Table of Contents

I. Overview of Laser Cutting Gases

Laser cutting, as a key technology in modern industrial manufacturing, is widely applied in various fields such as metal processing, automotive manufacturing, aerospace, and more. During the laser cutting process, auxiliary gases play a crucial role, not only influencing the cutting quality and efficiency but also relating to the equipment lifespan and production costs. This article will comprehensively introduce the various gases used in laser cutting and their application optimization methods.

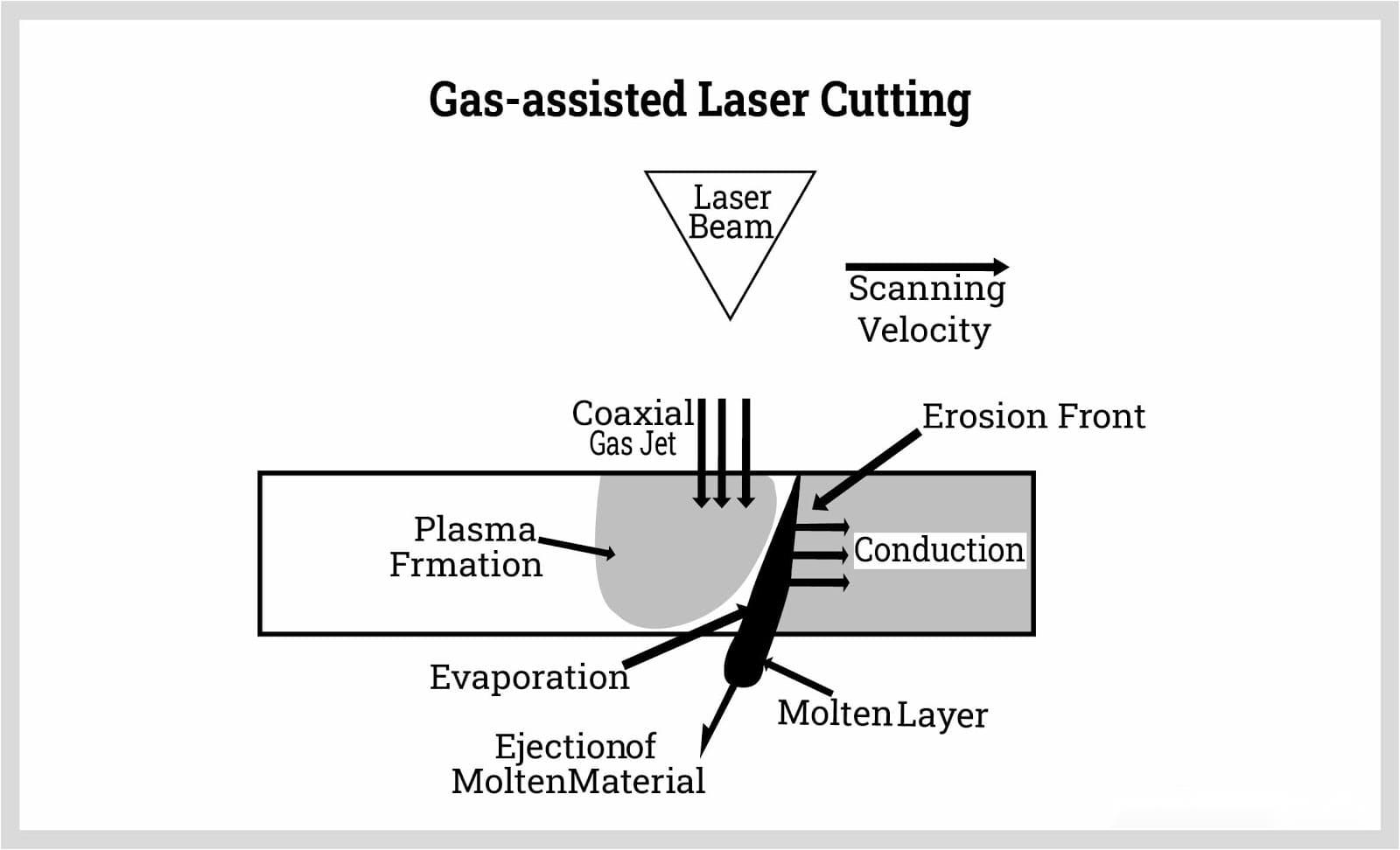

1.1 The Core Function of Auxiliary Gas

During the laser cutting process, the auxiliary gas mainly plays the following key roles:

Removing slag: The high-pressure gas quickly blows away the molten material in the cutting area from the cut edge, preventing slagging and ensuring a smooth cut. This is one of the most fundamental and important functions of the auxiliary gas, directly affecting the quality of the cutting surface.

Aiding thermal reactions: Active gases such as oxygen will react with the metal through oxidation and release heat, replenishing the cutting energy and increasing the cutting speed. The additional heat generated by this oxidation reaction can significantly improve the cutting efficiency, especially for thicker materials.

Protecting the lens: As the gas flows through the cutting head, it can absorb heat and prevent the focusing lens from being damaged by high temperatures. At the same time, it blows away the splashes to keep the lens clean. This not only protects the expensive optical components but also maintains the quality and stability of the laser beam.

Preventing oxidation: Inert gases such as nitrogen and argon can isolate oxygen during the cutting process, preventing the cutting surface from oxidizing. This is particularly important for materials that are sensitive to oxidation, such as stainless steel and aluminum alloys.

1.2 Common Types of Cutting Gases

The commonly used gases in laser cutting currently mainly include the following types:

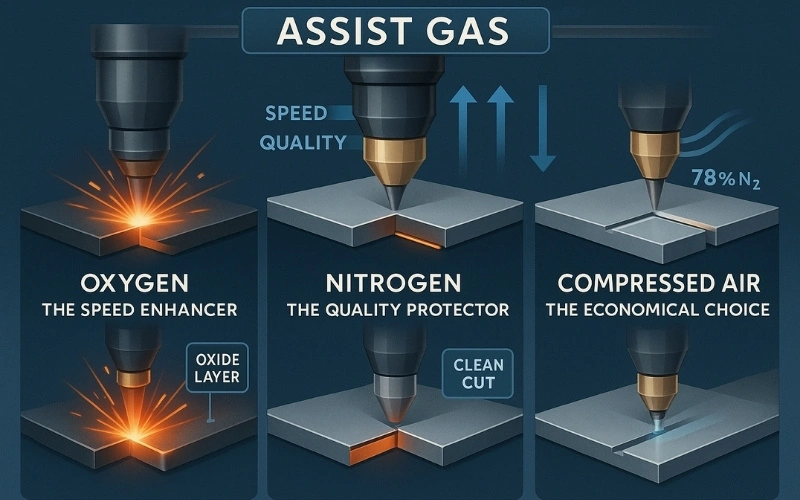

Oxygen: As the most commonly used active gas, oxygen provides additional heat through an oxidation reaction with the metal, significantly increasing the cutting speed. It is mainly used for cutting metals that are prone to oxidation, such as carbon steel.

Nitrogen: As an inert gas, nitrogen is mainly used for cutting materials that do not require oxidation reactions, such as stainless steel and aluminum alloys, resulting in non-oxidized cuts.

Air: Provided directly by an air compressor, it is cost-effective and mainly used for thin plate processing where the quality of the cut is not highly demanded.

Argon: Another inert gas, it has a better anti-oxidation effect than nitrogen, but is more expensive. It is usually used for high-reflection materials or in special requirements situations.

Mixed gases: In recent years, the application of mixed gases in laser cutting has gradually increased. For example, nitrogen-oxygen mixed gas combines the advantages of the two gases and can increase the cutting speed while reducing the formation of burrs.

Comparison of the characteristics of different gases in laser cutting:

| GAS TYPE | Main components | Main Function | main function | Applicable materials | Cut surface color | cost |

| Oxygen | O₂ | ≥99.5% | Aid combustion and increase cutting speed | Carbon steel, cast iron | Blackened / Dark yellow | Medium |

| Nitrogen | N₂ | ≥99.9% | Prevent oxidation and blow off the slag | Stainless steel, aluminum alloy | Silver | High |

| Air | 21% O₂+78% N₂ | – | Low-cost cutting | Thin plates and materials with low requirements for surface quality | yellowing | Low |

| Argon | Ar | ≥99.9% | Anti-oxidation, reduction of reflection | Titanium alloy, high-reflection material | Silver | Very high |

| Mixed gases | 97% N₂+3% O₂ | – | Increase speed and reduce burrs | Medium-thick carbon steel, aluminum alloy | Silver | high |

II. Detailed Analysis of Various Cutting Gases

2.1 Application of Oxygen in Laser Cutting

Oxygen is the most commonly used active gas in laser cutting, and it has the following characteristics and applications:

Mechanism of action: The main role of oxygen in laser cutting is to undergo an oxidation-reaction with the metal, providing additional cutting energy. When the laser beam strikes the metal surface, the metal is heated to its ignition point, and then undergoes a vigorous oxidation reaction with the rapidly ejected oxygen, generating a large amount of heat. These additional heats significantly increase the cutting speed and efficiency.

Purity requirements: The purity of oxygen used in laser cutting is typically required to be above 99.5%, with a pressure range of 0.3-0.8 megapascals. Insufficient purity will affect the full progress of the oxidation reaction and reduce the cutting speed, increasing the possibility of slag formation.

Applicable materials: Oxygen is mainly used for cutting metals that are prone to oxidation, such as carbon steel and cast iron. For carbon steel, especially thick carbon steel, oxygen cutting is the preferred method. It can also be used for cutting stainless steel, electroplated steel plates, copper and copper alloys, etc., but it will form an oxide film on the cutting surface.

Impact on cutting effect: The purity of oxygen has a significant impact on the cutting effect. Studies have shown that when the oxygen purity drops from 99.5% to 98%, the cutting speed will decrease by approximately 25%, and the gas consumption will increase by 50%. When the oxygen purity is below 95%, effective cutting may even not be possible.

Advantages: Significantly improves cutting speed; The heat generated by the oxidation reaction is helpful for cutting thicker materials; The cost is relatively low.

Disadvantages: The cutting surface will form an oxide layer, affecting the surface quality; Not suitable for materials that are sensitive to oxidation; The cutting surface color is darker, usually black or dark yellow.

Application scenarios: Oxygen cutting is widely used in the processing of building steel, mechanical manufacturing, and automotive manufacturing, especially in situations where high cutting speed is required and the surface oxidation is not very sensitive. For carbon steel plates less than 1.5mm, air or nitrogen cutting can also be considered, but the effect may not be as good as that of oxygen cutting.

2.2 Application of Nitrogen in Laser Cutting

Nitrogen, as an inert gas, has unique advantages in laser cutting:

Mechanism of action: The main function of nitrogen in laser cutting is to remove the molten material from the cutting edge and to isolate oxygen to prevent oxidation of the cutting surface. Unlike oxygen, nitrogen does not undergo oxidation reactions with metals, so it does not generate additional heat. The cutting process mainly relies on laser energy.

Purity requirements: When cutting stainless steel, the purity of nitrogen needs to be high, typically reaching 99.9%. For stainless steel with a thickness over 8mm, the purity of nitrogen should reach 99.999%, and the pressure is generally 1MPa. When cutting stainless steel with a thickness over 12mm or even up to 25mm, the pressure needs to be further increased to 2MPa or higher.

Applicable materials: Nitrogen is mainly used for materials that are sensitive to oxidation, such as stainless steel, aluminum alloy, brass, and electroplated steel plates. For these materials, using nitrogen can perform oxidation-free cutting, resulting in high-quality cutting surfaces. Additionally, nitrogen is also suitable for some carbon steel cutting scenarios with high surface quality requirements.

Impact on cutting quality: The purity of nitrogen has a direct impact on cutting quality. Low purity nitrogen may cause oxidation films, color changes, or burrs on the cutting surface. While high purity nitrogen (such as 99.999%) can ensure a smooth cutting surface without oxidation films, it has the characteristics of being able to be directly welded, coated, and has strong corrosion resistance.

Advantages: No oxidation on the cutting surface, high quality; suitable for materials sensitive to oxidation; the cutting surface is silver-white, beautiful, and has strong corrosion resistance.

Disadvantages: Slower cutting speed; higher cost; higher energy consumption, especially when cutting thick plates requires higher pressure and purity of nitrogen.

Application scenarios: Nitrogen cutting is widely used in fields that require high surface quality and corrosion resistance, such as food processing equipment manufacturing, medical device production, and decoration industries. In automotive manufacturing, especially for the processing of stainless steel components, nitrogen cutting has also been widely applied.

2.3 Application of Air in Laser Cutting

Air, as a naturally occurring mixture of gases, has unique advantages and limitations in laser cutting:

Mechanism of action: Air contains approximately 21% oxygen and 78% nitrogen, so its mechanism of action combines the oxidizing effect of oxygen and the protective effect of nitrogen. However, due to the relatively low oxygen content, the oxidation reaction in air cutting is not as intense as that in pure oxygen cutting.

Purity requirements: Air does not require additional purity requirements, but to ensure the cutting effect, it usually needs to be filtered and dried to remove moisture, oil, and impurities. When using compressed air directly provided by an air compressor, it is necessary to ensure the stability of the system and the air quality.

Applicable materials: Air is suitable for cutting a variety of materials, including aluminum, aluminum alloys, stainless steel, brass, electroplated steel, and non-metallic materials, etc. It is particularly suitable for thin plate processing with low requirements for the cutting surface, as well as for cost-sensitive application scenarios.

Impact on cutting effect: Due to the limited oxygen content in air, the cutting efficiency is much lower than that of pure oxygen cutting, and the cutting capacity is similar to that of nitrogen. A small amount of oxide film will appear on the cutting surface, but it can be used as a measure to prevent the coating layer from falling off. The cutting end face is usually yellow. For carbon steel plates less than 1.5MM, air and nitrogen can be used for cutting, but the control of welding slag is difficult. Once welding slag occurs, it needs to be ground with a grinding wheel.

Advantages: Extremely low cost, almost negligible; no need for an additional gas supply system; convenient to obtain, can be directly provided by an air compressor.

Disadvantages: Lower cutting efficiency than pure oxygen; lower cutting quality than nitrogen; cutting surface will have oxidation phenomena; higher requirements for air supply volume and air pressure stability of the air compressor.

Application scenarios: Air cutting is mainly used for thin plate processing with low requirements for cutting quality, such as advertising production, simple part processing, etc. In automotive manufacturing, for the cutting of some non-critical components, air cutting can also be considered to reduce costs.

2.4 Application of Argon Gas in Laser Cutting

Argon, as an inert gas, plays a significant role in laser cutting in specific fields:

Mechanism of action: The main function of argon in laser cutting is to prevent oxidation and nitridation, while reducing the reflection of the material on the laser. Since argon is an inert gas, it does not react chemically with metals and can form an effective protective barrier in the cutting area.

Purity requirements: The purity of argon is usually above 99.9%, and for some high-precision applications, it may require up to 99.99%. Due to the high cost of argon, precise control of the flow rate is necessary to balance cost and effectiveness.

Applicable materials: Argon is mainly used for materials that are extremely sensitive to oxidation, such as titanium and titanium alloys. Additionally, for copper, aluminum, and other materials with high reflectivity and fast heat conduction, argon also plays an important role, reducing the reflection of the material on the laser, protecting the laser head from “damage”, and effectively preventing oxidation. In the welding field, argon is also widely used as a shielding gas.

Impact on cutting effect: As an inert gas, argon provides excellent oxidation prevention protection, resulting in high-quality cutting surfaces without oxidation discoloration. Compared to other processing gases, argon is more expensive and will accordingly increase costs. Due to its excellent protective performance, argon is particularly suitable for applications with extremely high quality requirements.

Advantages: Excellent oxidation prevention effect; Reduces material reflection on the laser; High cutting surface quality; Suitable for materials with high reflectivity and fast heat conduction.

Disadvantages: Extremely high cost; Requires precise control of flow rate; Supply is not as convenient as oxygen and nitrogen.

Application scenarios: Argon is mainly used in aerospace, medical implants, high-end electronics, and other fields with extremely high requirements for quality and safety. In the processing of titanium alloys, special alloys, and materials with high reflectivity, argon is an ideal auxiliary gas choice.

2.5 Application of Mixed Gases in Laser Cutting

In recent years, the application of mixed gases in laser cutting has been increasing, especially in the field of high-power fiber laser cutting:

Common types of mixed gases: The most widely used mixed gas at present is a mixture of nitrogen and oxygen, with the most common ratio being approximately 97% nitrogen and 3% oxygen. In addition, there are other mixed gas ratios, such as 95% nitrogen and 5% oxygen, and the specific ratio depends on the application requirements and equipment characteristics.

Mechanism of action: The mechanism of action of mixed gases combines the advantages of nitrogen and oxygen. Taking the 97% nitrogen and 3% oxygen mixed gas as an example, the behavior of this mixed gas is very similar to the nitrogen cutting process, but adding a small amount of oxygen increases the available energy during the cutting process. This mixture allows the cutting speed to increase by up to 30% compared to using the same laser power for nitrogen cutting, while reducing burr formation and thus producing better quality cuts in thicker low-carbon steel.

Applicable materials: Mixed gases are mainly used for cutting medium-thickness low-carbon steel and aluminum materials. For some materials that originally required oxygen cutting, now they can be processed at a higher speed and with excellent quality using mixed gases. Especially for medium-thick carbon steel over 10mm, mixed gas cutting can achieve better quality than pure oxygen cutting.

Impact on cutting effect: Compared to pure nitrogen gas cutting, mixed gas cutting has several advantages:

Increased cutting speed: Compared to pure nitrogen gas cutting, mixed gas can increase the cutting speed by 20-30%.

Reduced burr formation: A small amount of oxygen in the mixed gas helps to bring the cut to the bottom, resulting in a slag-free edge.

Improved cutting quality: The edge quality of mixed gas cutting is better than that of pure nitrogen and pure oxygen cutting.

Expanding processing range: Mixed gas allows the use of the same laser power to process thicker materials.

Application scenarios: Mixed gas cutting was initially applied to non-dusty cutting of aluminum, and later gradually expanded to the cutting of medium-thick carbon steel. Currently, the cutting conditions of the highest-power fiber laser have been established around precise nitrogen-oxygen mixtures, with oxygen content being relatively low (usually between 1.5% and 5%, depending on the application and equipment). This technology is particularly suitable for industrial manufacturing scenarios that require high quality and efficiency in cutting and efficiency.

III. The Influence of Gas Purity on Laser Cutting Effect

3.1 The Impact of Purity on Cutting Speed

Gas purity is one of the key factors affecting the speed of laser cutting. The requirements and effects of different gas purities vary:

The impact of oxygen purity: The purity of oxygen has a significant impact on the cutting speed. Studies show that when the purity of oxygen decreases from 99.5% to 98%, the cutting speed will drop by approximately 25%, and the gas consumption will increase by 50%. When the purity of oxygen drops below 95%, effective cutting may not be possible. This is because a decrease in purity leads to insufficient oxidation reactions, reduced heat generation, and thus lower cutting efficiency.

The impact of nitrogen purity: For nitrogen cutting, higher purity requirements are needed, especially when cutting thicker materials. Low purity nitrogen may cause a decrease in cutting speed and poor cutting surface quality. For cutting stainless steel thicker than 8mm, the purity of nitrogen must reach 99.999% to ensure the cutting effect.

The impact of air purity: Although there are no strict purity requirements for air, moisture, oil stains, and impurities in it can affect cutting quality and equipment lifespan. Using air that has been well filtered and dried can improve cutting stability and quality.

The impact of mixed gas purity: The purity of the mixed gas mainly depends on the purity of each component gas and the accuracy of the mixing ratio. Inaccurate mixing ratios can affect the performance of the mixed gas. For example, too high oxygen content may lead to excessive oxidation and increased burrs, while insufficient oxygen content will not provide enough additional energy.

3.2 Impact of Purity on Cutting Quality

Gas purity directly impacts cutting quality, primarily in the following areas:

Oxidation of the cut surface: Insufficient gas purity can increase oxidation on the cut surface. For materials requiring oxidation-free cutting (such as stainless steel and aluminum alloys), using low-purity nitrogen may result in oxide films, discoloration, or decreased corrosion resistance. For example, when cutting stainless steel, if nitrogen purity falls below the required level, it will not effectively isolate oxygen, resulting in a darkening or yellowing of the cut surface. High-purity nitrogen (e.g., 99.999%) ensures a smooth, oxide-free cut surface.

Kerf cleanliness: Insufficient gas purity increases the oxygen content in the cut gap, leading to incomplete oxidation reactions and increased, difficult-to-remove slag at the cut bottom, compromising kerf cleanliness. High-purity gas can more effectively remove slag and reduce dross buildup.

Kerf roughness: High-purity gas ensures a more stable cutting process and smoother cut surfaces. Insufficient gas purity may increase cut surface roughness, especially when cutting thicker materials. For example, using high-purity nitrogen to cut stainless steel can produce a cut surface with lower surface roughness, while using low-purity nitrogen may result in increased surface roughness.

Cutting Accuracy: Gas purity also affects cutting accuracy. Impure gas can cause instability in the cutting process, affecting the accuracy of cut dimensions and edge straightness. The impact of gas purity on cutting accuracy is particularly significant in fine cutting and micromachining.

3.3 Impact of Purity on Cutting Cost

Gas purity not only affects cutting results but also directly impacts cutting costs:

Gas Consumption: Low-purity gas reduces cutting efficiency, significantly increasing gas consumption and cutting costs. For example, low oxygen purity not only reduces cutting speed but also significantly increases gas consumption. This is because lower purity requires a higher gas flow rate and longer cutting time to achieve the same cutting result.

Equipment Maintenance Costs: Low-purity gas may contain impurities, which can cause laser nozzle burns or contaminate laser lens elements, reducing laser power and increasing equipment maintenance costs and downtime. For example, moisture in the gas can dampen optical components, affecting laser transmission efficiency; oil contamination can contaminate lens elements, reducing lens life.

Processing Efficiency Costs: Reduced cutting speeds and quality issues caused by low-purity gas increase processing time and scrap rates per unit, thereby increasing overall production costs. This impact is particularly significant in large-scale production.

Overall Cost Analysis: Although high-purity gas typically has a higher unit price, the increased cutting speed, improved quality, and reduced equipment maintenance costs often result in lower unit processing costs. For example, cutting stainless steel with 99.999% high-purity nitrogen may incur higher gas costs, but the overall cost may be lower due to increased cutting speeds, lower scrap rates, and reduced equipment maintenance requirements.

3.4 Gas purity requirements for different materials

Gas purity requirements vary depending on the material’s chemical properties and sensitivity to oxidation:

Carbon Steel Requirements: Carbon steel cutting primarily uses oxygen, typically with a purity requirement of 99.5% or higher. For thin carbon steel sheets, lower-purity oxygen or air can be used, but thicker carbon steel sheets require higher-purity oxygen to ensure quality cuts.

Stainless Steel Requirements: Stainless steel cutting typically uses high-purity nitrogen, with a purity requirement of 99.9% or higher. For plates thicker than 8mm, the purity requirement reaches 99.999%. Using lower-purity nitrogen may cause oxidation on the cut surface, affecting surface quality and corrosion resistance.

Aluminum Alloy Requirements: Aluminum alloy cutting requires higher gas purity, typically using high-purity nitrogen or argon. For high-quality aluminum alloy cutting, nitrogen or argon with a purity of 99.99% or higher may be required. Titanium Alloy Material Requirements: Titanium alloys are extremely sensitive to oxidation, so they require the use of extremely high-purity inert gases, such as argon with a purity of at least 99.99%. Using low-purity gases can cause titanium alloys to react with oxygen and nitrogen in the air at high temperatures, causing embrittlement and a decrease in strength.

Copper and Copper Alloy Material Requirements: Copper and copper alloys have high reflectivity and thermal conductivity, making them challenging to cut. High-purity nitrogen or argon, with a purity requirement of at least 99.9%, is typically used. Argon, due to its reflectivity-reducing properties, is particularly suitable for cutting highly reflective materials.

Non-Metallic Material Requirements: Air is typically used as the auxiliary gas for cutting non-metallic materials, requiring relatively low purity. However, it should be noted that some non-metallic materials (such as acrylic and wood) can generate harmful gases during cutting, requiring a good ventilation system.

IV.Methods and technologies for improving gas purity

4.1 Selection and optimization of gas supply system

Choosing the right gas supply system is the first step in ensuring gas purity:

Nitrogen Generator: For laser cutting applications requiring high-purity nitrogen, consider a nitrogen generator using pressure swing adsorption (PSA) technology and equipped with high-performance carbon molecular sieves, such as those from Takeda in Japan or CarboTech in Germany, to improve nitrogen separation efficiency. A dual-tower adsorption system and optimized switching frequency ensure continuous gas supply and extend the life of the molecular sieve.

Oxygen Generator: When cutting materials such as carbon steel, requiring high-purity oxygen, select oxygen generators that produce high-purity oxygen. Some advanced oxygen generators utilize cryogenic distillation or pressure swing adsorption technologies to provide varying purities based on cutting requirements.

On-site Gas Generation System: For large-scale production or applications requiring extremely high gas purity, consider establishing an on-site gas generation system, such as a PSA system or membrane separation system, to provide a stable, high-purity gas supply.

Gas Storage Tank Selection: Select reliable, well-sealed gas storage tanks to store gas and prevent contamination or leakage during storage. The capacity of the gas storage tank should be appropriately selected based on the gas demand of the cutting equipment and the production plan.

Gas Pipeline System: Use corrosion-resistant, smooth-walled pipelines to transport gas to minimize gas adsorption and contamination on the pipeline’s inner wall. Additionally, a rationally designed pipeline layout minimizes pipeline length and the number of elbows to reduce pressure loss and the risk of leaks during gas transportation.

Multiple Gas Source Redundancy: For critical production equipment, a multiple gas source redundancy system can be designed to ensure a stable gas supply even if a single source fails.

Pressure Stabilization System: Install a gas pressure stabilizer to ensure stable gas pressure and prevent pressure fluctuations that affect cutting quality. Pressure fluctuations exceeding ±0.1 MPa can result in unstable cutting quality.

Gas Distribution System: A rationally designed gas distribution system ensures uniform gas pressure and flow across all cutting equipment.

4.2 Optimizing the Gas Pretreatment System

Gas pretreatment is a key step in improving gas purity and primarily involves the following aspects:

Refrigerated Dryer Installation: Before the gas enters the cutting equipment, a refrigerated dryer is installed to remove moisture from the gas. This dehumidification process reduces the gas temperature, condensing water vapor into liquid water. This is crucial for preventing ice formation in pipes and equipment, and minimizing the impact of moisture on cutting quality.

Adsorption Dryer Application: For applications with extremely high moisture requirements, an absorption dryer may be considered. Using an adsorbent to absorb moisture from the gas, an absorption dryer can reduce the gas dew point to below -40°C, meeting high-purity gas requirements.

Multi-Stage Filtration System: Equipped with multiple stages of precision filters, such as activated carbon filters and oil-water separators, these systems remove oil, impurities, and dust, preventing these contaminants from affecting gas purity and cutting performance.

Filter Grating: Select the appropriate filtration grain based on the gas and application requirements. Generally, laser cutting gas should be filtered to a filtration grain of 0.01μm to ensure the removal of fine particles and oil mist.

Regularly replace the filter element according to the equipment manufacturer’s recommendations to ensure effective filtration. Generally, air filters should be replaced every 6-12 months, and activated carbon filters every 3-6 months. The specific replacement frequency depends on the operating environment and air quality.

Regular Inspection: Regularly inspect the operating status of the refrigerated dryer, adsorption dryer, and filter to promptly detect and address any abnormalities.

Drainage Management: The refrigerated dryer and filter generate condensate, which needs to be drained regularly to prevent accumulation that may affect system performance.

Cleaning Management: Regularly clean the exterior and interior of the pretreatment system to prevent dust and debris from accumulating and affecting system operation.

4.3 Real-Time Monitoring and Control System

Real-time monitoring and control of gas purity are crucial for ensuring consistent cutting quality:

Oxygen Purity Analyzer: Install an online oxygen purity analyzer on the oxygen output pipeline to monitor oxygen purity in real time to ensure it meets cutting requirements.

Nitrogen Purity Analyzer: For nitrogen systems, install an online nitrogen purity analyzer to monitor parameters such as oxygen content in nitrogen in real time to ensure nitrogen purity remains stable at 99.9% or above.

Dew Point Analyzer: Install a dew point analyzer to monitor gas moisture content to ensure gas dryness meets requirements. For demanding applications, the dew point should be controlled below -40°C.

PLC Control System: A PLC control system automatically adjusts operating parameters of the gas generator, such as adsorption time and pressure, based on the test results of the online purity analyzer to ensure stable gas purity.

Automatic Switching System: For critical equipment, an automatic switching system can be designed to automatically switch to a backup gas source when gas purity is detected to be below standard, ensuring production continuity. Intelligent Alarm System: A smart alarm system generates prompt alerts when abnormalities in gas purity, pressure, or flow occur, notifying operators to address the situation.

Gas Parameter Recording: Real-time recording of gas purity, pressure, flow, and other parameters establishes a comprehensive quality traceability system.

Data Analysis: Regularly analyzes gas parameter data to identify potential issues and trends, enabling proactive preventative measures.

Optimization Recommendations: Based on data analysis results, gas system optimization recommendations are provided to continuously improve gas quality and cutting results.

4.4 Gas Management and Maintenance Strategy

An effective gas management and maintenance strategy is crucial to ensuring gas purity and cutting quality:

Comprehensive System Inspection: Regularly inspect and maintain the gas generation equipment, pretreatment system, and delivery pipelines to promptly detect and address equipment failures and leaks. For example, check the adsorption performance of molecular sieves and replace them promptly if any degradation occurs.

Gas Quality Testing: Regularly test gas quality, including purity, dew point, and particle content, to ensure gas quality meets standards.

Pressure and Flow Testing: Check that the gas system’s pressure and flow meet equipment requirements to ensure a stable cutting process.

Professional Training: Operators receive professional training to familiarize themselves with the operating specifications of the gas generator and cutting equipment, and master the correct gas purity testing and adjustment methods to ensure normal equipment operation and stable gas purity.

Emergency Plan Training: Operators are trained to identify and handle gas system anomalies. Detailed emergency plans are developed to ensure prompt and corrective action in emergency situations.

Best Practice Sharing: Operators regularly share best practices to improve overall operational performance.

Qualified Supplier Evaluation: Select qualified gas suppliers and evaluate their product quality, supply capabilities, and service levels.

Regular Audits: Regularly audit gas suppliers’ quality management systems to ensure they consistently provide gas products that meet requirements.

Technical Collaboration: Establish technical partnerships with gas suppliers to jointly resolve gas quality issues and explore new technologies and solutions.

Problem-Solving Process: Establish a gas quality problem-solving process to ensure that issues are addressed promptly and effectively.

Improvement Projects: Regularly conduct gas system improvement projects, applying new technologies and materials to improve gas quality and system efficiency.

Best Practice Promotion: Summarize and promote best practices in gas management to enhance overall management capabilities.

Wǔ, jīguāng qiēgē qìtǐ de xuǎnzé yǔ yìngyòng cèlüè 5.1 Gēnjù cáiliào lèixíng xuǎnzé héshì de qìtǐ

V. Laser Cutting Gas Selection and Application Strategies

5.1 Select the appropriate gas according to the material type

Selecting the appropriate cutting gas based on the material’s characteristics is key to achieving high-quality cutting results:

Gas Selection for Carbon Steel: Carbon steel is the most common laser cutting material, and oxygen is typically used as the assist gas. For thin carbon steel sheets under 1.5mm thick, air or nitrogen can be used. However, for medium- and thicker carbon steel plates over 1.5mm, oxygen with a purity of 99.5% or higher is recommended to ensure cutting quality and efficiency. Air is also an economical option for thin sheet cutting where quality requirements are less demanding, but the cut surface may show slight oxidation and burrs.

Gas Selection for Stainless Steel: High-purity nitrogen is typically used as the assist gas for stainless steel cutting to prevent oxidation. For stainless steel sheets under 8mm thick, 99.9% nitrogen is sufficient; for thicker stainless steel sheets over 8mm, high-purity nitrogen with a purity of 99.999% is required. In some cases, air can be used to cut stainless steel, but the cut surface will appear gray-black, and the reverse side may have minor burrs, which require light sanding with sandpaper.

Gas Selection for Aluminum Alloys: Aluminum alloy cutting requires high gas requirements, typically using high-purity nitrogen or argon. For aluminum alloy sheets 1-2 mm thick, 99.9% pure nitrogen at a controlled pressure of 1.0-1.2 MPa can be used. Thicker aluminum alloys may require higher purity gases and higher pressures. For high-quality aluminum alloy cutting, such as in aerospace applications, argon may be used for optimal results.

Gas Selection for Titanium Alloys: Titanium alloys are extremely sensitive to oxidation, requiring the use of extremely high-purity inert gases, such as argon with a purity exceeding 99.99%. Using low-purity gases can cause titanium alloys to react with oxygen and nitrogen in the air at high temperatures, resulting in embrittlement and a decrease in strength. To maintain the titanium alloy’s original metallic color and properties, an inert gas such as argon should be selected. If surface color is less critical, air can be used as the assist gas, but this may result in oxidation on the cut surface.

Gas Selection for Copper and Copper Alloys: Copper and copper alloys have high reflectivity and thermal conductivity, making them challenging to cut. High-purity nitrogen or argon is typically used as the assist gas. For 1mm thick copper plates, either nitrogen or air can be used, with a pressure of 1.2-1.5 MPa (nitrogen), a power setting of 2500-3000W, and a speed of 1500-2000 mm/min. Argon, due to its reflectivity-reducing properties, is particularly suitable for cutting highly reflective materials.

Gas Selection for Non-Metallic Materials: Air is typically used as the assist gas for cutting non-metallic materials. Adjustments to the gas type and parameters may be necessary for cutting certain non-metallic materials, such as acrylic and wood. Air is the most economical option and is suitable for cutting most non-metallic materials. However, it should be noted that some non-metallic materials can generate hazardous gases during cutting, requiring a good ventilation system.

5.2 Adjusting Gas Parameters Based on Cutting Thickness

Cutting thickness is another key factor influencing gas selection and parameter settings:

Thin plate generally refers to materials under 3mm thick. For thin plate cutting, the gas pressure should be kept low, otherwise it may deform the plate. For carbon steel thin plates 1-3mm thick, using oxygen as the assist gas at a pressure of 0.6-0.8 MPa can reduce power by 10% and increase speed by 20%. For stainless steel thin plates, using nitrogen at a pressure of 0.8-1.0 MPa increases power by 15% compared to carbon steel, but reduces speed by 15%.

Medium and thick plate generally refers to materials 3-10mm thick. For carbon steel 5-10mm thick, using oxygen at a pressure of 1.0-1.2 MPa, setting power between 2500-3500W, and speed between 800-1200 mm/min. For 5mm thick stainless steel, use nitrogen at a pressure of 1.2-1.5MPa, a power of 3000-4000W, and a speed of 800-1000mm/min. For cutting medium-thick plate, gas purity requirements are higher, and high-purity gas is generally required to ensure cutting quality.

Thick plate generally refers to material over 10mm thick. For thick plate cutting, use “oxygen + high pressure” (1.2-1.5MPa), combined with a low speed (500-800mm/min) and high power (above 4000W). This utilizes oxidation heat to aid penetration while preventing slag from clogging the cut edge. For particularly thick materials, a mixed gas, such as 97% nitrogen and 3% oxygen, may be used for better cut quality.

| Material Type | Thickness range | Recommended Gases | Gas pressure (MPa) | Cutting Speed (mm/min) | Laser Power (W) |

| Carbon Steel | 1-3mm | Oxygen | 0.6-0.8 | 2500-3500 | Reduced by 10% |

| Carbon Steel | 5-10mm | Oxygen | 1.0-1.2 | 800-1200 | 2500-3500 |

| Carbon Steel | >10mm | Oxygen/Gas Mixture | 1.2-1.5 | 500-800 | 4000 and above |

| Stainless Steel | 1-3mm | Nitrogen | 0.8-1.0 | 1500-2500 | 15% higher than carbon steel |

| Stainless Steel | 5mm | Nitrogen | 1.2-1.5 | 800-1000 | 3000-4000 |

| Stainless Steel | >8mm | High-Purity Nitrogen | 1.5-2.0 | 500-800 | 4000 and above |

| Aluminum Alloy | 1-2mm | Nitrogen | 1.0-1.2 | 2000-2500 | 2000-2500 |

| Copper | 1mm | Nitrogen/Air | 1.2-1.5 (Nitrogen) | 1500-2000 | 2500-3000 |

5.3 Gas Selection Strategies for Different Industries

Different industries have varying requirements for laser cutting quality and efficiency, resulting in varying gas selection strategies:

Automotive: The automotive industry places high demands on both cutting quality and efficiency. Carbon steel and stainless steel are the most commonly used materials in automotive manufacturing. For carbon steel materials such as automotive structural parts and chassis components, oxygen is typically used to improve efficiency and reduce costs. For stainless steel parts such as automotive trim and exhaust pipes, high-purity nitrogen is used to achieve high-quality cut surfaces. In recent years, with the trend toward lightweighting, aluminum alloy cutting has become increasingly common in automotive manufacturing, often using high-purity nitrogen or argon to ensure cutting quality.

Aerospace: The aerospace industry places extremely high demands on material quality and safety, typically utilizing high-purity gases. Nitrogen or argon with a purity exceeding 99.99% is typically used for cutting common aerospace materials such as aluminum alloys, titanium alloys, and high-temperature alloys. Mixed gases (e.g., a 2:1 nitrogen-oxygen ratio) are used in over 65% of aerospace applications due to their combined efficiency and thermal stability. In addition, the aerospace industry uses rare gases such as argon for cutting specialized materials to ensure cutting quality and maintain material properties.

Electronics Manufacturing: The electronics manufacturing industry often requires cutting thin sheet materials and precision parts, placing high demands on cutting accuracy and surface quality. Common materials used in electronics manufacturing include stainless steel, copper, and aluminum. High-purity nitrogen or argon is often used for cutting these materials to achieve oxidation-free, high-precision cutting results. Furthermore, the electronics manufacturing industry has extremely high gas purity requirements, typically requiring gases with a purity of 99.999% or higher to ensure cutting quality and the performance of electronic products.

Medical Device Industry: The medical device industry places extremely high demands on material biocompatibility and surface quality. Stainless steel and titanium alloys are the most commonly used materials in medical device manufacturing. High-purity nitrogen or argon is often used for cutting these materials to prevent oxidation on the cut surface and ensure biocompatibility and corrosion resistance. Implantable medical devices, in particular, require gases with a purity of 99.999% or higher to ensure cutting quality and product safety.

General Machinery Manufacturing: The industry handles a wide variety of materials, and the cutting quality requirements vary. For general structural components and common parts, oxygen or air is typically used to reduce costs. For critical parts and those requiring subsequent processing, high-purity nitrogen is used for superior cutting quality. The general machinery manufacturing industry typically selects the appropriate gas based on the criticality and quality requirements of the part, balancing cost and quality.

VI. Future Trends and Development Directions

6.1 Research and Development of New Gases and Mixed Gases

With the continuous advancement of laser cutting technology, the research and development of new gases and gas mixtures has become a key trend:

Development of New Gas Mixtures: Currently, nitrogen and oxygen mixtures are the most widely used, but in the future, more diverse gas mixtures may be developed, such as ternary mixtures of nitrogen, oxygen, and carbon dioxide, or mixtures of nitrogen, argon, and oxygen, to meet the needs of different materials and processes.

Expanding Applications of Rare Gases: In addition to traditional argon, other rare gases such as helium may also find wider application in specific applications. Helium, with its excellent thermal conductivity and stability, enhances laser output and may play a greater role in certain high-precision cutting applications.

Development of Specialty Gases: Targeted to specific materials and process requirements, specialized gases may be developed. For example, for cutting highly reflective materials (such as copper, gold, and silver), gases with special optical properties may be developed to enhance the material’s laser absorption rate.

Development of Environmentally Friendly Gases: With increasing environmental protection requirements, the development of environmentally friendly laser cutting gases will become a key direction. For example, developing gases with low global warming potential (GWP) to reduce carbon emissions and environmental impact during laser cutting.

6.2 Innovations in Gas Supply and Management Technologies

Innovations in gas supply and management technologies will have a significant impact on laser cutting efficiency and quality:

Intelligent gas supply systems: Future gas supply systems will be more intelligent, featuring features such as automated diagnostics, remote monitoring, and predictive maintenance. These systems can automatically adjust gas type, purity, and pressure based on the cutting task, achieving fully automated control of the entire process.

Integrated gas solutions: Future gas supply systems will tend to be integrated, integrating gas generation, purification, storage, and supply functions. This will reduce equipment footprint and improve system efficiency and reliability. For example, nitrogen generators, cold dryers, filters, and gas storage tanks can be integrated into a single design to create an all-in-one gas solution.

Distributed gas supply networks: For large-scale manufacturing companies, distributed gas supply networks will become a trend. Such networks can flexibly allocate gas resources based on regional needs, improve gas utilization efficiency, and reduce system costs.

Gas recovery and reuse technologies: Gas recovery and reuse technologies may be developed in the future, particularly for expensive rare gases such as argon and helium. Recovery and purification technologies can significantly reduce gas costs and improve resource utilization efficiency.

6.3 Coordinated Optimization of Gas and Laser Cutting Processes

Coordinated optimization of gas and laser cutting processes will be a key area of future development:

Coordinated optimization of gas and laser parameters: Future research will focus on coordinating the optimization of gas parameters (such as pressure, flow, and purity) with laser parameters (such as power, wavelength, and pulse width) to achieve optimal cutting results. For example, optimal gas-laser parameter combinations will be developed for specific materials and thicknesses to achieve the optimal balance between cutting speed, quality, and cost.

New cutting head design and gas flow field optimization: Future cutting head designs will prioritize optimizing the gas flow field, improving gas utilization efficiency and cutting results through improvements in nozzle design and gas channel structure. For example, nozzles that produce a more uniform and stable gas flow field will be developed to reduce turbulence and eddy currents, thereby improving cutting quality.

Real-time monitoring and adaptive control technology: Future laser cutting systems will be equipped with more advanced real-time monitoring and adaptive control technologies, capable of automatically adjusting gas and laser parameters based on actual cutting conditions, enabling intelligent control of the cutting process. For example, high-speed cameras and sensors will monitor the cutting area in real time, automatically adjusting gas pressure and flow based on the monitoring results to ensure consistent cutting quality.

Green manufacturing and energy efficiency: Future laser cutting technology will place greater emphasis on green manufacturing and energy efficiency. By optimizing gas parameters and cutting processes, energy and gas consumption can be reduced, waste generation can be minimized, and sustainable manufacturing can be achieved.

6.4 Improvement of Industry Standards and Certification Systems

With the widespread application of laser cutting technology, the improvement of industry standards and certification systems will become a key development direction:

Improvement of Gas Quality Standards: In the future, more comprehensive laser cutting gas quality standards will be established, clarifying requirements for gas purity, moisture content, and particle content in different application scenarios, providing clear guidance for gas suppliers and users.

Development of Gas System Safety Standards: To address the safety issues of laser cutting gas systems, more detailed and comprehensive safety standards will be formulated, covering all aspects of gas storage, transportation, and use to ensure the safety of operators and equipment.

Establishment of a Gas Management Certification System: In the future, a gas management certification system may be established to evaluate and certify companies’ gas system design, installation, operation, and maintenance, promoting improved gas management standards.

Publishing Industry Best Practice Guides: Industry associations and research institutions will publish best practice guidelines for laser cutting gas applications, summarizing and promoting advanced practices to help companies improve gas efficiency and cutting quality.

VII. Conclusions and Recommendations

7.1 Key Principles for Laser Cutting Gas Selection

Based on the analysis presented in this article, the following key principles should be followed when selecting a laser cutting gas:

Material Compatibility: Gas selection should primarily consider the characteristics of the material being cut, particularly its chemical properties and oxidation sensitivity. For easily oxidizable materials, such as carbon steel, oxygen can be selected; for oxidation-sensitive materials, such as stainless steel and aluminum alloys, high-purity nitrogen or argon should be chosen.

Quality Matching: Gas selection should match product quality requirements. For products with high quality requirements, high-purity gases should be selected; for products with average quality requirements, lower-cost gases, such as air or low-purity oxygen, can be selected.

Cost-Benefit Balance: When selecting a gas, factors such as gas cost, cutting efficiency, quality, and equipment maintenance should be comprehensively considered to maximize overall cost-effectiveness. Although high-purity gases have a higher unit price, they can potentially achieve lower unit processing costs by improving cutting efficiency, reducing scrap rates, and reducing equipment maintenance costs.

System Compatibility: Gas selection should consider compatibility with existing equipment and systems to avoid the additional costs of equipment modification and system adjustments due to gas changes. Safety and environmental protection priority principle: Gas selection should give priority to safety and environmental protection, and avoid the use of gases with high hazards or high environmental impact.

7.2 Gas Optimization Recommendations for Improving Laser Cutting Performance

Based on the analysis presented in this article, the following gas optimization recommendations are offered to improve laser cutting performance:

Use high-purity gas that meets requirements: Select gas of appropriate purity based on material and process requirements to ensure cutting quality.

Establish a gas quality monitoring system: Install online gas purity monitoring equipment to monitor gas quality in real time and ensure stable gas purity.

Regularly test gas quality: Regularly conduct comprehensive gas quality tests, including purity, dew point, and particle content, to promptly identify and resolve any problems.

Adjust gas pressure based on material and thickness: Different materials and thicknesses require different gas pressures, which should be adjusted based on actual conditions.

Optimize gas flow: Ensure an appropriate gas flow rate to effectively remove slag without interfering with the laser beam.

Select the appropriate nozzle: Select the appropriate nozzle based on gas type and pressure to ensure a uniform and stable gas flow field.

Regularly maintain the gas system: Establish a comprehensive gas system maintenance plan and regularly inspect and maintain the gas generator, pretreatment system, and delivery pipelines.

Replace filter cartridges promptly: Regularly replace filter cartridges according to the equipment manufacturer’s recommendations to ensure effective filtration. Maintain system cleanliness: Regularly clean the gas system to prevent the accumulation of impurities and oil, which can affect gas quality and equipment performance.

Train operators: Provide professional training to operators to enhance their ability to operate and maintain the gas system.

Establish standard operating procedures: Develop detailed standard procedures for gas system operation and maintenance to ensure consistent and standardized operations.

Continuous improvement: Establish a continuous improvement mechanism to continuously optimize the gas system and cutting process to improve cutting results and efficiency.

7.3 Strategies for Addressing Future Development Trends

Facing the future development trends of laser cutting gas technology, companies should adopt the following strategies:

Technology Tracking and Evaluation: Closely monitor the latest developments in laser cutting gas technology, regularly assess the applicability and economic viability of new technologies and products, and provide a basis for corporate decision-making.

Strategic Cooperation and Innovation: Establish strategic partnerships with gas suppliers, equipment manufacturers, and research institutions to jointly promote the innovative development of gas technology and cutting processes.

Talent Development and Recruitment: Cultivate and recruit professionals in gas technology and laser cutting to enhance the company’s technological innovation capabilities and application level.

Investment Planning and Implementation: Develop a reasonable gas system investment plan based on the company’s development strategy and technological trends, gradually upgrade and optimize the gas system, and enhance the company’s competitiveness.

Standardization and Certification: Actively participate in the development and certification of industry standards to promote the improvement of corporate gas management and the standardized development of the industry.

In short, the selection and application of laser cutting gas is a key factor affecting cutting quality, efficiency, and cost. Companies should select the appropriate gas type and purity based on their needs and material properties, optimize gas parameters and system design, and strengthen gas system maintenance and management to achieve optimal laser cutting results. At the same time, we should pay close attention to technological development trends, actively adopt new technologies and products, continuously improve gas systems and cutting processes, and enhance the competitiveness and sustainable development capabilities of enterprises.If you need to know more about laser cutting machine, please contact us.