In the field of metal processing, Sheet Metal Bending Machine is a key equipment for achieving accurate bending of metal sheets. Its performance directly affects the quality of processed products, production efficiency and the economic benefits of enterprises. However, there are many brands of Sheet Metal Bending Machine on the market, and the quality varies. How to identify a truly high-quality Sheet Metal Bending Machine from many products has become an important issue facing buyers and users. This article will take the Kraus electro-hydraulic bending machine as an example to deeply analyze the core evaluation criteria of high-quality Sheet Metal Bending Machine to help everyone make wise decisions when purchasing.

Table of Contents

1.A solid foundation: Weight and structural design are the cornerstones of quality.

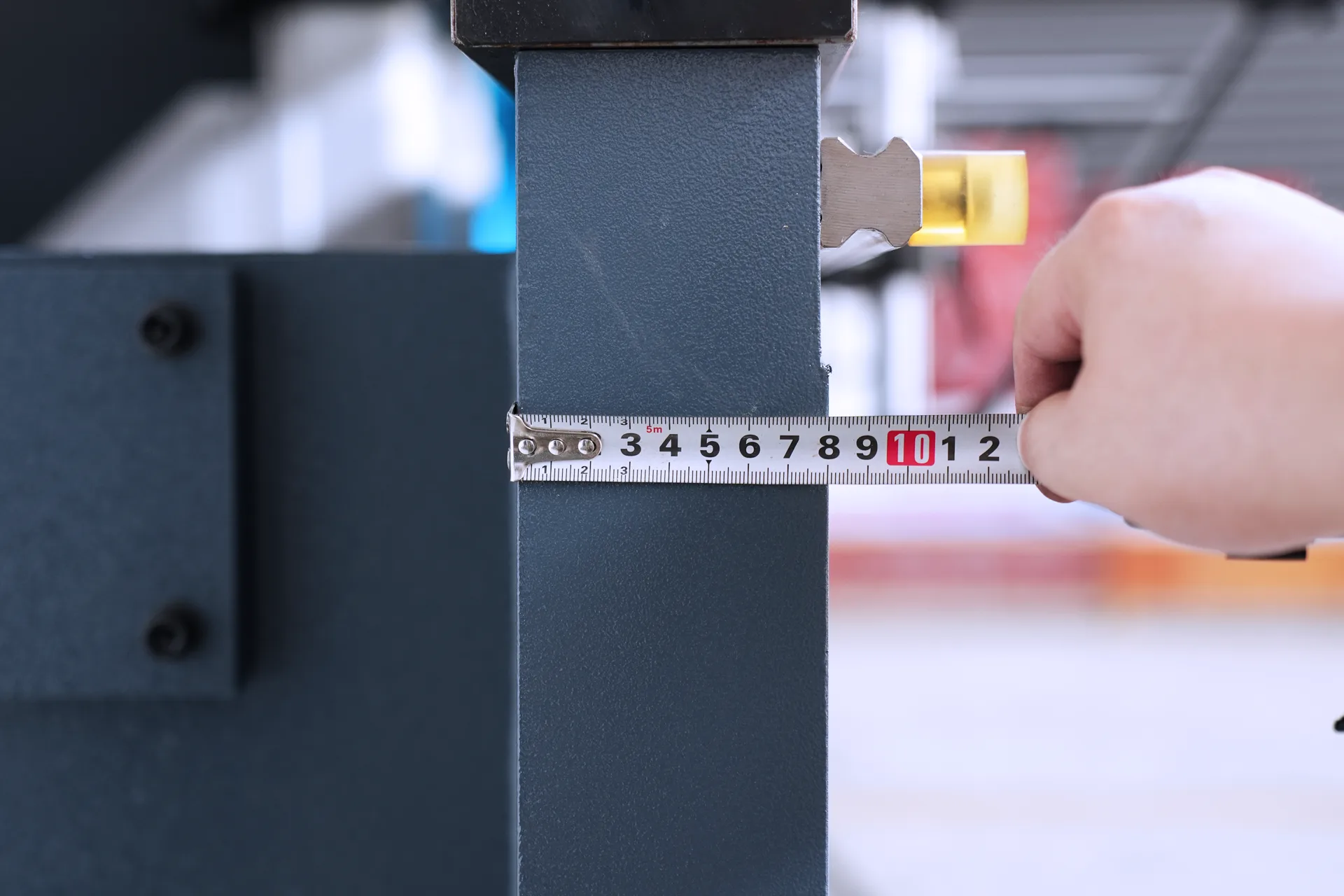

1.1Weight comparison shows the sincerity of materials

Weight is one of the important intuitive indicators to measure the quality of Sheet Metal Bending Machine. Taking the 110T 3200 model as an example, the weight of the Claus Sheet Metal Bending Machine is about 8.2T, while other ordinary brands of the same model of Sheet Metal Bending Machine on the market may only weigh 7.2T. Behind this 1T weight difference is Claus’s persistent pursuit of high quality. A heavier body means that more and better steel is used, which can effectively enhance the stability of the machine during operation and reduce the error caused by vibration, thereby ensuring the bending accuracy and processing quality.

In actual production, the Sheet Metal Bending Machine will generate a strong force during operation. If the body is not stable enough, a slight vibration may cause the bending angle to deviate, affecting the dimensional accuracy and appearance quality of the product. With solid materials, the Claus bending machine can still maintain stable operation when facing high-intensity and long-term work tasks, greatly reducing the defective rate and saving production costs for enterprises.

1.2Extra-thick wall panels create a solid body

The structural design of the Krrass Sheet Metal Bending Machine (110T3200) also reflects its extraordinary features, especially the thickness of its wall panels, which is far higher than that of ordinary brands. The thickness of the workbench vertical panel is 80mm, the thickness of the side wall panel is 50mm, and the thickness of the slider is 60mm. Such a thick wall panel not only improves the overall rigidity of the machine body, but also better withstands the huge pressure during the bending process, effectively prevents the deformation of the machine body, and prolongs the service life of the equipment.

Compared with ordinary Sheet Metal Bending Machine, the thick wall panel design of the Kraus Sheet Metal Bending Machine makes it more advantageous when processing high-strength metal sheets. For example, when processing titanium alloy sheets commonly used in the aerospace field, or thick steel plates in the construction industry, the Kraus Sheet Metal Bending Machine can rely on the solid body structure to ensure the precise execution of the bending action, avoid problems such as inadequate bending of the sheet metal and surface damage caused by insufficient body strength, and meet the stringent requirements of high-end manufacturing for product quality.

2.High-end accessories: international brands enable excellent performance

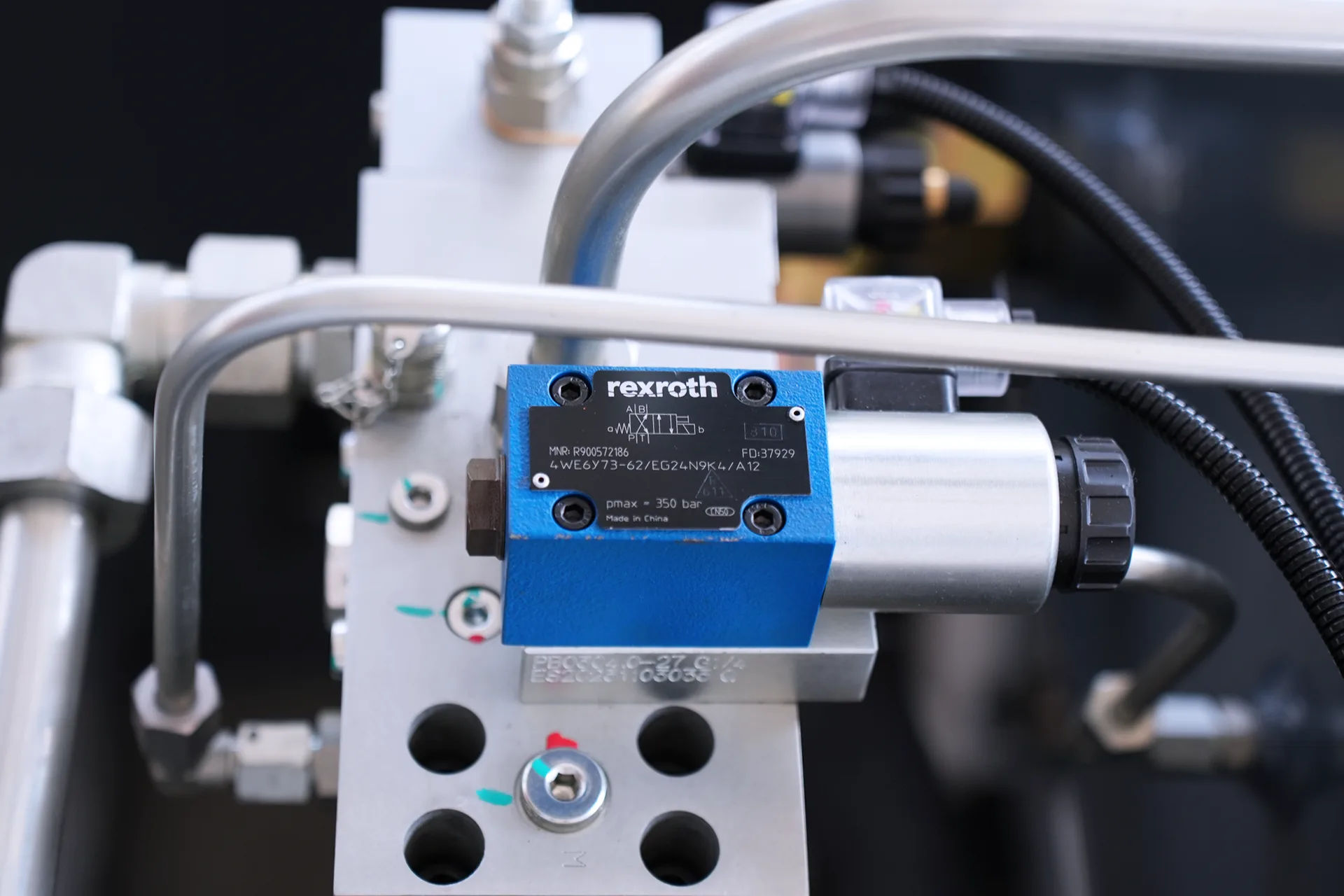

2.1German Rexroth valve group: the “heart” of the hydraulic system

The hydraulic system is the power core of the Sheet Metal Bending Machine, and the valve group is the key component of the hydraulic system. Kraus bending machine uses the German Rexroth valve group. As a leading brand in the field of global hydraulic technology, the Rexroth valve group is known for its high precision, high reliability and excellent control performance.

The German Rexroth valve group can achieve precise control of hydraulic oil, ensuring that the lifting and pressing of the slide of the Sheet Metal Bending Machine are smooth, smooth and responsive. During the bending process, it can accurately adjust the hydraulic pressure and flow according to different sheet materials, thicknesses and bending requirements, so that the bending angle error is controlled within a very small range. Whether it is a small angle precision bending or a large angle strong bending, the German Rexroth valve group can provide stable and reliable power support for the Kraus Sheet Metal Bending Machine to ensure the consistency and stability of the bending quality.

2.2The Dutch DELEM system: the “brain” of intelligent control

In terms of the control system of Sheet Metal Bending Machine, Krrass uses the Dutch DELEM system, which is an advanced intelligent bending control system. The DELEM system has powerful computing and processing capabilities. It can quickly generate the optimal bending solution based on the input plate parameters and bending process requirements, and accurately control each action of the Sheet Metal Bending Machine.

The operator only needs to enter the relevant data on the operation interface of the DELEM system, and the system can automatically calculate the parameters such as the stroke of the slider, bending pressure, and back gauge position, and perform precise control. In addition, the DELEM system also supports graphical programming. Operators can program by drawing bending graphics, which is intuitive and convenient, greatly improving programming efficiency and accuracy. At the same time, the system also has a fault diagnosis function, which can monitor the operating status of the equipment in real time, timely discover and warn potential faults, and facilitate maintenance personnel to quickly locate and solve problems, reduce equipment downtime, and improve production efficiency.

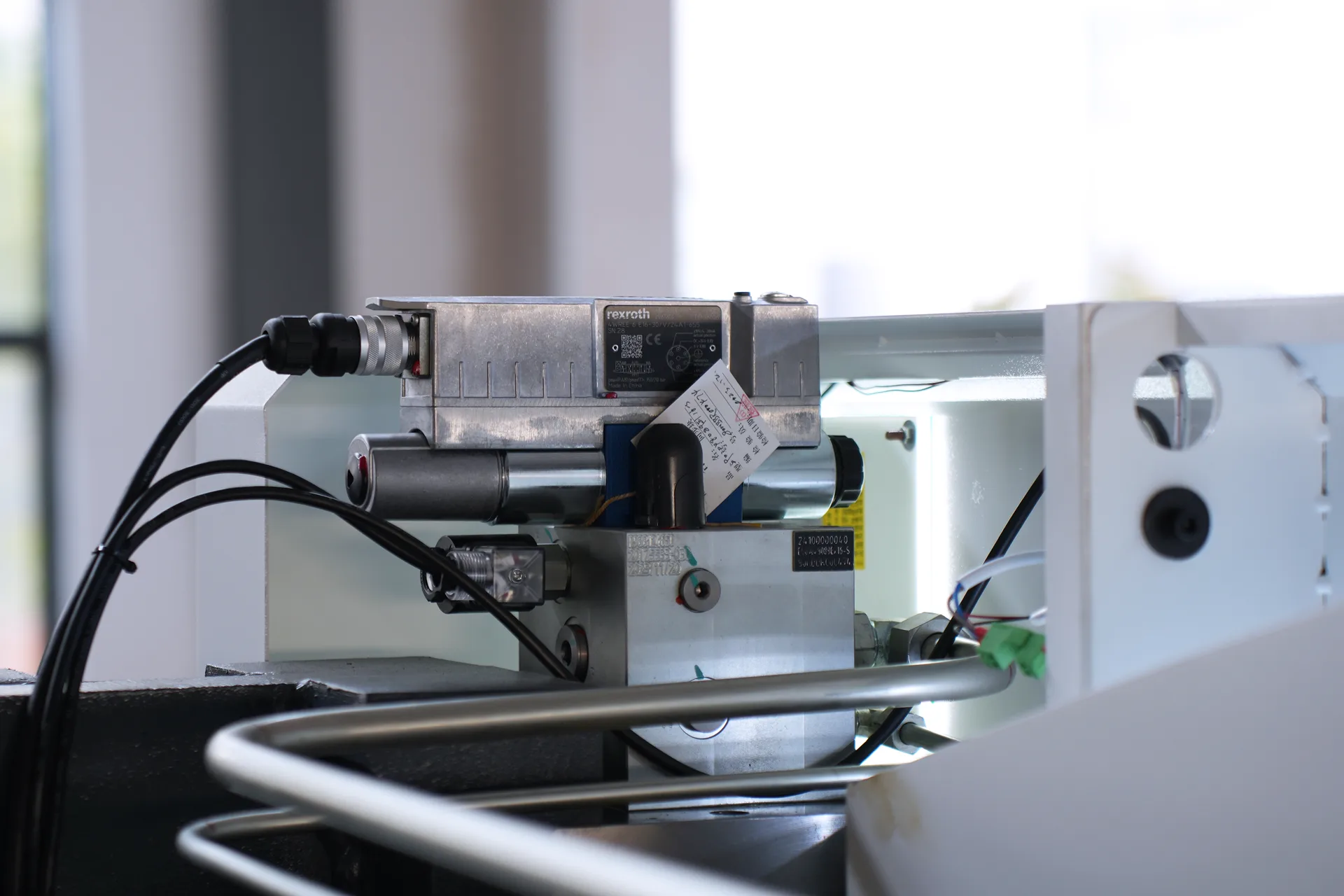

2.3FAGOR grating ruler: the “eyes” for precision assurance

In order to achieve high-precision bending processing, the Krrass Sheet Metal Bending Machine is equipped with a FAGOR grating ruler. FAGOR is a world-renowned manufacturer of measuring equipment, and its grating rulers have extremely high measurement accuracy and stability.

The FAGOR grating ruler can accurately measure the position and displacement of the slider in real time and feed the data back to the control system. The control system adjusts the movement of the slider in real time based on the feedback data to ensure the accuracy of the bending angle and size. Even in a long-term, high-intensity working environment, the FAGOR grating ruler can still maintain stable measurement performance, effectively avoiding the problem of reduced bending accuracy caused by measurement errors. In industries such as precision machinery manufacturing and electronic equipment manufacturing that require extremely high product accuracy, the Kraus Sheet Metal Bending Machine is equipped with a FAGOR grating ruler to meet strict processing accuracy standards and produce high-quality products.

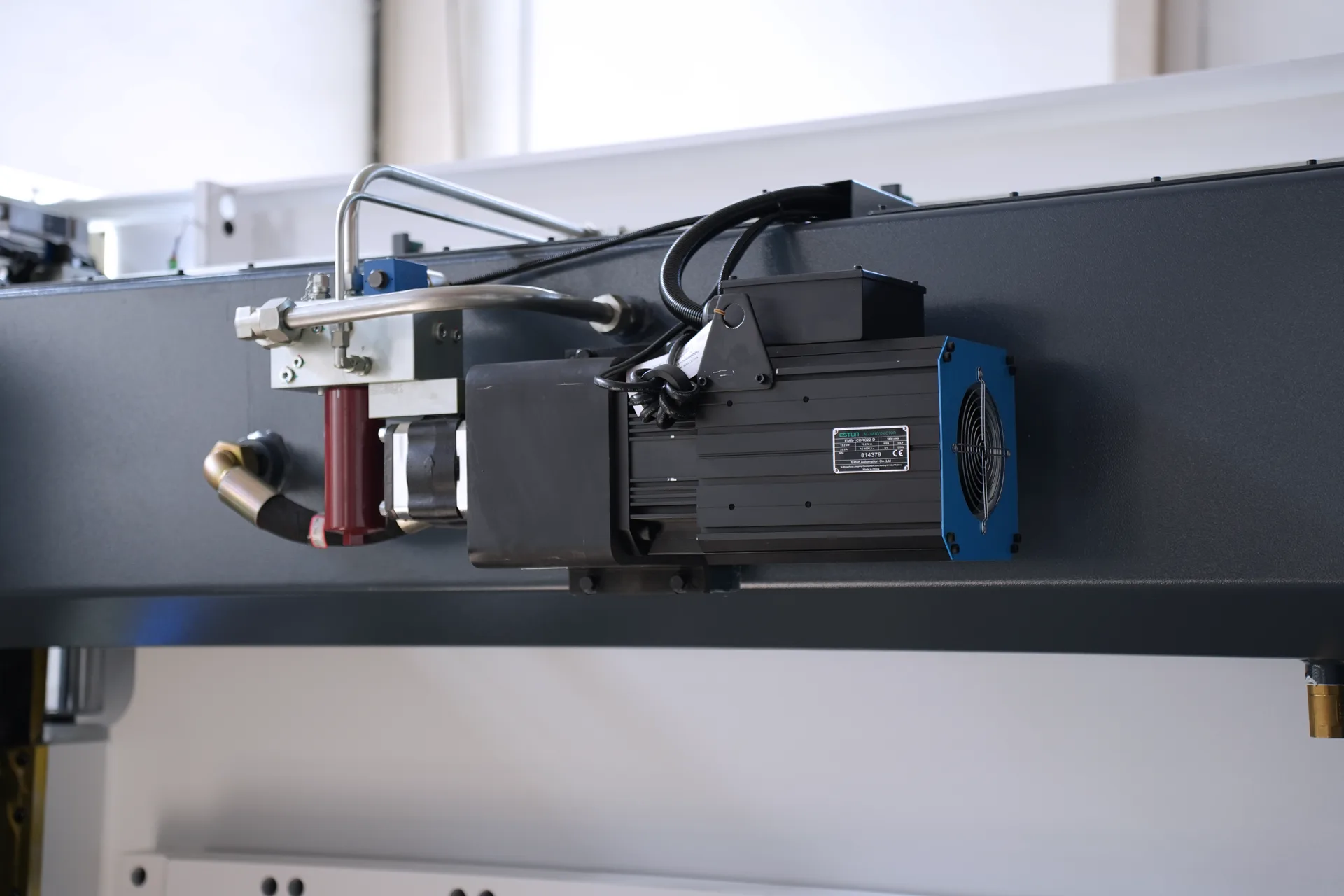

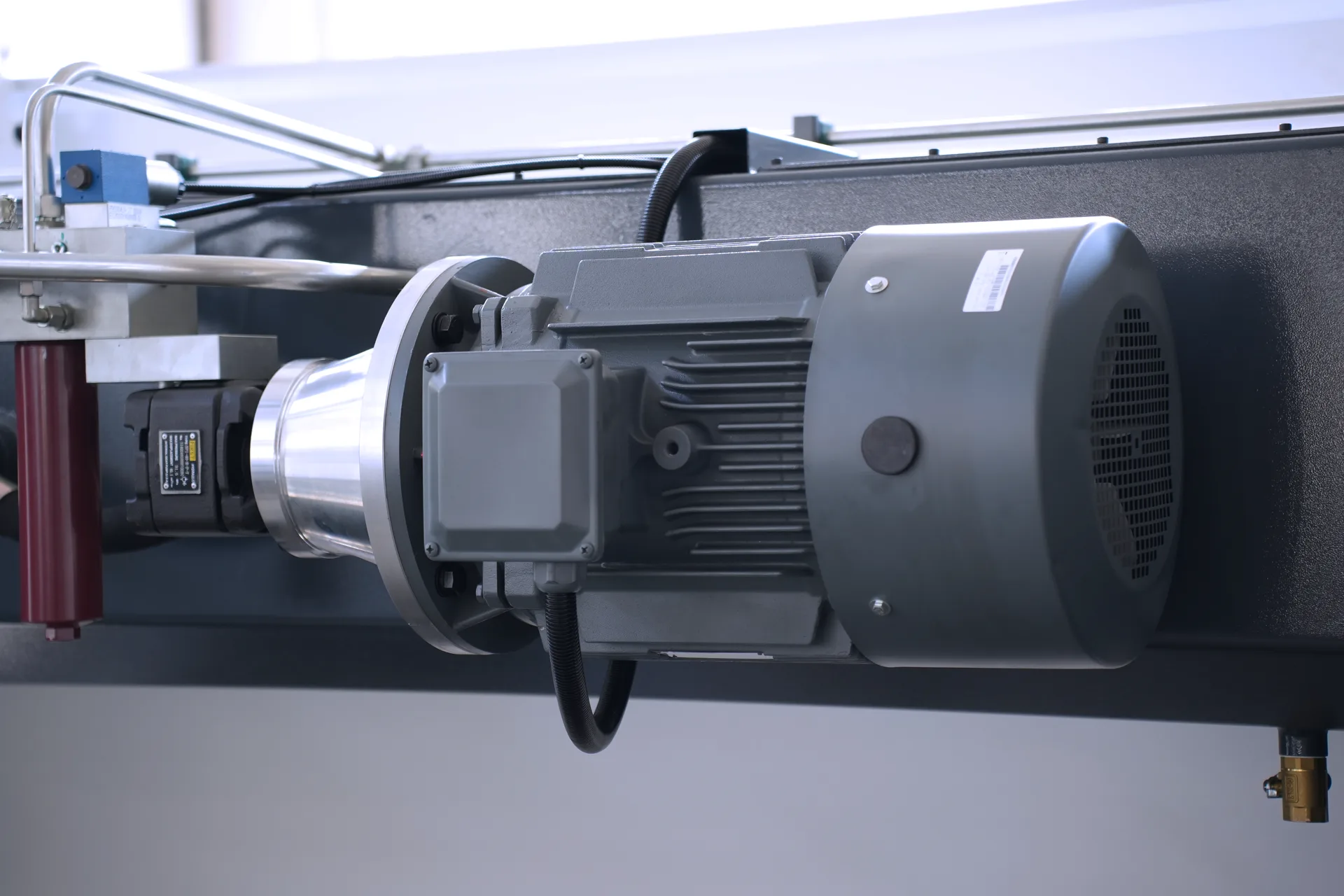

2.4Siemens motors: the source of stable power

The motor is the power source of the Sheet Metal Bending Machine. Krrass Sheet Metal Bending Machine uses Siemens motors to provide stable and reliable power for the operation of the equipment. As a giant in the global electrical field, Siemens’ motors are famous for their high efficiency, energy saving, durability and stable performance.

Siemens motors have strong torque output and can meet the power requirements of Sheet Metal Bending Machine under various working conditions. Whether it is running at no load or processing under heavy load, it can maintain a stable speed and output power to ensure the smooth operation of Sheet Metal Bending Machine. At the same time, Siemens motors use advanced heat dissipation technology and insulation materials, have good heat dissipation performance and electrical insulation performance, can effectively reduce the failure rate of motors, extend service life, and reduce equipment maintenance costs.

3.Core performance: perfect combination of high precision and high stability

3.1High-precision bending to meet diverse needs

With the synergy of the above high-end accessories, the Krrass Sheet Metal Bending Machine has excellent performance in bending accuracy. Its bending angle error can be controlled within ±0.1°, and the repeat positioning accuracy reaches ±0.02mm, which can meet the high-precision requirements of various complex bending processes.

In the automobile manufacturing industry, the bending accuracy of body panels directly affects the appearance and assembly quality of the entire vehicle. The Kraus Sheet Metal Bending Machine can accurately bend the plates of automobile doors, hoods and other parts to ensure the matching accuracy between parts and improve the sealing and safety of the entire vehicle. In the field of medical device manufacturing, the bending accuracy requirements for metal parts are more stringent. With its high-precision bending performance, the Kraus Sheet Metal Bending Machine can produce medical device metal parts that meet strict quality standards, providing guarantees for the reliability and safety of medical equipment.

3.2Highly stable operation to ensure production continuity

In addition to high precision, the high stability of the Krrass Sheet Metal Bending Machine is also one of its core advantages. From the body structure to the selection of core accessories, the stability requirements of the equipment during long-term operation are fully considered. The solid body structure reduces vibration during operation, and the reliability of high-end accessories ensures the stable operation of each system.

In large-scale production enterprises, the stability of the equipment is directly related to the production schedule and delivery period. Kraus bending machines can run continuously and stably for thousands of hours without failure, greatly reducing the frequency of equipment shutdown and maintenance. Even under high-intensity production tasks, they can still maintain stable performance, providing strong guarantees for enterprises to achieve efficient and continuous production and improve the market competitiveness of enterprises.

4.Advanced technology: heat treatment process improves equipment performance

Krrass Sheet Metal Bending Machine uses advanced heat treatment technology to treat key parts of the machine body, which is another important feature that distinguishes it from ordinary Sheet Metal Bending Machine. Heat treatment technology can improve the structure and performance of metal materials, and improve the strength, hardness, wear resistance and toughness of parts.

In the production process of Sheet Metal Bending Machine, after heat treatment, the internal structure of the workbench uprights, side wall panels, sliders and other parts are more uniform and the grains are refined, thereby enhancing the comprehensive mechanical properties of the parts. For example, the workbench uprights that have been heat treated are not easy to deform and crack when subjected to huge pressure, and can maintain a good working condition for a long time; after heat treatment, the slider has improved surface hardness, enhanced wear resistance, and a tighter fit with the guide rail, further improving the running accuracy and stability of the Sheet Metal Bending Machine.

In addition, the heat treatment process can also eliminate the internal stress generated by the parts during the processing process, reduce the deformation of the parts caused by the release of internal stress, and ensure the accuracy and stability of the equipment during long-term use. Compared with ordinary Sheet Metal Bending Machines that have not undergone heat treatment, Krauss Sheet Metal Bending Machines have obvious advantages in service life, performance stability and processing quality.