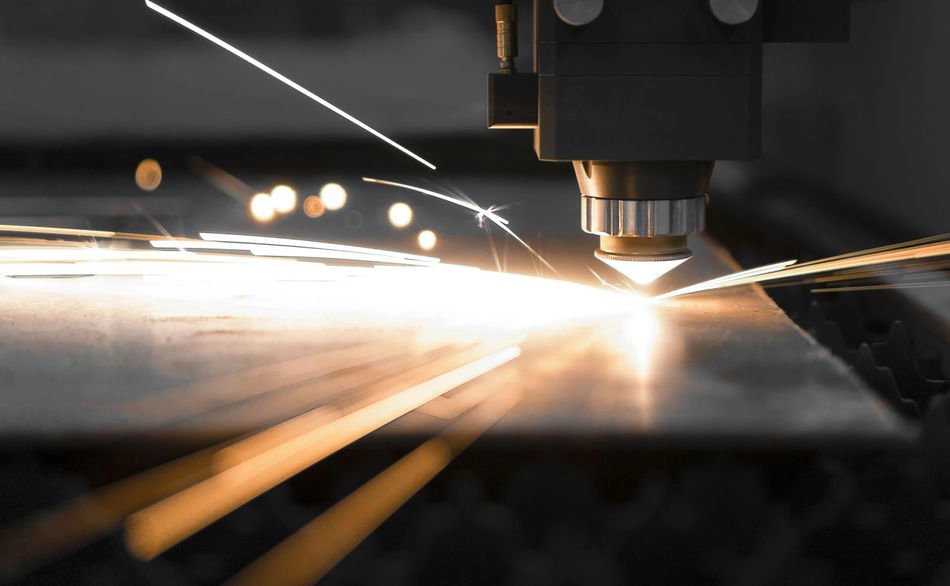

In modern manufacturing, laser cutting technology, with its high precision, high efficiency, and diverse processing capabilities, has become an indispensable component for many companies. However, with the wide variety of laser cutting machine brands and models on the market, choosing the right machine for your needs becomes a critical issue. This article will provide a comprehensive guide to the considerations when purchasing a laser cutting machine, taking into account various factors.

I.Clarify Your Needs and Budget

Clarify your processing requirements: Before purchasing a laser cutting machine, you must first clarify your processing needs. This includes the material type (e.g., metal, non-metal, composite materials), material thickness range, processing accuracy requirements, and whether special features (e.g., drilling, engraving, etc.) are required. Based on these requirements, you can initially determine the power range and configuration requirements of the laser cutting machine you need. For example, if you primarily cut metal materials with a thickness of less than 10mm, you can choose a medium-to-low-power fiber laser cutting machine. If you need to cut thick sheet metal, such as carbon steel or stainless steel over 20mm, you will need a high-power machine. For non-metallic materials like acrylic and wood, a CO2 laser may be more suitable. For those requiring fine engraving or precise drilling, pay attention to the machine’s accuracy and pulse performance.

Set a budget: Laser cutting machine prices vary depending on factors such as brand, model, and configuration. Therefore, it is important to set a reasonable budget before purchasing. Within your budget, choose a machine with the best value for money and avoid blindly pursuing low or high prices. Generally speaking, entry-level, low-power fiber laser cutting machines cost between 300,000 and 500,000 yuan, making them suitable for small-scale production or prototyping. Mid-range models with power levels of 2-3kW cost between 800,000 and 1.5 million yuan, meeting the daily production needs of most small and medium-sized enterprises. High-end, high-power, automated laser cutting machines can cost over 2 million yuan and are suitable for large-scale, high-efficiency industrial production. It’s important to note that your budget should not only cover equipment purchase costs but also allow for ongoing maintenance, consumables replacement, and potential upgrades.

II.Understand the Market and Manufacturers

Market Research: Before purchasing, thorough market research is essential. Understand the brands, models, performance specifications, and prices of mainstream laser cutting machines on the market. This information can be obtained through online searches, industry trade shows, and peer recommendations. Numerous professional industry websites and forums offer extensive product reviews, user feedback, and manufacturer information. Industry trade shows provide excellent opportunities for direct access to various types of equipment and communication with manufacturer technicians. Equipment recommended by peers has often undergone actual production testing and is therefore highly valuable. By integrating this information from these sources, you can gain a comprehensive and intuitive understanding of the laser cutting machines on the market.

Manufacturer Research: Choosing a reputable and reputable laser cutting machine manufacturer is crucial for purchasing a laser cutting machine. You can assess the manufacturer’s legitimacy and authenticity by reviewing their qualification certificates, production licenses, and quality management system certifications. Also, understand the manufacturer’s R&D capabilities, production capacity, and after-sales service system to ensure the quality and after-sales service of the equipment you purchase. Strong manufacturers typically have professional R&D teams that continuously introduce new technologies and models. Their production workshops are well-managed and their equipment is manufactured with sophisticated craftsmanship. A comprehensive after-sales service system includes a quick-response after-sales team, sufficient spare parts inventory, and regular equipment maintenance training, which can greatly reduce equipment downtime and ensure smooth production.

III.Focus on Equipment Performance and Configuration

Laser Type and Power: The laser is the core component of a laser cutting machine. Its type and power directly impact the machine’s cutting capacity and efficiency. Common laser types include CO₂ lasers, YAG solid-state lasers, and fiber lasers, each suited to different processing needs. When selecting a laser, choose the appropriate laser type and power based on your specific needs. Fiber lasers offer high photoelectric conversion efficiency, exceeding 30%, and are easy to maintain, making them suitable for processing medium-thin sheet metal, such as automotive parts and chassis and cabinets. CO₂ lasers are effective at cutting non-metals and thick sheet metal, making them commonly used in industries such as advertising and garment cutting. YAG lasers, with their pulsed output characteristics, are suitable for precision processing, such as micromachining of electronic components. Regarding power, 500W to 1kW is suitable for cutting thin sheets of 1 to 3mm; 2 to 3kW is suitable for medium sheets under 6mm; 4 to 6kW can cut sheets under 12mm; and 8kW and above are suitable for ultra-thick sheets over 20mm.More information about laser transmitters.

Cutting Head and Focusing Lens: The cutting head is a crucial component of a laser cutting machine, and its quality and performance directly impact cutting accuracy and stability. A high-quality cutting head should feature automatic focusing and height adjustment, and utilize a high-performance focusing lens to enhance cutting precision. The automatic focus function automatically adjusts the focal position based on material thickness, ensuring consistent cutting quality. Height adjustment prevents collisions between the cutting head and the material, extending its lifespan. A high-performance focusing lens focuses the laser beam into a smaller spot, increasing energy density and enabling finer and faster cutting.More about laser cutting heads.

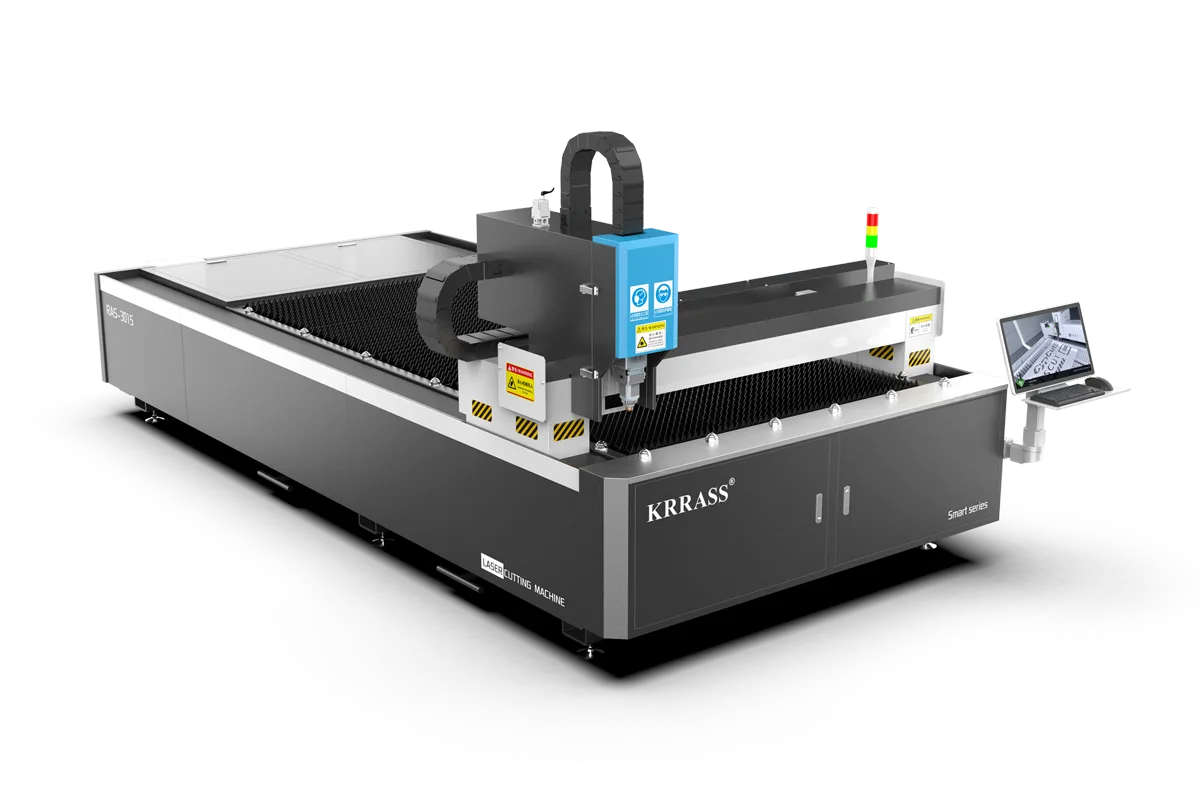

Machine Tool and Drive System: The machine tool is the foundation of the laser cutting machine. Its rigidity and stability significantly impact cutting accuracy. The drive system drives the cutting head, and its accuracy and speed are also crucial indicators of equipment performance. When selecting a machine tool, consider the machine tool’s material, structural design, and the type and performance of the drive system. Machine tools constructed of high-strength cast iron or high-quality steel offer superior rigidity, effectively reducing vibration during cutting and ensuring cutting accuracy. Gantry-style machine tools offer excellent stability and are suitable for processing large-scale plates; cantilever-style machines take up less floor space and are ideal for processing small parts. Regarding the drive system, linear guides are relatively low-cost and suitable for standard precision requirements; roller guides offer high rigidity and are suitable for heavy-load cutting; and linear motors achieve ultra-high speed and precision and are often used in high-end equipment.

Software and Control Systems: The software and control systems are the brains and nerves of the laser cutting machine, responsible for controlling the equipment’s operation and processing. When selecting a system, consider the software’s usability and compatibility, as well as the control system’s stability and responsiveness. User-friendly software systems feature a simple, clear interface, allowing operators to quickly master the system. They include functions such as graphic editing, layout, and parameter setting. Highly compatible software can interface with a variety of design software, facilitating the import of processing files in various formats. A stable control system ensures trouble-free operation for extended periods of time, while its fast response enables the cutting head to accurately follow command movements, achieving high-precision cutting.

IV.Consider After-Sales Service and Technical Support

After-sales Service System: A comprehensive after-sales service system is crucial for ensuring the normal operation of equipment. When selecting a manufacturer, it’s important to understand the scope, service content, and response speed of their after-sales service system. A high-quality manufacturer should provide timely technical support, repair and maintenance, and spare parts supply. A wide range of after-sales service coverage means rapid access to service, regardless of the equipment’s location. Services include equipment troubleshooting, scheduled maintenance, and technical consultation. A fast response time, such as on-site assistance within 24 hours, can significantly minimize losses caused by equipment downtime. A sufficient spare parts inventory ensures timely replacement of damaged parts during repairs, shortening repair times.

Technical Support and Training: In addition to after-sales service, technical support and training are also crucial. When selecting a manufacturer, it’s important to understand whether they offer technical support and training services, as well as the specific content and methods of these services. Technical support and training can help users better master equipment operation and maintenance techniques, thereby increasing equipment efficiency and lifespan. Technical support can include remote guidance, on-site commissioning, and process optimization. Training services should cover equipment operation, programming, and routine maintenance, and can be provided through on-site training, online courses, or by providing operating manuals and video tutorials. Through professional training, operators can fully utilize the equipment’s performance and reduce failures caused by incorrect operation.

V.On-site Inspection and Trial Experience

On-site Inspection: If conditions permit, it is recommended to visit the manufacturer in person. By visiting the production workshop and understanding the production process and quality control procedures, you can gain a more direct understanding of the manufacturer’s strengths, product quality, and service level. In the production workshop, you can observe the equipment’s manufacturing process, assembly precision, and quality inspection processes. Rigorous quality control processes, such as raw material inspection, key component testing, and complete machine commissioning, guarantee product quality. Interacting with the manufacturer’s technical staff can also provide a deeper understanding of the equipment’s technical features and advantages.

Trial Experience: Arrange a trial experience before purchasing. By actually operating the equipment and observing its cutting results and operating status, you can more accurately assess whether the equipment meets your needs and expectations, and whether there are any potential problems or risks. During the trial experience, cut actual materials to verify whether the cutting accuracy, surface quality, and cutting speed meet your requirements. Check the equipment’s stable operation and check for any abnormal noise or vibration. While operating the equipment, you can experience the ease of use of the software and control system. This trial experience provides a more comprehensive and realistic understanding of the equipment and helps you avoid purchasing a product that is not suitable for you. In short, purchasing a laser cutting machine is a significant investment decision that requires comprehensive consideration of multiple factors, including clarifying your needs and budget, understanding the market and manufacturers, focusing on machine performance and configuration, considering after-sales service and technical support, and conducting on-site inspections and trial runs. By gaining a deeper understanding of this information, you can make a more informed choice and find a high-quality laser cutting machine that suits your needs. If you need more information about laser cutting machines, please contact us.