form any residual materials, which reduces the debris in the air. Shearing machinery is a crucial part in the manufacturing process of the metal. The other major metal cutting procedures reminiscent of sandering are blank cutting.

Learn more:

Which are the machines used for sheet metal work?

This is one of the simplest tools to manufacture sheet metal sheets: hydraulic press brakes. Shearing Machines. ironworkers. These different types of sheet metal tools can help different manufacturing plants produce metal parts of different shapes and functions.

KRRASS: The Best Choice For All Sheet Metal Manufacturer

When considering the overall costs of purchasing, maintaining, and operating a sheet metal equipment setup, a sheet metal fabrication service: a shearing machine, is the best option. KRRASS has a tremendous reputation in the market due to its focus on consistency and quality at the most competitive price.

Whether sharing or any other application, our team of experts has the right combination of industry knowledge and the latest tools to provide you with the best products and services on the market. Moreover, we set ourselves apart with our advanced system that is completely online. Just let us know what your product needs, request a quote, and start the process.

Make a request and Get Started Today

Get Instant Quote

Planer machine

Planar machines have resembled shaper machines. The main distinction is that the cutting tool is still stationary and the workpiece moves along a straight line. These machines are usually bigger than the shaper. It helps to decrease material thickness and size through shaving off excess material at machining procedures. It can be employed in both flat surfaces and uneven surfaces.

Drilling machine

Drilling machines are one type of machine commonly seen within metal-working shops. These are used for numerous home repairs. The drilling machines are easily accessible and replaced which make the job very simple. These drill bits are suitable in various materials such as steel, cement, and some cement.

Saw Machine

The saw machine has three different kinds: circular saw or bands saw. This machine divides metal into small sections.

Circular Saw

The circular saws in hand or table saw variants have round blades rotating or reciprocating for cutting. This circular saw machine can easily be used for industrial work.

Hacksaw

The most commonly known saw is a Hacksaw. The machine uses hand tools that use straight blades to cut metal objects including pipes, tubes and other sheet metal.

Bandsaw

Band saws are excellent for cutting timbers as well. Easily create long-size and high quality pipes and solids - it can be used for pipe construction.

Summary

This article shares with you 10 types of machines used in metalworking industries. Some of these machines may be known to you and some may not. If you are or will be in the metalworking industry, you need to know something about it. No matter what kind of equipment in the metalworking industry, we must choose according to our actual production needs. I hope this article can help everyone.

Learn more about our products, please visit and subscribe to our Youtube channel