Introduction

The global push toward green manufacturing is transforming industries across the world. With governments, regulators, and consumers demanding more eco-friendly industry practices, manufacturers are turning to advanced technologies that reduce waste, save energy, and promote sustainability.

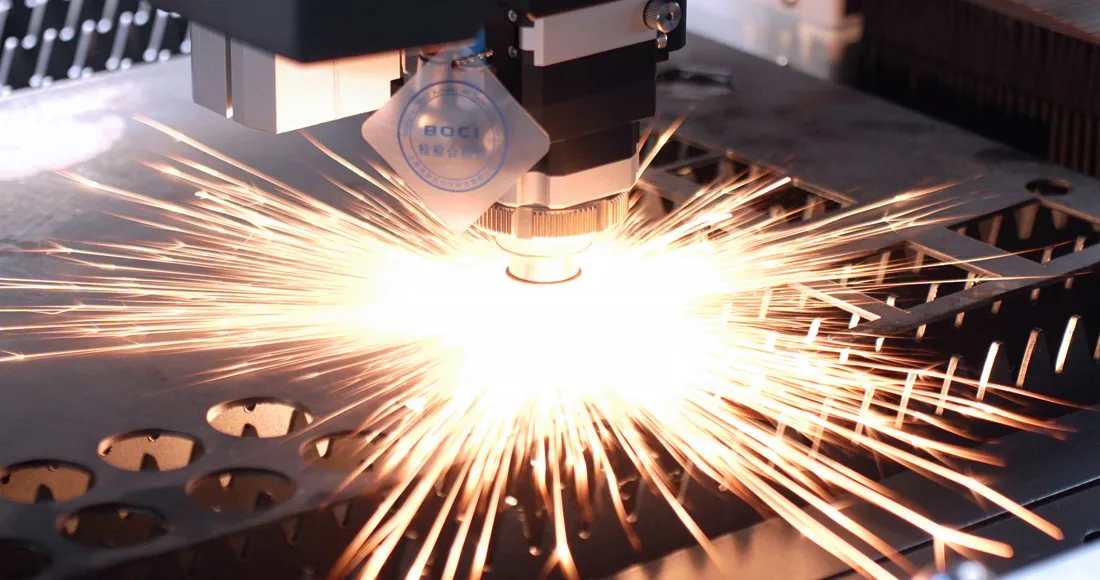

One of the most important breakthroughs in this shift is fiber laser cutting. Compared to traditional cutting technologies, fiber lasers are more efficient, versatile, and aligned with the goals of sustainable fabrication.

👉 Learn more about KRRASS’s company expertise in providing eco-friendly fiber laser solutions for global manufacturers.

1. Why Green Manufacturing Matters

Green manufacturing is not just about reducing environmental impact; it’s about creating long-term business value:

- Lower operational costs through reduced energy consumption

- Compliance with stricter government environmental regulations

- Stronger brand reputation in eco-conscious markets

- Improved worker safety with cleaner technologies

According to the World Steel Association, energy efficiency improvements in fabrication can cut industrial emissions by up to 30%.

2. Fiber Laser Cutting vs. Traditional Cutting Methods

Traditional methods like CO2 cutting and plasma cutting consume more energy and produce more waste compared to fiber laser cutting.

| Technology | Energy Consumption | Waste Generation | Maintenance | Sustainability Rating |

|---|---|---|---|---|

| Fiber Laser Cutting | Low | Minimal | Low | ★★★★★ |

| CO2 Laser Cutting | Medium-High | Moderate | High | ★★★ |

| Plasma Cutting | High | High (slag, fumes) | Moderate | ★★ |

(Source: The Welding Institute)

👉 Explore advanced fiber laser cutter solutions from KRRASS designed for sustainable fabrication.

3. How Fiber Laser Cutting Supports Sustainable Fabrication

3.1 Energy Efficiency

Fiber lasers use up to 70% less energy compared to CO2 systems. This directly reduces carbon emissions and lowers operational costs.

3.2 Reduced Material Waste

High-precision cutting minimizes offcuts and scrap, supporting eco-friendly industry initiatives.

3.3 Long Service Life

Fiber lasers have fewer consumables, meaning less frequent part replacement and reduced environmental impact.

3.4 Cleaner Operations

Unlike plasma cutting, fiber lasers emit fewer fumes and require less auxiliary gas.

4. Applications of Fiber Laser Cutting in Green Manufacturing

Industries adopting fiber laser cutting for sustainability include:

- Automotive – lightweight parts for fuel efficiency

- Construction – eco-friendly building materials

- Renewable Energy – solar panel frames, wind turbine components

- Aerospace – lightweight alloys for reduced fuel consumption

👉 Discover how KRRASS supports sustainable fabrication with its innovative laser cutter portfolio.

5. Fiber Lasers and Eco-Friendly Industry Trends

The rise of eco-friendly industry practices is linked to global standards such as:

- ISO 14001 Environmental Management Systems

- EU Green Deal targets for industrial emissions

- Energy.gov efficiency guidelines for industrial equipment (U.S. Department of Energy)

Fiber laser cutting directly supports compliance with these frameworks.

6. Integrating Fiber Lasers with Industry 4.0

Sustainability is not just about machines but also about data-driven optimization:

- IoT sensors monitor energy use in real time.

- AI software reduces scrap through smart part nesting.

- Predictive maintenance extends machine life and lowers waste.

This integration makes fiber laser cutting an essential tool for the fabrication future.

7. Case Study: Green Manufacturing with Fiber Lasers

A European automotive supplier switched from CO2 cutting to fiber laser cutting in 2024. Within one year:

- 30% reduction in energy consumption

- 25% less scrap waste

- Improved workplace air quality

- Compliance with EU sustainability standards

This case illustrates how fiber laser technology drives both environmental and financial performance.

Conclusion

The transition to green manufacturing is no longer optional—it’s a necessity for companies that want to remain competitive in global markets. By adopting fiber laser cutting, businesses can:

- Cut energy consumption

- Reduce waste

- Support sustainability initiatives

- Achieve compliance with international eco-standards