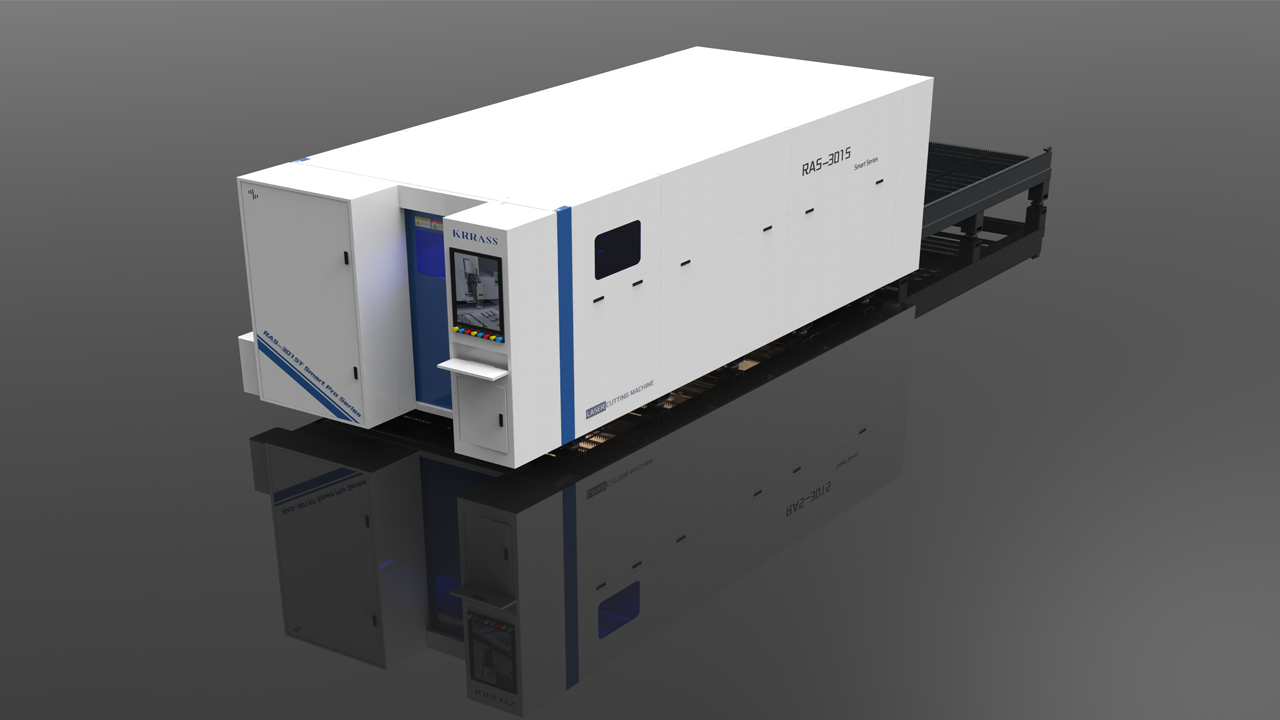

Fiber Laser Cutting Machine is a device that uses laser technology to cut materials. It generates a high-energy-density laser beam through a laser generator, and focuses the laser beam on the surface of the material to be cut through an optical system, so that the material quickly absorbs the laser energy, and the temperature rises sharply to reach the melting point, boiling point or ignition point of the material, thereby melting, vaporizing or burning the material. At the same time, with the help of auxiliary gas coaxial with the laser beam, the molten material is blown away from the cutting area. As the cutting head moves along the preset path, the material is accurately cut. Fiber Laser Cutting Machine has the advantages of high cutting accuracy, good quality, fast speed, strong flexibility, and non-contact processing. It is widely used in metal processing, non-metal processing, advertising logo production, aerospace, shipbuilding and other fields, and can meet the diverse needs of different industries for material cutting. Today, I will introduce to you how to choose accessories for Fiber Laser Cutting Machine.

Table of Contents

1.Fiber Laser Cutting Machine Bed

Fiber Laser Cutting Machine bed is the key component of Fiber Laser Cutting Machine. Its structure and performance directly affect the static and dynamic performance and processing accuracy of the machine tool. The following is a detailed introduction to the Fiber Laser Cutting Machine bed:

- Cast iron (material): It has high rigidity and stability, can withstand large cutting force and vibration, can effectively reduce vibration during cutting, and ensure cutting accuracy. However, cast iron is heavy, which is not conducive to the movement and installation of machine tools, and the casting process is relatively complex, and the production cycle is long.

- Steel: It has high strength and toughness, can withstand large loads and impacts, has good weldability, and is easy to process into various shapes and structures. At the same time, steel is relatively light, which is convenient for the movement and installation of machine tools, so it is widely used in the manufacture of Fiber Laser Cutting Machine bed.

- Box structure (structure): The overall box shape has high rigidity and stability, can withstand large cutting force and vibration, can effectively reduce the deformation of the machine tool during cutting, and improve cutting accuracy. However, its processing technology is relatively complex, requiring multiple welding and processing procedures, and the cost is high.

- Frame structure (structure): The frame is composed of beams and columns, which has good rigidity and stability, and is convenient for the installation and adjustment of machine tools. The connection between the components is relatively convenient, and can be flexibly combined and disassembled according to needs. The processing technology is relatively simple and the cost is low, which is suitable for small and medium-sized Fiber Laser Cutting Machine.

- Beam structure (structure): It mainly uses beams as support and force-bearing components, has good rigidity and stability, is suitable for large Fiber Laser Cutting Machine, and can withstand large loads and spans. However, the design and processing of beam structures need to consider factors such as the strength, rigidity and stability of the beams, and the processing technology is relatively complex and the cost is high.

2.Fiber Laser Souce

- IPG Photonics (USA): A global leader in fiber laser technology, focusing on the research and development and production of high-quality fiber laser sources. Its products are known for their excellent beam quality, high reliability and long service life, and are widely used in various industrial processing fields, such as metal cutting, welding, surface treatment, etc., but the price is relatively high, which limits the use of some small enterprises.

- TRUMPF (Germany): As a leading company in the field of sheet metal processing equipment and industrial laser applications in the world, it has a deep accumulation in laser source technology. Its laser source products have excellent performance and can meet the needs of high-precision and high-speed laser processing. They are widely used in automobile manufacturing, aerospace, electronics and other industries.

- COHERENT (USA): Founded in 1971, it was acquired by II-VI in 2022. It is a supplier of laser solutions such as lasers, sensors and optical devices, providing various lasers and laser parameter measurement products, such as argon/krypton ion lasers, CO₂ lasers, semiconductor lasers, etc., which are widely used in scientific research, medical treatment, communications and other fields.

- nLIGHT (USA): It has strong technical strength in the field of high-power laser emission sources, and its products have unique advantages in cutting high-reflectivity metal materials, such as aluminum and copper. It has a variety of series of laser emission source products that can meet the requirements of different industrial application scenarios for parameters such as power and wavelength.

- Raycus(China): It is a national high-tech enterprise specializing in the research, development, production and sales of fiber lasers and their key components and materials. Its laser emission source products are cost-effective, stable and reliable in performance, occupying an important position in the domestic market, and are widely used in metal processing, automobile manufacturing, shipbuilding and other industries. It is the preferred brand for many low-end laser cutting equipment.

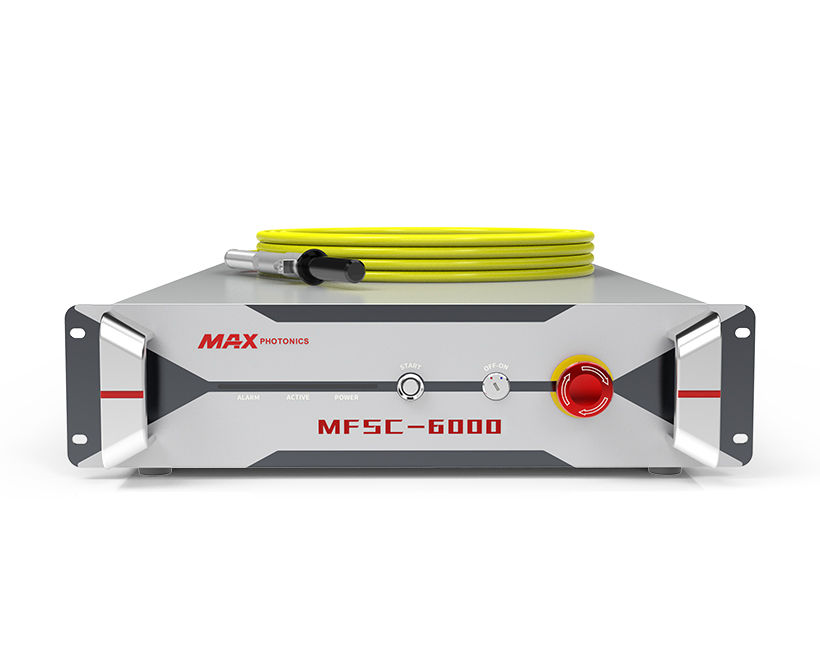

- MAX(China): It has strong innovation and market development capabilities in the field of fiber lasers. Its laser emission source products cover a variety of power and wavelength ranges to meet the personalized needs of different customers. The products are widely used in cutting, welding, marking and other fields, and are popular in the market with high performance and relatively low prices.

- Keplin(China): Founded in 2003, it is a global laser product and solution service provider, mainly engaged in high-performance semiconductor lasers, fiber lasers, ultrafast lasers, etc. Related products have spread to more than 60 countries around the world, and have advanced technical levels in semiconductor laser chip packaging technology, fiber coupling technology, etc.

- JPT(China): It has deep technical accumulation and continuous innovation capabilities in the field of laser technology. Its laser emission source products are known for their high beam quality, high stability and high precision. They are widely used in precision processing, scientific research, medical treatment and other fields, especially in some high-end application scenarios with high requirements for laser performance.

3.Fiber Laser Cutting Machine Head

The laser cutting head is a key component of the Fiber Laser Cutting Machine, which is mainly used to focus the laser beam and guide it to accurately cut the material. The following is a detailed introduction to its structure, principle and function:

Basic structure: The laser cutting head is usually composed of a focusing lens, a nozzle, a protective lens, a gas channel, a focusing tracking system and other parts. The focusing lens is used to focus the laser beam on the surface of the material to be cut to increase the energy density of the laser; the nozzle is used to spray auxiliary gas to help remove the slag and smoke generated during the cutting process and cool the cutting area; the protective lens is installed at the end of the cutting head close to the workpiece to prevent the spatter and dust during the cutting process from contaminating the focusing lens and other optical components; the gas channel provides a flow path for the auxiliary gas to ensure that the gas can be sprayed evenly; the focusing tracking system can adjust the distance between the cutting head and the workpiece in real time according to the fluctuations of the workpiece surface during the cutting process to ensure the accuracy of the focusing position.

Working principle: The laser cutting head uses the high energy density characteristics of the laser to focus the laser beam on the surface of the material through the focusing lens, so that the material quickly absorbs the energy of the laser, the temperature rises sharply, reaches the melting point or even the boiling point of the material, and the material quickly melts and vaporizes. At the same time, the auxiliary gas ejected from the nozzle blows the melted and vaporized material away from the cutting area to form a cutting seam, and finally the material is cut.

Function: The function of the laser cutting head is to accurately control the focus and transmission of the laser beam to achieve high-precision and high-efficiency cutting of various materials. It can concentrate the laser energy in a very small area, so that the cutting has higher precision and smaller heat-affected zone, and the cutting edge quality is good. It can meet the cutting needs of different materials and different shapes, and is widely used in many fields such as metal processing, automobile manufacturing, electronic equipment, aerospace, etc.

- Precitec: Founded in Baden-Baden, Germany in 1971. It has deep technical accumulation and rich experience in the field of laser cutting heads. Its products include automatic two-dimensional and three-dimensional laser cutting heads. Its cutting heads have the characteristics of high precision, high speed and high-quality cutting edges. Intelligent sensor technology can ensure stable process progress.

- LT Ultra: A German company founded in 1995, it has a high technical level in the manufacture of high-precision laser cutting heads. It focuses on providing precision laser cutting head solutions for high-end manufacturing. Its products are known for their ultra-high cutting accuracy and stability. They are often used in industries with extremely high cutting quality requirements such as automotive manufacturing and aerospace.

- Laser Mechanisms: Founded in Novi, Michigan, USA in 1980. The company focuses on designing and manufacturing parts for various laser processing equipment, especially laser cutting heads. Its products have good compatibility and stability, and can be adapted to a variety of different types and brands of Fiber Laser Cutting Machines, occupying a certain share in the global laser cutting head market.

- Jiaqiang: Jiaqiang (Shanghai) Intelligent Technology Co., Ltd. was established in 2009. The company has evolved from being an agent for foreign laser processing head products to developing its own laser processing head sensors and control systems. In 2015, the core components of laser equipment were gradually replaced by domestic ones2. In 2024, the company’s laser processing head sales will reach more than 50,000 sets, with a market share leading its peers in the segment. The cumulative sales of laser processing heads will reach 250,000, ranking first among its peers in the world2

- Bochu cutting head is a product of Shanghai Betchu Electronic Technology Co., Ltd., which has a high reputation and market competitiveness in the field of laser cutting. The BLT series of high-power intelligent laser cutting heads are easy to install, easy to debug, excellent in performance, and have complete sensors. They are one of the few intelligent cutting heads on the market. Some cutting heads also adopt modular component design, which is convenient for rapid on-site maintenance of equipment, and can help customers quickly restore production capacity and achieve 24-hour uninterrupted production. It has multiple intelligent technologies such as dual spot, focus closed-loop control, automatic centering, intelligent perforation, automatic return, air pressure monitoring, lens temperature monitoring, astigmatism monitoring, anti-collision, and anti-explosion, which can make the cutting process more efficient, stable, safe, and intelligent. For example, the BLTA180M cutting head uses a new generation of intelligent sensors. Its molten pool detection function can effectively control the lens temperature drift pain point, and can also detect the nozzle status in time to ensure stable cutting results. A variety of product series have been developed for different power segments and cutting application scenarios. For example, the plane cutting head has a combination of 3 series, 4 series, 6 series, 8 series, 9 series, A series and other products, which can meet the high and low power cutting needs of 3~120KW; the steel cutting head is aimed at 6~40KW steel cutting applications, and a product combination of 4 series + AB axis + seam finder has been developed; the pipe cutting head is aimed at 3~20KW pipe cutting applications, and there are 3T series, 4T series, 5H series and other product combinations.

4.Fiber Laser Cutting Machine Controller

The Fiber Laser Cutting Machine system consists of hardware and software, and plays a vital role in the laser cutting process. The Fiber Laser Cutting Machine system accurately controls the movement of the cutting head in the X, Y, and Z axes through high-precision motor drivers and motion control algorithms. When cutting complex graphics or delicate parts, it can ensure that the cutting head moves with extremely high precision along the preset trajectory, and the error can be controlled within a very small range, generally reaching an accuracy of ±0.01mm or even higher, so as to ensure that the cut workpiece size is accurate and the edge is smooth. The system is equipped with a position sensor to monitor the actual position of the cutting head in real time and feed the information back to the control system. Once the actual position is found to deviate from the preset trajectory, the system will immediately adjust to ensure that the cutting head always moves along the correct path, effectively avoiding cutting deviations and improving cutting quality. According to different cutting materials and thicknesses, the Fiber Laser Cutting Machine system can accurately adjust the output power of the laser.

- Bochu Electronics: The FSCUT series controllers of Shanghai Bochu Electronics Technology Co., Ltd. are quite influential in the domestic market. It uses advanced motion control algorithms to achieve high-speed and high-precision cutting motion control, supports a variety of laser cutting processes, and can easily set cutting parameters such as laser power, cutting speed, pulse frequency, etc. through the software interface. At the same time, it has perfect fault diagnosis and protection functions, can monitor the operating status of the cutting machine in real time, and stop the machine in time when encountering abnormalities to protect the safety of equipment and workpieces. The human-computer interaction interface is good and the operation is simple and intuitive.

- Han’s Intelligent Control: A company under Han’s Laser that focuses on control technology and control system research. The HAN’S 801 series CNC system is its core product and is one of the few CNC system products in China that is completely independent and has complete intellectual property rights. The system has advanced architecture, complete functions and excellent performance. It is widely used in laser cutting, laser tube cutting, laser welding and other industries, covering capacitive sensors, signal amplifiers, height adjustment boxes and other products. It uses the capacitance measurement principle to dynamically measure the distance between the bottom of the cutting head nozzle and the cut plate in real time. In addition, it also includes HAN’S Vision vision system, Han’s Mesys laser equipment information management system, Han’s LaserNest laser plane cutting nesting software, etc., providing comprehensive control and management solutions for laser cutting.

5.Fiber Laser Cutting Machine Servo Motor

- Yaskawa: A Japanese brand with a high reputation and market share in the field of servo motors. Its servo motors are characterized by high precision, high responsiveness and high stability. They can quickly and accurately track control signals and achieve precise movement of the cutting head of the Fiber Laser Cutting Machine. They have strong overload capacity and can adapt to different cutting processes and material requirements, and can maintain good performance even when running under high load. They have a rich product line and can choose the appropriate model according to the different power, speed and precision requirements of the Fiber Laser Cutting Machine.

- Panasonic: Also from Japan, Panasonic’s MINAS series servo motors are widely used in the laser cutting industry9. For example, the MINAS E7 family has upgraded the A7 core algorithm platform, which can achieve the optimal automatic adjustment to adapt to the equipment9. It has the advantages of small size, light weight and high power density, and can provide powerful power output in a limited space. It has high control accuracy. Through advanced control algorithms and encoder technology, it can achieve high-precision position control and speed control to ensure the accuracy and quality of laser cutting.

- Inovance: A leading enterprise in the field of domestic industrial automation. Its servo motors are characterized by high precision, high response and high reliability, and are widely used in robots, CNC machine tools and packaging equipment. The representative product is the IS series servo motor, whose core advantages are high cost performance, excellent dynamic performance and perfect after-sales service.

- Estun Automation: A leader in the field of industrial robots and automation control, its servo motors are widely used in industrial robots and intelligent equipment. The company has strong production capacity and technical reserves, and its products are highly competitive in domestic and foreign markets. The representative product is the ProNet series servo system, which has high response speed and wide industrial adaptability.

- Delta Electronics: It is well-known in the field of industrial automation. Its servo motors are known for their stability and energy saving, and are widely used in industries such as 3C electronic manufacturing and logistics automation. The representative product is the ASDA series servo system, which has the advantages of precise control, efficient energy conversion and multi-industry coverage.

6.Fiber Laser Cutting Machine reducer

- Japan SHIMPO: It has a high reputation in the field of reducers. Its planetary reducer products have the characteristics of high precision, high rigidity and low backlash, and are suitable for equipment with high precision requirements such as Fiber Laser Cutting Machine. For example, models such as VRB-140C are widely used in laser cutting equipment, providing stable reduction ratios and reliable performance.

- Germany NEUGART: A German precision reducer brand, its products have high precision and high torque, and can meet the requirements of Fiber Laser Cutting Machine for high-speed cutting and high-precision positioning. Its planetary reducer series can replace some products of other brands and are used in Fiber Laser Cutting Machine, manipulators, engraving machines and other equipment.

- Germany STOBER: It is a company specializing in the production of reducers, and its product quality is reliable and its technology is advanced. STOBER’s servo planetary reducers, such as PH421 and other models, are designed for equipment such as Fiber Laser Cutting Machine, have good dynamic performance and precision retention, and can adapt to different cutting processes and production requirements.

- FALATE, Taiwan: Founded in 1990, it is one of the earliest Taiwanese reducer manufacturers to enter the mainland market. The original product line was a turbine reducer, and later developed multiple series of servo motor-specific reducers and precision hollow rotary platform reducers. Its products are widely used in aerospace, semiconductor equipment, robotics and other industries, and also perform well on Fiber Laser Cutting Machine, with advantages such as high precision and low noise.

- CHANHUA, Taiwan: It has a certain degree of popularity in Taiwan, China. Its planetary reducer products have the characteristics of high torque, high precision, low noise and long service life. For example, planetary reducers such as AB060 are suitable for equipment such as fiber optic laser cutting machines, and can provide stable power transmission and precise deceleration control.

7.How to choose the best configuration

The optimal configuration of the Fiber Laser Cutting Machine will vary depending on the cutting material, cutting accuracy, cutting speed and other requirements. The following is the recommended high-quality configuration of each key component under normal circumstances:

- Laser: It is the core component of Fiber Laser Cutting Machine. Its power and type determine the cutting capacity and applicable material range.

- Power selection: For cutting thin plates (such as 0.5-3mm stainless steel or carbon steel), generally 1000-3000W fiber lasers are sufficient; for cutting medium and thick plates (3-10mm), it is recommended to use 3000-6000W lasers; for cutting thick plates above 10mm, a high-power laser of more than 6000W is required.

- Type selection: Fiber lasers are suitable for cutting metal materials, with the advantages of high photoelectric conversion efficiency, good beam quality, and low maintenance cost; carbon dioxide lasers are more suitable for cutting non-metallic materials, such as acrylic, wood, cloth, etc., with longer wavelengths and good absorption effects on non-metallic materials.

- Control system: directly affects the cutting accuracy, speed and stability.

- Brand selection: Han’s control system is widely used in the field of laser cutting. After years of mature use and continuous optimization, it has the characteristics of high performance, strong reliability and humanized operation2. In addition, some imported brands of control systems, such as German PA, Siemens 840D, etc., are also known for their high precision and powerful functions, but the price is relatively high.

- Functional requirements: It should have powerful graphic editing functions and support the import of multiple graphic formats, such as DXF, PLT, AI, etc.; it should have automatic typesetting functions to improve material utilization; at the same time, it should have real-time monitoring and fault diagnosis functions to promptly discover and solve problems that arise during the cutting process.

- Servo motor: Provide power for the cutting head to ensure cutting accuracy and speed.

- Brand recommendation: Servo motors from international brands such as Yaskawa and Panasonic have the characteristics of high precision, high responsiveness and high stability, and can quickly and accurately track control signals. Servo motors from domestic brands such as Inovance Technology and Estun also have good performance and high cost performance.

- Parameter selection: According to the table size, load weight and cutting speed requirements of the Fiber Laser Cutting Machine, select a servo motor with appropriate torque and speed. Generally speaking, the higher the cutting speed requirement, the greater the speed and torque of the required servo motor.

- Reducer: used to reduce the speed of the servo motor and increase the torque at the same time.

- Brand selection: Reducers of international brands such as Japan SHIMPO and Germany NEUGART have high precision, good rigidity and small backlash. Reducers of domestic brands such as Taiwan FALATE and Chanhua CHANHUA can also meet the general needs of Fiber Laser Cutting Machine and have a high cost performance 5.

- Type selection: Planetary reducer is a commonly used type in Fiber Laser Cutting Machine. It has the advantages of small size, light weight, high transmission efficiency and large load capacity.

- Transmission components: including ball screw, gear rack, linear guide, etc., which affect the precision and stability of cutting.

- Ball screw: It has the characteristics of high precision, high transmission efficiency and low friction, and can accurately convert the rotational motion of the servo motor into the linear motion of the cutting head. A ball screw with high precision grade (such as C5, C7), suitable diameter and pitch should be selected.

- Gear rack: suitable for large-stroke, high-speed cutting equipment, with high transmission efficiency and can withstand large loads. The ground gear rack imported from Germany is of good quality, high precision and strong wear resistance.

- Linear guide: provides precise guidance for the cutting head to ensure its stability and straightness during movement. High-rigidity, high-precision linear guides should be selected, such as products from Japanese brands such as THK and NSK.

- Cutting head: directly acts on the material for cutting, and its performance affects the cutting quality and effect.

- Brand and type: Cutting heads of imported brands such as Precitec and Lantek have high precision, high reliability and good focusing performance. Depending on the cutting material and process, different types of cutting heads can be selected, such as fiber laser cutting heads for metal cutting and carbon dioxide laser cutting heads for non-metal cutting.

- Automatic focusing function: The cutting head with automatic focusing function can automatically adjust the focal length according to the material thickness and cutting speed, ensuring that the beam is always focused on the material surface during the cutting process, improving the cutting quality and efficiency.

In addition to the above core components, the bed structure of the Fiber Laser Cutting Machine is also very important. It is generally welded with high-quality steel and undergoes heat treatment and aging treatment to eliminate internal stress and ensure the stability and rigidity of the bed. At the same time, it is also necessary to equip auxiliary equipment such as a good cooling system, gas system, and smoke and dust removal system to ensure the normal operation of the Fiber Laser Cutting Machine and the cleanliness of the working environment.