Introduction

In the evolving world of metal fabrication, the choice of cutting technology can determine a factory’s efficiency, quality, and competitiveness. For decades, plasma cutting and CO2 cutting dominated the industry. However, with the advancement of fiber laser cutting machines, manufacturers are rethinking their strategies.

So which one is right for your business? This article compares fiber laser cutting machines, CO2 cutting, and plasma cutting to help you make an informed decision.

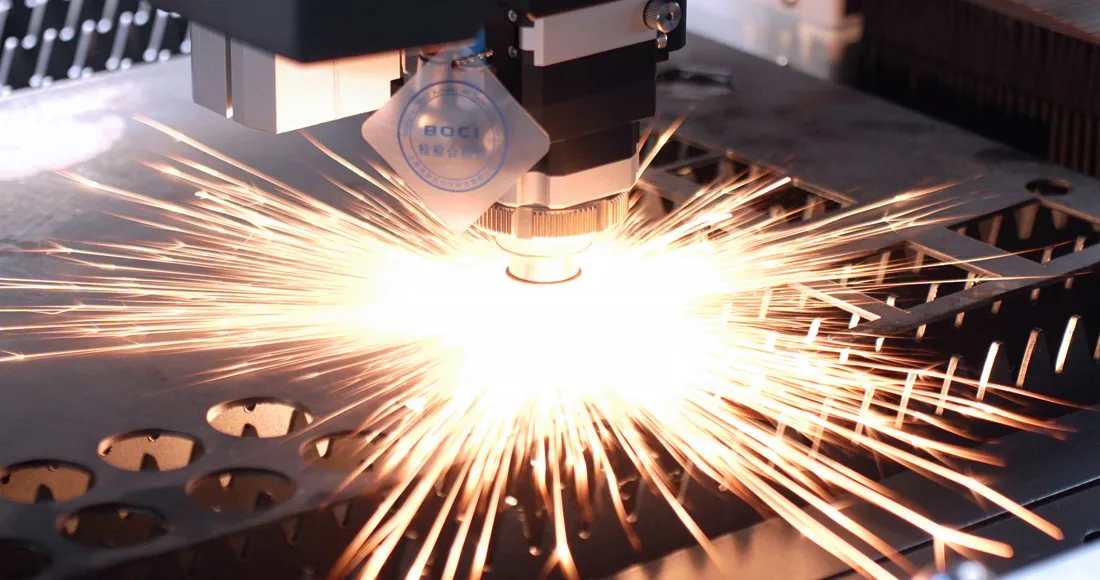

1. What Is Fiber Laser Cutting?

A fiber laser cutting machine uses optical fiber to deliver high-power laser beams, achieving ultra-precise cuts with minimal heat distortion. Unlike traditional methods, it is faster, more accurate, and capable of cutting complex geometries in sheet metal.

👉 Learn more about KRRASS’s company expertise in delivering advanced sheet metal solutions.

2. Traditional Cutting Technologies

Before fiber laser systems, plasma cutting and CO2 laser cutting were the standard choices.

- Plasma cutting: Uses electrically conductive gas to melt materials. Suitable for thick sheets but less precise.

- CO2 cutting: Uses a gas laser, offering smoother edges than plasma but requiring higher maintenance.

3. Fiber Laser vs. Plasma vs. CO2 Cutting

Here’s a detailed comparison table:

| Feature | Fiber Laser Cutting | CO2 Cutting | Plasma Cutting |

|---|---|---|---|

| Accuracy | ±0.05 mm | ±0.1 mm | ±0.3 mm |

| Cutting Speed | Very High | Moderate | High |

| Material Range | Metals, alloys, reflective materials | Metals, non-metals | Thick metals only |

| Maintenance | Low | High (mirrors, gas tubes) | Moderate |

| Energy Efficiency | Very High | Medium | Medium |

| Operating Cost | Lower (energy savings) | Higher | Lower equipment cost but high consumables |

(Source: The Welding Institute)

4. Key Advantages of Fiber Laser Cutting Machines

4.1 Superior Precision

Fiber lasers achieve exceptional laser technology accuracy, making them ideal for industries requiring tight tolerances.

4.2 Energy Efficiency

They consume less electricity than CO2 cutting and plasma cutting, lowering long-term costs.

4.3 Low Maintenance

No mirrors or gas tubes means reduced upkeep and downtime.

4.4 Flexibility

Fiber lasers cut reflective materials like copper and brass, which are challenging for CO2 lasers.

5. When to Choose Plasma or CO2 Cutting

Despite the benefits of fiber lasers, plasma cutting and CO2 cutting still have niches:

- Plasma remains cost-effective for very thick steel.

- CO2 cutting works well for non-metallic materials (e.g., wood, glass, plastic).

6. Fiber Laser Cutting in Metal Fabrication

Fiber laser cutting is now widely adopted in industries such as:

- Automotive: producing body panels with high consistency.

- Aerospace: manufacturing lightweight but strong components.

- Construction: delivering customized designs for architectural panels.

👉 Explore advanced bending solutions with KRRASS CNC press brakes, which often complement laser cutting lines.

7. Cost Considerations

Although fiber laser machines require a higher initial investment, they provide better ROI due to:

- Faster cutting cycles

- Reduced material waste

- Energy savings

- Longer machine life

8. Safety and Environmental Impact

Fiber laser cutting produces fewer emissions and is safer compared to plasma cutting, which releases fumes. This aligns with green manufacturing goals and global sustainability standards (World Steel Association).

9. Industry 4.0 and the Future of Cutting

Modern fiber laser cutting machines integrate with automation, IoT, and AI-based monitoring systems. They form the backbone of smart factories where every cut is tracked, optimized, and repeatable.

(Reference: Wikipedia on Laser Cutting)

Conclusion

When comparing fiber laser cutting machines, CO2 cutting, and plasma cutting, the choice depends on your priorities:

- Choose fiber laser cutting machines for precision, energy efficiency, and versatility.

- Stick with plasma cutting for thick, low-cost steel work.

- Opt for CO2 cutting if you need to process non-metals alongside metals.

For most modern factories, the fiber laser is the best long-term investment, offering unmatched performance in sheet metal fabrication.

👉 Learn more about KRRASS’s innovative solutions

👉 Browse our range of press brakes

👉 Have questions? Contact our experts

By adopting fiber laser technology, manufacturers not only improve production but also future-proof their operations in an increasingly competitive market.