In the field of metal processing, the Press Brake is the core equipment for shaping metal sheets. And Press Brake Crowning, as a key component of it, plays a crucial role in enhancing the bending accuracy and ensuring the processing quality.

I.The workbench classified by the “Crowning” method

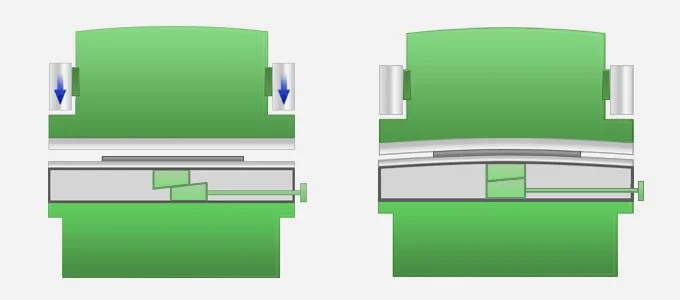

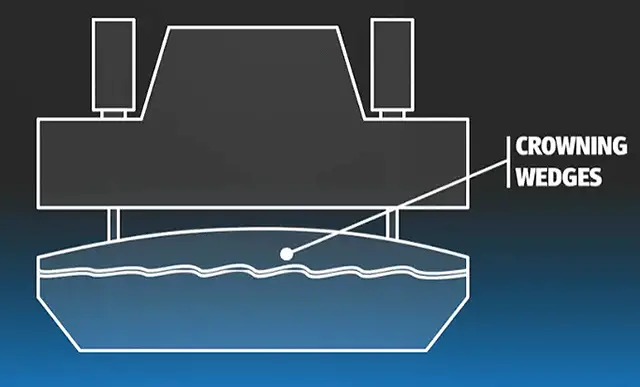

1 Mechanical Press Brake Crowning

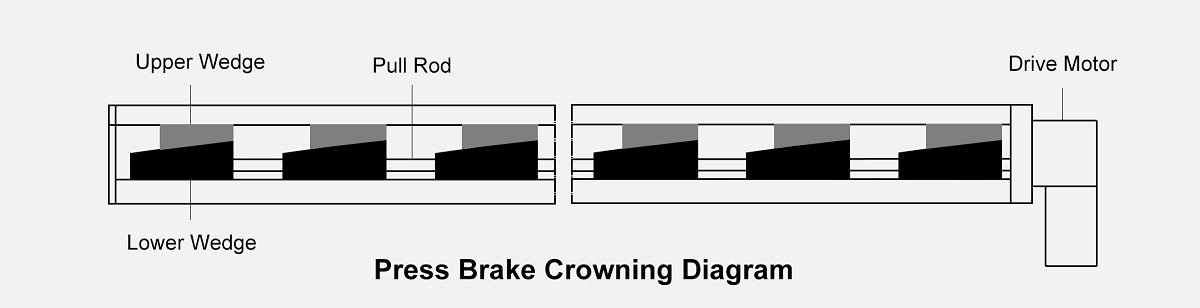

The combination structure of inclined block groups is adopted. Different inclined block groups are paired through different inclined planes. The upper and lower inclined block groups move relatively in the length direction, which can generate the Crowning curve for the deflection deformation of Press Brake. The fit accuracy can reach 0.03mm. T-slots can be opened on both the front and rear sides, and mold installation slots can be opened on the cover plate. The motor drive adopts a custom CNC integrated motor, which is perfectly connected with the Press Brake CNC system. The hand-cranked type also has an internal deflection Crowning value display. The structure is compact, the display is accurate, and the local fine-tuning structure can be set. Make Crowning adjustments more precise, with lower costs and easier operation.

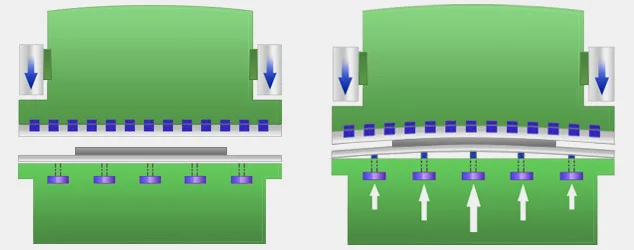

2.Hydraulic Press Brake Crowning

Hydraulic Press Brake Crowning utilizes the hydraulic system to provide Crowning force. High-pressure oil is delivered to the hydraulic cylinders beneath the workbench through a hydraulic pump. According to the instructions of the control system, the oil pressure and piston stroke of each hydraulic cylinder are precisely adjusted, thereby achieving precise control of the height of the workbench’s support points. The hydraulic Press Brake Crowning has the advantages of large Crowning force, fast response speed and high adjustment accuracy. It can adapt to the bending processing of larger-sized plates and is widely used in medium and large-sized Press brakes.

II.Workbenches classified by structure

1.Cantilever worktable: It features a movable cantilever for clamping workpieces. It is suitable for scenarios where workpieces need to be moved frequently or processed from multiple angles, such as suspending heavy components like engines in the automotive repair industry, facilitating inspection and repair by maintenance personnel.

2.Fixed worktable: Installed on a fixed bracket, it is used to support workpieces or serve as a process installation surface. It features a stable structure and strong load-bearing capacity, making it suitable for scenarios that require long-term fixed operations, such as supporting precision components like circuit boards in electronic and electrical production lines, facilitating workers’ operations like welding and inspection.

3.Single-sided linear workbench: Arranged in a straight line, one side is the operation surface and the other side is the passage or storage area. It is suitable for scenarios where space is limited but efficient utilization is required. It can be arranged along the wall to save space and improve work efficiency. It is commonly seen in small trolleys or laboratories.

4.Press Brake Bilateral Linear Workbench: Both sides are operation surfaces, and the middle is a passage or storage area. It is suitable for scenarios where two or more people need to work simultaneously, such as supporting components to be assembled in an assembly production line, facilitating workers’ assembly and debugging. It usually adopts a modular design and can be flexibly combined and expanded according to requirements.

5.Press Brake Circular Workbench: Arranged in a ring shape, with a passage or storage area in the middle. It is suitable for scenarios that require cyclic operations or multi-person collaboration, such as supporting printed materials and other materials in the printing industry, facilitating workers to perform printing, cutting and other operations.

III. Press Brake Workbenches Classified by Function

- Ordinary workbench: Mainly used to support workpieces and perform basic bending operations, it does not have special functions or devices. It is suitable for bending operations with low processing requirements and simple processes, and is particularly applicable to some small enterprises or situations with relatively small processing volumes.

- Press Brake Workbench with material support device: Equipped with material support devices such as rollers and balls, it can support and assist in the movement of the sheet during the bending process, reduce the deformation and friction of the sheet, and improve the bending quality. It is suitable for bending longer or thinner plates and can effectively prevent problems such as sagging and scratches caused by the plates’ own weight or friction during the bending process.

- Press Brake Worktable with Angle fine-tuning Function: It is equipped with an Angle fine-tuning mechanism. By turning the handle, adjusting the lead screw, etc., the local bending Angle can be precisely fine-tuned. For the processing of some workpieces with high requirements for the accuracy of bending angles, it can meet their precise adjustment needs, improve processing accuracy and product quality.

IV. Common Crowning Types?

In the practical application of Press Brake, the CNC hydraulic worktable, hydraulic Press Brake Crowning, pneumatic clamping and mechanical Crowning integrated worktable, mechanical Press Brake Crowning, fixed worktable, and worktable with material support device are the most commonly used types. They dominate in different scenarios with their own characteristics. The specific advantages are as follows:

1.Hydraulic Press Brake Crowning

Press Brake Crowning, as the core component of Press Brake, combines the advantages of numerical control technology, hydraulic drive and precision mechanical structure, and performs outstandingly in terms of processing accuracy, efficiency and adaptability. Its specific advantages are as follows:

a. Precise control by numerical control system: Equipped with professional bending numerical control systems (such as DELEM, CYBELEC, etc.), it can precisely set parameters such as bending Angle, depth, and speed, with errors controlled within ±0.1°, solving the problem of precision fluctuations caused by the reliance on manual experience in traditional mechanical Press Brake.

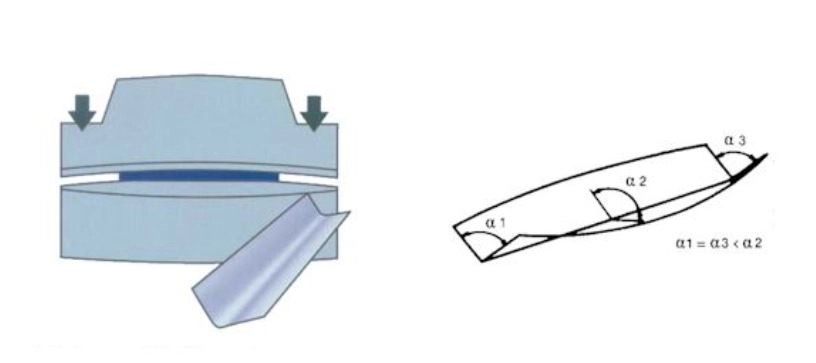

b. Real-time Deflection Crowning Most CNC hydraulic worktables integrate hydraulic or mechanical Crowning functions, which can automatically calculate the deformation of the worktable based on the thickness, length and bending force of the sheet. The Crowning amount can be adjusted in real time through hydraulic cylinders or mechanical sliders to ensure that the bending angles of long workpieces (such as sheets over 6 meters) are consistent throughout the entire length. Avoid the phenomenon of “the middle Angle being too large and the two ends being too small”.

C. High repeat positioning accuracy: The guiding mechanism between the worktable and the slider (such as linear guides, ball screws) fits precisely, with a repeat positioning error of ≤0.02mm. When bending the same batch of workpieces multiple times, the dimensional consistency is extremely strong, making it suitable for automotive parts

D. Program Pre-storage and Invocation: Supports the storage of hundreds of bending programs. Parameters can be directly retrieved for different workpieces without the need for repeated debugging. It is particularly suitable for multi-variety and small-batch production, with production changeover time reduced by more than 50%.

E. Interlocking control function: The workbench is interlinked with the rear stopper and the slider movement, which can automatically complete the processes of sheet positioning, bending, and return. The operator only needs to load materials and pick up parts, significantly reducing manual intervention. The single-shift production capacity is increased by 30% to 80% compared to traditional equipment.

F. Intelligent auxiliary functions: Some high-end models are equipped with devices such as laser positioning, automatic detection of sheet thickness, and anti-pressure hand protection, reducing manual measurement and adjustment time while lowering operational risks.

G. Wide range load capacity: The workbench is made of high-strength alloy steel (such as 45# steel quenched and tempered), and its surface is hardened by quenching (with a hardness of over HRC50), capable of withstanding bending forces ranging from hundreds to thousands of tons, and is suitable for bending requirements from 0.5mm thin steel plates to 50mm thick steel plates.

H. Compatible with multiple molds and processes: The worktable surface is processed with T-slots or positioning holes, allowing for the quick installation of standard bending molds, special-shaped molds, or multi-station combination molds. It supports complex processes such as V-shaped bending, U-shaped bending, Z-shaped bending, and arc bending, and can even achieve three-dimensional workpiece processing (such as boxes and frames) through multi-step bending.

I. Flexible adaptation to different plates: By adjusting the hydraulic pressure and slider speed through the numerical control system, it can be adapted to plates of different materials such as carbon steel, stainless steel, aluminum alloy, and copper, avoiding problems such as cracking and springback caused by differences in material hardness.

J. Visual programming interface: It adopts a touch screen or key-type operation panel, making program writing intuitive (through graphical programming or parameter input). Novices can start working after simple training, reducing the reliance on experienced technicians.

K. Self-Diagnosis and Feedback of Faults: The system is equipped with built-in sensors that can monitor the pressure, temperature and operating status of the workbench in real time. When any abnormality occurs, it will automatically alarm and display the fault code (such as “Crowning oil circuit blockage”, “positioning timeout”), facilitating quick troubleshooting and maintenance, and reducing downtime.

L. Remote Control and Data Management: Some smart models support iot connection, allowing for remote monitoring of processing progress and retrieval of production data via mobile phones or computers, facilitating workshop management and process optimization.

M. Smooth hydraulic drive: The servo hydraulic system is adopted, with precise flow and pressure control. The worktable operates without shock, reducing mechanical wear. It is also equipped with an oil temperature control system to prevent performance degradation caused by overheating.

N. Excellent structural rigidity: The worktable and the machine body are integrally welded and undergo aging treatment to eliminate internal stress, making it less prone to deformation over long-term use. Combined with hydraulic components with good sealing performance, the equipment’s mean time between failures (MTBF) can reach over 1000 hours.

Summary

2.Press Brake Pneumatic clamping and mechanical Crowning integrated worktable

The pneumatic clamping and mechanical Crowning integrated worktable is a typical representative of the integrated design in the Press Brake field. It integrates the functions of workpiece fixation (pneumatic clamping) and precision guarantee (mechanical Crowning) into one, demonstrating significant advantages in improving processing efficiency, ensuring bending accuracy, and simplifying operation procedures, as follows:

a. Rapid automatic clamping: With the built-in pneumatic clamps (mostly driven by cylinders), the workpiece can be positioned and fixed within 1-2 seconds, eliminating the need for manual tightening of the fixture or pressing with bolts. It is particularly suitable for batch processing of thin plates (0.5-6mm) or medium and small-sized workpieces (length ≤3 meters), reducing the single workpiece clamping time by more than 60%.

b. Adjustable and controllable clamping force: The pneumatic system can precisely control the clamping force through the pressure regulating valve (usually 0.3-0.8MPa), which not only ensures that the workpiece is stable and does not slide (avoiding dimensional errors caused by displacement during bending), but also prevents thin plates from deforming due to excessive clamping force (such as aluminum plates, galvanized plates and other fragile materials), and is compatible with various materials and thicknesses of plates.

c. Linkage with bending actions: After being integrated into the Press Brake numerical control system, it can achieve an automated and continuous operation of “loading – clamping – bending – releasing – picking up”, without the need for human intervention in intermediate links. It is suitable for matching with robots for loading and unloading to realize unmanned production.

d. Real-time deflection correction by mechanical Crowning: The worktable is equipped with a built-in mechanical Crowning mechanism (such as wedge groups, eccentric shafts or adjustable support blocks), which can manually or automatically adjust the local height of the worktable according to the magnitude of the bending force (through preset parameters or sensor feedback) to counteract the deflection deformation of the Press Brake caused by the load (especially for workpieces longer than 4 meters). Ensure angular consistency throughout the entire length range (error ≤0.5°).

e. Synergy between Clamping and Crowning: Pneumatic clamping ensures that the position of the workpiece does not shift during the Crowning process, while mechanical Crowning corrects the precision deviation caused by changes in the length and thickness of the workpiece. The combination of the two can control the bending dimensional tolerance within ±0.1mm, meeting the processing requirements of precision sheet metal parts (such as electrical cabinet frames and medical device components).

The F. Crowning structure is highly durable: The mechanical Crowning components are made of high-strength alloy steel (such as 40Cr) and processed by heat treatment, which has good wear resistance. The Crowning accuracy remains stable for a long time (generally, the accuracy attenuation does not exceed 0.02mm after 3-5 years of use), and the maintenance cost is lower than that of the hydraulic Crowning system.

J. Integrated control simplifies the process: The operation of pneumatic clamping and mechanical clamping is completed through the same control panel (such as the touch screen of the numerical control system). Parameters (clamping force, clamping quantity) can be digitally set and stored. When changing workpieces, the preset program can be directly called without re-debugging. Novices can get started after 1-2 hours of training.

K. Intuitive mechanical Crowning adjustment: Some models are equipped with Crowning scale dials or electronic displays. Operators can quickly adjust the Crowning value through hand wheels or motor drives, completing precision calibration without professional knowledge and solving the problem that traditional mechanical Crowning relies on experience.

L. Enhanced safety: The pneumatic clamping device is equipped with built-in overload protection (such as a pressure sensor). When the clamping force is abnormal, it automatically releases pressure to prevent the workpiece from flying out or damaging the equipment. Meanwhile, the clamping status can be displayed in real time through indicator lights, reducing the risk of misoperation.

M. Integrated design saves space: The pneumatic clamping components (cylinders, clamps) and the mechanical Crowning mechanism are integrated inside the workbench body, eliminating the need for additional independent clamping devices or Crowning equipment. This is particularly suitable for small and medium-sized enterprises with limited workshop space. The floor space occupied by the equipment is reduced by 30% compared with “split clamping + independent Press Brake Crowning”.

N. Compatible with multiple bending dies: The worktable surface retains T-slots or die installation holes, which can be adapted to standard V-shaped dies, arc dies, special-shaped dies, etc. Moreover, the position of the pneumatic clamp can be adjusted along the length of the worktable (some models are equipped with guide rail sliders), meeting the bending requirements of different workpieces, and its flexibility is superior to that of fixed dedicated clamping worktables.

O. Outstanding cost performance Compared with the combined solution of “pneumatic clamping + hydraulic Crowning”, mechanical Crowning has a lower manufacturing cost and does not require complex hydraulic pipelines and servo systems. The overall equipment procurement cost is reduced by 20% to 30%, making it suitable for enterprises with medium budgets that pursue a balance between efficiency and precision (such as small and medium-sized sheet metal processing plants and equipment suppliers).

Summary

The core advantage of the pneumatic clamping and mechanical Crowning integrated workbench lies in the “balance between efficiency and precision” : Pneumatic clamping has solved the problems of slow and vulnerable parts in traditional clamping, while mechanical Crowning ensures bending accuracy at a lower cost. The integration of the two is not only suitable for batch automated production but also can meet the precision processing requirements of multiple varieties and medium and small batches. It is a cost-effective choice for small and medium-sized sheet metal processing enterprises to increase production capacity and quality.

3.Mechanical Press Brake Crowning

The mechanical Press Brake Crowning is a key component in the Press Brake used to correct the accuracy deviation caused by load deformation. Its core actively offsets the deflection during the bending process through mechanical structures (such as wedge, eccentric shaft, adjustable support, etc.), and has significant advantages in terms of accuracy stability, cost control, and applicable scenarios. Specifically as follows:

A. Real-time offset of deflection deformation: When Press Brake processes long workpieces (especially those over 3 meters), under the action of bending force, the machine body and the worktable will experience slight deflection (droop in the middle and curl up at both ends), resulting in a bending Angle of “larger in the middle and smaller at both ends” for the workpiece. The mechanical Press Brake Crowning can precisely correct the Angle error within the full length range by manually or automatically adjusting the local support height (such as raising the middle area by 0.1-0.5mm), keeping the overall Angle consistency within ±0.5°. It is suitable for processing long workpieces with strict requirements, such as elevator guide rails and container frames.

B. Long-term stable rowning accuracy The mechanical Crowning components (such as wedge groups and alloy support blocks) are made of high-strength steel (40Cr, 42CrMo) and undergo quenching treatment, with a hardness of HRC50-55. They have excellent wear resistance and no problems such as hydraulic oil leakage or electrical component aging in the mechanical structure. After long-term use (3 to 5 years), the accuracy attenuation of Crowning does not exceed 0.02mm, which is much lower than the accuracy drift of the hydraulic Crowning system.

c. Adapted to complex bending scenarios: For asymmetrical workpieces and variable-thickness plates (such as 3mm at one end and 8mm at the other), mechanical Crowning can be adjusted in segments (for example, the worktable is divided into 3-5 independent Crowning sections) to specifically correct the deformation caused by local force differences. However, hydraulic Crowning, which relies on overall oil pressure, is difficult to achieve precise segmented control.

a. High mechanical structure reliability: The core components are purely mechanical transmission (such as hand-cranked wheels driving lead screws and eccentric shafts rotating to adjust height), without precision components like hydraulic pipelines, servo valves, and sensors. It is less affected by the environment (such as workshop dust and temperature fluctuations), and the failure probability is only 1/5 of that of the hydraulic Crowning system.

d. Easy maintenance with low threshold: Daily maintenance only requires regular cleaning of the guide rails and application of grease (1-2 times a month), without the need for professional technicians. If the components are worn out (such as the contact surface of the wedge), individual components can be directly replaced (at a cost of about several hundred yuan). However, if the hydraulic Crowning system leaks oil or the sensor malfunctions, the hydraulic station needs to be disassembled for maintenance, which usually costs several thousand yuan.

e. Long service life: The design life of mechanical Crowning mechanisms is generally over 10 years, and core components (such as lead screws and support blocks) can be replaced separately. The entire worktable does not need to be scrapped. Compared with hydraulic Crowning systems (where sealing parts need to be replaced as a whole every 3 to 5 years), the long-term usage cost is reduced by more than 40%.

a. Manual adjustment for quick response: For multi-variety and small-batch processing (such as changing 3-5 types of workpieces daily), operators can manually set the Crowning amount through the scale or digital display screen (preset based on the thickness and length of the workpiece by looking up the table). The adjustment process only takes 1-2 minutes and does not require complex programming, making it suitable for the flexible production mode of small and medium-sized sheet metal factories.

f. Compatible with multiple Press Brake models: The mechanical Press Brake Crowning structure is modular and can be adapted to Press Brakes of different tonnages (100-1000 tons) and different lengths (1-6 meters). It is particularly suitable for upgrading and transforming old equipment (without replacing the hydraulic system), and the transformation cost is only one-third of that of upgrading the hydraulic Crowning.

g. No power dependence: Some simple models do not require external power (purely manual adjustment), making them suitable for scenarios with unstable power supply or temporary processing. In contrast, hydraulic Crowning must rely on a hydraulic station and is more restricted by power.

h. Low procurement cost: The price of the mechanical Crowning system of the same specification (such as a 4-meter-long workbench) is only 50% to 70% of that of the hydraulic Crowning system, making it suitable for small and medium-sized enterprises with limited budgets but a need to ensure precision (such as distribution box processing and kitchenware manufacturing factories).

j. No additional energy consumption required: Mechanical Crowning (especially manual models) does not consume electricity or hydraulic oil, and the operating cost is almost zero. In contrast, hydraulic Crowning needs to continuously drive the hydraulic pump, increasing the annual electricity bill by approximately 2,000 to 5,000 yuan (depending on the frequency of use).

k. Adaptation to low-tonnage equipment: For small-tonnage Press brakes under 100 tons, mechanical Crowning is sufficient to meet the precision requirements (Angle error ≤1°), and there is no need to invest in expensive hydraulic Crowning, avoiding excessive functionality.

Summary

The core advantages of the mechanical Press Brake Crowning lie in “low cost + high reliability + easy maintenance”, which is particularly suitable for medium and small batch, multi-variety production scenarios, as well as enterprises that are sensitive to the initial investment and long-term maintenance costs of equipment. Although its degree of automation is lower than that of hydraulic Crowning (requiring manual adjustment or relying on simple numerical control linkage), it performs outstandingly in the balance between precision stability and economy, and is currently the mainstream choice for medium-length Press brakes of 3-6 meters.4.

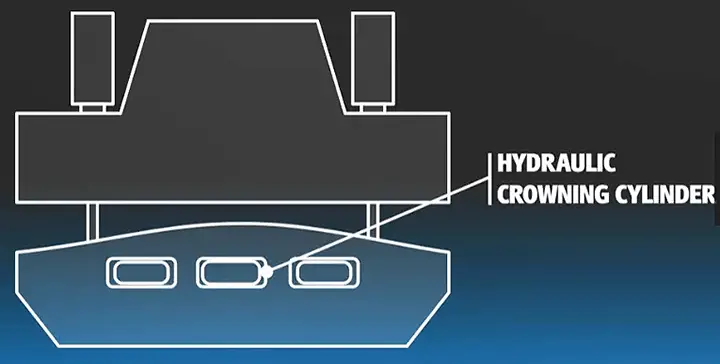

4.Hydraulic Crowning

The hydraulic Press Brake Crowning is a precision component in the Press Brake that adjusts the local height of the worktable through hydraulic drive to counteract the deflection deformation of the machine body and the worktable during the bending process. Its core utilizes the thrust of the hydraulic cylinder to change the height of the support block, achieving real-time and automatic precision correction It has unique advantages in terms of the degree of automation, Crowning efficiency, and adaptation scenarios, as follows:

a. Real-time dynamic response By providing real-time feedback data through pressure sensors (for detecting bending force) and displacement sensors (for monitoring the deflection of the worktable), the hydraulic system (controlled by servo valves) can drive the Crowning cylinder (independently controlled in 3 to 8 segments) to adjust the support height within 0.1 to 0.3 seconds, automatically offsetting the deflection differences caused by changes in sheet thickness, material, and bending Angle. For instance, when processing a 6-meter-long 5mm thick steel plate, the system can automatically lift the Crowning cylinder in the middle by 0.3mm based on the increased force in the middle section (approximately 30% higher than that at both ends), ensuring that the angular error of the entire section is ≤±0.3°, without the need for manual intervention.

b. Seamless integration with the numerical control system Integrated into the Press Brake numerical control system (such as DA56, Cybelec 8000), the Crowning parameters of different workpieces can be preset through programming (such as “Crowning 0.1mm for 1.5mm aluminum plate, Crowning 0.4mm for 8mm steel plate”). When changing production, the program can be directly called without manual adjustment. It is suitable for the production of large-scale standardized workpieces (such as air conditioner casings, switch cabinet frames), and the production change efficiency is 3 to 5 times higher than that of mechanical Crowning.

c. Adaptive complex bending process: For continuous multi-step bending (such as U-shaped → Z-shaped → arc), hydraulic Crowning can dynamically adjust according to the changes in bending force (real-time correction for each step of bending), while mechanical Crowning requires a fixed Crowning amount to be set in advance, making it difficult to adapt to working conditions with large fluctuations in force values.

c. Micron-level adjustment capability: The hydraulic cylinder adopts servo closed-loop control, with a minimum adjustment amount of 0.005mm. Combined with a high-precision grating ruler (resolution 0.001mm), it can achieve uniform Crowning throughout the entire length range. For instance, when processing 2-meter-long titanium alloy plates in the aerospace field, the Angle consistency can be controlled within ±0.2°, which is superior to the ±0.5° of mechanical Crowning.

d. Large deflection Crowning capability: The maximum Crowning stroke of the single-stage oil cylinder can reach 5-10mm (mechanical Crowning is usually ≤2mm), which is suitable for processing thick plates (more than 10mm) with large-tonnage Press Brake (such as over 1000 tons). At this time, the deflection of the machine body can reach 1-3mm, and the hydraulic Crowning can fully cover the deformation. However, due to the limited adjustment range of mechanical Crowning, “insufficient Crowning” may occur.

e. Symmetrical/Asymmetric Crowning at the same time: It can not only achieve overall uniform Crowning (such as symmetrical workpieces), but also achieve asymmetric Crowning (such as left end Crowning 0.2mm and right end Crowning 0.5mm) through segmented cylinders (such as a 6-meter worktable divided into 6 sections). It is suitable for the bending requirements of asymmetrical workpieces (such as L-shaped unequal Angle steel), while the segmented adjustment accuracy of mechanical Crowning is limited by the mechanical structure and it is difficult to achieve such fine differentiated control.

f. Integrated design saves space The Crowning cylinder is built inside the worktable (with a height increase of only 50-80mm), does not occupy additional space, and is suitable for the compact layout of high-precision Press brakes (such as CNC bending centers), while the wedge, lead screw and other structures of mechanical Crowning usually need to be externally attached, increasing the thickness of the worktable by approximately 100-150mm.

j. Compatible with ultra-long workbenches For super-large Press brakes over 8 meters (such as wind turbine tower flange processing), the hydraulic Crowning can be independently controlled in more than 10 sections. Through algorithm optimization, a gradual correction of “more Crowning in the middle and less Crowning at both ends” can be achieved. However, mechanical Crowning, due to the limited number of manual adjustment segments (usually ≤5 segments), is difficult to meet the precision requirements of the over-length range.

h. Disadvantages: Complex structure (including hydraulic station, servo valves, and sensors), high maintenance cost (average annual maintenance cost is about 2-3 times that of mechanical Crowning), and sensitive to the environment (hydraulic oil needs to be filtered regularly, and valve groups are prone to clogging in workshops with a lot of dust).

i. Applicable Scenarios: Suitable for the production of large quantities, high precision, long workpieces or complex processes, such as automotive parts (door frames, chassis brackets), high-end equipment (medical equipment frames), and other fields with strict requirements for precision and efficiency.

Summary

The hydraulic Press Brake Crowning, with “automation, high precision and dynamic response” as its core advantages, is the mainstream configuration of mid-to-high-end Press brakes, but its cost and maintenance threshold are relatively high. In contrast, mechanical Crowning is more suitable for medium and small batch production and low-cost scenarios. The choice between the two should be made by comprehensively considering production scale, precision requirements and budget.

5.Worktable with material support device

The workbench with a material support device is an enhanced workbench designed by Press Brake for large-sized and heavy plates (such as steel plates over 6 meters in length and alloy plates over 10mm in thickness). Its core provides stable support during the plate feeding and bending process through adjustable material support frames, auxiliary support rollers or magnetic/pneumatic lifting mechanisms. It solves problems such as difficult manual handling and sagging and deformation of boards. The specific advantages are as follows:

a. Replace manual load-bearing: For a 3-meter-long and 8mm thick steel plate (with a single weight of approximately 188kg), a traditional workbench requires 2 to 3 people to lift and feed the material. However, a workbench equipped with a material support device can lift the plate to be level with the workbench surface through an electric material support frame (with a load capacity of 500 to 2000kg). Workers only need to push the plate to align it, reducing physical exertion by more than 70%.

b. Avoid the risk of the board slipping: The material support device is usually equipped with anti-slip rubber rollers (with a friction coefficient of ≥0.8) or pneumatic grippers (with a clamping force of 50-300N), which fix the position of the plates during the feeding process. It is especially suitable for smooth-surface aluminum plates or stainless steel plates, reducing the occurrence of bumps (such as deformation of the plate edges and corners) or personnel injuries caused by slippage, and increasing the safety factor by 4-5 times.

c. Suitable for handling extra-long plates: When processing plates over 6 meters in length, the extended material support frame outside the workbench (which can be extended to 10 meters) can support the suspended section of the plate (avoiding a sag of ≥50mm in the middle). A single person can complete the feeding and alignment, eliminating the need for multiple people to cooperate on both sides of the workbench to “hold the plates”, solving the problem of “one person deviating and the entire section being wasted” in traditional operations.

d. Eliminating gravity sag error: When thick or long plates are not supported, the middle section may sag due to its own weight (for example, a 6-meter-long 5mm steel plate may sag by about 15-20mm), resulting in uneven force distribution at both ends and in the middle during bending, with an Angle error of up to ±1.5°. The material support device evenly supports through multiple sets of support rollers (with a spacing of 300-500mm), keeping the deflection of the entire sheet section within ≤3mm. Combined with the Press BrakeCrowning system, the Angle consistency can be improved to within ±0.3°.

e. Stable feeding positioning accuracy: The positioning baffle on the material support rack (with an alignment error of no more than 0.5mm with the workbench reference line) and the scale ruler (with an accuracy of 1mm) can assist workers in quickly aligning the edges of the sheet with the bending line. The positioning time has been shortened from the traditional 2-3 minutes to within 30 seconds, making it particularly suitable for batch processing of workpieces of the same size (such as shelf beams and elevator guide rails). The repeat positioning error is ≤±0.5mm.

f. Protecting the surface quality of the sheet: The material support rollers are made of polyurethane (with A hardness of 60-80 Shore A) or treated with chrome plating for rust prevention, avoiding direct friction with the sheet surface to prevent scratches (such as mirror-finish stainless steel plates, anodized aluminum plates), reducing the subsequent grinding process, and increasing the surface qualification rate from 85% to over 99%.

g. Linkage with loading and unloading equipment: The material support device can integrate sensors (such as laser beam switches). When the robotic arm places the sheet on the material support frame, the system automatically detects the position of the sheet and drives the material support frame to rise to the height of the worktable, achieving a seamless connection of “robotic arm loading → material support frame conveying →Press Brake processing”, without the need for manual transfer, and the single-shift production capacity is increased by more than 30%.

j. Support for multi-process continuous processing: For long workpieces that need to be bent multiple times (such as container side panels), the material support frame can extend and contract synchronously with the bending progress (driven by servo motors, with a speed of 0.5-1m/s). After the first bending, the workpiece can be lifted to rotate or move to the next bending position, avoiding positioning deviations caused by manual flipping. The total time consumption for multi-step bending is reduced by 40%.

h. Compatible with multiple types of plates: The material support mode can be switched for different materials – magnetic support (electromagnet suction force 100-500N) is suitable for iron plates and steel plates. Vacuum suction cup material support (negative pressure -0.6 to -0.8 bar) is suitable for aluminum plates and plastic plates. Pneumatic material support (with an air flow suspension height of 0.1-0.3mm) is suitable for ultra-thin brittle plates (such as 0.3mm silicon steel plates), and its versatility is superior to that of traditional fixed workbenches.

k. Adjustable height and width: The height of the material support frame can be adjusted by hydraulic cylinder or lead screw (range 500-1200mm), which is suitable for the center height of bending plates of different thicknesses. The width of the material support can be extended from 1 meter to 8 meters, meeting the support requirements for workpieces ranging from 1 to 6 meters in length, without the need to replace the worktable for workpieces of different sizes.

Summary

The core advantage of the workbench with a material support device lies in “cost reduction, efficiency improvement and precision preservation” – it not only solves the pain point of difficult handling of heavy and long plates, but also enhances the bending quality through stable support. It is particularly suitable for the production of large workpieces in fields such as metal processing, construction machinery and container manufacturing. Its compatibility with numerical control systems and automated equipment also makes it a key component of intelligent bending production lines.

V.How should I choose the appropriate Press Brake Crowning

When choosing the category of the Press Brake workbench, it is necessary to focus on five core elements: workpiece characteristics, production requirements, precision requirements, operation mode and budget, to avoid functional waste or insufficiency. The following are the specific selection methods and scene matching suggestions. The selection logic can be simplified as: “Workpiece determines the foundation (size/thickness) → precision determines Crowning (mechanical/hydraulic) → efficiency determines assistance (material support/clamping) → scale determines intelligence (automation)”. The core is to precisely match the functions of the workbench with the processing requirements, neither wasting the budget nor sacrificing quality and efficiency.

1.Clarify the core demand dimensions

Before making a choice, it is necessary to sort out the following key information clearly to provide a basis for decision-making:

Dimensions: Length (such as short parts ≤2 meters, regular parts 3-6 meters, extra long parts ≥8 meters), thickness (such as thin plates ≤3mm, medium and thick plates 5-12mm, thick plates ≥16mm)

Material: Low-carbon steel (easy to bend), stainless steel (scratch-resistant), aluminum alloy (precise Crowning required), etc. (Material affects bending force and deformation characteristics)

Angle error: such as ±1° (low precision), ±0.5° (medium precision), ±0.3° (high precision)

Consistency within the same batch: For mass production, it is necessary to ensure that the dimensional deviation is ≤±0.5mm

Output: Single shift ≤50 pieces (small batch), 100-300 pieces (medium batch), ≥500 pieces (large batch)

Production change frequency: Frequent specification changes (such as multiple varieties and small batches), long-term production of fixed specifications (large batches)

Manual feeding/Semi-automatic (with simple loading and unloading)/fully automatic (needs to be linked with mechanical arms and production lines)

Economy type (basic functions), mid-range (with Crowning/material support), high-end (automation + high precision, budget increase of 30%-80%

2.Match the workbench category according to the scene

1: Small-batch, low-precision (within an Angle of ±1°), short and thin workpieces (≤3 meters, ≤5mm thick), basic workbenches (with manual positioning), hardware accessories (such as brackets, small sheet metal parts), single-piece/small-batch production (such as distribution box shells, air conditioner brackets). It has a simple structure, low price (accounting for about 5%-10% of the total price of Press Brake), and is easy to maintain. It is suitable for scenarios with low precision requirements.

2 Medium batch, medium precision (within an Angle of ±0.5°), medium and thick plates (6-12mm), mechanical Press Brake Crowning or hydraulic Press Brake Crowning. The mechanical Crowning can adjust the bottom wedge block (Crowning amount) manually/electrically (0-5mm), offsets the deformation of the worktable caused by bending force, suitable for workpieces with small thickness fluctuations (such as steel structure connectors). The cost is moderate (15%-20% higher than the basic type), making it suitable for medium and small batch production.

Hydraulic Press Brake Crowning: The deflection is adjusted in real time through the servo cylinder (response speed ≤0.1s), which is suitable for scenarios with frequent thickness changes and batch production (such as automotive parts and elevator guide rails). It has higher precision (Angle error after Crowning ≤±0.3°), but the cost is higher (30%-50% higher than the basic type).

3: For extralong pieces (≥8 meters), heavy and thick plates (≥12mm), and those where manual feeding is difficult, workbenches with material support devices (can be equipped with Crowning function) : Support long plates to prevent sagging (for example, when an 8-meter-long steel plate is not supported, the sagging in the middle can reach 5-10mm, causing deviations in bending accuracy), reducing the burden on manual handling. Container side panels, bridge components, shells of large equipment, etc. The load-bearing capacity of the material support device should be no less than the weight of the workpiece (for example, a 10-meter-long 10mm steel plate weighs approximately 785kg, and the load-bearing capacity of the material support frame should be no less than 1000kg). The support spacing should be no more than 500mm (to prevent deformation of the plate).

4: High-frequency mold changing, automated production (such as linkage with mechanical arms) Pneumatic clamping + Crowning integrated workbench (or intelligent workbench) Pneumatic clamping: Mold fixation is completed within 3 seconds (80% faster than manual operation), suitable for multi-variety and small-batch production changes (such as home appliance panels, medical device accessories). Intelligent workbench: Equipped with laser positioning (±0.1mm accuracy), it can be linked with the numerical control system and connected to fully automatic production lines (such as batch production of automotive chassis parts), but the cost is relatively high (80%-150% higher than the basic type).

5: Low cost, low-frequency use (such as occasional processing of simple parts), simple manual workbench (with fixed stopper plate)

Applicable scenarios: Small processing plants, maintenance workshops, and rough workpieces with low processing accuracy requirements (such as scaffolding connection parts).

The price is extremely low (accounting for about 3%-5% of the total price of Press Brake), the structure is durable, and no complex maintenance is required.

3.Suggestions for Avoiding pitfalls and balancing

Avoid “excessive precision” : If the workpiece allows an Angle error of ±1° or more (such as a common bracket), there is no need to choose a hydraulic Crowning or intelligent worktable. The basic type is sufficient, which can save more than 30% of the cost.

Beware of “functional deficiency” : When processing long plates over 6 meters, if the material support device is omitted, the bending scrap rate will exceed 10% due to the sagging of the plates, which will instead increase the rework cost (far higher than the investment in the material support device).

Match the tonnage of the main machine: The load-bearing capacity of the worktable should be compatible with the tonnage of the Press Brake (for example, a 100-ton Press Brake is equipped with a worktable of ≤500kg, and a 300-ton Press brake is equipped with a worktable of ≥1000kg), to avoid deformation of the worktable caused by “a small horse pulling a big cart”.