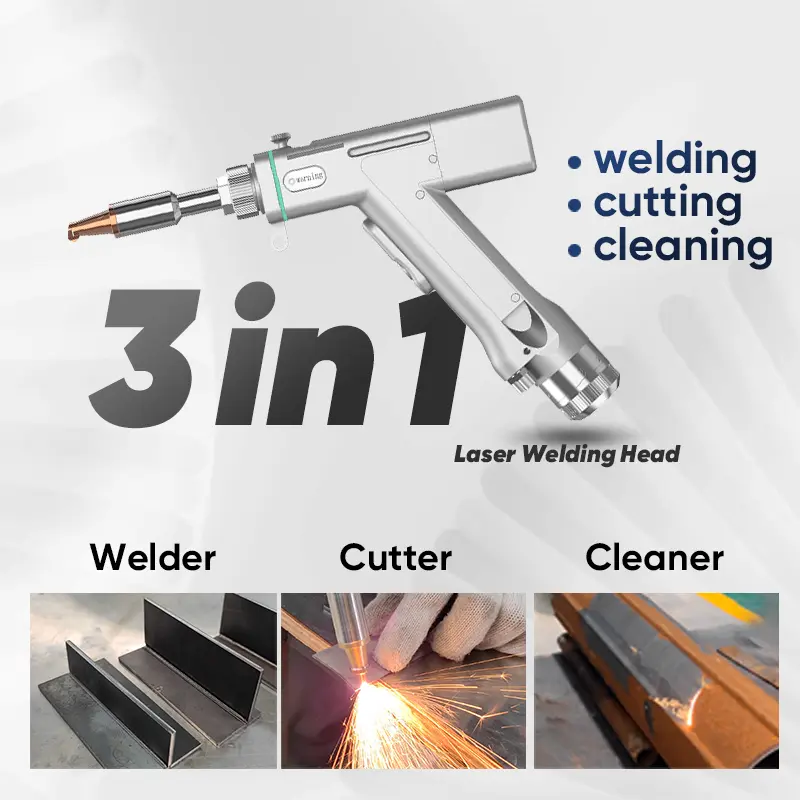

The three-in-one Laser Welding Machine, which integrates cleaning, welding and cutting functions, is a highly efficient all-rounder in the industrial processing field. With its multi-functional integration and flexible operation features, it meets diverse processing demands. Please provide the text you want to be translated.

Table of Contents

1.Laser Welding Machine Cleaning Function: An Effective Assistant for Pre-Cleaning Preparation

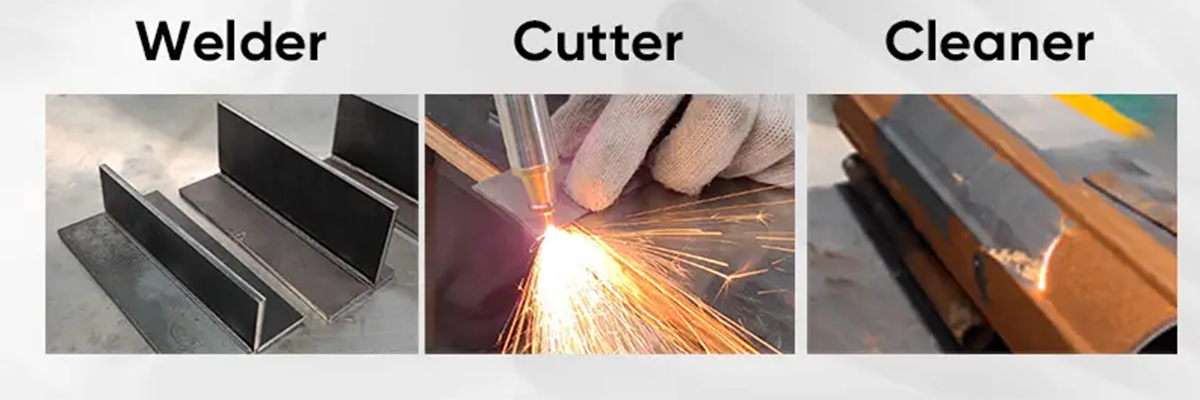

The cleaning function of the Laser Welding Machine is achieved through a high-energy laser beam. This laser beam can precisely focus on the surface of metals and other materials, quickly removing impurities such as oil stains, rust, oxide scales, coatings, etc. This cleaning method does not require the use of chemical agents and does not produce dust pollution, making it an environmentally friendly and efficient processing method. Before welding or cutting operations, cleaning the surface of the workpiece can remove impurities that affect welding quality or cutting accuracy, providing a clean foundation for subsequent processing and ensuring that the welded joints are firm and reliable, and the cutting edges are smooth and neat. For example, before welding steel plates that have been stored for a long time, using its cleaning function to remove the rust on the surface can effectively prevent rust from entering the weld seam and causing welding defects.

2.Laser Welding Machine Welding Function: Reliable Guarantee for Precise Connections

The welding function of the Laser Welding Machine also relies on laser technology. Through a high-energy-density laser beam, it instantly melts the materials to be welded, allowing them to fuse together to form a strong connection. The handheld design enables operators to flexibly handle workpieces of different shapes and sizes, whether it’s planar welding, corner welding, or complex curve welding, all can be easily accomplished. Compared to traditional welding equipment, it has a smaller heat-affected zone, less welding deformation, a beautiful weld seam, and high strength, suitable for welding of various metal materials such as stainless steel, aluminum alloy, copper, and carbon steel. In scenarios such as thin-walled workpiece welding and precise component assembly, its advantages are particularly prominent, ensuring that the welded workpieces maintain good dimensional accuracy and mechanical properties.

3. Laser Welding Machine Cutting Function: A Practical Tool for Efficient Separation

The cutting function of the Laser Welding Machine utilizes the high energy of the laser beam to melt the material and blow it away, achieving rapid and precise cutting. The handheld operation enables the equipment to adapt to different cutting environments, making it more flexible and convenient for cutting large workpieces and irregular shapes. It can cut various materials such as metals and non-metals, with fast cutting speed, smooth cuts, small heat affected zone, and reduced material deformation and waste. In the processes of cutting metal sheets and processing components, this cutting function can efficiently complete the cutting tasks and improve processing efficiency.

This three-in-one Laser Welding Machine integrates cleaning, welding and cutting functions, reducing the equipment’s floor space and lowering the cost for enterprises to purchase multiple machines. At the same time, operators do not need to frequently switch between different machines, saving process conversion time and significantly improving overall processing efficiency. It has broad application prospects in various industries such as automotive manufacturing, mechanical processing, hardware products, and kitchenware production.

Laser welding machine One machine for multiple uses: No need to purchase welding machine, cutting machine, cleaning machine separately, greatly reducing equipment procurement costs, saving space, one device replaces the functions of multiple devices, reducing the occupation of production space, especially suitable for workshops or small processing plants with limited space. Reduce equipment maintenance, maintaining a single device is more convenient than maintaining multiple devices, which can reduce maintenance costs and time investment.