What is the importance of Press Brake in sheet metal parts? Sheet metal parts are a comprehensive cold processing process for metal sheets (usually less than 6mm), including shearing, punching/cutting/compounding, folding, welding, riveting, splicing, and forming.

Features: Uniform thickness. For a part, the thickness of all parts is consistent, light weight, high strength, conductivity, low cost, and good performance in large-scale mass production.

Table of Contents

1.Shearing process

The equipment for the shearing process is a Hydraulic Shearing Machine, which can cut a sheet of metal into basic shapes. Advantages: low processing cost; Disadvantages: average precision, burrs when cutting, and a single cutting shape, which is a simple rectangle or other simple figures composed of straight lines.

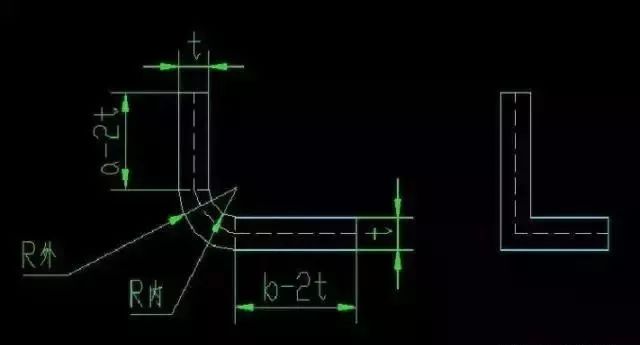

Before the shearing process, the unfolded size of the part must be calculated. The size of the unfolded size is related to the bending radius, bending angle, sheet material, and sheet thickness.

2.Stamping process

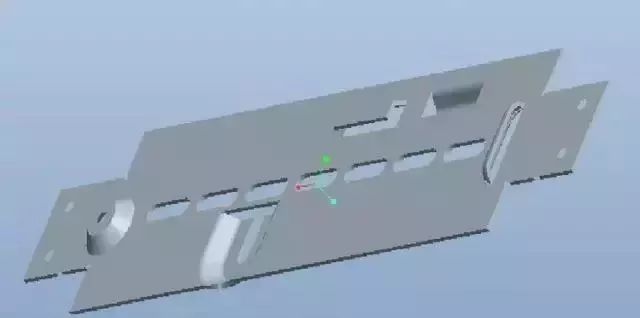

The punching process equipment is a punching machine, which can further process the cut materials into shapes. Different molds are needed to punch various shapes. Common molds include round holes, oblong holes, and bosses; they have higher precision.

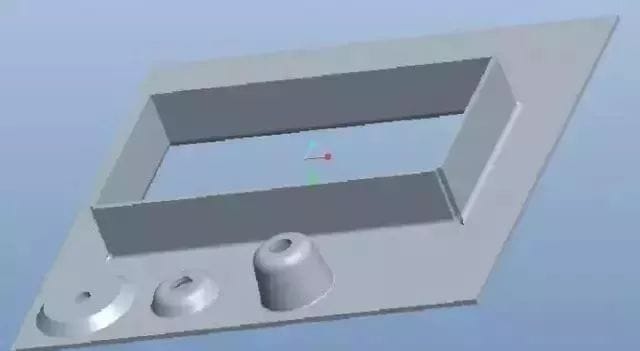

Boss: The material is not removed. Note that the height of the boss is limited, which is related to the material of the plate, the thickness of the plate, the angle of the boss bevel, etc.

There are many types of bosses, including heat dissipation holes, mounting holes, etc. Due to the influence of bending, the edge of the designed hole is limited from the edge of the plate and the bending edge

3.Laser cutting process

Fiber laser cutting machine, for the removal of materials that cannot be completed by Hydraulic Shearing Machine and Punching Machine, or for plates with high hardness that are easy to damage the mold, such as rounded corners, or when there is no ready-made mold to punch the required shape, Laser cutting machine can be used to complete the shaping of the material before bending. It has burr-free cutting, high precision, and can cut any graphics, such as leaves, flowers, etc.; the process cost is high

4.Bending (Press Brake, Plate Rolling Machine)

They can fold or roll metal sheets into the required shape, which is a forming process for parts. The process of cold pressing the metal sheet with the upper and lower knives of the Press Brake to deform it and obtain the required shape is called bending.

5.Press Brake Experience

Bending is the last step in sheet metal forming. There are several points that need to be paid attention to whether the parts can be unfolded and bent. The following editor will tell you.

- Lack of materials. As shown in the figure below, the boss is too high and exceeds the ductility of the material. The boss is generally used to raise the installation size or avoid installation conflicts. Therefore, the boss must be made without changing the internal structure of the material and affecting the structural strength. For example: the angle between the boss cone and the reference plane is 45°, and the height is 3 times the plate thickness

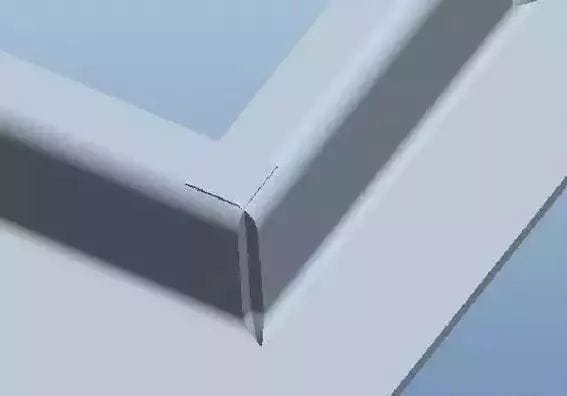

- Redundant materials: Redundant materials are often found at the places where multiple bending edges are closed, which is mostly due to process errors or drawing errors

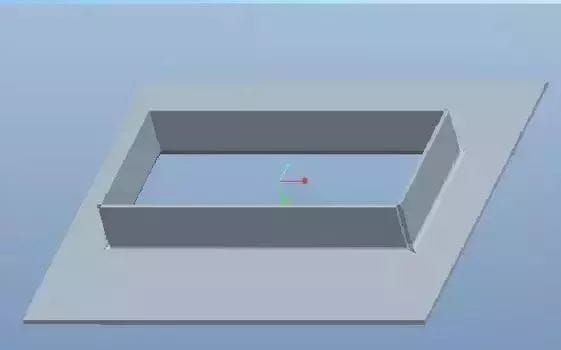

- Bending restrictions: Most bending machines have certain restrictions on bending

Single-side height: depends on the size of the bending machine and the height of the upper knife. The solution can be to use multi-sided large-angle bending

Double-side height: not greater than the maximum height of a single side. In addition to all restrictions on the single-side height, it is also restricted by the bottom edge: bending height < bottom edge - Since sheet metal parts are formed by bending a piece of thin metal plate, the contact of the bending edge is not sealed and there is no hard connection. If it is not processed, it will affect the strength. The usual processing method is welding. The technical requirements on the drawing are: welding angle, welding angle, rounding

- Surface treatment

Since the sheet metal parts are thin, they are not suitable for hot-dip galvanizing. Common surface treatment methods are: phosphating, electrostatic spraying, and the color varies with the project. This process is suitable for sheet materials with black parts that have not been treated on the surface