Table of Contents

一.Tube laser cutting machine usage positioning and scenarios

In the current market of Tube laser cutting machine, single-Chuck models have limited application scenarios (only suitable for short pipes of

≤3 meters and simple processes), accounting for less than 15% of the market share, and most of them have basic configurations. While dual-Chuck and triple-Chuck models, due to their ability to adapt to medium and long pipes and high-precision processing, occupy over 85% of the mainstream market share and have become the core choice for professional-level production.

1.Single chuck system: a supplementary option for niche scenarios

Market Status: Suitable only for simple processing of furniture, daily necessities, and pipes ≤3 meters in length, requiring low precision (radial runout ≤0.1mm). Due to the high far-end deflection (0.5mm/m) and low efficiency (capacity ≤50 pipes per shift) when processing long pipes, this type of pipe is gradually being replaced in industrial production.

Core Limitations: Unable to provide stable clamping for pipes longer than 6 meters. Cutting errors (perpendicularity error >0.1mm) are common when processing thick-walled pipes (>8mm). Therefore, this type of pipe is recommended only as a temporary transition option or for very small batch production.

2.Dual chuck system: mainstream configuration for industrial production

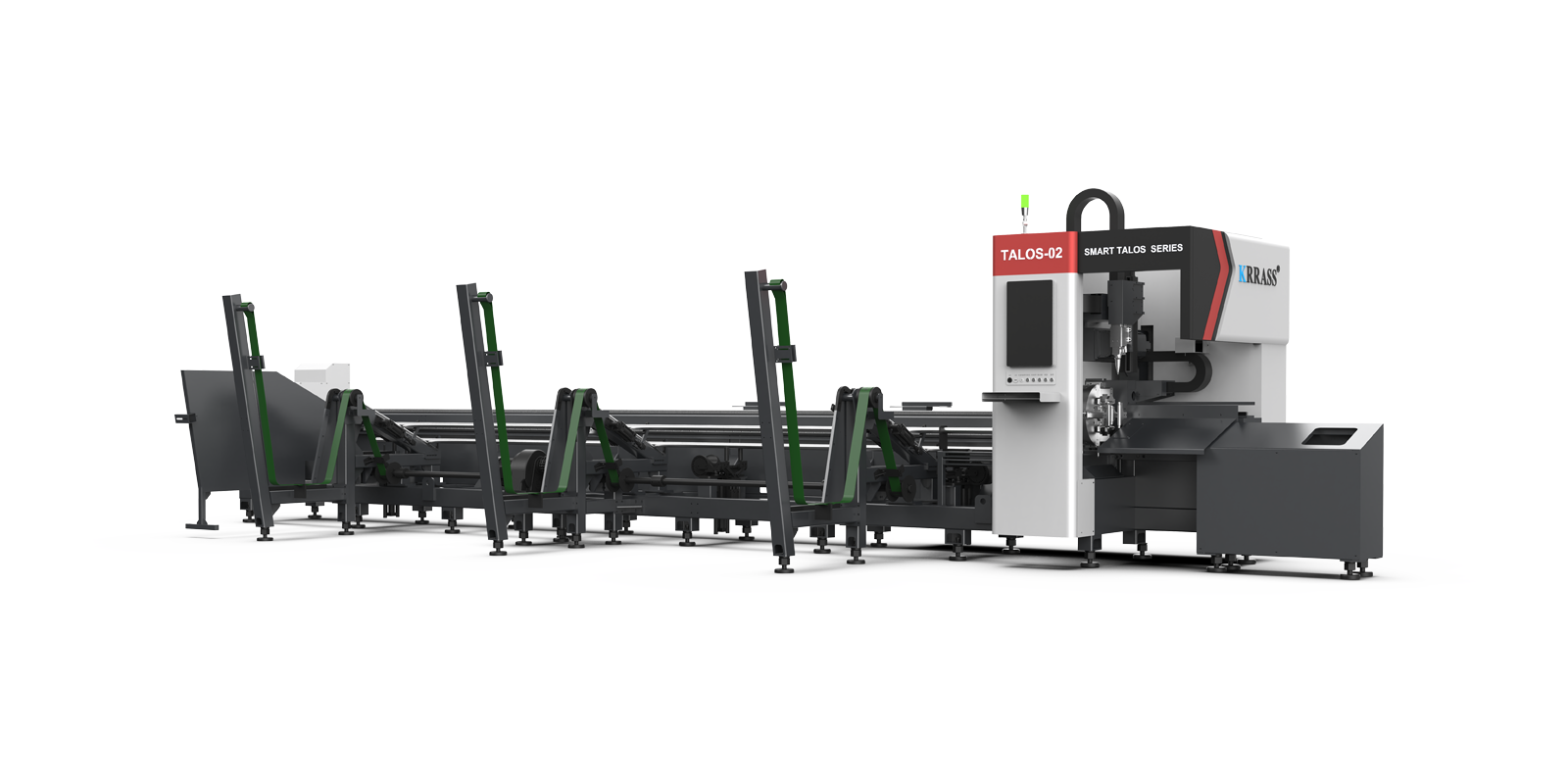

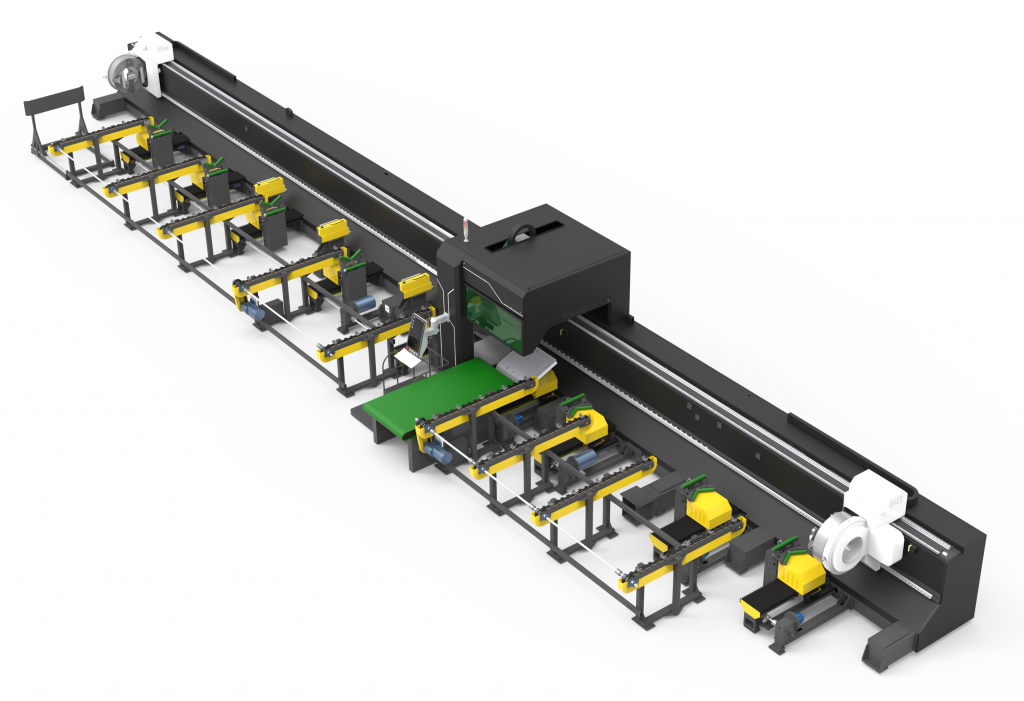

As a leading model with a market share exceeding 60%, the tube laser cutting machine features a dual-chuck system with a collaborative “front drive + rear follower” design, making it the optimal solution for batch processing of medium- and long tubes. Its technical features and application advantages are as follows:

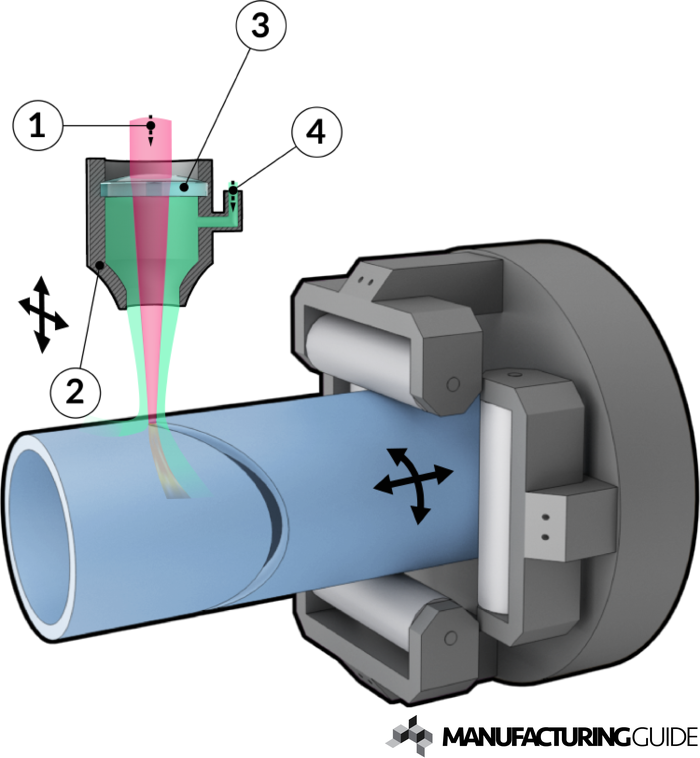

Structural Innovation:The tube laser cutting machine utilizes a symmetrical dual pneumatic chuck layout (adjustable spacing of 6-12 meters) with 3-5 sets of adaptive support rollers (load-bearing capacity ≤ 1000kg) positioned in the middle. Leveraging KRRASS’s patented synchronous servo algorithm, it achieves millisecond-level synchronization of tube rotation and feed (synchronization error ≤ 0.01mm), keeping radial runout to within 0.02mm, a 40% improvement in accuracy compared to a single-chuck system.

Core Advantages:Efficiency Breakthrough: Equipped with a fully automatic loading system, it can process 80-200 6-12 meter pipes (e.g., Φ150mm x 8mm carbon steel pipes) in a single shift, achieving 2-3 times the efficiency of single-chuck models and reducing unit processing costs by 30%.

Guaranteed Precision: When processing medium- and thick-walled pipes (5-15mm) from Φ100-Φ300mm, the cut verticality error is ≤0.05mm, and the bevel angle tolerance is ±0.5°, meeting core standards in the automotive manufacturing and construction machinery industries.

Flexible Adaptability: With adjustable clamping force (0-5000N) and polyurethane flexible jaws, it ensures both deformation prevention for thin-walled pipes (1-3mm) and slip prevention for thick-walled pipes (8-15mm).

Typical Application Scenarios:

Batch beveling of 6-meter-long Φ120mm × 10mm seamless steel pipes for automotive chassis, with a single-shift capacity of 300 pipes and a cut roughness Ra ≤ 3.2μm.

Multi-angle hole drilling of 8-meter-long Φ200mm × 8mm square pipes for the steel structure industry, achieving a hole position deviation of ≤ 0.08mm through dual chuck synchronized control.

Continuous cutting of 12-meter-long Φ80mm × 5mm oval pipes for fitness equipment, with a scrap rate below 0.3%.

3.Three-chuck system: the exclusive solution for high-end precision machining

Targeting ultra-long tubes (>12 meters), ultra-thick tubes (>15mm), and precision-grade processes, three-chuck tube laser cutting machines, with a market share of less than 20%, support core processing in high-end sectors such as wind power, nuclear power, and aviation.

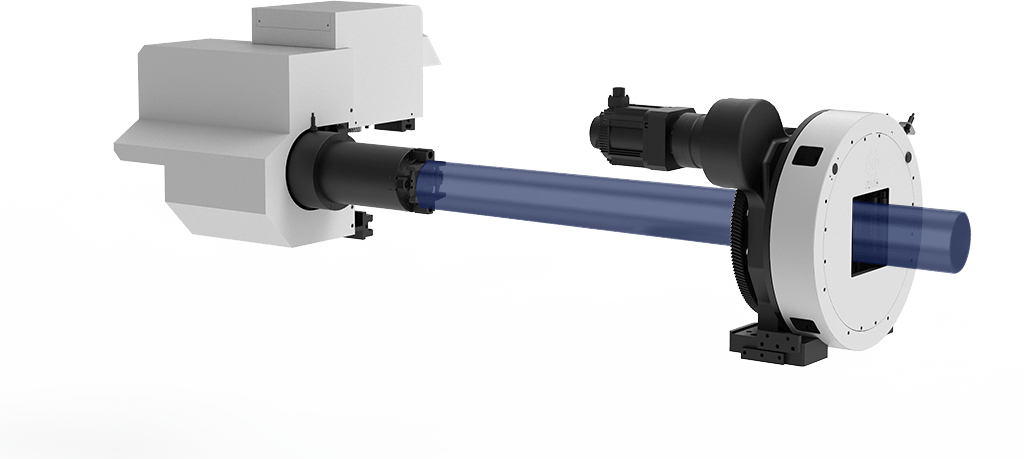

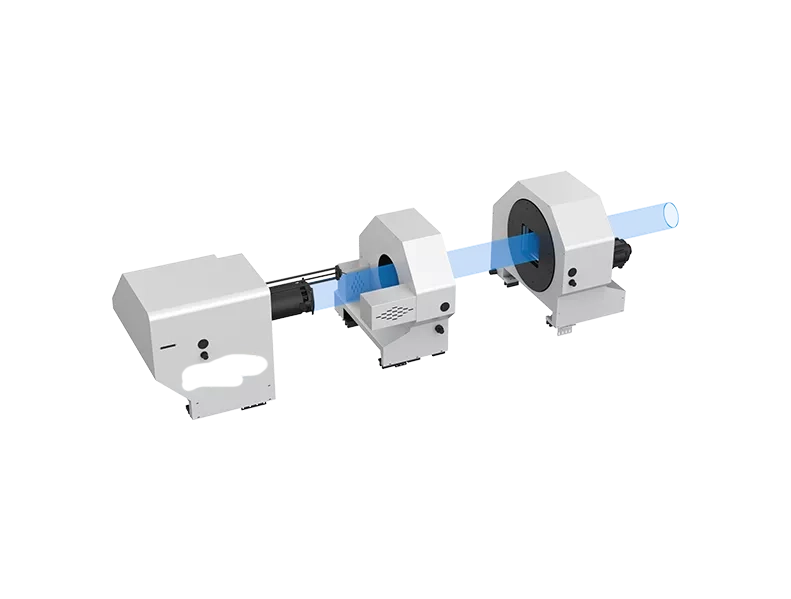

Structural breakthrough: a three-stage layout consisting of a “front drive chuck + center adjustment chuck + rear support chuck.” The center chuck slides along the machine bed (positioning accuracy ±0.01mm), allowing for a total clamping length of 12-18 meters and a maximum clamping force of 0-8000N. By distributing stress across multiple support points, the machine mitigates bending deformation caused by the weight of long tubes (deflection ≤0.03mm/m).

Technical Barrier: The KRRASS intelligent pressure feedback system monitors tube wall thickness and material hardness in real time, dynamically adjusting the three-chuck clamping force (for example, maintaining 5000-6000N when processing a 16mm alloy tube), preventing tube deformation caused by over-clamping.

Irreplaceable Scenarios:

Cutting 12-meter-long Φ500mm x 20mm thick-walled steel pipes for wind turbine towers, ensuring a straightness of ≤0.5mm along the entire length

Processing ±45° spiral bevels on nuclear power pipelines, with a bevel angle tolerance of ≤±0.3°

Precision cutting of 16-meter ultra-long alloy pipes for aerospace applications, with a length tolerance of ±0.1mm

二.Depth selection dimensions for double and triple chucks

1.Rigid matching of pipe length and processing accuracy

| Pipe length | Precision requirement (radial runout) | The only option | Core guarantee indicator |

| 6-12 m | ≤0.05mm | Double chuck | Synchronization error ≤ 0.01mm |

| >12 m | ≤0.03mm | Triple chuck | Deflection ≤ 0.03mm/m |

| 6-12 m + Thickness > 15mm | ≤0.05mm | Triple chuck(recommend) | Multi-point anti-deformation mechanism |

2.Optimal balance between production scale and cost-effectiveness

Double Chuck model: When processing 50-200 6-12 meter pipes per day, the unit processing cost is the lowest. Taking carbon steel pipes with a diameter of 200mm and a thickness of 10mm as an example, the processing time per single pipe is shortened by 40% compared to the single-Chuck model, and the labor cost is reduced by 50% (no need for manual auxiliary support).

Triple Chuck model: When processing more than 200 12-meter-long pipes on average per day, the efficiency advantage becomes prominent. Through dynamic adjustment of the intermediate Chuck, the need for secondary clamping of long pipes is reduced, and the single-shift production capacity can reach over 300 pipes. Compared with the Double Chuck model, the unit energy consumption is 15% lower (due to the optimization of the path, reducing idle travel).

3.Targeted Adaptation of the Characteristics of the Tube laser Cutting Machine Industry

| Industry field | Core requirements | Recommended chuck type | Technical support |

| Automobile manufacturing | 6-12 meters pipe batch beveling (±0.5°) | Double Chuck | Synchronous servo + Automatic feeding |

| Steel structure | 12-meter-long H-shaped steel intersection line cutting | Triple Chuck | Multiple-point support + Section compensation |

| Wind power / Nuclear power | Φ300mm and above thick-walled pipes (>20mm) | Triple Chuck | Intelligent pressure control + Constant temperature compensation |

| Engineering machinery | Mixed processing (mainly 6-12 meters) | Double Chuck | Flexible clamping + Efficiency balance |

3.The collaborative matching strategy for the technical parameters of the Tube Laser Cutting Machine

Power adaptation for dual chuck models

6000W: Suitable for pipes with a wall thickness of 6-12mm, such as Φ300mm × 10mm carbon steel pipe, with a cutting speed of up to 1.5m/min and a cut roughness of Ra ≤ 3.2μm.

8000W: Covers wall thicknesses of 8-16mm and is suitable for processing thick-walled square pipes (150×150mm×12mm) for construction machinery. Burr-free cutting is achieved with high-pressure nitrogen (20bar).

Power configuration of three-chuck model

10,000W: Suitable for cutting Φ400mm×20mm carbon steel pipes with a wall thickness of 16-25mm at a speed of 0.8m/min, with a heat-affected zone ≤0.3mm.

12,000W and above: Suitable for cutting ultra-thick wall pipes of 25-40mm, such as Φ500mm×30mm steel pipes used in wind turbine towers. A dual-module laser is required to ensure stable energy output.

4.Decision Verification and Implementation Path

Key points of trial cutting verification for tube fiber laser cutting machine

Double Chuck: Test the verticality deviation of the cutting edges at both ends of the 12-meter pipe (should be ≤ 0.05mm), and the dimensional consistency of the continuous 50 processed pieces (the range of difference should be ≤ 0.1mm).

Triple Chuck: Measure the deflection difference between the middle section and both ends of the 16-meter pipe (it should be ≤ 0.03mm), and the angle fluctuation of the bevel on the 16mm thick-walled pipe (it should be ≤ ±0.3°).

Tube fiber laser cutting machine Long-term planning adaptation

If there is a demand for pipe processing of 12 meters or more in the future, even if the current processing mainly involves pipes ranging from 6 to 12 meters, it is recommended to choose the Triple Chuck model (which can also handle short pipe processing), to avoid the investment in additional equipment (the cost of upgrading from Double Chuck to Triple Chuck is approximately 60% of the cost of a new machine).

5.Conclusion

When selecting KRRASS professional Tube fiber Cutting Machine, it is essential to closely follow the industry trend of “medium and long pipes being the mainstream, with high precision as the core”: The Double Chuck model has the core advantages of processing 6-12 meters of pipes and achieving batch production, making it the preferred choice for 80% of industrial scenarios; The Triple Chuck model focuses on processing ultra-long pipes over 12 meters and ultra-thick-walled precision parts, providing indispensable technical support for the high-end sector. Enterprises should base their selection on the pipe length, precision requirements, and production capacity scale, and prioritize choosing the chuck configuration that matches their long-term production needs to maximize the investment return of the equipment.