In many factories, the “NC press brake vs CNC” question is framed as a technology debate. In reality, it is a business system decision that affects labor structure, quality risk, delivery promises, and how quickly you can turn a 2D drawing into consistent parts. An NC press brake can be the most rational choice for stable, repetitive bending work where complexity is low and the team already has strong hands-on experience, while a CNC press brake typically wins when you need faster changeovers, multi-part families, tighter tolerance control, and a training process that scales across shifts.

This article breaks the comparison into three measurable dimensions—cost, accuracy, and training—so you can decide with a spreadsheet mindset instead of a spec-sheet mindset. It also reflects how modern bending is managed today, including offline programming and simulation practices widely discussed by leading industry resources. The Fabricator

Table of Contents

NC Press Brake vs CNC in One Page: What Changes—and What Doesn’t

The bending physics is the same, but the control philosophy is not

Whether you run an NC press brake or a CNC press brake, the physics still depends on the same fundamentals: material thickness variation, yield strength scatter, tool condition, bend allowance assumptions, and machine deflection under load. That means the “perfect bend” is never purely a controller issue, and no control type can ignore material reality.

What does change is how your process absorbs that variability. An NC press brake typically depends more on operator judgment and manual adjustments, while a CNC press brake is designed to reduce those judgment calls by using richer axis control, stored programs, and (often) automated sequence planning or simulation features. delem.com

The practical dividing line: axes + feedback + repeatability practices

Most factories experience the difference in three tangible places:

- how precisely the machine positions the backgauge and ram across repeated parts,

- how quickly the operator can set up the next job without trial-and-error bending, and

- whether programming knowledge lives in one “master operator” or becomes a standardized process the whole team can execute.

This is why the NC press brake vs CNC conversation should not start with controller brand names. It should start with your mix/volume, your tolerance commitments, and how you train operators to produce consistent bends under real-world material variation. The Fabricator

What an NC Press Brake Is: Typical Architecture, Strengths, and Limits

How a typical NC press brake is built and controlled

In many market configurations, an NC press brake is a hydraulically driven brake with comparatively limited programmable control—often focusing on X-axis backgauge positioning and basic ram stroke control. In practice, many NC press brake designs emphasize a simpler electrical/control stack and rely on mechanical or simplified synchronization methods rather than full servo-hydraulic closed-loop approaches for multiple axes.

That simplicity is not “inferior” by default. It can be a purposeful design choice when your production is dominated by straightforward bends, short programs, and repeat runs where the setup is stable and the operator team already understands how to compensate for variation quickly.

Where an NC press brake usually fits best

An NC press brake is often a strong fit when your factory environment looks like this: you run low-complexity parts, bend sequences are short, flange positioning is not highly constrained across multiple bends, and you are not constantly retooling for high-mix schedules. In these conditions, you can realize value quickly because the learning curve for basic operation is shorter and the machine investment is lower.

However, it is important to recognize a trade-off that many managers underestimate. If your quality results rely heavily on a single experienced operator’s “feel,” your risk is not the machine—it is knowledge concentration, which becomes visible when you add shifts, hire new staff, or accelerate delivery schedules.

The hidden operational cost: manual setup loops and human dependency

Factories often evaluate an NC press brake by the purchase price and ignore the “soft costs” that show up after installation. If you need repeated test bends, manual gauge tweaks, and trial sequence adjustments each time a job returns, the machine may be cheaper but the process can be expensive in labor minutes and scrap risk.

This is one reason modern bending discussions increasingly emphasize setup time reduction and standardized procedures, even before you upgrade to full offline programming. Reducing variability in setup is usually the fastest way to improve throughput on either type of press brake, but CNC-enabled workflows make standardization easier to scale.

What a CNC Press Brake Adds: Axes, Simulation, and Scalable Consistency

Multi-axis control changes what “repeatability” means in production

A CNC press brake typically expands controllability beyond basic X/Y concepts by enabling richer axis combinations and synchronized behavior. In many modern configurations, this includes independent control of ram sides (commonly described as Y1/Y2 behavior in the industry) plus additional backgauge axes that improve part positioning for complex geometries.

The manufacturing impact is not academic. When you can program and recall multi-axis positions with confidence, the factory can reduce manual “micro-adjustment” time and make changeovers less dependent on one person’s memory or notes.

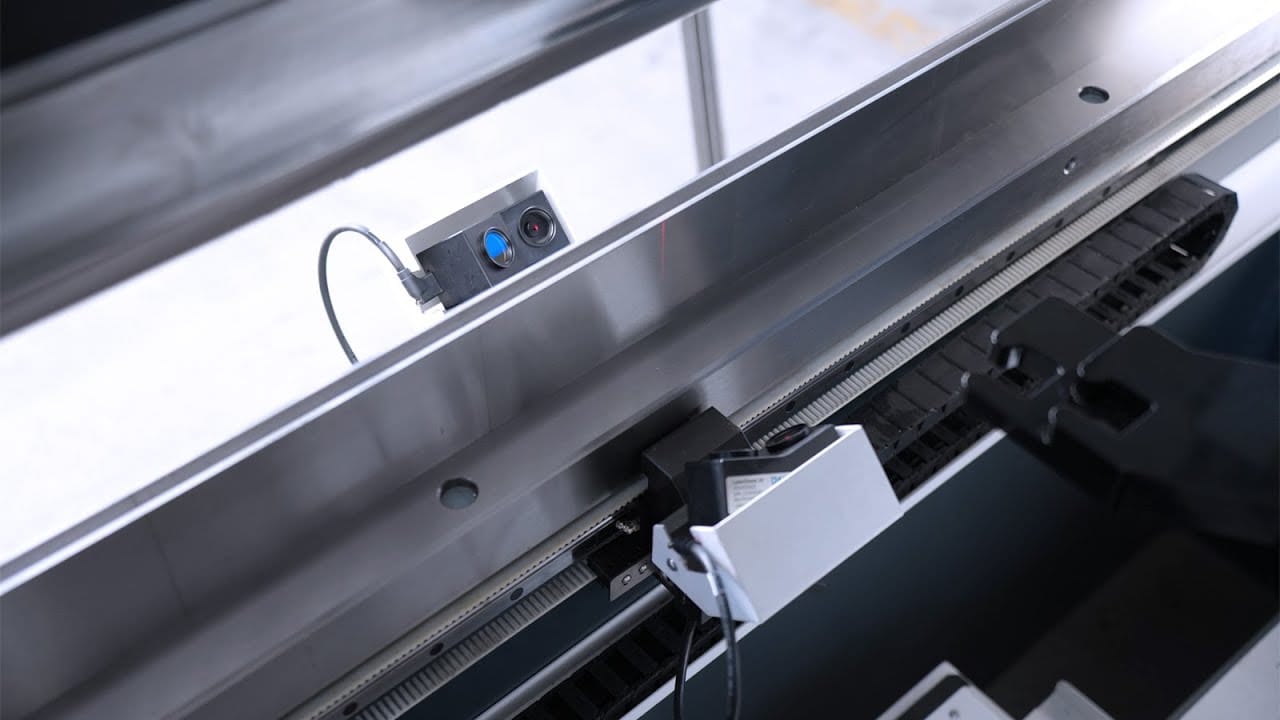

Backgauge performance is measurable, and some OEMs publish tight repeatability figures

Backgauge repeatability is one of the easiest CNC benefits to explain with numbers. For example, AMADA has published backgauge repeatability figures on certain platforms (e.g., L-axis repeatability stated as ±0.003 mm for an EG series description), illustrating the level of precision modern systems target when the mechanical and control architecture is optimized. Amada

You do not need to match a specific OEM’s claim to benefit from the concept. The management takeaway is that CNC architectures are designed to treat positioning as a controlled variable rather than an operator-managed variable, which directly supports repeatable flange lengths and reduces rework loops on returned jobs. amada.com

Offline programming and simulation reduce downtime and prevent predictable mistakes

One of the strongest production arguments for CNC is not “the machine bends better.” It is that programming can move away from the machine, allowing the brake to keep producing while engineering/programming prepares the next job. This is a widely discussed benefit of offline programming in bending, and it also supports better scheduling and fewer tool-change surprises. metal-interface.com

Additionally, modern controller ecosystems emphasize workflow support such as bend sequence calculation and collision visualization. Even when features differ by controller platform, the strategic value is consistent: fewer on-machine trials, fewer collisions, and a more teachable process for new operators. delem.com

Cost: CapEx Is Only the First Line in the Spreadsheet

Price ranges are broad, so compare “configured capability,” not just tonnage

Press brake pricing varies dramatically based on tonnage, working length, frame class, control package, backgauge axes, crowning/compensation method, safety system, and automation readiness. Industry discussions routinely show that “press brake price” is not a single number but a spectrum that can range from entry-level machines to very high-end automated cells.

This matters because NC press brake vs CNC is often mistakenly framed as “cheap vs expensive.” A better framing is: “What level of repeatable capability do we need, and how much labor are we currently spending to compensate for missing capability?” That question tends to produce a clearer answer than comparing only purchase quotes.

The “real” cost drivers: setup time, scrap, rework, and staffing model

If your factory bends a handful of stable parts every day, labor is predictable and the NC press brake advantage is straightforward. If your factory runs a high mix of brackets, enclosures, panels, and short-run orders, labor becomes nonlinear because each new job brings setup time, tooling decisions, and first-article verification.

This is why many productivity discussions around bending focus on setup time reduction and process standardization. Even conservative sources emphasize that reducing non-productive time (tool changes, program preparation, searching tools, correcting sequences) is where ROI shows up first, and CNC workflows generally support those improvements more directly.

A practical 3-year comparison model (illustrative, but decision-useful)

The table below is not meant to be a universal quote. It is a decision model showing why an NC press brake can be cheaper and still cost more overall in certain high-mix conditions, because labor and scrap scale differently than CapEx.

Assumptions (example only): 1 shift, 250 working days/year, average loaded labor cost varies by region, and scrap/rework cost is highly factory-specific. You should substitute your own numbers to make this “your” model.

| Cost Element (3-Year View) | NC Press Brake (Typical Pattern) | CNC Press Brake (Typical Pattern) | Why It Matters |

|---|---|---|---|

| Purchase + installation | Lower initial investment | Higher initial investment | The first-year cash impact is real, but it is not the full story. |

| Setup time per job | Higher in high-mix | Lower with stored programs / repeatability | Setup time is often the largest hidden cost in bending operations. The Fabricator |

| Scrap & rework from first-article loops | Higher risk when reliance is manual | Typically reduced when process is standardized | Material variation still exists, but process control reduces “unknowns.” amada.com |

| Staffing flexibility | Heavily dependent on experienced operators | Easier to scale across shifts with standardized programs | Training becomes a controllable system rather than tribal knowledge. OSHA |

| Engineering/programming time | Minimal for very simple jobs | Can shift offline and reduce machine downtime | The brake makes parts while programming happens elsewhere. |

| Changeover/tooling organization impact | Often informal | Often formalized via databases / program packages | Good 5S and tool management helps both, but CNC enables discipline. |

This type of table is what procurement teams should use to align operations and finance. When you attach your own production mix to the model, the “NC vs CNC” answer often becomes obvious without argument.

Accuracy: How to Think in Degrees, Millimeters, and Microns

Accuracy is not one metric—separate angle accuracy from dimensional accuracy

In bending, “accuracy” usually means two different things that get mixed together. One is bend angle accuracy (degrees), and the other is linear positioning accuracy (flange length, hole-to-bend distance, and related dimensions measured in mm or inches).

A factory can hit angle targets but still miss flange dimensions if backgauge behavior, material slip, or bend deduction assumptions are unstable. That is why disciplined bending teams treat accuracy as a system property—machine + tools + material + method—rather than a single spec line.

What “typical accuracy” looks like in published discussions

Some industry articles describe practical press brake performance in terms of approximate bend angle tolerance and linear positioning ranges when the machine is properly maintained. For example, one published discussion frames typical bend angle tolerance around ±0.5° and linear positioning around ±0.1–0.2 mm as an “in practice” reference under appropriate conditions.

Separately, AMADA has also discussed the repeatability and accuracy of modern press brakes as “exceptional,” describing very small bend-to-bend variation in a technical context. The key point is not the marketing language; it is that modern systems aim to reduce variation so your process spends less time chasing the same bend repeatedly. amada.com

Where CNC tends to win: repeatability and control of known variables

A CNC press brake tends to improve accuracy outcomes through repeatability and controllability. When axis positions, bend sequences, and compensation settings are stored and recalled reliably, you reduce “re-figuring-out” time and lower the chance that two operators run the same part differently.

An NC press brake can still produce excellent parts, but achieving consistent outcomes typically demands stronger operator technique, more careful manual verification, and tighter discipline in how setups are recorded and repeated. This is a critical distinction for factories that need to scale bending capacity with new hires or multiple shifts.

Backgauge repeatability is a meaningful lever for flange-length consistency

Backgauge capability is often where production teams immediately “feel” the CNC advantage. Some machine suppliers publish repeatability figures such as ±0.001″ (±0.025 mm) in certain high-speed backgauge contexts, while others publish even tighter figures for specific platforms.

Even if your chosen configuration has different numbers, the operational concept holds. If your backgauge positioning is stable, you reduce flange-length drift, reduce measurement time, and cut rework caused by cumulative tolerance stack-ups across multiple bends.

Material variability is the “silent driver” of accuracy problems

Many accuracy complaints attributed to the machine are actually caused by material scatter: thickness tolerance, yield strength variation, surface condition, grain direction, and inconsistent coating or film. This is why experienced bending teams emphasize controlling the material supply chain and documenting bend allowances and K-factors for your recurring alloys and thickness ranges.

CNC workflows help because they make compensation strategies more repeatable and easier to teach. They do not eliminate physics, but they reduce the amount of on-machine experimentation required to converge on a stable process window. amada.com

Training: NC Is Simpler to Start, but CNC Is Often Easier to Scale

Start with safety and compliance—because it is part of “training cost”

Training is not only “how to program.” It also includes safe operating behavior, safeguarding discipline, and consistent procedures that protect both people and production. OSHA guidance on machine guarding for powered press brakes highlights hazard areas and safeguarding considerations that should be part of every operator’s baseline training. OSHA

In addition, OSHA has referenced ANSI B11.3 as an applicable standard in press brake safeguarding context, illustrating how standards and enforcement interpretation can intersect. Even if your factory is outside the U.S., aligning training to widely recognized safeguarding principles is still beneficial because it reduces incident risk and supports customer audits. OSHA

Why an NC press brake can feel easier in week 1

An NC press brake can be faster to put into production for basic work because the control interactions are typically more limited and the operator focuses on direct adjustment and execution. For factories with experienced brake operators, this can be a legitimate advantage because the team already understands how to “drive” the bend by observation, measurement, and iterative correction.

However, that same simplicity can become a constraint when you need to produce complex parts with consistent results across different operators. In that situation, training becomes less about button knowledge and more about transferring judgment, which is inherently slower and more variable.

Why CNC training often becomes more standardized (and therefore scalable)

CNC press brake training can look intimidating because it includes program structure, axis definitions, tooling libraries, and sometimes offline software. Yet modern CNC workflows often standardize knowledge: the sequence is defined, the tooling is documented, and the operator executes a known method rather than reinventing it for each job.

Industry discussions on offline programming emphasize how software and simulation reduce setup time and improve repeatability, and that benefit also translates into training. When a new operator learns from structured programs and simulations, the learning curve becomes a process you can manage rather than an apprenticeship dependent on one mentor.

A baseline training map you can actually plan against (overview table)

The table below summarizes a practical way factories structure training. It intentionally separates operator execution from process engineering/programming, because mixing those roles is a common cause of training delays.

| Role | NC Press Brake Training Focus | CNC Press Brake Training Focus | Typical Outcome |

|---|---|---|---|

| New Operator (Execution) | Safe operation, measurement habits, manual setup discipline | Safe operation, program selection, setup execution, verification steps | CNC makes “repeat jobs” easier to repeat consistently. |

| Senior Operator (Setup Lead) | Tool selection, bend deductions, troubleshooting accuracy | Tool database discipline, process optimization, controlled adjustments | CNC enables the lead to create reusable standards for others. |

| Programmer / Engineer | Often minimal formal role | Offline programming, simulation, scheduling optimization | Machine uptime improves when programming moves offline. |

| Supervisor / QA | Tolerance control, inspection standardization | Same, but with stronger traceability via stored programs | Standardization reduces argument and improves audits. OSHA |

This table is only an overview, but it leads to a critical management insight. If your factory plans to expand bending capacity by adding people, CNC training often creates less long-term friction because it converts experience into repeatable documentation and programs.

Training Roadmap That Works in Real Factories

Training should start with fundamentals, not buttons

Many press brake training programs fail because they start with controller screens and skip metal behavior. A strong program begins with material deformation, springback, bend allowance assumptions, and how tooling geometry influences the result, because these concepts determine whether operators can troubleshoot intelligently. That “start at the beginning” approach is repeatedly emphasized in industry discussions focused on building safe and productive operators. The Fabricator

When you train operators this way, you also reduce the most expensive type of mistake: the one that looks “random” on the floor but was predictable from fundamentals. This is especially important whether you run an NC press brake that relies on operator judgment or a CNC press brake where the operator still must validate first-piece quality.

Safety is part of training cost, not a separate topic

Your training plan must include safeguarding discipline and point-of-operation hazard awareness, because safe work methods are inseparable from consistent output. OSHA’s machine guarding framework and related guidance on safeguarding press brake operations is a practical reference point for structuring operator behavior and supervisor audits. OSHA

In the U.S. context, ANSI B11.3 is widely referenced as the press brake–specific consensus standard, and OSHA has historically referenced it as an appropriate standard in safeguarding interpretations. Even outside the U.S., using those principles creates a stronger baseline for audits, customer visits, and internal safety culture.

A Factory-Ready Training Plan for NC Press Brake Operators

30-day NC press brake plan that produces reliable operators

An NC press brake can be trained quickly for simple parts, but consistency requires a structured routine for setup, measurement, and correction. The goal is not to create a “hero operator,” but to create operators who follow the same workflow and produce predictable results.

Below is a 30-day plan that many factories can implement with minimal disruption. It assumes the operator will run production under supervision while training progresses, which keeps output moving and builds confidence.

| Timeframe | Skill Focus (NC Press Brake) | On-the-floor Deliverable | Supervisor Verification |

|---|---|---|---|

| Days 1–3 | Safety, guarding behavior, pinch-point awareness, basic machine anatomy | Safe start/stop routine, correct PPE, correct approach to point-of-operation risk | Daily checklist sign-off aligned to guarding principles OSHA |

| Days 4–7 | Tool identification, punch/die selection rules, V-die basics, minimum flange awareness | Tool setup completed without damage risk and with correct alignment | Tooling setup audit and first-piece inspection checklist |

| Week 2 | Backgauge use, measurement discipline, test-bend method, springback correction routine | First-piece approval within a controlled number of iterations | Iteration count tracked; root cause notes captured |

| Week 3 | Repeat-job setup sheets, standardized setup documentation, changeover habits | Setup sheet created and stored for repeat jobs | Setup sheet completeness audit (tools, positions, notes) |

| Week 4 | Troubleshooting: angle drift, flange variation, material scatter; basic maintenance habits | Stable output across a full batch with documented checks | Scrap/rework reasons coded consistently for analysis |

This plan works because it treats training like process engineering. It aligns with lean press brake best practices that emphasize standardization, repeatable sequencing, and organized tooling practices to reduce setup time and human variability. Wilson Tool

The key NC press brake training metric: “iterations to first good part”

If you want one KPI that tells you whether an NC press brake training program is working, track the number of adjustment loops required to approve the first part. When training is weak, new operators will wander through trial-and-error without a repeatable method, and that creates both scrap and time loss.

When training is strong, operators learn a controlled loop: verify material, verify tool selection, produce a test bend, measure angle and flange, and apply a documented correction pattern. That single habit can reduce quality variation more than adding features to the machine.

A CNC Press Brake Training Plan That Scales Across Shifts

CNC training looks harder, but it scales better when standardized

A CNC press brake introduces programming logic, axis definitions, program libraries, and often tool databases. That can feel like a higher barrier, but it also creates a structured system where knowledge becomes reusable rather than personal. This is a major reason factories adopt CNC workflows: they convert bending from “craft knowledge” into an operational standard.

Modern industry commentary increasingly highlights that software and offline workflows reduce setup time and enhance repeatability, letting operators focus on higher-value tasks rather than repeatedly “figuring it out” at the machine.

6-week CNC press brake training roadmap (operator + lead + programmer)

A scalable program splits responsibilities: operators execute, lead operators optimize setups, and programmers/engineers prepare jobs offline where possible. This separation is strongly aligned with the logic behind offline programming: if the machine is being programmed at the brake, it is not producing parts.

| Week | Operator (Execution) | Lead Operator (Setup/Optimization) | Programmer/Engineer (Offline/Process) | Output Target |

|---|---|---|---|---|

| Week 1 | Safety, machine navigation, selecting programs, safe setup routine | Tooling alignment, clamping discipline, baseline bend checks | Create standard templates for program naming and job folders | Operators run repeat jobs with low variability |

| Week 2 | Backgauge axis understanding, first-piece inspection workflow | Reduce setup time using setup sheets and organized tooling | Build tool library and material tables; define default bend strategies | Faster first-piece approval on repeat jobs |

| Week 3 | Program edits within permission limits, controlled corrections | Optimize sequences, reduce reposition risk, prevent collisions | Begin offline programming/simulation where applicable | Less machine downtime for “program figuring” |

| Week 4 | High-mix changeover discipline, documentation habits | SMED-style changeover actions and tool staging | Standardize offline workflows and release packages | Changeovers become predictable and measurable |

| Week 5 | Complex part families, multi-bend stability, quality records | Root-cause mapping for recurring errors | Improve templates and libraries based on shop feedback | Lower rework rate on complex bends |

| Week 6 | Independent execution with audit trail | Train-the-trainer capability | Formalize SOPs and training checklists | Program-driven consistency across shifts |

This roadmap aligns well with widely published press brake setup time reduction strategies, which emphasize setup lists/sheets and organized workflows for recurring jobs. It also aligns with the practical logic behind offline programming and simulation: maximize productive bending time by shifting preparation work away from the machine. The Fabricator

The key CNC training metric: “time-to-changeover stability”

For CNC systems, track how many changeovers are completed within a target time window and still produce a correct first piece. When CNC training is strong, changeover time variance shrinks, and so does the spread in quality outcomes between operators.

This metric matters because high-mix factories do not lose money when the ram is moving. They lose money during the idle periods between jobs, which is exactly why lean press brake guidance focuses on setup time and flow. Wilson Tool

Cost and ROI: A Simple Worksheet You Can Use Immediately

Stop debating price; start modeling setup minutes

In press brake operations, setup time is often the dominant cost driver in high-mix environments. Industry resources repeatedly emphasize setup reduction tactics and the productivity benefit of moving programming offline, because every minute the machine is not bending is lost capacity. The Fabricator

If you want an ROI model that decision-makers accept quickly, build it around measurable time and labor. You can always add scrap, rework, and delivery penalties later, but setup minutes alone frequently justify the upgrade from an NC press brake to a CNC press brake.

The core formula set (use your own numbers)

Use these four formulas as your baseline:

- Annual setup hours = (Setups/day × Setup minutes/setup ÷ 60) × Working days/year

- Annual setup labor cost = Annual setup hours × Loaded labor rate

- Annual saved labor = (NC annual setup cost − CNC annual setup cost)

- Payback period = CNC price premium ÷ Annual saved labor

This approach is consistent with the logic used in many lean and productivity discussions: setup is a fixed time cost for each transition, and reducing it increases flexibility and capacity. EZIIL – Steel Fabrication Software

Example ROI scenarios (illustrative, but decision-useful)

The numbers below are examples to show how the math behaves. Replace them with your own setup counts, minutes, and labor cost to get your real answer.

Assumptions for both examples: 250 working days/year, loaded labor rate = $25/hour. These assumptions are placeholders and should be replaced with your factory reality.

| Scenario | Factory Mix Pattern | NC Setup Time | CNC Setup Time | Setups/Day | Annual Labor Saving | Interpretation |

|---|---|---|---|---|---|---|

| A | Low-mix, repeat runs | 20 min | 14 min | 3 | $1,875 | CNC may still help, but ROI depends more on quality risk and future scaling |

| B | High-mix, frequent changeovers | 30 min | 15 min | 12 | $18,750 | CNC often pays back quickly from setup labor alone |

| C | High-mix + offline programming discipline | 30 min | 12 min | 12 | $22,500 | Strong workflows can make CNC ROI very compelling |

How the Scenario B saving was computed:

- NC setup hours/year = (12 × 30 ÷ 60) × 250 = (6) × 250 = 1,500 hours

- CNC setup hours/year = (12 × 15 ÷ 60) × 250 = (3) × 250 = 750 hours

- Saved hours = 750 hours/year

- Saved labor = 750 × $25 = $18,750/year

This is why so many productivity-focused press brake discussions keep returning to setup time reduction, standardized setup sheets, and offline programming. They attack the largest recurring time loss in high-mix bending. The Fabricator

Add a scrap/rework layer for a more realistic total cost view

Setup labor is only one layer. Scrap and rework costs often matter more when you bend stainless, thick plate, or tight-tolerance enclosures where a wrong bend can destroy a high-value blank.

A simple scrap model looks like this:

- Annual scrap cost = Annual material spend × Scrap rate

- Scrap saving = Material spend × (NC scrap rate − CNC scrap rate)

If your annual bent material spend is $300,000 and your scrap rate drops from 2.0% on an NC process to 1.2% with a CNC-standardized process, the annual saving is:

$300,000 × (0.020 − 0.012) = $300,000 × 0.008 = $2,400/year.

That scrap saving alone will not always justify CNC, but combined with setup labor savings it can materially shorten payback. It also aligns with the repeatability and setup reduction themes repeatedly described in industry discussions about software and standardized workflows.

Accuracy and Quality: How to Control Outcomes on NC and CNC

Accuracy is a system; document the system

Whether you run an NC press brake or a CNC press brake, accuracy depends on disciplined handling of the same variables: tooling condition, material variation, bend allowance assumptions, and inspection method. The difference is how easily you can standardize that control across people and shifts.

A strong quality system documents: tool selection rules, test-bend procedures, inspection frequency, and correction actions. When these are documented, both NC and CNC environments improve, but CNC environments usually improve faster because programs and libraries store the “how,” not just the “what.”

How to tighten results on an NC press brake without buying a CNC

If you currently run an NC press brake and need better consistency, focus on operational discipline. Create setup sheets for recurring jobs, store the tooling combination and gauge positions, and require a consistent first-piece approval routine before full batches run.

This approach matches well-established setup reduction guidance: recurring jobs should use documented setup lists or sheets to reduce time and prevent repeated trial-and-error. It is not glamorous, but it is one of the highest ROI actions an NC environment can take.

How CNC improves accuracy in production reality

CNC press brakes generally improve accuracy outcomes by improving repeatability, recallability, and workflow structure. When backgauge positions, sequences, and known corrections are stored and recalled, you reduce variance between operators and reduce the “re-learning tax” on returning jobs.

Offline programming and simulation can also reduce predictable mistakes, such as collision risks or inefficient sequences, and it increases productive bending time by moving preparation away from the machine. This is repeatedly emphasized in bending-focused discussions of offline programming and workflow modernization.

Setup Time: The Most Underrated Battleground in NC Press Brake vs CNC

Changeover is where high-mix factories win or lose

High-mix factories are not usually limited by cycle time. They are limited by changeover time, tooling search time, program preparation time, and the small idle delays that accumulate between jobs. Lean press brake best-practice guidance emphasizes organized tooling and standardized sequencing precisely because those actions reduce the non-cutting, non-bending time that damages throughput. Wilson Tool

A practical example from bending-industry commentary highlights how production often looks in reality: adjustment, then a limited window of bending time, then another changeover. When your average production window between changeovers is short, setup becomes the primary lever for capacity. Metal Interface

SMED principles apply directly to press brake operations

SMED (Single-Minute Exchange of Die) is a proven approach for cutting changeover time. When applied to press brakes, it typically means staging tools, standardizing clamping, reducing motion waste, and minimizing “search and decide” time during setup.

Many factory-oriented press brake work instruction frameworks explicitly recommend SMED-style thinking for press brake efficiency, because it targets the actual bottleneck: the time between jobs.

CNC plus disciplined workflow amplifies setup reduction

A CNC press brake can reduce setup time on its own through program recall and axis positioning. However, the biggest step change comes when you combine CNC with offline programming discipline and standardized tooling management.

This is why industry sources emphasize that software reduces setup time and enhances repeatability. The machine becomes more productive when preparation work is shifted away from the brake and into repeatable planning workflows. The Fabricator

A Decision Matrix You Can Use to Choose NC Press Brake or CNC

Score your factory needs instead of arguing preferences

The matrix below is designed for real purchasing decisions. It does not assume that CNC is always better. It assumes that the best choice depends on your mix, tolerance risk, and staffing model.

Scoring method: 1 = low need, 5 = high need. Add the weighted totals and compare.

| Criterion | Weight | NC Press Brake Fit | CNC Press Brake Fit | How to Score Your Need |

|---|---|---|---|---|

| Part mix (how often jobs change) | 5 | 2 | 5 | If you do many small lots per day, score 4–5 |

| Tolerance sensitivity | 4 | 3 | 5 | Tight flange requirements or multi-bend stack-ups score 4–5 |

| Operator experience stability | 4 | 2 | 5 | If you hire frequently or add shifts, score 4–5 |

| Repeat-job frequency | 3 | 4 | 5 | If jobs repeat monthly/weekly, CNC libraries help a lot |

| Need for traceability/audits | 3 | 3 | 5 | ISO/customer audits favor standardized programs |

| Engineering support availability | 2 | 2 | 4 | CNC benefits increase when programming discipline exists |

| Budget constraint priority | 4 | 5 | 2 | If CapEx is the primary constraint, NC scores higher |

This matrix reflects the operational realities emphasized in modern press brake productivity thinking: standardized programming, reduced setup time, and workflow discipline become decisive when mix and complexity rise. Wilson Tool

Common outcomes from the matrix

If your factory is high-mix, has multiple shifts, and wants predictable delivery with reduced dependency on one expert operator, a CNC press brake is usually the rational choice. If your factory runs stable, simple work with a strong, experienced team and limited changeovers, an NC press brake can be the best economic decision and can deliver excellent output.

The key is that you should not buy CNC “just to have CNC.” You should buy CNC because your operating model benefits from standardized repeatability and scalable training.

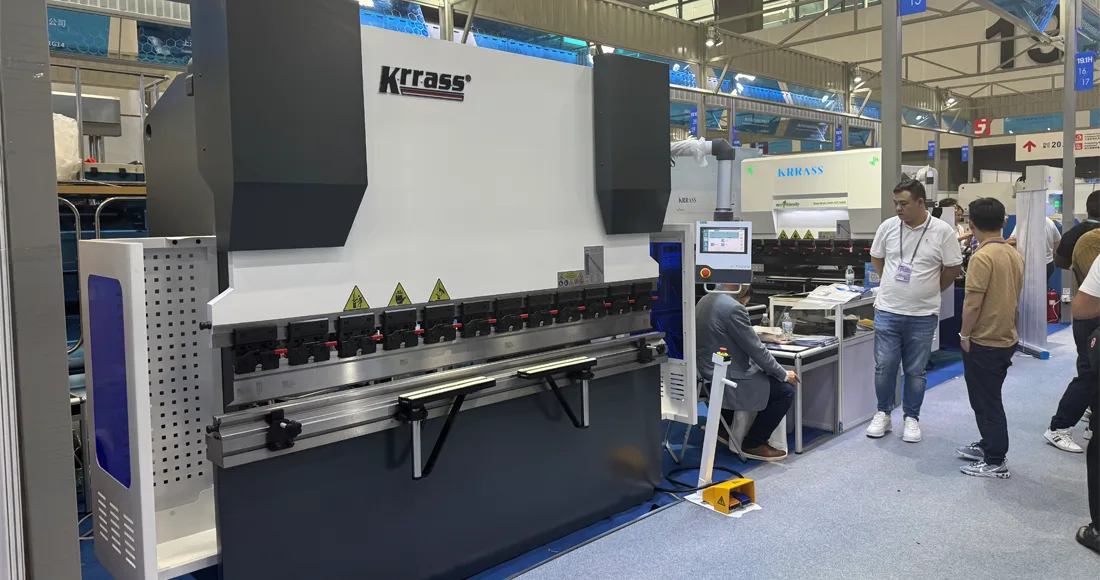

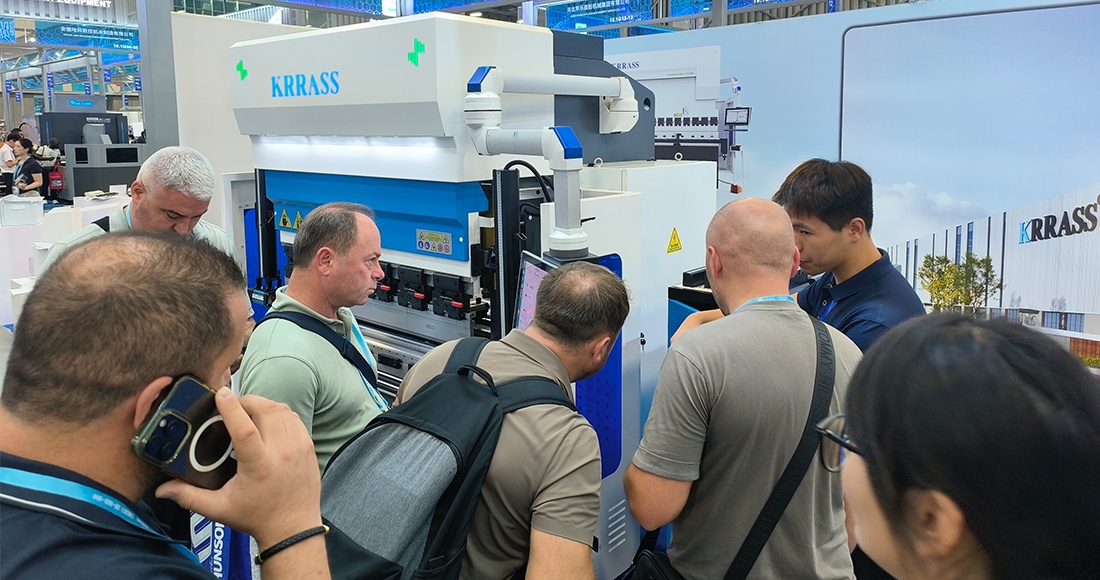

Buying Checklist: How to Compare KRRASS with other brands

Compare suppliers using the same technical and operational checklist

With a consistent checklist that connects machine configuration to production outcomes. This prevents the evaluation from turning into a marketing comparison and keeps the decision anchored to your part mix and tolerance requirements.

Below is a practical checklist you can use for any brand—including KRRASS—when selecting an NC press brake or CNC press brake.

NC press brake checklist (what matters most)

| Category | What to Confirm | Why It Matters |

|---|---|---|

| Frame & deflection | Frame design approach, accuracy stability under load | Deflection affects angle consistency across length |

| Backgauge | Travel, stability, ease of adjustment | Controls flange length repeatability |

| Tooling | Compatibility with common standards, clamping method | Tooling impacts both safety and setup time |

| Safety | Guarding approach and operator protection | Safety discipline reduces accidents and disruptions |

| Documentation | Setup sheet templates and support | Helps reduce setup time and stabilize repeat runs |

CNC press brake checklist (what matters most)

| Category | What to Confirm | Why It Matters |

|---|---|---|

| Axis configuration | Which axes are included and how they improve your parts | Determines complexity capability and setup speed |

| Controller workflow | Program storage, usability, error prevention | Influences training speed and human variation |

| Offline readiness | Supported offline workflow and documentation | Reduces machine downtime for “program figuring” |

| Tool library discipline | How tools/materials are managed in the workflow | Standardization is the foundation of scalable training |

| Service and training | Onboarding plan, remote support, spare parts strategy | Determines real uptime, not just theoretical specs |

This is also where KRRASS can position strongly: not only by supplying the machine, but by supplying the workflow package—training SOPs, setup sheets, tooling recommendations, and remote support routines that help your factory reach stable productivity faster. The machine matters, but the implementation system is what determines how quickly you get ROI.

Implementation Plan: How KRRASS Reduces Risk After the PO

Pre-acceptance: prove the process with your parts

A professional implementation starts before shipment. KRRASS can request your representative parts (drawings + material + tolerances) and build a bending plan that includes tooling selection and process steps, so the machine is configured around your workload rather than generic assumptions.

This approach reduces the risk of “we bought the right tonnage but still struggle with setup and quality.” It also accelerates training because operators learn on familiar parts rather than abstract demos.

Commissioning: install a repeatable workflow, not just a machine

During commissioning, the goal is not simply “machine runs.” The goal is “machine runs with a documented process.” That means establishing: first-piece approval procedure, setup sheet format, tool storage logic, and a standard for program naming and revision control on CNC machines.

This aligns directly with best-practice guidance on lean press brake operations: standardize programming and sequencing, and organize tooling to reduce setup time. Wilson Tool

Post-installation: stabilize with measurable KPIs

KRRASS can help customers establish simple KPIs that demonstrate progress and prevent regression:

- Setup time per job (median and spread)

- Iterations to first good part

- Scrap and rework reasons (coded consistently)

- On-time delivery vs. bend department delays

These KPIs are easy to track and directly reflect the operational levers emphasized in industry discussions about setup reduction and offline programming benefits. The Fabricator

Choosing NC Press Brake vs CNC Without Guesswork

An NC press brake is often the best economic tool when your work is stable, your bend sequences are simple, and your operators are experienced and consistent. A CNC press brake usually becomes the better system choice when your factory runs high-mix production, needs faster changeovers, wants repeatable quality across shifts, or needs training that scales reliably.

If you want the decision to be defensible to management, use the ROI worksheet and decision matrix in this article. If you want the result to be operationally successful, treat training, setup discipline, and documentation as part of the machine purchase—not as optional extras.